Professional Documents

Culture Documents

Alternator Lesnewile 4000

Uploaded by

help3rOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alternator Lesnewile 4000

Uploaded by

help3rCopyright:

Available Formats

7585 Empire Drive | Florence, KY 41042 | (800) 354-0560 | www.prestolite.

com

TSM1001 2/09

Technical Service Manual

Service Manual

for the 12 Diode

4000 Series Alternator

Troubleshooting, Diagnostics

and Repair

www.prestolite.com 2

Causes of Charging System Failure 3

Alternator Disassembly 4

Negative Rectifer Ring Removal 5

Postive Rectifer Ring Removal 6

Front Bearing Removal 6

Rear Bearing Removal 7

Alternator Diagnostic / Component Testing 7

Positive Rectifer Test 7

Negative Rectifer Test 9

Alternator Field Test 10

Rotor Test 11

Brush Inspection 12

Stator Test 12

Regulator Test 13

Alternator Re-assembly Instructions 14

Front bearing Installation 14

Rotor Installation 14

Rear Bearing Installation 15

Rear Bearing Seal Installation 15

Regulator / Brushbox Assembly Instructions 16

Positive Rectifer Installation 17

Negative Rectifer Installation 18

Stator Installation 18

Alternator Final Re-assembly 19

Parts Diagram 20

Table of Contents

3

Description:

The 4000 series alternators are air cooled, belt

driven units designed for heavy duty diesel engine

applications.

These units feature an integral/external voltage

regulators, fully enclosed brushes, built-in rectifer

assemblies with solid lead frame and extra large

heat sinks, a dynamically balanced rotor, and heavy

duty stator and bearings. The 4000 series comes

in a vast array of features which includes, remote

sense, self excite, ignition excite, lamp and Multip-

ower Technology.

Mode of operation:

The vehicle battery supplies excitation to the feld

coil (rotor coil) through the regulator and brushes, to

create a magnetic feld around the rotor and through

the stator.

When the rotor is set in motion, the moving magnetic

feld induces an alternating current (AC) in the sta-

tor windings. This output current increases with the

speed of the rotor.

The (AC) produced in the stator is converted to

direct current (DC) by the positive and negative recti-

fer assemblies. The rectifer assemblies are con-

nected to the alternator output terminals to provide

(DC) output for charging the batteries and to satisfy

the vehicle electrical loads.

The regulator monitors the output voltage through

sensing leads which are connected to the positive

and negative rectifer assemblies, or on some mod-

els this is done externally through a remote sense

(S) terminal. When the output voltage deviates from

the set voltage, the regulator takes corrective action

to maintain the output voltage at the proper level.

For more detailed information on how an alternator

works please see our training CD PP-1216.

Causes of Charging System Failure:

Charging system malfunction is identifed by the bat-

tery

1. OVERCHARGED BATTERIES caused by one or a

combination of the following:

A. Defective Battery.

B. Defective regulator.

C. Poor sensing lead contact to regulator or rectifer

assembly.

2. UNDERCHARGED BATTERIES caused by one or a

combination of the following:

A. Loose belts; corroded, broken, loose or dirty

terminals; broken wiring; undersize wiring;

defective batteries.

B. Alternator feld circuit malfunction caused by one

or a combination of the following:

a. Poor contacts between regulator and brushes.

b. No residual magnetism in rotor.

(Refer to TSB-1034 to restore residual magnetism.)

c. Defective regulator.

d. Damaged or worn brushes.

e. Damaged or worn slip rings.

f. Poor connection between slip ring assembly

and feld coil leads.

g. Rotor coil shorted, open, or grounded.

C. Alternator generating section malfunction caused

by one of the following:

a. Stator phase(s) shorted, open, or grounded.

b. Rectifer assembly grounded.

c. Rectifer(s) shorted or open.

On- Vehicle or Test Stand Troubleshooting:

Detailed information can be found on our web site at

www.prestolite.com.

When on our web site, look up the alternator model

you have questions on and you will fnd hyperlinks that

will take you to information pertaining to that model.

You can also contact our technical support hot line at

1-866-288-9853.

Good information to reference would be our training

www.prestolite.com 4

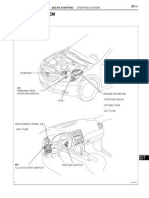

Alternator Disassembly

SCREWS

Step 1: Remove fan and 4 screws that attach

the regulator to alternator.

See Fig 1.

Step 2: Lift regulator from alternator and remove all

hardware that attaches regulator to alternator.

See Fig 2.

Step 3: Remove brushes and regulator from brushbox.

See Fig 2.

Step 4: Remove through bolts from alternator.

See Fig 3 Pad mount alternators.

See Fig 4 J-180 mount alternators.

Fig 1

Fig 2

Loosen and remove

through bolts

Fig 3

Fig 4

Loosen and remove

through bolts

Screws

Brushes

Remove fan

Remove

hardware

Step 5: Tap front housing with a soft face

mallet to separate the front

housing/ rotor assembly from the

rear housing/ stator assembly.

See Fig 5.

Step 6: Pull front housing/ rotor assembly

from rear housing/ stator assembly.

See Fig 6.

Tap front housing

with soft face mallet

Fig 5

Fig 6

5

Step 7: Remove three stator nuts holding stator to rear housing and remove stator.

See Fig 7 and 8.

Pemove three stator nuts

Fig 7

Fig 8

Step 1: Remove two bolts holding

negative cover plate.

Step 2: Remove negative plate.

See Fig 1.

Fig 1

Fig 2

Step 3: Remove three 1/4 AC tap

nuts. See Fig 2.

Step 4: Remove two 1/4 bolts.

See Fig 2.

Step 5: Remove two screws. See Fig 2.

Step 6: Remove negative rectifer ring

from alternator.

See Fig 3.

Negative Rectifer Ring

Removal

Remove two bolts

Remove three 1/4 AC tap nuts

Remove two screws

Remove two 1/4 bolts

Fig 3

Negative rectifer

ring removed.

www.prestolite.com 6

Positive Rectifer Ring Removal

Step 1: Remove hardware.

See Fig 1

Step 2: Flip alternator housing and remove

hardware. Remove output studs.

See Fig 2.

Step 3: Remove positive rectifers from

rear housing. See Fig 3.

Note: Brush box will come out of rear housing

when rectifer is removed.

Fig 1

Remove hardware

Fig 2

Remove hardware and push output

bolts from rear housing

Fig 3

Rotor Removal

Step 1: Place front housing/ rotor assembly on a

press.

Step 2: Press rotor from front housing.

See Fig 1 for steps 1 and 2.

Fig 1

Front Bearing Removal

Step 1: Remove screws that attach the bearing

retainer to the front housing. See Fig 1.

Step 2: Press bearing from front housing.

See Fig 2.

Loosen and remove screws

Fig 1

Fig 2

7

Rear Bearing Removal

Step 1: Place rear housing on a press.

See Fig 1.

Step 2: Press rear bearing/ seal from rear

housing.

See Fig 2.

Fig 1

Fig 2

Alternator Diagnostic/ Component Testing

All tests are designed to be performed

off the vehicle.

Positive Rectifer Test

(TP-1)

(TP-2)

(TP-3)

Fig 1

(TP-1)

(TP-2)

(TP-3)

Fig 2

Note: You will need a multimeter to perform the fol-

lowing tests.

Test for complete alternator.

Step 1: Set multimeter to diode check mode ( ).

Step 2: Connect positive test lead (+) to alternator

AC post (TP-1) and negative test lead (-)

to alternator B+ post. Move the positive test

lead (+) to (TP-2) and (TP-3).

Record readings at all three TP locations.

See Fig 1.

Voltage readings for a good unit: 0.4V-0.5V.

If voltage does not fall into these parameters

then their is a possibility that the rectifer is

faulty. Continue to step 3.

Step 3: Reverse test leads.

Connect positive test lead (+) to alternator

B+ post and negative test lead (-) to

alternator AC post (TP-1). Move the Negative

test lead (-) to (TP-2) and (TP-3). Record

readings at all three TP locations. See Fig 2.

Voltage readings for a good unit: 1V - 2V.

If voltage does not fall into these parameters

then their is a possibility that the rectifer is

faulty. Continue to steps 4 and 5.

www.prestolite.com 8

Note: You will need a multimeter to perform the fol-

lowing tests.

Test for rectifer ring only.

Step 4: Connect positive test lead (+) to diode post

(TP 1) and negative test lead (-) to rectifer

heatsink. Move the positive test lead (+) to

(TP-2), (TP-3), (TP-4), (TP-5) and (TP-6).

Record readings at all six TP locations.

See Fig 3.

Voltage readings for a good unit: 0.4V-0.5V.

If voltage does not fall into these parameters

then the rectifer is defective.

Step 5: Reverse test leads.

Connect positive test lead (+) to rectifer

heatsink and negative test lead (-) to diode

post (TP-1). Move the Negative test lead

(-) to (TP 2), (TP 3), (TP-4), (TP-5) and

(TP-6).

Record readings at all six TP locations.

See Fig 4.

Voltage readings for a good unit: or OL.

If voltage does not fall into these parameters

then the rectifer is defective.

Note: Due to the wiring confguration of the rectifer,

the tests above will not identify an open diode.

TP-1

TP-2

TP-3

TP-4

TP-5

TP-6

Fig 3

TP-1

TP-2

TP-3

TP-4

TP-5

TP-6

Fig 4

9

Negative Rectifer Test

Note: You will need a multimeter to perform the fol-

lowing tests.

Test for complete alternator.

Step 1: Set multimeter to diode check mode.

Step 2: Connect positive test lead (+) to alternator

negative post and negative test lead (-) to

alternator AC post (TP-1). Move the negative

test lead (-) to (TP 2) and (TP 3).

Record readings at all three TP locations.

See Fig 1.

Voltage readings for a good unit: 0.4V-0.5V.

If voltage does not fall into these parameters

then their is a possibility that the rectifer is

faulty. Continue to step 3.

Step 3: Reverse test leads.

Connect positive test lead (+) to alternator

AC post (TP-1) and negative test lead (-) to

alternator negative post. Move the positive

test lead (+) to (TP-2) and (TP-3). Record

readings at all three TP locations. See Fig 2.

Voltage readings for a good unit: 1V - 2V.

If voltage does not fall into these parameters

then their is a possibility that the rectifer is

faulty. Continue to steps 4 and 5.

Test for rectifer ring only.

Step 4: Connect positive test lead (+) to rectifer

heatsink and negative test lead (-) to diode

post (TP-1). Move the negative test lead (-)

to (TP-2), (TP-3), (TP-4), (TP-5) and (TP-6).

Record readings at all six TP locations.

See Fig 3.

Voltage readings for a good unit: 0.4V-0.5V.

If voltage does not fall into these parameters

then the rectifer is defective.

(TP-1) (TP-2) (TP-3)

Fig 1

(TP-1) (TP-2) (TP-3)

Fig 2

(TP-1)

(TP-2)

(TP-3)

(TP-4)

(TP-5)

(TP-6)

Fig 3

www.prestolite.com 10

Step 5: Reverse test leads.

Connect positive test lead (+) to diode post

(TP-1) and negative test lead (-) to rectifer

heatsink. Move the positive test lead

(+) to (TP-2), (TP-3), (TP-4), (TP-5) and

(TP-6).

Record readings at all six TP locations.

See Fig 4.

Voltage readings for a good unit: or OL.

If voltage does not fall into these parameters

then the rectifer is defective.

Note: Due to the wiring confguration of the rectifer,

the tests above will not identify an open diode.

(TP-1)

(TP-2)

(TP-3)

(TP-4)

(TP-5)

(TP-6)

Fig 4

Alternator Field Test

Full Field

Access Hole

Fig 1

The test below will help determine if the alternator feld is

working properly.

Set multimeter to diode check mode.

Step 1: Insert 1/16 drill bit or mechanics wire into

alternators full feld access hole. Insert straight

into hole until it stops about 1/4 (Do not Force).

Hold frmly in place to ensure appropriate

contact. See Fig 1.

Step 2: Connect voltmeter where one test lead connects

to the wire or drill bit inserted into the full feld

access hole and the other test lead connects to

the alternator B+ terminal. Observe reading on

multimeter.

Note: While performing this test, you may need to rotate

the rotor to make sure the brushes are making contact to

the slip rings.

If a low voltage reading (0V) is observed on the multim-

eter then the feld circuit is good.

If a high voltage reading ( or OL) on the multimeter

then the feld circuit is open.

Possible causes for an open feld circuit.

1) Poor contact between regulator and

brushes.

2) Poor contact between brushes and slip

rings.

2) Damaged or worn brushes.

3) Rotor coil open.

4) Positive regulator sense lead damaged or

a loose connection.

5) Defective regulator.

6) Worn or damaged slip rings.

11

Rotor Test

The tests below will help determine if the rotor is within

specifcations.

Set multimeter to check resistance (R X 1) scale.

Step 1: Connect multimeter test leads per Fig 1. Move

test lead to (TP-2). Record readings at both TP

locations.

If a high resistance reading is observed then the rotor is

good. Continue to step 2.

If a low resistance (Short) is observed then the rotor is

defective. Rotor will need to be replaced.

Step 2: Connect multimeter test leads per Fig 2 and

record resistance reading.

Note: It may be necessary to clean the carbon coating

off the slip rings with a strip of emery cloth.

Determine the voltage and amperage rating of the

alternator you are testing and compare your reading to

the chart below.

Voltage Amperage Rotor Resistance

12V 185 A 1.9 - 2.1 Ohms

12V 200 A 2.6 - 2.8 Ohms

12V 220 A 2.8 - 3.0 Ohms

12V 270 A 2.2 - 2.5 Ohms

12V 320 A 1.9 - 2.0 Ohms

24V 200 A 4.0 - 4.3 Ohms

If the resistance reading measured does not compare

then the rotor is defective and will need to be replaced.

(TP-1) (TP-2)

R X 1 Scale

Fig 1

(TP-1) (TP-2)

R X 1 Scale

Fig 2

1.057

26.847mm

.6688/16.987mm

Fig 3

Step 3: Check shaft diameter for wear, where it contacts

the rear bearing. If the diameter is less than

.6688/ 16.987mm then rotor will need to be replaced.

Step 4: Check slip ring diameter for wear. If the diameter

is less than 1.057/ 26.847mm then the rotor will

need to be replaced.

www.prestolite.com 12

Brush Inspection

If brushes appear burned, cracked, broken or if they are

worn to a length of 3/16 or less, brushes must be replaced.

Check shunt lead within the brush spring. If the shunt lead is

broken,frayed or damaged install new brushes.

3/16

Fig 1

Stator Test

Tests below will help determine if stator is within

specifcations.

Set multimeter to check resistance (R X 1) scale.

Step 1: Connect one test lead to a bare metal surface on

the stator lamination and the other test lead to

(TP-1). Move test lead to (TP-2) and (TP-3).

Record reading at all three TP locations. See Fig 1.

If a high resistance reading () is recorded then the stator is

good. Continue to step 2.

If a low resistance reading (Short) is recorded then the stator

will need to be replaced.

Note: It is recommended that a High Pot test be

performed on a stator for grounds by a qualifed electrical

shop.

Note: To perform the test below, a digital ohmmeter with

1/1000th of a ohm (m ) display capability must be used.

Step 2: Connect test leads to stator terminals (TP-1 & TP-2),

(TP-2 & TP-3) and (TP-1 & TP-3). Record

measurements at all three locations.

Refer to chart for correct readings. If readings are not within

specifcations, then stator is defective.

Minimum brush length

(TP-1)

(TP-2)

(TP-3)

(TP-1)

(TP-2)

(TP-3)

(TP-1)

(TP-2)

(TP-3)

(TP-1)

(TP-2)

(TP-3)

Fig 2

Wheatstone Bridge or

Ohmmeter with 1/1000 scale

Voltage Current Phase to Phase Resistance

Ohms

12 185 amps 0.020 - 0.023

12 200 amps 0.012 - 0.016

12 220 / 270 amps 0.008 - 0.010

12 320 amps 0.007 - 0.009

24 200 amps 0.022 - 0.026

13

Regulator Test

The tests below will help determine if any faults are in the

regulator.

Note: It may be necessary to have the regulator tested on a Transpo

regulator tester by a qualifed electrical shop. The tests below will

diagnose about 80% of regulator failures.

Set multimeter to diode check mode.

Step 1: Connect one test lead to a bare metal surface on the

regulator housing and the other test lead to (TP-1).

Move test lead to (TP-2), (TP-3), (TP-4), (TP-5).and (TP-6).

If a terminal is not shown in Fig 1 make sure all terminals

are tested.

Record readings at all TP locations.

If a high reading (OL) is recorded then the regulator is good.

Continue to step 2.

If a low reading (0V) is recorded then the regulator is defective and

needs to be replaced.

Step 2: Connect negative test lead (-) to regulator positive terminal.

Connect positive test lead (+) to (TP-1).

Record measurement. See Fig 2.

If a low reading (0V) is recorded then the regulator is good.

Continue on with Step 2.

If a high voltage reading (OL) is recorded then the regulator is

defective and needs to be replaced.

Step 2 (Cont): Move positive test lead (+) to (TP-2).

Record measurement. See Fig 2.

If a voltage reading of 0.4V to 0.5V is recorded then the regulator is

good. Continue to Step 3. If the measurements are not within these

values then the regulator is defective and needs to be replaced.

Step 3: Connect test leads per Fig 3 and record the reading.

If a voltage reading of 0.4V to 0.5V is recorded then the regulator

is good. If the measurements are not within these values then the

regulator is defective and needs to be replaced.

(TP-1)

(TP-2)

(TP-3)

(TP-4)

(TP-5) (TP-6)

Diode Check

Fig 1

(TP-1)

Diode Check

(TP-2)

Fig 2

Diode Check

Fig 3

www.prestolite.com 14

Alternator Assembly Instructions

Front bearing installation

Step 1: Place bearing into front housing and press into place.

See Fig. 1

Note: To prevent damage to the front bearing, press on the

bearings outer race. Use of an appropriate bearing press

adaptor, socket or pipe that contacts the entire diameter of

the bearing outer race is recommended.

Step 2: Place bearing spacer into front housing. See Fig. 2

Note: On some models, a wider front bearing will be utilized.

If your alternator uses this wider bearing then the front bear-

ing spacer used in step 2 will not be needed.

Step 3: Place bearing retainer on front housing and tighten

mounting screws to 33-39 in-lbs. See Fig. 3.

Note: Apply Blue 242 Locktite to mounting screws before

assembly.

Step 1: Slide spacer onto rotor shaft. See Fig 4.

Note: On some models, a wider front bearing will be utilized.

If your alternator uses this wider bearing then the spacer

shown in Fig 4 will not be needed.

Step 2: Press rotor into front bearing. See Fig 5.

Press bearing on outer race to prevent damage.

Fig 1

Fig 2

Torque screws to 33-39 in-lbs..

Fig 3

Rotor installation

Insert bearing spacer.

Fig 4 Fig 5

Note: To prevent damage to the front bearing, press on the

bearings inner race.

Note: Use of a brass or copper block between the press and

the rotor shaft will prevent damage to the end of the rotor shaft.

See Fig.5

Spacer

15

Rear bearing installation

Step 1: Determine the length of bearing you are installing.

See Fig 1, 1a

Step 2: Place bearing into rear housing and press into place.

See Fig. 2

Note: Use fgure 3 and 3 a to determine correct depth to

press bearing.

Note: To prevent damage to the front bearing, press on the

bearings outer diameter. Use of an appropriate bearing

press adaptor, socket or pipe that contacts the entire diam-

eter of the bearing outer race is recommended. Use caution

not to get debris inside bearing during assembly.

.7

2

5

.9

4

0

Fig 1 Fig 1a

Long Bearing Short Bearing

.28

.30

.22

.19

Long Bearing Short Bearing

Fig 3 Fig 3a

Rear bearing seal installation

Step 1: Place rear bearing seal into rear housing. See Fig 4.

Note correct orientation of seal before pressing into place.

Step 2: Press seal into place.

Note: To prevent damage to the rear bearing seal, press on

the seal outer diameter. Use of an appropriate press

adaptor, socket or pipe that contacts the entire diameter of the

seal outer diameter is recommended.

Use caution not to get debris inside bearing during assembly.

After assembly coat lip of seal with a high quality synthetic

bearing grease.

Fig 2

Fig 4

www.prestolite.com 16

Regulator/ brushbox assembly

instructions.

Step 1: Attach regulator wires to regulator and brush box.

See Fig 1. If your model has a rubber grommet or any

additional wires, attach them at this time.

Torque value: #10-32 nuts: 17-23 in-lbs.

Note: Many different regulator models exist with different

wiring confgerations to the brush box. Please refer to

TSB-1134 that will aid in identifying these wires.

Step 2: Place regulator onto brush box. See Fig 2.

Note: Make sure regulator (red) and (black) leads are

properly seated into notches before securing regulator.

Step 3: Insert four regulator screws and tighten.

Torque screws to 11-13 in-lbs. See Fig 3

Step 4: Turn over assembly and place brushes into brush box.

See Fig 4.

Step 5: With brush placed into holder, compress entire brush

into holder and retain brush into opening with a safety

pin. Install second brush following the same

procedure; slipping retaining pin forward through front

opening of brush box to secure both brushes.

See Fig 5

Fig 1

Fig 2

Fig 3 Fig 4 Fig 5

Attach regulator wire.

Torque to 17-23 in-lbs.

Make sure leads are properly seated

into notches before securing regulator.

Tighten screws to 11-13 in-lbs.

Attach regulator wires.

17

Positive rectifer installation

Step 1: Place insulators into rear housing. See Fig 1

Step 2: Install positive rectifer ring into rear housing. Make

sure insulators are properly seated. Install two bottom

bolts do not tighten. See Fig 2

Step 3: For proper orientation of hardware and insulators refer

to Fig 3.

Step 4: Install brush box assembly into rear housing.

See Fig 4.

Step 5: Insert positive bolt and shorter 5/16 carrage bolt into

rectifer ring. Slight downward pressure on the brush

box assembly may be needed in order to pass

the bolts through the brush box. See Fig 5

Note: Location of bolts are dependant on application. Review

possible clearance issues on application and determine best

location for the positive stud.

Step 6: Tighten two lower rectifer mounting bolts and torque

to 20-25 in-lbs. See Fig 6

Step 7: Route regulator sense leads per (Fig 6) and attach

mounting screws. Torque to 17-25 in-lbs.

Note: On remote regulated models, regulator sense leads will

not be present.

Step 8: Turn rear housing over and install hardware to output

post and torque to 80-100 in-lbs. See Fig 7

Fig 1

Fig 2

Place insulators into

rear housing.

Install rectifer ring

Install two bottom bolts.

(Do not tighten)

Fig 3

Fig 4

Install bolts.

Fig 5

Attach red lead.

Torque: 17-25 in-lbs.

Attach black lead.

Torque: 17-25 in-lbs.

Torque bolts.

20-25 in-lbs.

Fig 6

Attach nuts to output posts.

Torque: 80-100 in-lbs.

Fig 7

www.prestolite.com 18

Negative rectifer installation

Step 1: Place negative rectifer ring onto rear housing and

install hardware. Torque hardware per Fig 1

Step 2: Install hardware to alternator AC terminals. See Fig 1

Note: If model applies, connect regulator AC terminals to

alternators AC posts.

Note: Use Fig 2 for proper orientation of hardware that

attaches rectifer rings to rear housing.

Torque: 50-60 in-lbs.

Torque: 20-25 in-lbs.

Install AC nuts.

Torque: 50-60 in-lbs.

Fig 1

Fig 2

Stator Installation

Step 1: Place stator on rear housing and attach stator

terminals to alternator AC studs. Attach nuts and

torque to 17-23 in-lbs. See Fig 3

Note: On 4800 J-180 models it is important to line up the

stator through bolt holes with the rear housing holes in order

to insert the through bolts. See Fig 4

Install AC nuts.

Torque: 50-60 in-lbs.

Fig 3

Stator through bolt holes must line up.

Fig 4

19

Alternator fnal assembly

Step 1: Insert front housing/ rotor assembly into rear housing/

stator assembly.

Step 2: On pad mount alternators, place the alternator on a

fat surface so the front and rear pads are in line. No

rocking should be present between the front and rear

pads. See Fig 1

Step 3: Insert through bolts and torque in a cross pattern to

90-110 in-lbs. See Fig 2

Step 4: On J-180 mount alternators, insert a 1/2 rod through

the two mounting holes. This will aid in lining up the

through bolts holes. See Fig 3

Step 5: Insert through bolts and torque nuts to 45-50 in-lbs.

See Fig 4

Fig 1

Fig 2

#1

#2

#3

#4

Fig 3

Fig 4

Tighten nuts

Torque: 45-50 in-lbs.

Step 6: Pull brush retaining pin. See Fig 5

Step 7: Install negative cover plate and tighten mounting

bolts. See Fig 6

Fig 5

Install Cover and mounting

bolts.

Fig 6

www.prestolite.com 20

Manufacturing OE Sales

400 Main Street

Arcade, NY USA 14009

Phone: (585) 492-1700

Fax: (585) 492-1660

Distribution, Aftermarket Sales

7585 Empire Drive

Florence, KY USA 41042

Phone: (859) 525-8801

(800) 354-0560

Fax: (800) 997-6202

You might also like

- Engine Pressure Sensor Open or Short Circuit - TestDocument10 pagesEngine Pressure Sensor Open or Short Circuit - TestGustavo GarzaNo ratings yet

- Charging System - Test: Previous ScreenDocument15 pagesCharging System - Test: Previous ScreenWalterNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- String Harmonics in Ravel's Orchestral WorksDocument97 pagesString Harmonics in Ravel's Orchestral WorksYork R83% (6)

- 3334SIDocument30 pages3334SIElectrival Tcataller0% (1)

- Voltage During CrankingDocument5 pagesVoltage During CrankingGomzalez Bin GembozNo ratings yet

- Range Rover Maunual ElectricsDocument146 pagesRange Rover Maunual ElectricsVítor SoaresNo ratings yet

- Engine Pressure Sensor Open or Short PDFDocument14 pagesEngine Pressure Sensor Open or Short PDFNydRomG100% (2)

- DC Alternator TestDocument5 pagesDC Alternator TestAbdul KhaliqNo ratings yet

- Alternator Regulator TroubleshootingDocument2 pagesAlternator Regulator Troubleshootingsheba1023No ratings yet

- 2AZ FE StartingDocument16 pages2AZ FE StartingLuks FernandezNo ratings yet

- Alternator DiagnosticDocument19 pagesAlternator Diagnosticvickers100% (1)

- Fuel Rack Solenoid - TestDocument6 pagesFuel Rack Solenoid - TestAdolfo Dario SaavedraNo ratings yet

- 175 Alternators - KTRv3Document17 pages175 Alternators - KTRv3Quintin Du PlooyNo ratings yet

- Alternator and RegulatorDocument6 pagesAlternator and Regulatorsonny1234No ratings yet

- Ac To DC Stator Conversion KTMDocument5 pagesAc To DC Stator Conversion KTMJim Stewart100% (1)

- Engine Speed Senzor TestDocument7 pagesEngine Speed Senzor TestHusi NihaNo ratings yet

- Leece Neville 4000 Series Alternator Service ManualDocument21 pagesLeece Neville 4000 Series Alternator Service ManualOneil Campbell100% (1)

- Agamata Chapter 5Document10 pagesAgamata Chapter 5Drama SubsNo ratings yet

- Service Manual Delco-Remy CS-130Document10 pagesService Manual Delco-Remy CS-130api-2614064475% (4)

- ZFPumpen E 08Document22 pagesZFPumpen E 08help3rNo ratings yet

- Akai LCT37Z6TA CMO (11-27-06) LCDDocument135 pagesAkai LCT37Z6TA CMO (11-27-06) LCDRicardo PicassoNo ratings yet

- Prueba Speed Timing C9Document11 pagesPrueba Speed Timing C9guido albinoNo ratings yet

- Cat 740B-2011Document17 pagesCat 740B-2011Tom Souza100% (2)

- Ford Tempo Topaz 1984-1994 Repair GuideDocument11 pagesFord Tempo Topaz 1984-1994 Repair GuideFer VN100% (2)

- Ford Think Service Manual - Section 3 PowertrainDocument16 pagesFord Think Service Manual - Section 3 PowertrainDennis Jason AntiNo ratings yet

- Philippine Folk Dances Explored in DetailDocument7 pagesPhilippine Folk Dances Explored in DetailLee Mah Ri60% (5)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Lenksysteme NKW eDocument40 pagesLenksysteme NKW eKabilan Muthukannan100% (2)

- Lenksysteme NKW eDocument40 pagesLenksysteme NKW eKabilan Muthukannan100% (2)

- Antrieb Actuators O & M CatalogueDocument12 pagesAntrieb Actuators O & M Catalogueysr3ee6926100% (3)

- Seismic Aspects of Dam Design PDFDocument12 pagesSeismic Aspects of Dam Design PDFAlokNo ratings yet

- Tech - Speed Strength Endurance in 400Document7 pagesTech - Speed Strength Endurance in 400jeyNo ratings yet

- ZF Rack and Pinion Power Steering Gears: For Passenger Cars and Light Commercial VehiclesDocument14 pagesZF Rack and Pinion Power Steering Gears: For Passenger Cars and Light Commercial VehiclesAniket SankpalNo ratings yet

- Rozruszniki DIXI DENSODocument0 pagesRozruszniki DIXI DENSOhelp3rNo ratings yet

- Toyota Camry 2006-2011 2AZ-FE ChargingDocument21 pagesToyota Camry 2006-2011 2AZ-FE ChargingMichael MatthewsNo ratings yet

- CX New EngineDocument68 pagesCX New Enginehelp3r100% (1)

- 20764C ENU Companion PDFDocument192 pages20764C ENU Companion PDFAllan InurretaNo ratings yet

- Industrial VDO CatalogDocument44 pagesIndustrial VDO Cataloghelp3rNo ratings yet

- Alt I Service ManualDocument12 pagesAlt I Service ManualgustavoespinosamNo ratings yet

- DYNA Power Control Manual For Plus 1, Plus 2, Plus 4 and Plus 6 Ft. Lb. SystemsDocument18 pagesDYNA Power Control Manual For Plus 1, Plus 2, Plus 4 and Plus 6 Ft. Lb. SystemsDavid Coronado100% (1)

- 641 - 2051B ManualDocument10 pages641 - 2051B ManualPirv Maria AncaNo ratings yet

- 5CKMR Service BullitenDocument7 pages5CKMR Service Bullitenchrist6989No ratings yet

- Cb750 Service 2Document136 pagesCb750 Service 2gabimaier31No ratings yet

- Basic System Troubleshooting and RepairDocument20 pagesBasic System Troubleshooting and RepairCric CricNo ratings yet

- Troubleshooting For M38 InstrumentsDocument7 pagesTroubleshooting For M38 Instrumentsm606No ratings yet

- SM 67Document12 pagesSM 67eys.automotricesNo ratings yet

- Volkswagen - New Beetle - Wiring Diagram - 2007 - 2008Document13,861 pagesVolkswagen - New Beetle - Wiring Diagram - 2007 - 2008Harshad NaringrekarNo ratings yet

- Como Probar Sistema Electrico AlternadorDocument18 pagesComo Probar Sistema Electrico AlternadorEckard GuendelNo ratings yet

- Engine ElectricalDocument44 pagesEngine ElectricalLuis Ramiro CajasNo ratings yet

- 2GR FE ChargingDocument25 pages2GR FE Chargingmink4uNo ratings yet

- 04 06 0424 en 1000Document18 pages04 06 0424 en 1000Sujoy BanikNo ratings yet

- RectifierDocument10 pagesRectifierMahmoudA.AbdlsalamNo ratings yet

- Universal TCC Lock-Up Kit For 700R4 and 2004RDocument7 pagesUniversal TCC Lock-Up Kit For 700R4 and 2004RRaulNo ratings yet

- Electric Starting System - Test: Testing and AdjustingDocument5 pagesElectric Starting System - Test: Testing and Adjustingmanuel100% (1)

- Problem 1 - No AC VoltageDocument2 pagesProblem 1 - No AC Voltagedamian_pelonNo ratings yet

- Technical Suplement JT4020ATTh3 R&P CouleurDocument83 pagesTechnical Suplement JT4020ATTh3 R&P CouleurEmmanuel QUESTENo ratings yet

- Title:To Practically Configuration and Characteristic ofDocument14 pagesTitle:To Practically Configuration and Characteristic ofKelvin YipNo ratings yet

- Installation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"Document2 pagesInstallation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"thailanNo ratings yet

- Testing The Starter On The Engine (1453,1450,1401)Document6 pagesTesting The Starter On The Engine (1453,1450,1401)Cristopher LaosNo ratings yet

- Whitlock DNFTDocument4 pagesWhitlock DNFTJoe TorrenNo ratings yet

- Electric Starting System - Test: Shutdown SIS Previous ScreenDocument5 pagesElectric Starting System - Test: Shutdown SIS Previous ScreenGabriel Paredes E.0% (1)

- Charging System: PrecautionDocument17 pagesCharging System: PrecautionlogammicNo ratings yet

- Trouble Shooting Pancake GeneratorsDocument7 pagesTrouble Shooting Pancake GeneratorsRomel José Londoño CamachoNo ratings yet

- Troubleshooting and Service Information For Voltmaster GeneratorsDocument15 pagesTroubleshooting and Service Information For Voltmaster GeneratorsMd Rodi Bidin100% (1)

- ChassisElectrical PDFDocument111 pagesChassisElectrical PDFDhany SiregarNo ratings yet

- Charging System Troubleshooting (1406) : Instrucción EspecialDocument16 pagesCharging System Troubleshooting (1406) : Instrucción EspecialMiguel GutierrezNo ratings yet

- IM05805023K - XTJP - Op - Manual - RH2 - 06-07-12Document12 pagesIM05805023K - XTJP - Op - Manual - RH2 - 06-07-12melgarcia829No ratings yet

- Lucas Generator and Control Box TestsDocument28 pagesLucas Generator and Control Box Testsruben_balea100% (1)

- Engine Speed/Timing Sensor Circuit - Test: TroubleshootingDocument13 pagesEngine Speed/Timing Sensor Circuit - Test: TroubleshootingRodrigo Herrera GodosNo ratings yet

- K25 8Document17 pagesK25 8mushfiq66No ratings yet

- Owner'S Manual: Automatic Positive Locking Traction DifferentialDocument24 pagesOwner'S Manual: Automatic Positive Locking Traction Differentialhelp3r0% (1)

- PDF Manual r900 With Mondial Amp Cat 70Document48 pagesPDF Manual r900 With Mondial Amp Cat 70help3rNo ratings yet

- Volvo Penta 2002 WorkshDocument35 pagesVolvo Penta 2002 Workshhelp3rNo ratings yet

- Alternators ISKRADocument21 pagesAlternators ISKRAhelp3rNo ratings yet

- Czujniki Temperatury MOTOMETERDocument7 pagesCzujniki Temperatury MOTOMETERhelp3rNo ratings yet

- Conectores IIDocument404 pagesConectores IIPancho CamposNo ratings yet

- Delco - 44MT BrochureDocument4 pagesDelco - 44MT Brochurehelp3rNo ratings yet

- Rozruszniki DensoDocument2 pagesRozruszniki Densohelp3rNo ratings yet

- Delco 10SI TechnicalDocument8 pagesDelco 10SI Technicalhelp3rNo ratings yet

- Delco 2009Document0 pagesDelco 2009JIMJEONo ratings yet

- Alternator Prestolite 4000Document4 pagesAlternator Prestolite 4000help3rNo ratings yet

- Denso r5 App Guide d1473.331Document28 pagesDenso r5 App Guide d1473.331help3rNo ratings yet

- Rozruszniki DensoDocument2 pagesRozruszniki Densohelp3rNo ratings yet

- Denso r5 App Guide d1473.331Document28 pagesDenso r5 App Guide d1473.331help3rNo ratings yet

- Delco - 44MT BrochureDocument4 pagesDelco - 44MT Brochurehelp3rNo ratings yet

- Heavy Duty Starters for Toughest EnginesDocument2 pagesHeavy Duty Starters for Toughest Engineshelp3rNo ratings yet

- R5.0 Starters for On-Road Applications Quick Reference GuideDocument2 pagesR5.0 Starters for On-Road Applications Quick Reference Guidehelp3rNo ratings yet

- DENSO 24v Planetary Gear Redution Starter Sell SheetDocument2 pagesDENSO 24v Planetary Gear Redution Starter Sell Sheethelp3rNo ratings yet

- High torque. Outstanding durability. So you can be stress freeDocument2 pagesHigh torque. Outstanding durability. So you can be stress freehelp3rNo ratings yet

- AZ D Permanent Magnet Starter Motors GuideDocument32 pagesAZ D Permanent Magnet Starter Motors Guidehelp3rNo ratings yet

- Start TestDocument2 pagesStart Testhelp3rNo ratings yet

- Wp220 Service ManualDocument0 pagesWp220 Service Manualhelp3rNo ratings yet

- Data Acquisition Systems Communicate With Microprocessors Over 4 WiresDocument2 pagesData Acquisition Systems Communicate With Microprocessors Over 4 WiresAnonymous Y6EW7E1Gb3No ratings yet

- MSO 1st Year Assignments 2017-18 (English) PDFDocument7 pagesMSO 1st Year Assignments 2017-18 (English) PDFAmritpal BhagatNo ratings yet

- Propaganda AssignmentDocument3 pagesPropaganda Assignmentapi-653920203No ratings yet

- Chara LesDocument5 pagesChara Lesx456456456xNo ratings yet

- Maintain Records and Bond EmployeesDocument5 pagesMaintain Records and Bond EmployeesAngel Frankie RamosNo ratings yet

- SLI ProfileThe title "TITLE SLI Profile" is less than 40 characters and starts with "TITLEDocument3 pagesSLI ProfileThe title "TITLE SLI Profile" is less than 40 characters and starts with "TITLEcringeNo ratings yet

- Fardapaper Community Based Corporate Social Responsibility Activities and Employee Job Satisfaction in The U.S. Hotel Industry An Explanatory StudyDocument9 pagesFardapaper Community Based Corporate Social Responsibility Activities and Employee Job Satisfaction in The U.S. Hotel Industry An Explanatory StudyDavid Samuel MontojoNo ratings yet

- SAP Training Program Proposal for StudentsDocument2 pagesSAP Training Program Proposal for StudentsAjay KumarNo ratings yet

- Kamala Das Poetry CollectionDocument0 pagesKamala Das Poetry CollectionBasa SwaminathanNo ratings yet

- Beacon Finland JAK ATB Coupling System PDFDocument6 pagesBeacon Finland JAK ATB Coupling System PDFsyahrir anasNo ratings yet

- 1 Prepositions With AnswersDocument6 pages1 Prepositions With AnswersManal El ShafieNo ratings yet

- Depository Receipts: Presented By-Vikash Sharma (51) Ruchi BangaDocument12 pagesDepository Receipts: Presented By-Vikash Sharma (51) Ruchi Bangasuraj kumar0% (1)

- NCLT Orders Relief To Home BuyersDocument7 pagesNCLT Orders Relief To Home BuyersPGurusNo ratings yet

- AbstractDocument23 pagesAbstractaashish21081986No ratings yet

- Criminal Law Notes SummaryDocument12 pagesCriminal Law Notes SummaryPurplaawNo ratings yet

- History of English - IntroductionDocument58 pagesHistory of English - IntroductionPaul Edward GuevarraNo ratings yet

- GUINNESS F13 Full Year BriefingDocument27 pagesGUINNESS F13 Full Year BriefingImoUstino ImoNo ratings yet

- Chapter 8Document3 pagesChapter 8sasafoadjeiNo ratings yet

- Creating A Seasonal Greeting Card RubricDocument3 pagesCreating A Seasonal Greeting Card Rubricapi-244997750No ratings yet

- P - 3Y - Test Paper - Motion in 2 Dimension.Document5 pagesP - 3Y - Test Paper - Motion in 2 Dimension.sudhir_kumar_33No ratings yet

- Employee Retention Plan QuestionnaireDocument5 pagesEmployee Retention Plan QuestionnaireThayyib MuhammedNo ratings yet

- Brochure KTM April 2008Document2 pagesBrochure KTM April 2008sthapitNo ratings yet

- Word Meanings From ContextDocument4 pagesWord Meanings From ContextUsagi Yuki AnaNo ratings yet

- Female by CourseDocument40 pagesFemale by CourseMohamed AymanNo ratings yet