Professional Documents

Culture Documents

218

Uploaded by

jokishCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

218

Uploaded by

jokishCopyright:

Available Formats

PR

O C E S S I N G

Better fractionation hikes ULSD yields, hydrotreater run lengths

Scott Golden Process Consulting Services Houston

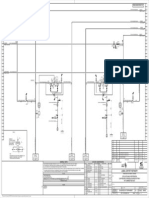

SpECIAL Improved fractionation will allow many refiners to increase their ultralow-sulfur diesel Rening Report (ULSD) yields and hydrotreater run lengths by segregating the easy and difficult-to-treat sulfur species. When ULSD specifications heat removal, lower crude preheat temtake effect in the US, refiners will have perature, and other effects. to control hydrotreater feed stream Some refiners are modifying fracyields tightly so that the ULSD product tionation systems to allow recovery of sulfur specification is met at an accept- nearly the entire range of diesel maable catalyst life. New high-pressure hy- terials that contain easy-to-treat sulfur drotreaters are being built based upon species and concentrate difficult-to-reassumed feed-stream compositions. move sulfur compounds by producing In some instances, high endpoint vacuum diesel and heavy LCO. straight-run (SR) diesel, FCC light cycle oil (LCO), and light coker gas R EFINERY CONFIGURATION oil (LCGO) stream compositions are assumed to remain unchanged after ULSD production begins. Yet many Kerosine refiners will have to undercut the ULSD SR diesel hydrotreater feed streams to lower the endpoint, which will reduce the amount of difficult-to-treat sulfur speVacuum diesel cies feeding the ULSD hydrotreater. FCC feed hydrotreater diesel Light Crude Table 1 shows some data for true vacuum gas oil boiling point (TBP) distillations of feed streams to the diesel hydrotreater. Heavy LCO Medium vacuum Although these distillation 90%-end gas oil point temperatures are high, today it FCC feed Heavy vacuum may be possible to mask the end point gas oil with large volumes of kerosine while still meeting sulfur specifications. Undercutting SR diesel, LCO, and LCGO has several consequences includLCGO ing more diesel-boiling-range material to the FCC feed hydrotreater and FCCU, lower product and pump-around draw temperatures, reduced pump-around

Crude unit FCC feed hydrotreater FCCU Delayed coker

Report

Refinery configuration (Fig. 1) and crude source differences between US and non-US refiners will play a significant role in ULSD hydrotreater catalyst life. FCC capacity outside the US is relatively low and few refiners operate cokers. Furthermore, many nonUS refiners produce light and heavy gas oil (diesel boiling range) products from the crude unit, with most vacuum units producing heavy gas oil. These crude-unit design differences allow non-US refiners better to segregate the 610 F. and lighter portion of the SR diesel from the 610 F. and heavier boiling range material that conFig. 1

Renery conguration, crude source

ULSD Hydrotreater ULSD Hydrotreater Light LCO

Low-severity ULSD product

High-severity ULSD product

Reprinted from the March 13, 2006 edition of OIL & GAS JOURNAL Copyright 2006 by PennWell Corporation

2 x 2.5

No. z060313OGJsgo01

PR

O C E S S I N G

Fig. 2 250

4, 6-DMDBT DISTRIBUTION

200 4, 6-DMDBT, ppm (wt)

150

100

580590

590600

600610

610620

620630

630640

640650

650660

660670

670680

680690

690700

Cut boiling points, F .

LCGO 4,6-DMDBT DISTRIBUTION

600 500 4, 6-DMDBT, ppm (wt) 400 300 200 100 0

2.5 x 2

Fig. 3

580590

590600

600610

610620

620630

630640

640650

650660

660670

670680

680690

690700

Cut boiling range, F .

LCO 4,6-DMDBT DISTRIBUTION

2,000 1,800 1,600 4, 6-DMDBT, ppm (wt) 1,400 1,200 1,000 800 600 400 200 0 580590 590600 600610 610620

2.5 x 2

Fig. 4

620630

630640

640650

650660

660670

670680

680690

690700

Cut boiling points, F .

2.5 x 2

No. z060313OGJsgo04

No. z060313OGJsgo03

No. z060313OGJsgo02

50

tains the majority of the hard-totreat sulfur species. Segregating difficult-to-treat sulfur compounds allows the refiner to process them in different hydrotreating units, which takes advantage of severity differences. Refiners that have severe FCC feed hydrotreating have an added degree of flexibility. Crude source also influences the amount of hard-to-treat sulfur feeding the ULSD hydrotreater. Several US refiners process heavy and extra heavy crudes; and future crude supplies will include more oil-sands-based sour crudes from Canada. Some of these contain coker LCGO that is blended with the bitumen to increase API gravity and SR material in the bitumen, which contain much higher percentages of hard-to-treat sulfur species than most crudes. More coker capacity will be added to US refineries. Ultimately, heavy crudes produce less SR diesel that contains more difficult-to-treat

Rening Report

Steam

Steam Vacuum tower bottoms

on the species and screen 2 x 2.5 STREAM dIsTIllATION TAIls Table 1 Each refiners distillation potential options to segre Product stream TBP distillations, F. column design and column gate easy and hard-to-treat Fraction, Straight- Light coker gas Light heat balance (internal reflux) sulfur species feeding the vol % run diesel oil cycle oil varies tremendously. Some ULSD hydrotreater. Hard-to80 620 653 648 90 655 681 683 have many trays and high treat sulfur distribution was 95 675 719 715 End point 720 777 780 internal reflux, which leads separated by boiling range to excellent product fractionto allow us to characterize ation. Others have few trays, increasing the amount of hard-to-treat the crude, FCC, and delayed little internal reflux, poor tray design, sulfur species. But this requires crudecoker feed streams in the process model and operate at high charge rates result- unit modifications. including the distribution of hard-toing in poor fractionation. During a refinery ULSD study, we treat sulfur from total sulfur. Reducing product yields and imfractionated hydrotreater feed streams Fig. 2 shows the 4,6-DMDBT in proving fractionation can lower SR to quantify the amount of hard-tothe atmospheric column diesel for a diesel, LCGO, and LCO product sulfur treat sulfur species in each stream and medium-sulfur crude. The 4,6-DMDBT levels. Furthermore, refiners charging explore various options for segregating begins to distill in the 600-610 F. TBP large volumes of diesel-boiling-range easy and hard-to-treat sulfur species. cut and peaks in the 620-630 F. cut. hydrocarbons to the FCC have an adSR diesel, LCGO, and LCO were frac- Very little is present in the 650 F. and ditional opportunity to recover the tionated into 10 F. boiling range cuts heavier cut. material containing easy-to-treat sulfur in an ASTM 2892 still. We then analyzed Fig. 3 shows the LCGO product compounds. each sample for various 4,6-DMDBT from a coker Table 2 shows a combined atmosulfur species including 4processing medium-sulfur CRudE uNIT FCC Table 2 vacuum residue. The 4,6spheric gas oil, light and heavy vacuum methyl dibenzothiophene, fEEd TBP gas oil stream from one refiners crude 4,6-DMDBT, and other DMDBT begins to distill distillation unit. This crude unit promulti-substituted dibenzo- dIsTIllATION in the 610-620 F. TBP cut Frac- FCC stream tion, TBP distilladuces 40,000 b/d of FCC feed. thiophene species. and peaks in the 620-630 vol % tions, F. Recovering the 600 F. and lighter Determining the F. cut. Very little is present Initial boiling hydrocarbons from the FCC feed and quantity of hard-to-treat in the 660 F. and heavier point 430 5 560 sending it directly to ULSD increases sulfur species by boiling cut. LCGO contains much 10 600 15 615 diesel production without materially range helped quantify the more hard-to-treat sulfur 20 641 influence of fractionation than SR diesel.

Renery distillation, sulfur

No. z060313OGJsgo05

sulfur species. Heavier crudes produce more FCC feed resulting in a higher LCO product yield; 35% or more of the crude goes to the coker, which increases LCGO product yield. All these make ULSD production more difficult. The remaining sulfur compounds in current US road diesels are nearly all difficult-to-treat 4,6-dimethyl dibenzothiophene (DMDBT) and other multisubstituted compounds. Hydrotreater operating experience will determine the actual severity and feed stream undercutting needed to maintain acceptable run length when processing high percentages of cracked stock. US refiners are likely to have some surprises due to difficulties processing cracked stock and because they are not focused on diesel hydrotreater feed quality.

A TMOSPHERIC, VACUUM DIESEL PRODUCTION

Ejector

Fig. 5

Vacuum diesel

SR diesel

Light vacuum gas oil

Atmospheric gas oil pumparound Atmospheric gas oil product

Medium vacuum gas oil Heavy vacuum gas oil

Crude charge

PR

O C E S S I N G

Fig. 6 Wet gas

D ELAYED COKER MAIN FRACTIONATOR MODIFICATIONS

H EAVY LCO DRAW

Gasoline and lighter

Fig. 7

FCC main fractionator Wild naphtha Light LCO product (620 F . and lighter)

LCGO product Higher reux

Reactor efuent No. z060313OGJsgo06

Heavy LCO product (620-660 F .) No. z060313OGJsgo07 Fig. 8

FCC LCO contains the highest quan1.5 x 2.5 tity of hard-to-treat sulfur compounds. Fig. 4 shows the 4,6-DMDBT in the FCC LCO from a hydrotreated FCC feed processed from a medium-sulfur crude. The 4,6-DMDBT begins to distill in the 630-640 F. TBP cut and peaks in the 650-660 F. cut. Very little is present in the 680 F. and heavier cut.

FCC MAIN FRACTIONATOR

Light LCO Light-heavy LCO fractionation

Most difficult-to-treat sulfur comHeavy LCO pounds feeding the ULSD hydrotreater are in the LCO product with lesser Heavy LCOheavy cycle oil amounts in crude diesel and coker fractionation LCGO streams. Undercutting both crude unit diesel and LCGO product increases the FCC charge rate unless the FCC feed hydrotreater has a fractionator. Heavy cycle oil pump-around Undercutting LCO product increases slurry production and sometimes raises slurry product API gravity above carbon black market specifications. Undercutting decreases product and pump-around draw temperatures, which makes product fractionation increasingly difficult because exchanging pump-around heat generates column internal refluxes. For example, decreas- removed from the pump-around. 1 LCO x3 ing LCO product draw temperature Often a refiner increases slurry reduces the amount of heat that can pump-around duty to avoid higher

Product undercutting

overhead 1.5 x condenser 2.5 duty, thereby reducing reflux below the LCO product draw. This results in more undercutting required as fractionation deteriorates. If a refiners FCC charge rate is already limited, undercutting crude unit diesel and LCGO product has a high cost. Undercutting may appear to be an inexpensive option to reduce hard-totreat sulfur in the ULSD hydrotreater feed, but it may be costly. Most US refiners produce diesel from the atmospheric distillation column. Yet maximizing recovery of 610 F. and lighter hydrocarbons and segregating the 610-660 F. boiling range requires diesel production from both the atmospheric and vacuum columns. Most European refiners already do this because their motor fuels market is predominantly diesel; maximum recovery has always been important. Because US refiners focus on gasoline production, many have poor recovery of diesel and high quantities of diesel-boilingrange hydrocarbons in the FCC feed. Fig. 5 shows an optimized crudeunit design with diesel produced in the atmospheric and vacuum columns.

Crude units

No. z060313OGJsgo08

Rening Report

Most US refineries crude Some refiners are already FCC FEED HYDROTREATING Fig. 9 units are currently running at producing HCO that is maximum capacity. Typically blended to fuel oil. But the Atmospheric diesel this reduces diesel recovery fuel oil market cannot take because the crude heater all the future LCO underULSD ULSD LCGO outlet temperature must be cutting. Some refiners have hydrotreater reduced to process more already installed a heavy Light LCO crude. LCO product draw that allow A lower temperature them to produce 620 F. and increases the amount of lighter LCO and a 620 F. and diesel-boiling-range material heavier LCO draw (Fig. 7). feeding the vacuum column Fig. 8 schematic shows and reduces atmospheric a recent main fractionator Diesel-boilingcolumn internal reflux below design with a new lightrange hydrocarbon the diesel draw. A low liquidheavy LCO fractionation. vapor ratio below the diesel Heavy LCO product is drawn draw increases the amount of between the light LCO and 610 F. and lighter hydrocarheavy-cycle-oil product bons containing the easy-todraws. The heavy LCO matetreat sulfur species into the rial boils at 620-660 F. FCC atmospheric gas oil product. The advantage of overfeed Vacuum diesel FCC feed Many US refiners comproducing a heavy-cycle oil hydrotreater monly have 10% or more is that the heavy LCO can Heavy LCO 610 F. and lighter hydrocarfeed a high-severity ULSD bons in the FCC feed. hydrotreater whereas heavyMaximizing crude unit cycle oil will have an 850diesel recovery requires the 900 F. end point. In a few production of a diesel-boilcases the heavy LCO matecompounds in the LCGO ing-range product from the vacuum rial can feed a high-severity FCC feed 1.5 x 3 product by more than 50% while minimizing unit. This allows a lower atmospherichydrotreater (Fig. 9). column diesel product end point while product yield loss at relatively low cost In some instances this heavy LCO (Fig. 6). recovering the 610-660 F. boiling must be sold as a low-value stream to Undercutting LCGO without range hydrocarbons as vacuum diesel. maintain acceptable ULSD hydrotreater improving fractionation significantly Processing atmospheric gas oil run length. through the vacuum column further in- increases FCC charge rate. Those refiners creases recovery. Producing two crude- that have an FCC feed hydrotreater can unit diesel streams allows the refiner to recover some of the diesel-boilingrange material and feed this stream to process the lower-sulfur atmospheric the ULSD hydrotreater. The FCC feed column diesel in the lower-severity hydrotreater severity will determine ULSD hydrotreater and process the The author vacuum diesel in a higher-severity unit. whether this makes sense. Scott W . Golden (sgolden@ revamps.com) is a chemical engineer with Process ConsultDelayed coker FCC main fractionator ing Services Inc., Houston. His main fractionator LCO contains the highest percentprevious experience includes LCGO yield will depend on the ULSD ages of the most refractory sulfur refinery process engineering and hydrotreater severity and targeted unit compounds of any of the hydrotreater distillation troubleshooting and run length. Most cokers can increase the feed streams; therefore, many refiners design. Golden holds a BS in recovery of 620 F. and lighter hydrowill have to undercut LCO to reduce its chemical engineering from the University of Maine and is a registered professional carbons from the HCGO product. end point to manage catalyst life and engineer in Texas. A low internal reflux between the run length. Furthermore, those refiners LCGO and HCGO and an inferior tray selling slurry product as decant oil will design cause poor fractionation. In have to be ensure that the slurry API some instances, the refiner can reduce gravity still meets carbon black market the amount of hard-to-remove sulfur specifications.

No. z060313OGJsgo09

Process Consulting Services, Inc. 3400 Bissonnet Suite 130 Houston, Texas 77005 U.S.A. Phone: [1]-(713)-665-7046 Fax: [1]-(713)-665-7246 E-mail: info@revamps.com Website: www.revamps.com

You might also like

- Notes on Plant layout Part 1Document1 pageNotes on Plant layout Part 1jokishNo ratings yet

- Bound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatDocument1 pageBound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatjokishNo ratings yet

- How A Steam Jet EjectorDocument1 pageHow A Steam Jet EjectorjokishNo ratings yet

- Objectives Boiler Water TreatmentDocument1 pageObjectives Boiler Water TreatmentjokishNo ratings yet

- DryingDocument1 pageDryingjokishNo ratings yet

- Bound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatDocument1 pageBound Moisture. This Is Water Retained So That It Exerts A Vapour Pressure Less Than ThatjokishNo ratings yet

- DryingDocument1 pageDryingjokishNo ratings yet

- Jet PumpsDocument3 pagesJet PumpsjokishNo ratings yet

- Impeller TypesDocument1 pageImpeller TypesjokishNo ratings yet

- Wire RopeDocument1 pageWire RopejokishNo ratings yet

- What Is CommissioningDocument1 pageWhat Is CommissioningjokishNo ratings yet

- Chemical Engineering ReferenceDocument2 pagesChemical Engineering Referencejokish0% (1)

- Pressure Relief DeviceDocument1 pagePressure Relief DevicejokishNo ratings yet

- Applications of Liquid Ejectors and Jet PumpsDocument1 pageApplications of Liquid Ejectors and Jet PumpsjokishNo ratings yet

- ConductanceDocument1 pageConductancejokishNo ratings yet

- Typical Overall Heat-Transfer CoefficientsDocument2 pagesTypical Overall Heat-Transfer CoefficientsjokishNo ratings yet

- Calculate LFL and UFL of Gas MixturesDocument1 pageCalculate LFL and UFL of Gas MixturesjokishNo ratings yet

- BafflesDocument1 pageBafflesjokishNo ratings yet

- Process Systems ReviewDocument2 pagesProcess Systems ReviewjokishNo ratings yet

- Mixing and AgitationDocument1 pageMixing and AgitationjokishNo ratings yet

- Humid PDFDocument4 pagesHumid PDFFrank MtetwaNo ratings yet

- Natural Draft Cooling TowersDocument2 pagesNatural Draft Cooling TowersjokishNo ratings yet

- EjectorsDocument1 pageEjectorsjokishNo ratings yet

- How To Do Sundarkand Path & BenifitsDocument1 pageHow To Do Sundarkand Path & BenifitsjokishNo ratings yet

- Preliminary Heat Exchanger Design ExampleDocument4 pagesPreliminary Heat Exchanger Design ExamplejokishNo ratings yet

- Fundamentals of Heat Exchanger Theory and DesignDocument3 pagesFundamentals of Heat Exchanger Theory and DesignSakthikumar ChandrasekaranNo ratings yet

- Stress AnalysisDocument1 pageStress AnalysisjokishNo ratings yet

- FansDocument1 pageFansjokishNo ratings yet

- Intro to Mechanical Draft Coolers and Heat ExchangersDocument1 pageIntro to Mechanical Draft Coolers and Heat ExchangersjokishNo ratings yet

- PumpsDocument1 pagePumpsjokishNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- American Institute of Chemical EngineersDocument35 pagesAmerican Institute of Chemical EngineersPathik PandyaNo ratings yet

- Catalysts A Adsorbents Catalogue-EnglishDocument14 pagesCatalysts A Adsorbents Catalogue-EnglishNathalia DelgadoNo ratings yet

- Hydroconversion Tut Sheet Tut 6BDocument2 pagesHydroconversion Tut Sheet Tut 6BRohit SahuNo ratings yet

- ShubhiDocument132 pagesShubhiAmit SinghNo ratings yet

- 106Document1 page106ahm3d16n100% (1)

- Material Selection HandbookDocument127 pagesMaterial Selection HandbookAdi SutardiNo ratings yet

- Refinery Process DescriptionDocument24 pagesRefinery Process DescriptionjeyalaksNo ratings yet

- Hydroprocessing Pilot PlantsDocument4 pagesHydroprocessing Pilot PlantsNattapong PongbootNo ratings yet

- RefineryDocument100 pagesRefineryshaliq28No ratings yet

- Title / Link To Download Bidding DocumentDocument24 pagesTitle / Link To Download Bidding Documentarjun SinghNo ratings yet

- Oil and Gas BrochureDocument12 pagesOil and Gas BrochureHasnah MalindaNo ratings yet

- Refinery Operations Planning GuideDocument95 pagesRefinery Operations Planning GuideMarwa NabilNo ratings yet

- Annual Corrosion Survey Report 2013-14Document140 pagesAnnual Corrosion Survey Report 2013-14Jay Lawson100% (2)

- Hydrotreating - UOP - A Honeywell CompanyDocument59 pagesHydrotreating - UOP - A Honeywell CompanySamNo ratings yet

- ERC Refinery ProjectDocument16 pagesERC Refinery ProjectTarek Fawzy100% (1)

- Crude Oil Refining ProcessDocument45 pagesCrude Oil Refining ProcessAnubhav Tiwari100% (2)

- Basics of Refining and Optimization Dec 2019Document31 pagesBasics of Refining and Optimization Dec 2019AranyosiMártonNo ratings yet

- Summer Internship/Vocational Training Report: - Mr. Bardan LamaDocument40 pagesSummer Internship/Vocational Training Report: - Mr. Bardan Lamachemical todiNo ratings yet

- Conocophillips S Zorb Diesel Process: Ed Sughrue and John S. ParsonsDocument6 pagesConocophillips S Zorb Diesel Process: Ed Sughrue and John S. ParsonsBharavi K SNo ratings yet

- Chemical Reaction and Reactor DesignDocument408 pagesChemical Reaction and Reactor Designrodrigonpimentel86% (7)

- VolsampDocument153 pagesVolsampSonny HutomoNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2010/0043279 A1Document13 pagesPatent Application Publication (10) Pub. No.: US 2010/0043279 A1vitorio netoNo ratings yet

- Refinery Workbook A: Siting AppendicesDocument533 pagesRefinery Workbook A: Siting AppendicesNitish ReddyNo ratings yet

- Lubricant SelectionDocument9 pagesLubricant Selectionrahim08No ratings yet

- Assessment Reports Final PDFDocument235 pagesAssessment Reports Final PDFFarhan KhanNo ratings yet

- Godara Phase 3Document20 pagesGodara Phase 3Devandra GodaraNo ratings yet

- 1 s2.0 S0960852416307313 Mainjetfuel PDFDocument9 pages1 s2.0 S0960852416307313 Mainjetfuel PDFAllBetaNo ratings yet

- CDHydro - CDTECH PDFDocument37 pagesCDHydro - CDTECH PDFVuToanThangNo ratings yet

- Miniaturization of Hvdrowocessina Catalvst Testing System Sie 1996 AIChE Journal PDFDocument10 pagesMiniaturization of Hvdrowocessina Catalvst Testing System Sie 1996 AIChE Journal PDFBrenda Rubí Hdz BetancourtNo ratings yet

- 1CD1213A-DI-8110-PD-0000-0007-Preliminary Data For Refining UnitsDocument11 pages1CD1213A-DI-8110-PD-0000-0007-Preliminary Data For Refining UnitsРоман БелоусовNo ratings yet