Professional Documents

Culture Documents

2007-04-06 CQAP Ph1-FSWC Rev1 Appendix A

Uploaded by

alaajabbarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2007-04-06 CQAP Ph1-FSWC Rev1 Appendix A

Uploaded by

alaajabbarCopyright:

Available Formats

Construction QC/QA Plan

APPENDIX A SAMPLE QUALIFICATION TEST SCHEDULES

Revision 1 April, 2007

Construction QC/QA Plan

TABLE A-1 Example Qualification Test Schedule Onsite Borrow Materials

Test Parameter Soil Classification Atterberg Limits Grain- Size Distribution Moisture Content

Test Method ASTM D2487 ASTM D4318 ASTM D422 or C136 ASTM D2216/ D2974

Minimum QC Testing Frequency by contractor 1 per 1,000 cubic yard and source change 1 per 1,000 cubic yard and source change 1 per 1,000 cubic yard and source change 1 per 1,000 cubic yard and source change

Acceptance Criteria (verified by QA) GW, GP, GM, GC, SW, SP, SM, SC, or ML In accordance with Section 02205 In accordance with Section 02205. Article 2.01.I In accordance with Section 02201 through 02205 and Section 02911

Notes: 1. Borrow soil must be from approved on-site borrow source with test results provided in Section 02205. Any change in material must be consistent with approved material characteristics as determined by CM. New moisture content curves will need to be plotted for change in material. 2. Note: this table is for illustration only and is not intended to replace or modify contract specifications that will form the basis of actual CQCP submittals by contractors

Revision 1 April, 2007

Page A1

Construction QC/QA Plan

TABLE A-2 Example of Qualification Test Schedule Aggregate Materials

Test Parameter Coarse Aggregate Grain-Size Distribution

Test Method

Minimum QC Testing Frequency by Contractor

Acceptance Criteria (verified by QA)

ASTM D422 or C136 ASTM D2974

1 per stockpile and In accordance with table source change in Article 2.01B in Section 02205 1 per stockpile and As reported for source change establishing the range of optimum moisture content 1 per stockpile and As reported for source change establishing the range of optimum compaction

Moisture Content

Compaction Characteristics Fine Aggregate Grain-Size Distribution

ASTM D1557

ASTM D422 or C136 ASTM D2974

1 per stockpile and In accordance with table source change in Article 2.01 B in Section 02205 1 per stockpile and As reported for source change establishing the range of optimum moisture content

Moisture Content

1 per stockpile and As reported for source change establishing the range of optimum compaction Note: this table is for illustration only and is not intended to replace or modify contract specifications that will form the basis of actual CQCP submittals by contractors

Compaction Characteristics

ASTM D1557

Revision 1 April, 2007

Page A2

Construction QC/QA Plan

TABLE A-3 Example Qualification Test Schedule Cementatious Materials

Test Parameter Portland Cement Chemical & Physical Requirements

Test Method

Minimum QC Testing Frequency by Contractor

Acceptance Criteria (verified by QA)

ASTM C150

Prior to use in concrete mix in absence of material certification

In accordance with tables in ASTM C150 for Type II Low Alkali

Fluidized Bed Ash In accordance with tables in ASTM C311 for Class F material, except loss on ignition shall not exceed 4% Note: this table is for illustration only and is not intended to replace or modify contract specifications that will form the basis of actual CQCP submittals by contractors. Chemical & Physical Requirements ASTM C311 Prior to use in concrete mix in absence of material certification

Revision 1 April, 2007

Page A3

Construction QC/QA Plan

TABLE A-4 Example Qualification Test Schedule Stone Aggregate Materials

Test Parameter Sieve Analysis

Test Method ASTM C136; C33 and as required by NYSDOT Specification 703.02

Minimum QC Testing Frequency by Contractor Prior to use in concrete mix and whenever character or source is changed

Acceptance Criteria (verified by QA) Max coarse aggregate size of No. 57 or 67 gradation per ASTM C33. Fine aggregate shall pass No. 4 sieve, gradation to conform with ASTM C33 and NYSDOT as specified in Article 2.01- C in Section 03001 Fine aggregate not darker than reference standard color per ASTM C40. Sand exhibiting a color darker than the referenced color shall be rejected. Loss resulting after 5 cycles not to exceed 8% for coarse aggregate or 10% for fine aggregate when using sodium sulfate solution or 11% for coarse aggregate or 14% for fine aggregate when using magnesium sulfate per ASTM C33 Loss not to exceed 10.5% after 100 revolutions, 42% after 500 revolutions

Organic Impurities

ASTM C40

Prior to use in concrete mix and whenever character or source is changed Prior to use in concrete mix and whenever character or source is changed

Soundness

ASTM C33

Abrasion

ASTM C131

Prior to use in concrete mix and whenever character or source is changed Prior to use in concrete mix and whenever character or source is changed

Deleterious Materials

ASTM C33

In accordance with tables in ASTM C33

Revision 1 April, 2007

Page A4

Construction QC/QA Plan

TABLE A-5 Qualification Test Schedule Concrete Mix

Test Parameter Compressive Strength

Test Method ASTM C39

Minimum QC Testing Frequency by Contractor Preliminary testing of mix design; test at 28 days

Acceptance Criteria (verified by QA) Min 5000 PSI Min 4000 PSI Min 3000 PSI Min 2500 PSI

Water/Cement Ratio

Preliminary testing of mix design

Limit to 0.35, 0.45,0.58 and max by weight accordance with section 03001 article 2.05 All concrete not containing a high range water-reducing admixture (super plasticizer) shall conform to these Max. slump values: Reinforced concretegeneral 4, Non-reinforced concrete 3, pavement, sidewalk 3, Slab on grade 3 and Floor toppings 2.

Slump Test

ASTM C143

1 per batch prior to pouring concrete

Notes 1. Preliminary testing of the mix design will be performed by Construction Contractors Independent Testing Laboratory (Third Party lab services). 2. This table is for illustration only and is not intended to replace or modify contract specifications that will form the basis of actual CQCP submittals by contractors

Revision 1 April, 2007

Page A6

Construction QC/QA Plan

TABLE A-4 (cont.) Example Qualification Test Schedule Stone Aggregate Materials

Test Parameter Material Finer 200 Sieve Than

Test Method ASTM C117

Minimum QC Testing Frequency by Contractor Prior to use in concrete mix and whenever character or source is changed Prior to use in concrete mix and whenever character or source is changed Prior to use in concrete mix and whenever character or source is changed

Acceptance Criteria (verified by QA) Not to exceed 1% for gravel or 1.5% for crushed aggregate per ASTM C33 Aggregates considered innocuous in accordance with ASTM C289

Alkali Reactivity

ASTM C227

Quality not less than 75 for average of three Specification identical samples nor less 703.02 than 70 for an individual sample Note: this table is for illustration only and is not intended to replace or modify contract specifications that will form the basis of actual CQCP submittals by contractors

Cleanliness and Sand Equivalent

NYSDOT

Revision 1 April, 2007

Page A5

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ACI E702 Buried Concrete Basement Wall DesignDocument9 pagesACI E702 Buried Concrete Basement Wall DesignleodegarioporralNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Storage Tank Design CalculationDocument12 pagesStorage Tank Design Calculationhtutswe80% (15)

- Ingersoll Rand Dryer O&M Manual 80442833-EnDocument48 pagesIngersoll Rand Dryer O&M Manual 80442833-EnBill BrighamNo ratings yet

- Design of Equipment FoundationsDocument28 pagesDesign of Equipment Foundationsapi-379773793% (42)

- ECIV 3016 Slab Thickness Calculation and Dead Load of Reinforced Concrete StructuresDocument10 pagesECIV 3016 Slab Thickness Calculation and Dead Load of Reinforced Concrete StructuresAlaa SalimNo ratings yet

- ECIV 3016 Slab Thickness Calculation and Dead Load of Reinforced Concrete StructuresDocument10 pagesECIV 3016 Slab Thickness Calculation and Dead Load of Reinforced Concrete StructuresAlaa SalimNo ratings yet

- Thermal Expansion Loop Sizing for Pipes and TubingDocument2 pagesThermal Expansion Loop Sizing for Pipes and Tubingzshehadeh0% (1)

- 500 Shell DesignDocument28 pages500 Shell DesignOkondu Chiedu100% (3)

- 500 Shell DesignDocument28 pages500 Shell DesignOkondu Chiedu100% (3)

- 500 Shell DesignDocument28 pages500 Shell DesignOkondu Chiedu100% (3)

- 500 Shell DesignDocument28 pages500 Shell DesignOkondu Chiedu100% (3)

- Recycling ConcreteDocument56 pagesRecycling ConcreteReshmita PallaNo ratings yet

- Pile Soil InteractionDocument250 pagesPile Soil Interactionnallay1705100% (3)

- Wind Load and Roof Load CalculationDocument20 pagesWind Load and Roof Load CalculationleodegarioporralNo ratings yet

- API 653 Tank Inspection StandardsDocument7 pagesAPI 653 Tank Inspection StandardsEngr Shahid AliNo ratings yet

- Eurocode 1 2.1Document36 pagesEurocode 1 2.1shtou2100% (2)

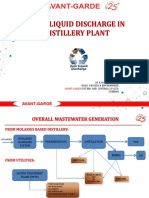

- Avant-Garde Mr. K Mohan KumarDocument46 pagesAvant-Garde Mr. K Mohan KumarSivakumar SelvarajNo ratings yet

- STD 146Document18 pagesSTD 146nirajbnb8417No ratings yet

- 2013 Summary of Confined Masonry Design PDFDocument13 pages2013 Summary of Confined Masonry Design PDFjeffrey1980No ratings yet

- 2013 Summary of Confined Masonry Design PDFDocument13 pages2013 Summary of Confined Masonry Design PDFjeffrey1980No ratings yet

- Attachment 1 - 1 TAKREER LPG - Cross Section - Flat FoundationDocument40 pagesAttachment 1 - 1 TAKREER LPG - Cross Section - Flat FoundationalaajabbarNo ratings yet

- Concrete Footing DetailsDocument5 pagesConcrete Footing DetailsMaimai Rea CondeNo ratings yet

- 37p NRMCADocument0 pages37p NRMCAsmishra2222No ratings yet

- 14171Document16 pages14171alaajabbarNo ratings yet

- 213Document333 pages213alaajabbarNo ratings yet

- Concrete Repair & ProtectionDocument20 pagesConcrete Repair & ProtectionmohsinNo ratings yet

- ACI TorsionDocument8 pagesACI TorsionNeil Duldulao100% (1)

- Arabic Version ISO 9001-2008Document40 pagesArabic Version ISO 9001-2008Mohammed FattoumNo ratings yet

- 101 132Document32 pages101 132alaajabbarNo ratings yet

- Activity6 1 1structural CalculationsDocument9 pagesActivity6 1 1structural CalculationsalaajabbarNo ratings yet

- What You Need Today: - Text - Notebook - Calculator (Optional) - 1/8" 1' Print of Foundation (Basement) PlanDocument24 pagesWhat You Need Today: - Text - Notebook - Calculator (Optional) - 1/8" 1' Print of Foundation (Basement) PlanalaajabbarNo ratings yet

- Arabic Version ISO 9001-2008Document40 pagesArabic Version ISO 9001-2008Mohammed FattoumNo ratings yet

- 347Document6 pages347adammzjinNo ratings yet

- Example RC Floor Analysis PDFDocument9 pagesExample RC Floor Analysis PDFalaajabbarNo ratings yet

- 347Document6 pages347adammzjinNo ratings yet

- One Way Solid SlabDocument26 pagesOne Way Solid SlabalaajabbarNo ratings yet

- How Enzymes Dissolve EggsDocument3 pagesHow Enzymes Dissolve Eggsbhanuday100% (1)

- Flue-Gas Desulfurization - Wikipedia, The Free EncyclopediaDocument8 pagesFlue-Gas Desulfurization - Wikipedia, The Free EncyclopediaPraveen KhatriNo ratings yet

- Insulate Walls to Meet Building CodesDocument18 pagesInsulate Walls to Meet Building CodesAlberto LeónNo ratings yet

- King Saud University Mass Transfer ExamDocument7 pagesKing Saud University Mass Transfer ExamAnnisa RahmaditaNo ratings yet

- High Efficiency Compressed Air Filtration & Water SeparationDocument8 pagesHigh Efficiency Compressed Air Filtration & Water SeparationMelvic BinosNo ratings yet

- Sap kr97Document79 pagesSap kr97tva400% (1)

- Salari A Tabarsa T Khazaeian A, Saraeian A. Effect of Nanoclay On Some AppliedDocument12 pagesSalari A Tabarsa T Khazaeian A, Saraeian A. Effect of Nanoclay On Some AppliedArif AnsariNo ratings yet

- Chemsheets GCSE 1069 Allotropes of CarbonDocument1 pageChemsheets GCSE 1069 Allotropes of CarbonNoah KellerNo ratings yet

- Melting Point Determination Experiment ResultsDocument2 pagesMelting Point Determination Experiment ResultsMaej OragaNo ratings yet

- Dvm+s+y+joint Mcu+port+twin Submittal 09192018Document3 pagesDvm+s+y+joint Mcu+port+twin Submittal 09192018Luis Fernado PaizNo ratings yet

- Bronze Trolley Wire: Standard Specification ForDocument6 pagesBronze Trolley Wire: Standard Specification ForYayan RnsNo ratings yet

- Full Scale Test FacilitiesDocument2 pagesFull Scale Test FacilitiesChangjiang DuNo ratings yet

- A Review On Rubber Compound Mixing in Banbury Mixer at Tire Industries-864 PDFDocument4 pagesA Review On Rubber Compound Mixing in Banbury Mixer at Tire Industries-864 PDFJin HernNo ratings yet

- Manganese Steel 3401Document1 pageManganese Steel 3401kazdoelahNo ratings yet

- Micro Electro Mechanical Systems: S. MeenatchisundaramDocument15 pagesMicro Electro Mechanical Systems: S. MeenatchisundaramkksundariNo ratings yet

- VIBRATION PROBLEM IN A HYDRO-TURBINE GENERATOR SETDocument7 pagesVIBRATION PROBLEM IN A HYDRO-TURBINE GENERATOR SETAnonymous NUn6MESxNo ratings yet

- Smart Axis Automatic Chasing Machine ManualDocument38 pagesSmart Axis Automatic Chasing Machine Manualvser19No ratings yet

- Brochure Husker RollsDocument2 pagesBrochure Husker RollsEmerson OliveiraNo ratings yet

- Reaktor (R-01) DesignDocument5 pagesReaktor (R-01) DesignalNo ratings yet

- First Part Lab ManualDocument6 pagesFirst Part Lab ManualInfo EsocketNo ratings yet

- CIC Total Product List 2016Document1 pageCIC Total Product List 2016RAMI HAMADNo ratings yet

- Corrapol Clear Corrugated Sheet Ranges Technical GuideDocument8 pagesCorrapol Clear Corrugated Sheet Ranges Technical GuideDavid Galvis VelozaNo ratings yet