Professional Documents

Culture Documents

Solar PV water pumping

Uploaded by

JP GuptaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solar PV water pumping

Uploaded by

JP GuptaCopyright:

Available Formats

SOLAR PHOTOVOLTAIC WATER PUMPING SYSTEMS

I. DEFINITION

A solar photovoltaic (SPV) water pumping system consists of a PV array, a DC/AC surface mounted/ submersible/ floating motor pump set, electronics, if any, interconnect cables and an On-Off switch. PV Array is mounted on a suitable structure with a provision of tracking. Electronics could include Maximum Power Point Tracker (MPPT), Inverter and Controls/Protections. Storage batteries will not constitute a part of the SPV Water Pumping System. Components and parts used in the SPV water pumping system including the PV modules, pumps, metallic structures, cables, junction box, switch, etc. should conform to the BIS/ IEC/ international specifications, wherever such specifications are available and applicable. II. PERFORMANCE SPECIFICATIONS AND REQUIREMENTS (DUTY CYCLE)

The Solar PV Water Pumping System should provide a minimum of 85 liters of water per watt peak of PV array used per day under average daily solar radiation conditions of 5.5 KWh/sq.m. on a horizontal surface, from a total head of 10 metres (Suction head up to a maximum of 7 metres). For Deep Well Pumps, the water discharge should be a minimum of 28 liters of water per watt peak of PV array capacity used per day from a total head of 30 metres. In case of High Head, Deep Well Pumps, the water discharge should be a minimum of 17 liters of water per watt peak of PV array capacity used per day from a total head of 50 metres. Use of a tracking system to enhance the availability of solar radiation to lift desired quantity of water is desirable. It should be specified whether the minimum water output is achieved directly or through tracking of PV Array. The actual duration of pumping of water on a particular day and the quantity of water pumped could vary depending on the location, season, etc. PV ARRAY The SPV water pumping system should be operated with a PV array capacity in the range of 200 Watts peak to 5000 Watts peak, measured under Standard Test Conditions (STC). Sufficient number of modules in series and parallel could be used to obtain the required PV array power output. The power output of individual PV modules used in the PV array, under STC, should be a minimum of 74 Watts peak, with adequate provision for measurement tolerances. Use of PV modules with higher power output is preferred.

Indigenously produced PV module (s) containing mono/ multi crystalline silicon solar cells with following features should be used in the PV array for the SPV Water Pumping systems: Modules supplied with the SPV water pumping systems should have certificate as per IEC 61215 specifications or equivalent National or International/ Standards. Modules must qualify to IEC 61730 Part I and II for safety qualification testing. The efficiency of the PV modules should be minimum 13% and fill factor should be more than 70%. The terminal box on the module should have a provision for Opening for replacing the cable, if required. Each PV module must use a RF identification tag (RFID), which must contain the following information: (i) Name of the manufacturer of PV Module (ii) Model or Type Number (iii) Serial Number (iv) Month and year of the manufacture (v) I-V curve for the module (vi) Peak Wattage of the module at 16.4 volts (vii) Im, Vm and FF for the module (viii) Unique Serial No and Model No of the module Until March 2013, the RFID can be inside or outside the module laminate, but must be able to withstand harsh environmental conditions. However from 1st April 2013 onwards; RFID shall be mandatorily placed inside the module laminate A distinctive serial number starting with NSM will be engraved on the frame of the module or screen printed on the tedlar sheet of the module. III. MOTOR PUMP-SET

Following types of motor pump sets could be used in the SPV water pumping systems: I. II. III. IV. V. Surface mounted DC motor pump-set Submersible DC motor pump set Submersible AC motor pump set Floating DC motor pump set Any other type of motor pump set after approval from Test Centers of the Ministry.

The Motor Pump Set should have the following features: The mono block DC/ AC centrifugal motor pump set has its driving unit and impeller mounted on a common shaft, thereby giving it a perfect alignment. The pump should be provided with specially developed mechanical seals which ensure zero leakage.

The motor is of 1-5 HP having spring loaded carbon brushes in case of D.C. Motor Pump Sets. The suction and delivery head will depend on the site specific condition of the field. Submersible pumps could also be used according to the technical need of the particular case. . The suction/ delivery pipe (GI/HDPE), electric cables, floating assembly, civil work and other fittings required to install the system. The following details should be marked indelibly on the motor pump set (a) (b) (c) Name of the Manufacturer or Distinctive Logo. Model Number. Serial Number.

V.

MOUNTING STRUCTURES and TRACKING SYSTEM

To enhance the performance of SPV water pumping systems, it is desirable to use a tracking system. Manual, passive and auto tracking are permitted. The PV modules will be mounted on metallic structures of adequate strength and appropriate design, which can withstand load of modules and high wind velocities up to 150 km per hour. The support structure used in the pumping system will be hot dip galvanized iron (G.I). Facilities to be provided in the structure: Seasonal tilt angle adjustment and Three times manual tracking in a day The G.I. structures for mounting the Solar panels could be so designed, that these can be manually/ auto adjusted for optimal tilt throughout the year. A simple provision is to be provided so that the panel can be manually adjusted three times a day (East-SouthWest) to face the sun optimally. This adjustment could be done in the early morning, noon time and afternoon to increase the total input solar radiation on the solar panel surface substantially. This provision helps the motor pump set to start early in the morning and function efficiently till late in the afternoon, thereby increasing the total output of the pumping system. The Mounting Structure should have the following features: The modules support structure shall be mild steel, hot dipped galvanized (120 micron) iron for holding the PV modules. The size of angle iron should not be less than 50x50x5 mm. Each panel frame structure shall be so fabricated as to be grouted on ground or roof on its legs. It will withstand severe cyclone/ storm with the speed of 150 Km/Hr. Each panel frame structure shall have provision to adjust its angle of inclination to the horizontal between 10 to 40 degrees with a step of 10 degree, so that the inclination can be adjusted at the specified tilt angle whenever required.

Each panel frame shall be complete with a weatherproof junction box as per the relevant BIS specifications, where the module terminals shall be interconnected and output taken. All nuts and bolts should be made of very good quality and should be corrosion resistant. The structure should be designed to allow easy replacement of any module. The array structure shall be so designed that it will occupy minimum space without sacrificing the output from the SPV panels.

VI.

ELECTRONICS AND PROTECTIONS Use of Maximum Power Point Tracker (MPPT) is encouraged to optimally use the Solar panel and maximize the water discharge. Inverter could be used, if required, to operate an A.C. Pump. Adequate protections should be incorporated against dry operation of motor pump set, lightning, hails and storms. Full protection against open circuit, accidental short circuit and reverse polarity should be provided.

VII.

ON/OFF SWITCH

A good reliable switch suitable for DC / AC use is to be provided with the motor pump set. Sufficient length of cable should be provided for inter-connection between the PV array and the motor pump set. VIII. O/M MANUAL

An Operation and Maintenance Manual, in English and the local language, should be provided with the solar PV pumping system. The following minimum details must be provided in the Manual: (a) (b) (c) (d) (e) (f) (g) (h) (i) (j) About photovoltaics About solar pump About PV module About motor pump set About tracking system Clear instructions about mounting of PV module. About electronics used in AC motor pump sets, if any DO's and DONT's, Clear instructions on regular maintenance and Trouble Shootingof the pumping system. Name & address of the person or Centre to be contacted in case of failure or complaint.

IX.

INDICATIVE TECHNICAL SPECIFICATIONS

General Information: The information given here under is indicative only and the designer must satisfy himself regarding quantity and quality wise supply of Solar Modules / panel, Solar Photovoltaic (SPV) Pump, and GI support structure as well as all aspects of commissioning of solar infrastructural facility. The scope of work includes supply, installation & commissioning of Solar PV Water Pumps on bore-well of minimum 4" diameter (to be provided by the user) at various sites as per the technical specification mentioned below. The whole system including submersible/ surface pumps shall be warranted for 5 years, The PV Modules must be warranted for output wattage, which should not be less than 90% at the end of 10 years and 80% at the end of 25 years.

TECHNICAL SPECIFICATIONS OF SOLAR SHALLOW WELL PUMPING SYSTEM

Description Solar PV array Motor pump set type Motor capacity Operating voltage Suction Head Max. total dynamic head Module mounting structure Required shadow free area Water Output *

Model-I 900 Wp Centrifugal DC monoblock 1 HP 60 V DC (nominal) 7 metres 10 metres MS hot dipped galvanised, three times manual tracking facilities 30 sq. Metres

Model-II 1800 Wp Centrifugal DC monoblock 2 HP 60 V DC (nominal) 7 metres 15 metres MS hot dipped galvanised, three times manual tracking facilities 75 sq. Metres

Model-III 2700 Wp Centrifugal DC monoblock 3 HP 90 V DC (nominal) 7 metres 25 metres MS hot dipped galvanised, three times manual tracking facilities 120 sq. Metres

77,000 litres per day 154,000 litres per 115,000 litres per from a total head day from a total head day from a total head of 10 metres of 10 metres of 20 metres

*. Water output figures are on a clear sunny day with three times tracking of SPV panel when solar radiation on horizontal surface is: 5.5 KWH/sq.m/day

TECHNICAL SPECIFICATIONS OF SOLAR DEEPWELL PUMPING SYSTEM

Description Solar PV array Motor pump set type

Model I 1200 Wp

Model II 1800 Wp

Model III 3000 Wp Submersible electronic controller 80 Metres

Model IV 4800 Wp with Submersible electronic controller 80 Metres with

Submersible with Submersible electronic with electronic controller controller Max. total 50 Metres 50 metres dynamic head Module MS hot dipped MS hot dipped mounting galvanised, three galvanised, structure times manual three times tracking facilities manual tracking facilities Required 45 Sq. Metres 75 sq. Metres shadow free area Water 34,000 Litres per 51,000 litres per Output * day from a total day from a total head of 30 head of 30 metres metres

MS hot dipped galvanised, three times manual tracking facilities 120 sq. Metres

MS hot dipped galvanised, three times manual tracking facilities 200 sq. Metres

51,000 litres per 82,000 litres per day from a total day from a total head of 50 metres head of 50 metres

*. Water output figures are on a clear sunny day with three times tracking of SPV panel when solar radiation on horizontal surface is: 5.5 KWH/sq.m/day

Details of Solar Pump Models and configuration to be provided*

S. SPV Array No Wp (900/ . 1200/ 1800/ 2700/ 3000/ 4800) Proposed No of SPV modules with Wp& Make MotorPump set Model & Make Type of MotorPump set DC/ AC Type of Motor- Total Motor-Pump Pump Dynami set set c Head Surface/ HP (M) Submersible Water Output** (Ltrs./ day)

* Head v/s discharge characteristic curves along with details of Motor-pump set should be provided with this document. **. Water output figures are on a clear sunny day with three times tracking of SPV panel when solar radiation on horizontal surface is: 5.5 KWH/sq.m/day.

You might also like

- Nse Seminar Sept, 2015Document36 pagesNse Seminar Sept, 2015ToniNo ratings yet

- Consultancy Service For Detailed Engineering Design For Abu Hamad - Karima RoadDocument28 pagesConsultancy Service For Detailed Engineering Design For Abu Hamad - Karima RoadAfolabi OladunniNo ratings yet

- Pile Foundation ConstructionDocument36 pagesPile Foundation Constructionsunil_rathore20073921No ratings yet

- Hackney Community Centre Condition SurveyDocument42 pagesHackney Community Centre Condition SurveyFederico OrtizNo ratings yet

- Calculating 100-Year Peak Flows for Culvert SizingDocument10 pagesCalculating 100-Year Peak Flows for Culvert SizingKaushik KumarNo ratings yet

- Precast Concrete BookDocument39 pagesPrecast Concrete BookpolysourceNo ratings yet

- Structural Engineering NotesDocument5 pagesStructural Engineering NotesRishabh LalaNo ratings yet

- Pump ManualDocument68 pagesPump Manualsaid19712011No ratings yet

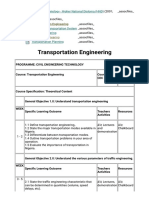

- Civil Engineering Technology - Higher National Diploma (HND) : Transportation: Transportation Engineering - 1597859336315Document4 pagesCivil Engineering Technology - Higher National Diploma (HND) : Transportation: Transportation Engineering - 1597859336315Stephen TorwoedzorNo ratings yet

- Bid Bulletin No 6 - MTCL PACKAGE 4 BOSO-BOSO PUMPING STATION AND RESERVOIRDocument7 pagesBid Bulletin No 6 - MTCL PACKAGE 4 BOSO-BOSO PUMPING STATION AND RESERVOIRFrancis Nano FerrerNo ratings yet

- Weigh-In-Motion TechnologyDocument50 pagesWeigh-In-Motion Technologychillerz69No ratings yet

- PPSC Test Questions For Irrigation Department - Civil Engineers PKDocument5 pagesPPSC Test Questions For Irrigation Department - Civil Engineers PKAli naveedNo ratings yet

- Runway and airfield pavement designDocument18 pagesRunway and airfield pavement designspruhatechNo ratings yet

- Estimating Overhead ContingenciesDocument15 pagesEstimating Overhead Contingenciesasd123456789asdcomNo ratings yet

- Seismic EvaluationDocument33 pagesSeismic EvaluationAshish Gone100% (1)

- Videx Sectional Tanks-BrochureDocument8 pagesVidex Sectional Tanks-BrochureRendani VeleNo ratings yet

- Ugandan Gravel Road Design GuideDocument64 pagesUgandan Gravel Road Design GuideTracy KevinNo ratings yet

- Drainage DesignDocument16 pagesDrainage DesignChaerudin Imam100% (1)

- Common Plumbing Fixtures and Installation RequirementsDocument23 pagesCommon Plumbing Fixtures and Installation RequirementsashuNo ratings yet

- RTA Spec. - Soil InvenstigationDocument2 pagesRTA Spec. - Soil InvenstigationSheril Chandrabose100% (1)

- CED Design Alternatives-1Document38 pagesCED Design Alternatives-1Liban HalakeNo ratings yet

- KL City Car Park Construction MethodsDocument5 pagesKL City Car Park Construction MethodsAbubakar DanmashiNo ratings yet

- Pre Bored Steel H Piling System Engineering EssayDocument6 pagesPre Bored Steel H Piling System Engineering EssayfieeeeyNo ratings yet

- Sewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDocument38 pagesSewerage and Sewage Treatment of Panvel, Maharashtra (Presentation) PDFDhruv MudgalNo ratings yet

- In-Situ Concrete CulvertDocument3 pagesIn-Situ Concrete CulvertBenjamin IpeNo ratings yet

- Generator Set RoomsDocument7 pagesGenerator Set RoomsAnonymous TvOpvXNo ratings yet

- Recycled Materials in Rigid Pavements ReviewDocument6 pagesRecycled Materials in Rigid Pavements ReviewCleber de Souza CunhaNo ratings yet

- Green Drop Report 2013: Status and Performance of South African Wastewater SystemsDocument7 pagesGreen Drop Report 2013: Status and Performance of South African Wastewater SystemsrendaninNo ratings yet

- Green Drop Requirements - 2021 Requirements - DraftDocument20 pagesGreen Drop Requirements - 2021 Requirements - DraftSkhulie Sque DubeNo ratings yet

- Computer-Aided District Road Network Planning in NepalDocument31 pagesComputer-Aided District Road Network Planning in NepalChandra Bahadur ShresthaNo ratings yet

- QBNPO Topographic Survey Specification For Urban Projects April 2009Document260 pagesQBNPO Topographic Survey Specification For Urban Projects April 2009robertdqNo ratings yet

- GEO3701 Assessment 6 2021Document7 pagesGEO3701 Assessment 6 2021Tyburg R DhliwayoNo ratings yet

- Electro-Mechanical Material List PDFDocument8 pagesElectro-Mechanical Material List PDFmehmetNo ratings yet

- DSR ReportDocument451 pagesDSR ReportPramod Gaikwad100% (2)

- Stormwater Analysis and Solution of Waterlogging in Kothrud Region, PuneDocument11 pagesStormwater Analysis and Solution of Waterlogging in Kothrud Region, PuneIJRASETPublicationsNo ratings yet

- Draft TRH 20 The Structural Design, Construction and Maintenance of Unpaved Roads 1990Document40 pagesDraft TRH 20 The Structural Design, Construction and Maintenance of Unpaved Roads 1990winzo01100% (1)

- Types of ManholesDocument6 pagesTypes of ManholesEvonYongNo ratings yet

- Mechanistic Pavement Design Using IRC & AI MethodsDocument39 pagesMechanistic Pavement Design Using IRC & AI MethodsAmit Ruchi Yadav100% (1)

- Bus Lane Pattern Live LoadingDocument19 pagesBus Lane Pattern Live Loadingamangirma100% (1)

- Economic and Financial Analysis of Water Supply and Sanitation ProjectDocument7 pagesEconomic and Financial Analysis of Water Supply and Sanitation ProjectwaheedanjumNo ratings yet

- Recommendations On Site Investigation TechniquesDocument64 pagesRecommendations On Site Investigation Techniquesbilal afzalNo ratings yet

- Conduits, Pipes, and Culverts Associated With Dams and Levee SystemsDocument404 pagesConduits, Pipes, and Culverts Associated With Dams and Levee SystemsRaveeNo ratings yet

- Basic Concepts of Traffic EngineeringDocument5 pagesBasic Concepts of Traffic EngineeringAbdirizak HussienNo ratings yet

- Project Integration Management: Initiation Planning Executing Monitoring and Controlling ClosingDocument5 pagesProject Integration Management: Initiation Planning Executing Monitoring and Controlling Closingvikram122No ratings yet

- SIX Monthly Progress Report SummaryDocument3 pagesSIX Monthly Progress Report SummaryZainab BangashNo ratings yet

- Headwork (Diversion Weir) Design - For AGP SSIP-by AberaChalaDocument49 pagesHeadwork (Diversion Weir) Design - For AGP SSIP-by AberaChalaAbera ChalaNo ratings yet

- STAAD Seismic Analysis 7314Document17 pagesSTAAD Seismic Analysis 7314Harry BasadaNo ratings yet

- 8M-Digest VOL 6 PDFDocument52 pages8M-Digest VOL 6 PDFSamuel AcidriNo ratings yet

- Presentation On Reinforcing Detailing of R.CDocument16 pagesPresentation On Reinforcing Detailing of R.CbertazcorpNo ratings yet

- New Beam To Old Column Connection PDFDocument6 pagesNew Beam To Old Column Connection PDFVan BGNo ratings yet

- Colombo Port City Causing Unimaginable Environmental HarmDocument6 pagesColombo Port City Causing Unimaginable Environmental HarmThavam RatnaNo ratings yet

- 17CV73 Module 1 5Document115 pages17CV73 Module 1 5shivaraj salimathNo ratings yet

- Water Specs English-FinalDocument266 pagesWater Specs English-FinalMohammed HanafiNo ratings yet

- Construction of Flyover in Patna: A Project ReportDocument45 pagesConstruction of Flyover in Patna: A Project ReportRajeev AshokaNo ratings yet

- Solar Pumping Systems for Drinking WaterDocument6 pagesSolar Pumping Systems for Drinking WaterrenuNo ratings yet

- Micropump Specs 030817Document9 pagesMicropump Specs 030817Deepak PrmNo ratings yet

- SPV Water Pumping System SpecificationsDocument28 pagesSPV Water Pumping System SpecificationssharmaNo ratings yet

- Technical-Specification Spwps 2013 14Document14 pagesTechnical-Specification Spwps 2013 14Deepak PrmNo ratings yet

- 100 KW SolarTender With NetmeetringDocument28 pages100 KW SolarTender With NetmeetringAnant energyNo ratings yet

- Yemen Mobile Solar ProjectDocument9 pagesYemen Mobile Solar Projectrasnowmah2012No ratings yet

- Rooftop PV System by JpguptaDocument1 pageRooftop PV System by JpguptaJP GuptaNo ratings yet

- Rooftop in Indian Context JpguptaDocument8 pagesRooftop in Indian Context JpguptaJP GuptaNo ratings yet

- Waaree RecDocument9 pagesWaaree RecJP GuptaNo ratings yet

- Waaree Mnre Grading Mnre GradingDocument0 pagesWaaree Mnre Grading Mnre GradingJP GuptaNo ratings yet

- WAAREE Energies PVT Ltd-LatestDocument40 pagesWAAREE Energies PVT Ltd-LatestJp Gupta100% (2)

- Waaree Corporate Presentation Ver 1Document17 pagesWaaree Corporate Presentation Ver 1JP GuptaNo ratings yet

- WAAREE Energies Pvt Ltd guide to solar water pumpsDocument30 pagesWAAREE Energies Pvt Ltd guide to solar water pumpsJp GuptaNo ratings yet

- Waaree Corporate ProfileDocument60 pagesWaaree Corporate ProfileJP GuptaNo ratings yet

- Kolayat Rays PowerDocument6 pagesKolayat Rays PowerJP GuptaNo ratings yet

- User Manual for Sungrow PV InvertersDocument72 pagesUser Manual for Sungrow PV Invertersanh nguyenNo ratings yet

- Kenya Energy SituationDocument162 pagesKenya Energy SituationArudo Elly OkaraNo ratings yet

- Product Overview: PVT HybridDocument8 pagesProduct Overview: PVT Hybridfasolis2No ratings yet

- Sunfuel CatalogueDocument28 pagesSunfuel CatalogueAbhay KumNo ratings yet

- Solar Energy Installation in NigeriaDocument12 pagesSolar Energy Installation in NigeriavicaschendeNo ratings yet

- VCE Summer Internship Program ModulesDocument1 pageVCE Summer Internship Program ModulesMiral Sandipbhai MehtaNo ratings yet

- 60CELL 1000V: KU265-6MCA Cutting Edge TechnologyDocument2 pages60CELL 1000V: KU265-6MCA Cutting Edge TechnologytariqNo ratings yet

- IEC61727 - Characteristics of The Utility Interface - Design Qualification For InvertorsDocument28 pagesIEC61727 - Characteristics of The Utility Interface - Design Qualification For InvertorsCliffNo ratings yet

- 5KWp Building Integrated Photo Voltaic BDocument39 pages5KWp Building Integrated Photo Voltaic BsparkCENo ratings yet

- Zero Energy Buildings and Sustainable Development Implications - A ReviewDocument10 pagesZero Energy Buildings and Sustainable Development Implications - A ReviewJoao MinhoNo ratings yet

- Islanding: Prepared byDocument32 pagesIslanding: Prepared byMiGuelNo ratings yet

- Compression SheetDocument21 pagesCompression Sheetnilambar.mahalaNo ratings yet

- PV System Design-Stand Alone Ac SystemDocument7 pagesPV System Design-Stand Alone Ac SystemTapera Mangezi100% (9)

- Sharma 2017 Solar TrackingDocument6 pagesSharma 2017 Solar TrackingsashaNo ratings yet

- A Short Review of Reactive Power Management For Distributed GenerationDocument4 pagesA Short Review of Reactive Power Management For Distributed GenerationHai Pham ManhNo ratings yet

- 45KVA Solar Energy Solution Layout Diagram.Document1 page45KVA Solar Energy Solution Layout Diagram.peter LamurenNo ratings yet

- India's renewable energy potential and current statusDocument20 pagesIndia's renewable energy potential and current statusMiitNo ratings yet

- Simulation and Analysis of Wind-Solar Hybrid Energy Converstion SystemDocument3 pagesSimulation and Analysis of Wind-Solar Hybrid Energy Converstion SystemUsama RiazNo ratings yet

- Project Report ON Solar Tile: Submitted ToDocument31 pagesProject Report ON Solar Tile: Submitted Tojanita gargNo ratings yet

- Project Report of Buck Boost RegulatorDocument15 pagesProject Report of Buck Boost RegulatorAnshul YadavNo ratings yet

- GTZ-Windenergy Study-Brazil China India 2007Document394 pagesGTZ-Windenergy Study-Brazil China India 2007shruti_indiaNo ratings yet

- Residential Contract AgreementDocument11 pagesResidential Contract AgreementArchitect Erwin MutucNo ratings yet

- Vikram Solar Corporate PresentationDocument75 pagesVikram Solar Corporate PresentationTejinder Ammla100% (1)

- Surge Protector For Off-Grid PV System, Imax 20ka, 100VdcDocument3 pagesSurge Protector For Off-Grid PV System, Imax 20ka, 100VdcGabriel Montoya CorreaNo ratings yet

- Solar Electric Rebate Program 110802025911 Rebate InstructionsDocument9 pagesSolar Electric Rebate Program 110802025911 Rebate InstructionssandyolkowskiNo ratings yet

- A Complete Guide About Solar Panel InstallationDocument4 pagesA Complete Guide About Solar Panel InstallationJoel RemegioNo ratings yet

- NABCEP Prep QuestionsDocument108 pagesNABCEP Prep QuestionsIoNo ratings yet

- Roland Berger Energy Storage FinalDocument32 pagesRoland Berger Energy Storage FinalAman BansalNo ratings yet

- Singapore Energy Statistics 2018 (EMA)Document136 pagesSingapore Energy Statistics 2018 (EMA)Tan Swee KoonNo ratings yet

- Smart Grids GermanyDocument32 pagesSmart Grids GermanyFranklin Jesus Simeon PucuhuaylaNo ratings yet