Professional Documents

Culture Documents

A Steepest Descent Algorithm For Circularity Evaluation

Uploaded by

Tao YeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Steepest Descent Algorithm For Circularity Evaluation

Uploaded by

Tao YeCopyright:

Available Formats

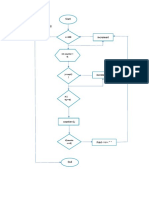

A steepest descent algorithm for circularity evaluation

Li-Min Zhu

a

, Han Ding

a,

*

, You-Lun Xiong

b

a

School of Mechanical Engineering, Shanghai Jiaotong University, Shanghai 200030, People's Republic of China

b

School of Mechanical Science & Engineering, Huazhong University of Science and Technology, Wuhan 430074, People's Republic of China

Received 31 May 2001; revised 15 November 2001; accepted 17 November 2001

Abstract

This paper presents a novel algorithm for evaluating the circularity of a mechanical part by using measurement points obtained with a

coordinate measuring machine (CMM). Following the minimum zone criterion set forth in the current ANSI and ISO standards, evaluation of

circularity is formulated as a non-differentiable unconstrained optimization problem, and based on the geometric representation of the

necessary and sufcient condition for the optimal solution, an efcient steepest descent optimization procedure is proposed to nd the

circularity value. The steepest descent direction is determined by the method of calculating the minimum translational distance between two

convex polygons, which is initially introduced in the eld of robot path planning, and the length of the moving step is exactly determined by a

presented geometrical method. A computational geometry-based method for pre-processing the measured data is also proposed. In compari-

son with existing methods, this algorithm has the advantages of computational efciency and high precision. Simulations and practical

example conrm the validity of the presented algorithm. q 2002 Elsevier Science Ltd. All rights reserved.

Keywords: Circularity evaluation; Minimum zone solution; Optimization; Minimum translational distance; Computational geometry

1. Introduction

The geometric form of any manufactured feature will

always deviate from its nominal design to some degree,

owing to random and/or systematic errors. In order to satisfy

certain functional requirements or assembly conditions,

geometric tolerances are usually assigned to some selected

features, serving as allowable variations. Traditional ways

of qualifying mechanical parts are through manual checking

against some standard gages. Nowadays rapid advances in

numerical control (NC) and precision machining techniques

have turned coordinate measuring machines (CMMs) into

de facto choice of inspection tools in most manufacturing

applications. To yield critical geometric deviations of the

measured part, data obtained by a CMM must be analyzed

or interpreted using appropriate algorithms, which should

conform to the specications laid down in the standards.

The circular feature is one of the most basic geometric

primitives because many mechanical parts depend on a

small circularity error to have adequate performance.

Four methods are commonly used to evaluate the circular-

ity error: least-squares circle (LSC) method, maximum

inscribed circle (MIC) method, minimum circumscribed

circle (MCC) method, and minimum radial separation

(MRS) method (also known as minimum zone circle

(MZC) method). Although the former three ones have

their attractive advantages [1], only the MRS method

complies with ANSI and ISO standards. With the MRS

method, two concentric circles with minimum radial separa-

tion (MRS circles) are found that contain the prole. The

radial difference between these two circles gives the value

of the circularity error. The median circle of the MRS circles

is known as the MZC, an ideal circle such that the maximal

deviation between it and the actual measured data has the

least possible value. Let S {p

i

[ R

d

; 1 # i # k} be the

dataset measured by a CMM, where d 2: Here not den-

itely setting d to be 2 is to show that when d 3; most of the

conclusions drawn in this paper are still valid, i.e. they are

also applicable to sphericity evaluation. Evaluation of circu-

larity error based on the MRS method could be formulated

as the following non-differentiable unconstrained optimiza-

tion problem, of which the optimal value gives the circular-

ity value.

P1 min

u[R

d

Eu max

p

i

[S

ip

i

2ui 2min

p

i

[S

ip

i

2ui

where notation ii denotes Euclidean norm, i.e. ixi

x

T

x

p

with superscript T representing transposition. The optimal

solution provides the center of the MRS circles (MRS

center). Introducing two extra variables j

1

and j

2

; problem

Computer-Aided Design 35 (2003) 255265

COMPUTER-AIDED

DESIGN

0010-4485/02/$ - see front matter q 2002 Elsevier Science Ltd. All rights reserved.

PII: S0010-4485(01)00210-X

www.elsevier.com/locate/cad

* Corresponding author.

E-mail addresses: mehding@cityu.edu.hk (H. Ding), hding@mail.

sjtu.edu.cn (H. Ding).

P1 could be re-formulated as the following differentiable

constrained optimization problem.

P2 min

u[R

d

;j

1

;j

2

Hu; j

1

; j

2

j

1

2j

2

s:t:

ip

i

2ui # j

1

;

ip

i

2ui $ j

2

_

1 # i # k

Note that a feasible solution u; j

1

; j

2

to the problemP2 has

the intuitive interpretation of two concentric circles with

center u, and with j

1

and j

2

being the radii of the larger

and smaller circles, respectively. The points in S belong to

the region bounded by these two circles.

So far a number of methods have been presented for

resolving these two optimization problems. Due to the

non-differentiable nature of the problem P1, some uncon-

strained optimization methods that do not rely on the deri-

vative information, such as simplex algorithm [2,3], genetic

algorithm [4] and simulated annealing algorithm [5], are

used to nd its global optimal solution. However, all of

these algorithms have little solid basis in mathematical

theory, thus offer no guarantees of efcient numerical

convergence. Wang, Hu and Shi et al. [6] construct a differ-

entiable unconstrained optimization problem, which is

approximately equivalent to the problem P1, and resolve

it by the standard optimization techniques. However,

serious numerical problem may be encountered in the opti-

mization procedure because that objective function often

becomes ill-conditioned when the variable, in vector form,

nears the optimal solution. If the measured part is well-

aligned with the measurement datum, Euclidean norm in

problem P1 and P2, as a function of u, could be linearized

(also geometrically known as the technique of limacon

approximation), which yields two simplied linear models.

Algorithms of linear programming [7], linear Chebyshev

approximation [8] and exchange point [9] are efcient for

resolving them. If the alignment requirement is not perfectly

satised or high accuracy result is needed, some standard

constrained optimization methods could be used to directly

resolve problem P2 [10,11]. As general-purpose numerical

methods, all the approaches mentioned above do not fully

utilize the geometric specialties of the circularity evaluation

problem, which greatly decreases the computational ef-

ciency. Another well-known family is geometric method.

Ventura and Yeralan [12] develop a necessary condition

for the optimal solution of problem P1 (or P2), stating

that there are at least a total of four points on the outer

and inner circles of the MRS circles, with at least one

point on the outer or the inner circle. Based on this conclu-

sion, an enumeration method is used to check all four points

combinations to nd the global optimal solution of problem

P1 (or P2). The complexity of this approach is O(k

5

), also a

heuristic algorithm is proposed to improve the efciency.

Other two heuristic algorithms are proposed by Rajagopal

and Anand [13], and Jywe, Liu and Chen [14]. Although

they are very efcient in some examples, their convergences

are not guaranteed due to their heuristic nature. Etesami and

Qiao [15] exploit the properties of Voronoi diagrams to

show that the MRS center is located at one vertex of the

intersection between the farthest and nearest regions. Thus,

the optimal solution could be obtained by checking all

vertices and picking the one which gives minimum objec-

tive value. The complexity of this algorithm is O(k

2

). A

method based on the similar idea is proposed by Roy and

Zhang [16] with step-by-step implementation procedure

being described in detail. Huang [17] further categorizes

the vertices into X and Y-types, and shows that only the X-

type vertex, i.e. an intersection point between the edges of

the farthest and the nearest Voronoi diagrams, can host the

optimum solution, hence only such vertices should be

enumerated. Since the construction of the Voronoi diagrams

around all data points is a time-consuming work, Huang also

presents a strategy to isolate the critical data points as early

as possible so that the computation around redundant data

points can be reduced [18]. For the measured points of

which the angular order is known, an improved Voronoi

diagram-based algorithm has complexity O(k log k) [19].

Samuel and Shunmugam [20] point out that coordinate

data obtained using CMM and form data obtained using

roundness measuring instrument have to be handled differ-

ently. They use the equi-angular Voronoi diagrams to

process the form data. It is seen that, with geometric

methods, the exact global optimal solution are found by

exhaustively checking every candidate of local minimum,

however, no any directive information is used during the

enumeration. Lai and Chen [21] propose a new method

that transforms the circularity error evaluation problem

into a minimum zone straightness problem using a non-

linear mapping. It is known that minimum zone straightness

tolerance requires only two points on one edge of the toler-

ance zone and one point on the other edge, this property

contradicts the result that there must exist at least two points

on the outer circle and two points on the inner circle of the

MRS circles [17,19]. Therefore, this method cannot provide

optimal solution. By using algebraic distance as a surrogate

for geometric distance, Gass, Witzgall and Harary [22]

develop a linear programming approach to locate the

MRS center approximately. In most of the given examples,

the centers found coincide with the true ones. Recently,

Wang, Cheraghi and Masud [23] propose a direct descent

algorithm to resolve problem P1, which has an explicit

geometric meaning, but do not answer how to nd the

best descent direction.

This paper will present a novel algorithm to nd the value

of circularity error according to the minimum zone criterion.

Essentially, it is the steepest descent optimization algorithm,

however, it fully exploits the geometric information implied

in problems P1 and P2, thus exhibits high accuracy and

efciency. The remainder of this paper is organized as

follows. In Section 2, a computational geometry-based

method for pre-processing the measured data is developed.

In Section 3, the algebraic and geometric representations of

L.-M. Zhu et al. / Computer-Aided Design 35 (2003) 255265 256

the necessary and sufcient condition for the optimal solu-

tion are introduced and claried. In Section 4, the novel

algorithm for circularity error evaluation is presented,

with the methods of determining the steepest descent direc-

tion and the moving step length being specied in detail. In

Section 5, the global optimality of the solution obtained by

the proposed algorithm is analyzed. Simulations and real

application are given in Section 6, and conclusions in

Section 7.

2. Computational geometry-based method for pre-

processing the measured data

Denition 1. Given a point u [ R

d

; r

u

min

denotes the mini-

mum distance from u to S, i.e. r

u

min

min

p

i

[S

ip

i

2ui; the

set of nearest neighbors of u in S is dened as NNu

{p

i

[ Suip

i

2ui r

u

min

}: Similarly, r

u

max

denotes the maxi-

mum distance from u to S, i.e. r

u

max

max

p

i

[S

ip

i

2ui; the

set of farthest neighbors of u in S is dened as FNu

{p

i

[ Suip

i

2ui r

u

max

}:

Evidently there is at least one point in NNu or FNu:

Normally, for d 2; the total number of points in sets

NNu and FNu is no more than four because four points

are enough to determine a pair of concentric circles, if there

are more than four points lying on the two concentric

circles, some additional constraints must be satised. For

the point u and the data points shown in Fig. 1, NNu

contains points p

n

1

and p

n

2

while FNu contains the points

p

f

1

and p

f

2

.

Theorem 1. Let the convex hull of the points set S be

CHS; and the vertices set of CHS be CHVS: There

exists FNu # CHVS ;u:

Proof. Obviously we only need to prove that FNu >

CHVS f where overbar denotes complement. Assume

that CHVS {p

1

; p

2

; ; p

m

} where m # k: ;p

i

[

CHVS can be represented as a positive convex combina-

tion of a subset of CHVS; which is denoted as

{p

i

1

; p

i

2

; ; p

i

J

} where J $ 2 and 1 # i

j

# m 1 # j # J;

i.e.

p

i

J

j1

b

j

i

p

i

j

where

J

j1

b

j

i

1; and b

j

i

. 0 for 1 # j # J

Note that function gx ix 2ui

2

; where x; u [ R

d

; is

strictly convex with respect to the variable x, hence we get

ip

i

2ui

2

gp

i

g

J

j1

b

j

i

p

i

j

_

_

_

_

,

J

j1

b

j

i

gp

i

j

J

j1

b

j

i

ip

i

j

2ui

2

# r

u

max

_ _

2

which means p

i

FNu; so FNu >CHVS f: A

Therefore, only the points in CHVS should be con-

sidered when calculating the max term in the optimization

problem P1. When d 2 or 3, there are standard convex

hull algorithms to quickly get CHVS from S [24].

Although in the case d 2; the same conclusion has been

drawn using geometric method [15], the algebraic analysis

presented here shows that it is also applicable to high

dimension problem such as sphericity evaluation.

3. Necessary and sufcient condition for the optimal

solution

For u [ R

d

; v [ S

d21

; where S

d21

denotes the unit hyper-

sphere of dimension d, let a

v

i;u

be the angle determined by

the vectors v and up

i

-!

; i.e. cos a

v

i;u

up

i

-!

v=ip

i

2ui where

bolddot denotes scalar product, then we give the following

denition.

Denition 2. Given a point u [ R

d

and a vector v [ S

d21

;

a

v

n;u

denotes the minimum angle determined by the vectors v

and up

i

-!

for p

i

[ NNu; i.e. a

v

n;u

min

p

i

[NNu

a

v

i;u

or

cos a

v

n;u

max

p

i

[NNu

cos a

v

i;u

; MINNu; v; the set of mini-

mum angle (with respect to v) nearest neighbors of u, is

dened as MINNu; v {p

i

[ NNuua

v

i;u

a

v

n;u

}: Simi-

larly, a

v

f ;u

denotes the maximum angle determined by the

vectors v and up

i

-!

for p

i

[ FNu; i.e. a

v

f ;u

max

p

i

[FNu

a

v

i;u

or cos a

v

f ;u

min

p

i

[FNu

cos a

v

i;u

; MAFNu; v; the set of

maximum angle (with respect to v) farthest neighbors of

u, is dened as MAFNu; v {p

i

[ FNuua

v

i;u

a

v

f ;u

}:

L.-M. Zhu et al. / Computer-Aided Design 35 (2003) 255265 257

Fig. 1. Nearest and farthest neighbors.

Obviously, if d 2; there are at most two elements in set

MINNu; v or MAFNu; v: By using Taylor expansion we

easily obtain

ip

i

2u 1lvi ip

i

2ui 2l cos a

v

i;u

1

l

2

2

sin

2

a

v

i;u

ip

i

2ui

1Ol

3

1

where l is a positive innitesimal value. Therefore, if l is

small enough, MINNu; v and MAFNu; v would be,

respectively, the nearest and farthest neighbors of the

point u 1lv; i.e. NNu 1lv MINNu; v and FNu 1

lv MAFNu; v: Hence, we have

Eu

0

1lv Eu

0

1l cos a

v

n;u

0

2cos a

v

f ;u

0

_ _

1

l

2

2

sin

2

a

v

f ;u

0

ir

u

0

max

i

2

sin

2

a

v

n;u

0

ir

u

0

min

i

_ _

1Ol

3

2

Obviously, if there exists a vector v [ S

d21

such that

cos a

v

n;u

0

# cos a

v

f ;u

0

; or equivalently, there exists a circular

cone with apex at u

0

and axis along v such that points of

FNu

0

lie in its interior or border while points of NNu

0

lie

in its exterior or border, then u

0

would not be a local mini-

mum and v gives a descent direction. Hence, the necessary

condition for u

0

being the optimal solution of the problem

P1 is that one has cos a

v

n;u

0

. cos a

v

f ;u

0

for all v [ S

d21

; or

equivalently, points sets NNu

0

and FNu

0

cannot be

separated by a circular cone with apex at u

0

. On the other

hand, it is straightforward that u

0

must be an optimal solu-

tion if cos a

v

n;u

0

. cos a

v

f ;u

0

holds for all v [ S

d21

; therefore

the necessary condition is also the sufcient condition.

Denition 3. Given a point u [ R

d

; PNNu; the central

projection of NNu onto the unit hypersphere centered at u,

is dened as PNNu {p

i

2u=r

u

min

up

i

[ NNu}: Simi-

larly, PFNu; the projection of FNu; is dened as

PFNu {p

i

2u=r

u

max

up

i

[ FNu}:

As shown in Fig. 2, for the point u and the data points

depicted in Fig. 1, points n

1

and n

2

are the projections of

the nearest neighbors p

n

1

and p

n

2

while points f

1

and f

2

are the

projections of the farthest neighbors p

f

1

and p

f

2

, where the

circle represented by dashed line is the unit circle. Observ-

ing that the intersection between a circular cone and a

hypersphere is contained in a hyperplane, the previous

necessary and sufcient condition can also be stated saying

that PNNu

0

cannot be separated from PFNu

0

by a hyper-

plane, which is easily found to be equivalent to neither

riCHPNNu

0

>riCHPFNu

0

f nor PNNu

0

and PFNu

0

are actually contained in a hyperplane, by

using the properties of convex set and the separation theo-

rem [25], where notation ri denotes the relative interior of a

set.

For circularity error evaluation d 2; as indicated by

Wang, Cheraghi and Masud [23], there are two cases in

which the preceding necessary and sufcient optimality

condition is satised. The rst one is that there exist three

points in NNu

0

and three points in FNu

0

such that the

nearest points are located on the lines that connect u

0

to the

farthest points, as shown in Fig. 3(a). The other one is that

there exist two points in NNu

0

and two points in FNu

0

such that these four points are distributed alternatively

around u

0

, as shown in Fig. 3(b). However, in practical

applications, the rst case would never occur because it

suggests an incompatible measurement strategy where

measurements at the same nominal point on the circle

give two different extreme values for departure from circu-

larity. So, for practical circularity error evaluation, the

necessary and sufcient condition for u

0

being the MRS

center is that there exist two farthest neighbors and two

nearest neighbors of u

0

such that they interlace anglewise

as seen from u

0

, or equivalently, there exist two points

f

1

; f

2

[ PFNu

0

and two points n

1

; n

2

[ PNNu

0

such

that the segments f

1

f

2

and n

1

n

2

intersect internally, as

shown in Fig. 4.

4. Algorithm for circularity error evaluation

4.1. Determination of the steepest descent direction

From Eq. (2), the steepest descent direction of the objec-

tive function in P1, at the current solution u

0

, is the optimal

solution of the following optimization problem:

P3

min

v[S

d 21

f v cos a

v

n;u

0

2cos a

v

f ;u

0

max

p

i

[NNu

0

cos a

v

i;u

0

2 min

p

j

[FNu

0

cos a

v

j;u

0

Or, equivalently,

P4 max

v[S

d 21

gv min

a

i

[PFNu

0

;b

j

[PNNu

0

v

T

a

i

2b

j

L.-M. Zhu et al. / Computer-Aided Design 35 (2003) 255265 258

Fig. 2. Projections of the nearest and farthest neighbors.

Note that any unit vector cannot be represented as the

convex combination of the other unit vectors [26], so the

points set PNNu

0

is also the vertices set of CHPNNu

0

and the points set PFNu

0

is also the vertices set of

CHPFNu

0

: Then, when d 2 or 3, it is interesting to

nd that the problem P4 is exactly the denition of the

minimum translational distance (MTD) between the two

convex hulls CHPNNu

0

and CHPFNu

0

; which is

initially introduced in the eld of robot collision-free path

planning [27,28]. Let v

p

be the optimal solution, we can

dene a distance vector d

p

gv

p

v

p

; which is the shortest

translational vector to move CHPNNu

0

into contact with

CHPFNu

0

: The sign of gv

p

species three different

topological relationships between CHPNNu

0

and

CHPFNu

0

; i.e. (I) if gv

p

. 0; CHPNNu

0

and

CHPFNu

0

are disjoint; (II) if gv

p

, 0; CHPNNu

0

and CHPFNu

0

intersect; (III) if gv

p

0; CHPNNu

0

and CHPFNu

0

just contact. Following the discussion in

Section 3, the second status occurs if, and only if, u

0

is an

optimal solution. For practical circularity evaluation d

2; the third status would never occur because the point in

PFNu would not coincide with any point in PNNu:

There is a standard algorithm for computing the MTD

between two 2D or 3D convex hulls [27]. In the remainder

of this paper, we will consider d to be 2. Let uXu denote the

cardinality of the set X, a simple geometric algorithm for

resolving problem P4 will be intuitively introduced as

follows. The detail description can be found in Ref. [27].

Once u

0

is judged to be an optimal solution, this sub-

algorithm and, obviously, the whole optimization algorithm

will terminate. If this sub-algorithm returns a result v

p

; then,

as mentioned before, gv

p

must be greater than zero.

Case 1. uPFNu

0

u 1; uPNNu

0

u 1: Assume that f

1

[

PFNu

0

and n

1

[ PNNu

0

; then d

p

n

1

f

1

--!

and v

p

d

p

=id

p

i; as shown in Fig. 5(a). The point, of which the

projection is f

1

; forms the set MAFNu

0

; v

p

; while the

point, of which the projection is n

1

; forms the set

MINNu

0

; v

p

:

Case 2. uPFNu

0

u 1; uPNNu

0

u $ 2: Assume that f

1

[

PFNu

0

; and n

1

; n

2

[ PNNu

0

are the two neighbors of f

1

:

If the projection of f

1

onto the line n

1

n

2

lies within the

boundaries of n

1

n

2

; then v

p

is perpendicular to the line

n

1

n

2

; and directs to the point f

1

; as shown in Fig. 5(b), the

point, of which the projection is f

1

; forms the set

MAFNu

0

; v

p

; while the two points, of which the projec-

tions are n

1

and n

2

; form the set MINNu

0

; v

p

: Otherwise,

the shorter one of the vectors n

1

f

1

--!

and n

2

f

1

--!

is the distance

vector d

p

and v

p

d

p

=id

p

i; as shown in Fig. 5(c), the point,

of which the projection is f

1

; forms the set MAFNu

0

; v

p

;

while the point, of which the projection is n

1

(or n

2

), forms

the set MINNu

0

; v

p

:

Case 3. uPFNu

0

u $ 2; uPNNu

0

u 1: Assume that n

1

[

PNNu

0

; and f

1

; f

2

[ PFNu

0

are the two neighbors of n

1

:

L.-M. Zhu et al. / Computer-Aided Design 35 (2003) 255265 259

Fig. 4. Distribution pattern of the nearest and farthest neighbors of the

practical MRS center.

Fig. 3. Distribution patterns of the nearest and farthest neighbors of the optimal solution.

If the projection of n

1

onto the line f

1

f

2

lies within the

boundaries of f

1

f

2

; then v

p

is perpendicular to the line f

1

f

2

;

and directs away from the point n

1

; as shown in Fig. 5(d),

the two points, of which the projections are f

1

and f

2

; form

the set MAFNu

0

; v

p

; while the point, of which the projec-

tions are n

1

; forms the set MINNu

0

; v

p

: Otherwise, the

shorter one of the vectors n

1

f

1

--!

and n

1

f

2

--!

is the distance vector

d

p

and v

p

d

p

=id

p

i; as shown in Fig. 5(e), the point, of

which the projection is f

1

(or f

2

), forms the set

MAFNu

0

; v

p

; while the point, of which the projection is

n

1

; forms the set MINNu

0

; v

p

:

Case 4. uPFNu

0

u 2; uPNNu

0

u 2: Assume that

f

1

; f

2

[ PFNu

0

and n

1

; n

2

[ PNNu

0

: If the two segments

f

1

f

2

and n

1

n

2

intersect, the current solution u

0

is a local

optimal solution. Otherwise, the perpendicular distances

from points f

1

and f

2

to line n

1

n

2

are, respectively, calcu-

lated, and the point having the shorter distance is recorded,

assume it is f

1

and the corresponding distance is d

f

1

2n

1

n

2

:

Similarly, the perpendicular distances from points n

1

and n

2

to line f

1

f

2

are, respectively, calculated and the point having

the shorter distance is recorded, assume it is n

1

and the

corresponding distance is d

n

1

2f

1

f

2

: If d

n

1

2f

1

f

2

, d

f

1

2n

1

n

2

;

points n

1

; n

2

and f

1

are selected, and the successive pro-

cedures are the same as those in Case 2, otherwise, points

f

1

; f

2

and n

1

are selected, and the successive procedures are

the same as those in Case 3.

Case 5. uPFNu

0

u $ 2; uPNNu

0

u $ 2: Let M

uPFNu

0

u 1uPNNu

0

u; and dene an array ag[M]. Firstly,

the points in the set PNu

0

; which is the union of PFNu

0

and PNNu

0

; are ordered in the positive (counterclockwise)

direction. Secondly, the array elements are set values

according to the following rule: if the ith element of

PNu

0

is provided by PFNu

0

; then set flagi 1; other-

wise, set flagi 21: Thirdly, the variable count, which is

dened as follows, is calculated.

count uflagM 2flag1u 1

M21

i1

uflagi 2flagi 11u

_ _

=2

The value of count indicates the number of interlacement of

the nearest and farthest neighbors around u

0

. If count .2,

the current solution u

0

is a local optimal solution. Otherwise,

the sign alteration of the array elements just occurs twice,

corresponding to which there are four points f

1

; f

2

[

PFNu

0

and n

1

; n

2

[ PNNu

0

; the successive procedures

are the same as those in Case 4.

L.-M. Zhu et al. / Computer-Aided Design 35 (2003) 255265 260

Fig. 5. Determination of the steepest descent direction.

If the circular order of the measurement points is known,

then only the operation of index comparison is needed to

nd n

1

; n

2

in Case 2 or f

1

; f

2

in Case 3. In practical situations,

as explained in Section 2, Case 5 seldom appears. Addition-

ally it is worthwhile mentioning that in Case 2 or Case 3, the

steepest descent direction is not always perpendicular to the

line n

1

n

2

or f

1

f

2

:

4.2. Determination of the length of the moving step

As concluded in Section 3, if the moving step length l is

small enough, MINNu

0

; v

p

and MAFNu

0

; v

p

are, respec-

tively, the nearest and farthest neighbors sets of the new

point u

0

1lv

p

: Obviously, they are also, respectively, the

minimum angle nearest and maximum angle farthest

neighbors sets of the point u

0

1lv

p

(with respect to the

direction v

p

), i.e. MINNu

0

1lv

p

; v

p

MINNu

0

; v

p

and

MAFNu

0

1lv

p

; v

p

MAFNu

0

; v

p

: From Eq. (2), we

have

Eu

0

1lv

p

1dv

p

Eu

0

1lv

p

1d cos a

v

p

n;u

0

1lv

p

2cos a

v

p

f ;u

0

1lv

p

_ _

1

d

2

2

sin

2

a

v

p

f ;u

0

1lv

p

ir

u

0

1lv

p

max

i

2

sin

2

a

v

p

n;u

0

1lv

p

ir

u

0

1lv

p

min

i

_ _

1Od

3

3

where d is a positive innitesimal value. It is stressed here

that l and d are two different quantities for different

purposes. Assume that p

n

is one point in MINNu

0

; v

p

and p

f

is one point in MAFNu

0

; v

p

; as shown in Fig. 6,

the steepest descent direction v

p

always directs away from

the points p

n

, for any point u

0

1lv

p

on the radial with apex

at u

0

and direction along v

p

, the angle determined by the

vectors v

p

and u

0

1lv

p

p

n

----------!

is always greater than the

one determined by the vectors v

p

and u

0

1lv

p

p

f

---------!

; i.e.

cos a

v

p

n;u

0

1lv

p

, cos a

v

p

f ;u

0

1lv

p

; it follows from Eq. (3)

that v

p

is still a descent direction at the point u

0

1lv

p

:

Therefore, with the increase of the value of l, the value

of the objective function in problem P1 will monotonously

decrease until a new nearest or farthest neighbor is

encountered. If the value of l increases any more,

MINNu

0

1lv

p

; v

p

and MAFNu

0

1lv

p

; v

p

will not

keep being MINNu

0

; v

p

and MAFNu

0

; v

p

; respectively,

i.e. p

n

and p

f

may not belong to MINNu

0

1lv

p

; v

p

and

MAFNu

0

1lv

p

; v

p

; respectively, thus the aforemen-

tioned analysis does not take effect, as a result, v

p

would

not be guaranteed to be the descent direction of the point

u

0

1lv

p

; and the value of the objective function would not

monotonously decrease.

From Fig. 7, if p

i

becomes the new nearest point after

moving the candidate MRS center from u

0

to u

0

1l

i

n

v

p

;

then ip

i

2u

0

1l

i

n

v

p

i ip

n

2u

0

1l

i

n

v

p

i; resulting in

l

i

n

p

i

p

n

--!

u

0

l

i

--!

p

i

p

n

--!

v

p

where l

i

p

i

1p

n

=2

Similarly, if p

i

becomes the new farthest point, then ip

i

2

u

0

1l

i

f

v

p

i ip

f

2u

0

1l

i

f

v

p

i; resulting in

l

i

f

p

i

p

f

--!

u

0

m

i

--!

p

i

p

f

--!

v

p

where m

i

p

i

1p

f

=2

So the length of the moving step should be

l

p

minl

n

; l

f

where l

n

min

l

i

n

.0

l

i

n

for p

i

[ S and l

f

min

l

i

f

.0

l

i

f

for

p

i

[ CHVS:

Obviously, the union of the points p

i

satisfying l

i

n

l

p

and MINNu

0

; v

p

yields NNu

0

1l

p

v

p

; while the union

of the points p

i

satisfying l

i

f

l

p

and MAFNu

0

; v

p

yields

FNu

0

1l

p

v

p

:

4.3. Determination of the initial solution

As with any non-linear optimization problem, good initial

L.-M. Zhu et al. / Computer-Aided Design 35 (2003) 255265 261

Fig. 6. The relationships among v

p

, p

n

and p

f

.

Fig. 7. Determination of the moving step length.

estimates are needed. Note that the real manufactured parts

have circularity error to the order of micron, i.e. the

measurement points almost lie on an ideal circle, thus, the

center of the ideal circle passing through three equi-spaced

points uniformly distributed on the whole nominal circle or

the center of the approximate LS circle [2931] can be

taken as the initial solution of the problem P1. They are

very close to the MRS center, i.e. the initial solution is

very close to the optimal solution, so the algorithm will

converge rapidly. Since LS tting procedure is much less

sensitive to the effects of asperities, the second approach is

preferred in the case that the data points are sampled from a

partial circle.

As described before, if the current solution is not an

optimal solution, a new candidate solution with smaller

objective function value will be generated, since the objec-

tive function in problem P1 is bounded ($0), the presented

algorithm certainly converges to an optimal solution.

5. Global optimality of the optimal solution

Optimization problem P1 is not a convex programming

problem, so there may exist some local minima. It has been

demonstrated that, given an angular order of a set of points,

there is at most one local minimum compatible with this

given order [19]. As indicated in Section 4.3, the initial

solutions recommended are very close to the global optimal

solution, thus, the global optimal solution one is looking for

should preserve the order that observed from those initial

solutions. Because such an optimal solution is unique, we

can assert that for practical circularity evaluation problem,

the solution found by the presented algorithm must be the

global optimal solution. This conclusion can also be drawn

by using the concept of essential subset [32].

6. Performance evaluation

Computer program of the proposed algorithm is written in

C language and run on Celeron 366 MHz machine for the

data available in the literature, the simulated data and the

real data to test the accuracy, the efciency and the prac-

ticality of the algorithm, respectively.

Example 1. The CMM dataset is available in literature

[20], and is included in Appendix A. The initial solution

is set to be the center of the ideal circle passing through

the rst, the ninth and the 17th points. The steepest descent

algorithm terminates after three moves. The results obtained

by the computational geometry method are u

p

40:0007; 50:0015

T

mm and Eu

p

29:2816 mm [20],

while the results obtained by the novel algorithm are u

p

(40.000739,50.001530)

T

mm and E(u

p

) 29.2801747 mm.

There is minor difference between the two results because

double-precision number is employed in the program.

Example 2. The coordinates of the simulated data points

are generated using the following formulas.

x

i

r cos2pi=k 1w;

y

i

r sin2pi=k 1h; i 1; 2; ; k

The above terms without w; h represent points around a

theoretically perfect circle with radius r, which is set to be

13.0 here. Parameters w and h are uniformly distributed

random numbers in the interval 20:1; 0:1 and are used

to introduce variations to the generated points.

Sample sizes of 25, 50, 100, 200, 300, 400, 500, 600, 700,

800, 900 and 1000 are selected and for each sample size

10,000 simulation runs are carried out. The initial solution is

set to be

k

i1

x

i

=k;

k

i1

y

i

=k

T

: Two criteria used as

measures of efciency are the number of moves imple-

mented by the algorithm before arriving at optimal solution

and average CUP time. A summary of the simulation results

is shown in Table 1. The integer number in the table repre-

sents the number of the simulation runs in which the optimal

solution is found after a specic number of moves. The

average computational elapsed time is also shown in Fig. 8.

L.-M. Zhu et al. / Computer-Aided Design 35 (2003) 255265 262

Table 1

Efciency of the algorithm for different sample size problems

Sample size Number of moves Avg. CUP time (ms)

1 2 3 4 5 6 7 8

25 0 5923 3316 661 94 6 0 0 0.511

50 0 5673 3406 809 103 8 1 0 1.011

100 0 5506 3439 888 155 11 1 0 1.956

200 0 5471 3477 879 149 22 2 0 4.191

300 0 5530 3394 920 143 13 0 0 6.421

400 0 5508 3430 892 156 14 0 0 8.371

500 0 5597 3357 873 155 17 0 1 10.820

600 1 5443 3547 863 126 18 2 0 12.809

700 2 5556 3397 880 152 12 1 0 15.324

800 0 5469 3457 919 138 16 1 0 17.088

900 1 5571 3406 880 130 10 2 0 19.669

1000 0 5528 3421 910 123 16 2 0 21.338

As may be observed from the table and the gure, the

CPU times are negligible, even for large size problems. For

instance, it takes the algorithm an average of about

21.338 ms to nd the optimal solution to the problem with

1000 points. It is also found that the average CPU time is

proportional to the sample size. The efciency of the algo-

rithm in terms of the number of moves is also very promis-

ing. In 10,000 simulation runs for each sample size, more

than half of the optimal solutions are found in only two

moves, and 98% of the optimal solutions are found within

four moves.

The same simulation has been conducted by Wang,

Cheraghi and Masud [23]. The percentages of the optimal

solutions found by the two approaches within a specic

number of moves are compared in Table 2. The number

under S is the result of the steepest descent algorithm

while that under W is the result of Wang's algorithm.

Since the computational burdens of the two algorithms dur-

ing each move are almost the same, our algorithm is

superior to Wang's algorithm. Furthermore, it is found

that our algorithm is little affected by the sample size

while Wang's algorithm degrades greatly with the increase

of the data point number.

Example 3. The coordinates of the simulated data points

are generated according to the following formulas.

r

i

9:0 1r

0

; x

i

r

i

cosu; y

i

r

i

sinu;

i 1; 2; ; k

Parameters r

0

and u are uniformly distributed random

numbers in the interval 0:0; 1:0 and 0:0; 2p: They make

the coordinate of each data point unpredictable. The data

point numbers are selected from 100 to 1000. For each

selected data point number, 100 simulation runs are carried

out. The initial solution is set to be

k

i1

x

i

=k;

k

i1

y

i

=k

T

:

The average CUP times are shown in Table 3 alone with the

results reported by Huang [18]. Note that Pentium-III

machine runs much faster than Celeron-366 machine,

hence our algorithm is better than Huang's algorithm,

which is the fastest computational geometry-based

approach.

Example 4. The real CMM dataset is sampled from a

cross-section of a cylindrical part, and is included in

Appendix B. The initial solution is set to be the approximate

LSC center u

0

82:989744; 97:009120

T

mm; which gives

a circularity value Eu

0

39:104 mm: The steepest descent

algorithm terminates after two moves. The results are u

p

82:990941; 97:008387

T

mm and Eu

p

38:231 mm: The

circularity value found by MRS method is indeed smaller

than that provided by LSC method. The rst and the

sixteenth points are the nearest neighbors of u

p

while the

eighth and the 20th points are the farthest neighbors of u

p

. It

is easy to verify that the distribution of the two nearest and

the two farthest neighbors satises the necessary and suf-

cient condition for u

p

being the optimal solution.

7. Conclusions

From the point of view of optimization, the presented

algorithm is the steepest descent optimization algorithm.

L.-M. Zhu et al. / Computer-Aided Design 35 (2003) 255265 263

Fig. 8. Average CUP time versus sample size.

Table 2

Percentages of optimal solutions found within a specic number of moves

Number of moves

Sample size #2 #4 #6

S (%) W (%) S (%) W (%) S (%) W (%)

25 59.23 60 99.00 99.9 100.00 100.0

50 56.73 50 98.88 98.6 99.99 100.0

100 55.06 47 98.33 96.2 99.99 99.8

200 54.71 38 98.27 82.7 99.98 99.2

500 55.97 20 98.27 84.2 99.99 94.2

1000 55.28 9 98.59 58.7 99.98 86.3

Table 3

Average CUP times (ms)

Sample size 100 200 300 400 500 600 700 800 900 1000 Machine

Steepest descent algorithm 3.3 7.2 10.4 14.2 18.1 22.5 28.0 30.2 33.5 37.4 Celeron-366

Huang's algorithm 22 24 32 36 37 41 40 42 43 48 Pentium-III

Both the steepest descent direction and the moving step

length are exactly determined by geometrical methods with-

out any search procedures. It is easily veried that the inter-

mediate point visited by the algorithm is either on the edge

of the nearest or farthest Voronoi diagram, or just the vertex

of the intersection between the nearest and farthest regions.

During the optimization procedure, the solution moves from

one intermediate point to another one, with the monotonous

decrease of the value of the objective function, until the

optimal solution is found. For example, in some cases

(Fig. 5(b) and (d)), the candidate MRS center moves alone

the perpendicular bisector between two nearest points or

two farthest points until a new nearest or farthest point is

encountered, this procedure is equivalent to that the candi-

date MRS center moves along the edge of the nearest or

farthest Voronoi diagram until it attains a vertex of the

intersection between the nearest and farthest regions. In

contrast, traditional computational geometry-based methods

exhaustively enumerate all such vertices or all X-type

vertices. Hence, the presented algorithm may also be

regarded as a directive search-based computational geome-

try method although no denite concepts of computational

geometry are employed in the algorithm. So, this novel

algorithm is superior to the traditional optimization-based

and computational geometry-based methods.

After minor revisions, this algorithm is also applicable to

analyze the data obtained from the form measuring instru-

ments. Based on its principle, the similar algorithms for

determining the MIC and the MCC used for function-

oriented error evaluation can be easily constructed. Further-

more, most of the conclusions drawn in this paper still hold

true when d 3; enabling the algorithm to be extended to

evaluate the sphericity error.

Acknowledgements

This research is supported by the Natural Science Fund of

China grant Nos. 59990470 and 59985004.

Appendix A. CMM Data 1

Table A1

Appendix B. CMM Data 2

Table B1

References

[1] Chou SY, Woo TC, Pollock SM. On characterizing circularity. J Des

Manufact 1994;4:25363.

[2] Tsukada T, Kanada T, Okuda K. An evaluation of roundness from

minimumzero center by means of an optimisation technique. Bull Jpn

Soc Prec Engng 1984;18(4):31722.

[3] Murthy TSR. A comparison of different algorithms for circularity

evaluation. Prec Engng 1986;8(1):1923.

[4] Lu P, Lu JS. A calculating method of circle error using genetic

L.-M. Zhu et al. / Computer-Aided Design 35 (2003) 255265 264

Table A1

No. x (mm) y (mm) No. x (mm) y (mm) No. x (mm) y (mm)

1 70.0150 50.0000 11 16.1556 68.2304 21 45.5204 20.5021

2 68.7900 58.4734 12 12.7184 62.4905 22 55.3996 24.2692

3 65.4060 65.9372 13 10.6380 56.0806 23 62.3561 30.0114

4 59.5675 72.7493 14 10.0183 49.2149 24 67.3540 37.6492

5 51.3791 77.7452 15 11.4275 40.8264 25 69.6190 45.2028

6 44.7944 79.6013 16 14.1050 34.8682

7 40.8903 79.9958 17 18.8168 28.7427

8 32.0312 78.9306 18 24.6321 24.2200

9 27.2296 77.1385 19 31.6833 21.1862

10 20.3993 72.7076 20 39.1626 20.0207

Table B1

No. x (mm) y (mm) No. x (mm) y (mm) No. x (mm) y (mm)

1 107.5811 114.2119 9 55.7576 109.7039 17 85.6152 67.1081

2 102.2909 119.9906 10 53.4073 102.2180 18 93.2669 68.7926

3 95.6848 124.2034 11 53.0774 94.3816 19 100.2245 72.4009

4 88.2128 126.5634 12 54.7849 86.7302 20 106.0093 77.6929

5 80.3826 126.9159 13 58.4107 79.7824 21 110.2199 84.3073

6 72.7251 125.2311 14 63.7075 74.0083 22 112.5676 91.7864

7 65.7612 121.6196 15 70.3176 69.8019 23 112.8977 99.6156

8 59.9721 116.3233 16 77.7899 67.4519 24 111.2129 107.2695

algorithms. Trans Nanjing Univ Aeronaut Astronaut 1999;31(4):393

7 in Chinese.

[5] Chen MC, Tsai DM, Tseng HY. A stochastic optimization approach

for roundness measurements. Pattern Recogn Lett 1999;20:707

19.

[6] Wang ZY, Hu XS, Shi BC, Li Z. Non-differentiable optimization

algorithm for roundness evaluation. Chin J Sci Instrum 1997;18(3):

3303 in Chinese.

[7] Chetwynd DG. Applications of linear programming to engineering

metrology. Proc Inst Mech Engrs 1985;199(B2):93100.

[8] Dhanish PB, Shunmugam MS. An algorithm for form error evalua-

tionusing the theory of discrete and linear Chebyshev approxima-

tion. Comput Meth Appl Mech Engng 1991;92:30924.

[9] Xiong YL. Computer aided measurement of prole error of complex

surfaces and curves: theory and algorithm. Int J Mach Tools Manufact

1990;30(3):33957.

[10] Gou JB, Chu YX, Li ZX. Geometric theory of form, prole and

orientation tolerances. Prec Engng 1999;23(2):7993.

[11] Wang Y. Minimumzone evaluation of form tolerances. Manufact Rev

1992;5(3):21320.

[12] Ventura JA, Yeralan S. The minimax center estimation problem for

automated roundness inspection. Eur J Oper Res 1989;41:6472.

[13] Rajagopal K, Anand S. Assessment of circularity error using a selec-

tive data partition approach. Int J Prod Res 1999;37:395979.

[14] Jywe WY, Liu CH, Chen CK. The minmax problem for evaluating

the form error of a circle. Measurement 1999;26:27382.

[15] Etesami F, Hong Q. Analysis of two-dimension measurement data for

automated inspection. J Manufact Syst 1990;9:2134.

[16] Roy U, Zhang X. Establishment of a pair of concentric circles with the

minimum radial separation for assessing roundness error. Comput

Aided Des 1992;24:1618.

[17] Huang J. An exact solution for the roundness evaluation problems.

Prec Engng 1999;23:28.

[18] Huang J. A new strategy for circularity problems. Prec Engng

2001;25:3018.

[19] Garcia-Lopez J, Ramos PA, Snoeyink J. Fitting a set of points by a

circle. Discrete Comput Geom 1998;20:389402.

[20] Samuel GL, Shunmugam MS. Evaluation of circularity from coordin-

ate and form data using computational geometric techniques. Prec

Engng 2000;24:25163.

[21] Lai J, Chen I. Minimum zone evaluation of circles and cylinders. Int J

Mach Tools Manufact 1996;36(4):43551.

[22] Gass SI, Witzgall C, Harary HH. Fitting circles and spheres to coor-

dinate measuring machine data. Int J Flexible Manufact Syst 1998;

10:525.

[23] Wang M, Cheraghi SH, Masud ASM. Circularity error evaluation

theory and algorithm. Prec Engng 1999;23:16476.

[24] Preparata FP, Shamos MI. Computational geometry: an introduction.

New York: Springer, 1985.

[25] Rockafellar RT. Convex analysis. Princeton: Princeton University

Press, 1972.

[26] Liu J, Wang XM. Saddle point programming and geometric error

evaluation. Dalian: Dalian University of Technology Press, 1996 in

Chinese.

[27] Buchal RO, Cherchas DB, Sassani F, Duncan JP. Simulated off-line

programming of welding robots. Int J Robotics Res 1989;8(1):3143.

[28] Buckley CE. A foundation for the exible-trajectory approach to

numeric path planning. Int J Robotics Res 1989;8(3):4464.

[29] Zhang GX, Ouyang JF. The least square solution of a circle measured

in Cartesian coordinate. Acta Metrol Sinica 1987;8(3):237330 in

Chinese.

[30] Forbes AB. Least-squares best-t geometric elements. In: Mason JC,

Cox MG, editors. Algorithms for approximation II, London:

Chapman & Hall, 1990.

[31] Kim NH, Kim SW. Geometrical tolerances: improved linear approx-

imation of least squares evaluation of circularity by minimum

variance. Int J Mach Tools Manufact 1996;36(3):35566.

[32] Anthony GT, Anthony HM, Bittner B, Bulter BP, Cox MG,

Drieschner R, Elligsen R, Forbes AB, Gross H, Hannaby SA, Harris

PM, Kok J. Reference software for nding Chebyshev best-t

geometric elements. Prec Engng 1996; 19:2836.

L.-M. Zhu et al. / Computer-Aided Design 35 (2003) 255265 265

Li-Min Zhu is currently a faculty member of

Shanghai Jiaotong University. Born in February

1973, he received the BE degree (with honors)

and the PhD degree in mechanical engineering

from Southeast University in 1994 and 1999,

respectively. From November 1999 to October

2001, he worked as a postdoctoral fellow in

Huazhong University of Science and Technol-

ogy (HUST). His research interests include

robotic manipulation, kinematic geometry,

geometrical reasoning, computational metrology

and mechanical signature analysis.

Han Ding obtained the PhD degree from

Huazhong University of Science and Technol-

ogy (HUST) in 1989. Supported by Alexander

von Humboldt Foundation, he worked at

University of Stuttgart, Germany from 1993

to 1994. From 1994 to 1996, he worked at

School of Electrical and Electronic Engineer-

ing, Nanyang Technological University,

Singapore. He was the recipient of National

Distinguished Youth Scientic Fund of China

(former Premier Fund) in 1997. He published

more than 70 papers in international journals

and proceedings. From 1997 to 2001, he was a Professor of HUST. He is

now a `Cheung Kong' Chair Professor (Special Appointment of the

Yangtze Scholars Award Plan) of Shanghai Jiaotong University. Prof.

Ding is a senior member of IEEE and has served as a reviewer for various

international journals, including Computer-Aided Design. His research

interests include application of computational geometry to design and

manufacturing, robot technology and application, computational intelli-

gence, computational manufacturing and virtual prototyping.

You-Lun Xiong graduated from the Depart-

ment of Mechanical Engineering and Postgrad-

uate School at Xi'an Jiatong University, Xi'an,

China, in 1962 and 1966, respectively. From

1966 to 1980 he was employed by the Depart-

ment of Mechanical Engineering at Huazhong

University of Science and Technology

(HUST), Wuhan, China. From 1980 to 1982,

he was a visiting scholar in the Department of

Control Engineering at Shefeld University,

Shefeld, UK. In 1982, he returned to the

Department of Mechanical Engineering at

HUST, where he is a professor. From 1988 to 1989, he was a visiting

professor in the Department of Aeronautical and Mechanical Engineering

at the University of Salford, Salford, UK. In 1995 he was elected as Acade-

mician of Chinese Academy of Sciences. His research interests include

manufacturing automation, robotics, metrology, computational geometry

and intelligence manufacturing.

You might also like

- Analysis and Modeling of Roundness Error PDFDocument6 pagesAnalysis and Modeling of Roundness Error PDFCarlosQuelartNo ratings yet

- Book - IOI Selected Papers - Volume2 PDFDocument208 pagesBook - IOI Selected Papers - Volume2 PDFSinggih Satrio Wibowo100% (1)

- Maab GuidelinesDocument315 pagesMaab GuidelinesVikas Patel100% (1)

- An Experimental Method For Validating Compressor Valve Vibration Theory PDFDocument15 pagesAn Experimental Method For Validating Compressor Valve Vibration Theory PDFTao YeNo ratings yet

- PSPD - Lkat DFC10212 PSPDDocument68 pagesPSPD - Lkat DFC10212 PSPDKayu 1106No ratings yet

- Straightness and Flatness Evaluation Using Data Envelopment AnalysisDocument10 pagesStraightness and Flatness Evaluation Using Data Envelopment Analysisakjeevanantham79No ratings yet

- Vectorial Method of Minimum Zone Tolerance For Flatness, Straightness, and Their Uncertainty EstimationDocument14 pagesVectorial Method of Minimum Zone Tolerance For Flatness, Straightness, and Their Uncertainty Estimationakjeevanantham79No ratings yet

- NeurIPS 2023 Path Following Algorithms For Ell - 2 Regularized M Estimation With Approximation Guarantee Paper ConferenceDocument11 pagesNeurIPS 2023 Path Following Algorithms For Ell - 2 Regularized M Estimation With Approximation Guarantee Paper ConferencefordicusoNo ratings yet

- Applications of A General Curve Fitting Procedure To Aasho Road Test DataDocument25 pagesApplications of A General Curve Fitting Procedure To Aasho Road Test DataBella NovitaNo ratings yet

- Applied SciencesDocument29 pagesApplied SciencesJHON LEWIS LORA CHINCHIANo ratings yet

- CMM InterpetationDocument6 pagesCMM InterpetationJai UshaNo ratings yet

- Application of Convex Hull in The Assessment of Roundness ErrorDocument4 pagesApplication of Convex Hull in The Assessment of Roundness ErrorbangjjNo ratings yet

- ROM For Nonlinear Structural AnalysisDocument23 pagesROM For Nonlinear Structural AnalysisLê QuỳnhNo ratings yet

- Evaluating Circularity Error Using Computational GeometryDocument8 pagesEvaluating Circularity Error Using Computational Geometryganesh_the_aviatorNo ratings yet

- Topology Optimization of Fluid Problems Using Genetic Algorithm Assisted by The Kriging ModelDocument19 pagesTopology Optimization of Fluid Problems Using Genetic Algorithm Assisted by The Kriging ModelrajibNo ratings yet

- Wcsmo6 CollardDocument10 pagesWcsmo6 CollardAnonymous LU3Dz3TKtVNo ratings yet

- Manuscript Revised RGDocument24 pagesManuscript Revised RGcyberyogi07No ratings yet

- Interior Gradient and Proximal Methods For Convex and Conic OptimizationDocument29 pagesInterior Gradient and Proximal Methods For Convex and Conic Optimizationhitzero20032131No ratings yet

- Multigrid methods for isogeometric discretizationDocument13 pagesMultigrid methods for isogeometric discretizationtomar_skNo ratings yet

- Blade Design Optimization Maximizes Aerodynamic LoadDocument3 pagesBlade Design Optimization Maximizes Aerodynamic LoadalkadyasNo ratings yet

- Constrained Fitting of B-Spline Curves Based Onthe Force Density MethodDocument7 pagesConstrained Fitting of B-Spline Curves Based Onthe Force Density MethodBobNo ratings yet

- Simulation-Based Automatic Generation Signomial and Posynomial Performance Models Analog Integrated Circuit SizingDocument5 pagesSimulation-Based Automatic Generation Signomial and Posynomial Performance Models Analog Integrated Circuit Sizingsuchi87No ratings yet

- 501 2459 1 PBDocument7 pages501 2459 1 PBKishan GhataliyaNo ratings yet

- PDF 3Document17 pagesPDF 3Pranesh SBNo ratings yet

- Efficient Model Reduction of Parametrized Systems by Matrix Discrete Empirical InterpolationDocument32 pagesEfficient Model Reduction of Parametrized Systems by Matrix Discrete Empirical InterpolationTerence DengNo ratings yet

- Form Errors Primal-Dual Interior Point MethodDocument6 pagesForm Errors Primal-Dual Interior Point MethodS.Abinith NarayananNo ratings yet

- Hindawi Pso PDFDocument14 pagesHindawi Pso PDFHouda BOUCHAREBNo ratings yet

- 1 s2.0 S0031320303001195 MainDocument13 pages1 s2.0 S0031320303001195 MainajgallegoNo ratings yet

- Afmc16 Dfo CFD PDFDocument4 pagesAfmc16 Dfo CFD PDFdatam38No ratings yet

- Ik 4Document17 pagesIk 4AQEEL ANWARNo ratings yet

- Ansys Lab ManualDocument87 pagesAnsys Lab Manualaravind174No ratings yet

- (2016) A Self-Adaptive Modified Chaos Control Method For Reliability-Based Design OptimizationDocument13 pages(2016) A Self-Adaptive Modified Chaos Control Method For Reliability-Based Design OptimizationJONATHAN JUSTINO APOS CASSIMIRONo ratings yet

- GEOMETRIC-TOLERANCE-FITDocument8 pagesGEOMETRIC-TOLERANCE-FITJosephRomeraloNo ratings yet

- Adjoint of A Median-Dual Finite-Volume Scheme Application To Transonic Aerodynamic Shape OptimizationDocument39 pagesAdjoint of A Median-Dual Finite-Volume Scheme Application To Transonic Aerodynamic Shape OptimizationOlivier AmoignonNo ratings yet

- Improving Middle Square Method RNG Using. 2011Document5 pagesImproving Middle Square Method RNG Using. 2011MustikaSariNo ratings yet

- 1992 - A Method For Registration of 3-D Shapes - ICP - OKDocument18 pages1992 - A Method For Registration of 3-D Shapes - ICP - OKluongxuandanNo ratings yet

- Three-Dimensional Face Stability Analysis of Shallow Tunnels Using Numerical Limit Analysis and Material Point MethodDocument29 pagesThree-Dimensional Face Stability Analysis of Shallow Tunnels Using Numerical Limit Analysis and Material Point MethodfabriciofernandezNo ratings yet

- Stiffness Metrics For Design of 3-RRR Flexible Manipulator: K.V.Varalakshmi, Dr.J.SrinivasDocument7 pagesStiffness Metrics For Design of 3-RRR Flexible Manipulator: K.V.Varalakshmi, Dr.J.SrinivasIJMERNo ratings yet

- Scientific Inquiry and Review (SIR) : ArticleDocument9 pagesScientific Inquiry and Review (SIR) : ArticleUMT JournalsNo ratings yet

- Steepest Descent Algorithms For Optimization Under Unitary Matrix Constraint PDFDocument14 pagesSteepest Descent Algorithms For Optimization Under Unitary Matrix Constraint PDFAMISHI VIJAY VIJAYNo ratings yet

- A Methodology To Learn Designing Optimal Mechanisms For Path GenerationDocument6 pagesA Methodology To Learn Designing Optimal Mechanisms For Path GenerationBilal OraikNo ratings yet

- Math 07 09 929Document32 pagesMath 07 09 929Irani GonçalvesNo ratings yet

- Teh Chin ChainDocument14 pagesTeh Chin ChainNoelia RevolloNo ratings yet

- 6415 Ijdps 01Document13 pages6415 Ijdps 01ijdpsNo ratings yet

- A Direct Least-Squares (DLS) Method For PNPDocument8 pagesA Direct Least-Squares (DLS) Method For PNPMarcusNo ratings yet

- Idealization of Cad Geometry Using Design and Analysis Integration Features ModelsDocument11 pagesIdealization of Cad Geometry Using Design and Analysis Integration Features Modelser_paramjeetgillNo ratings yet

- 2014 PR Unsupervised Segmentation and Approximation of Digital Curves With Rate-distortion Curve ModelingDocument11 pages2014 PR Unsupervised Segmentation and Approximation of Digital Curves With Rate-distortion Curve ModelingAlexander KolesnikovNo ratings yet

- Computers and Geotechnics: Morteza Ahmadabadi, Rainer PoiselDocument11 pagesComputers and Geotechnics: Morteza Ahmadabadi, Rainer Poiselzimbazimba75No ratings yet

- Icfd10 Eg 30i1Document8 pagesIcfd10 Eg 30i1NextScribeNo ratings yet

- Big Bang - Big Crunch Learning Method For Fuzzy Cognitive MapsDocument10 pagesBig Bang - Big Crunch Learning Method For Fuzzy Cognitive MapsenginyesilNo ratings yet

- An Optimization-Based Computational Method For Surface Fitting To Update The Geometric Information of An Existing B-Rep CAD ModelDocument8 pagesAn Optimization-Based Computational Method For Surface Fitting To Update The Geometric Information of An Existing B-Rep CAD ModelAguz JmjNo ratings yet

- Stope Boundary Optimization Using A 3D Approximate Hybrid AlgorithmDocument14 pagesStope Boundary Optimization Using A 3D Approximate Hybrid AlgorithmKENNY BRANDON MAWODZWANo ratings yet

- Phase Unwrapping Via IBFS Graph CutsDocument12 pagesPhase Unwrapping Via IBFS Graph CutsLovely BabuNo ratings yet

- Adaptive Reproducing Kernel Particle Method Using Gradient Indicator For Elasto-Plastic DeformationDocument13 pagesAdaptive Reproducing Kernel Particle Method Using Gradient Indicator For Elasto-Plastic DeformationDesmondd MondNo ratings yet

- LDL FactorizacionDocument7 pagesLDL FactorizacionMiguel PerezNo ratings yet

- Finite Element MethodDocument37 pagesFinite Element Methodaditya2053No ratings yet

- 3D Morphing Without User Interaction: Submitted To Eurographics Symposium On Geometry Processing (2004)Document10 pages3D Morphing Without User Interaction: Submitted To Eurographics Symposium On Geometry Processing (2004)tsigelakistisNo ratings yet

- Dynamic Analysis of A Car Chassis Frame Using The Finite Element MethodDocument10 pagesDynamic Analysis of A Car Chassis Frame Using The Finite Element MethodNir ShoNo ratings yet

- Research Article: Articulated Arm Coordinate Measuring Machine Calibration by Laser Tracker MultilaterationDocument12 pagesResearch Article: Articulated Arm Coordinate Measuring Machine Calibration by Laser Tracker MultilaterationtomNo ratings yet

- The Upper Bound Property For Solid Mechanics of The Linearly Conforming Radial Point Interpolation Method (Lc-Rpim)Document21 pagesThe Upper Bound Property For Solid Mechanics of The Linearly Conforming Radial Point Interpolation Method (Lc-Rpim)billyman0505No ratings yet

- UntitledDocument11 pagesUntitledapi-197704391No ratings yet

- Validación Formulario CMM y Software Evaluación ToleranciaDocument10 pagesValidación Formulario CMM y Software Evaluación ToleranciaAdolfo RodriguezNo ratings yet

- Planar Linkage Synthesis: A modern CAD based approachFrom EverandPlanar Linkage Synthesis: A modern CAD based approachNo ratings yet

- Analysis of Steady-State Characteristics of Misaligned Hydrodynamic Journal Bearings With Isotropic Roughness EffectDocument12 pagesAnalysis of Steady-State Characteristics of Misaligned Hydrodynamic Journal Bearings With Isotropic Roughness EffectTao YeNo ratings yet

- Mobility MethodDocument7 pagesMobility MethodTao YeNo ratings yet

- Theoretical and Experimental Analysis of Liquid Flooded CompressiDocument622 pagesTheoretical and Experimental Analysis of Liquid Flooded CompressiTao YeNo ratings yet

- C. Flowchart. (Prime Numbers) : StartDocument13 pagesC. Flowchart. (Prime Numbers) : Startbong bongNo ratings yet

- L1 Algorithms, Decomposition and AbstractionDocument20 pagesL1 Algorithms, Decomposition and AbstractionHazzaYT HicksNo ratings yet

- Imed BCA Structure and Syllabus 2018Document43 pagesImed BCA Structure and Syllabus 2018Sanchit SainiNo ratings yet

- Grade 7 SyllabusDocument11 pagesGrade 7 SyllabusSarah May CruzNo ratings yet

- FlowchartDocument7 pagesFlowchartsharmashnNo ratings yet

- 1 e 13 ModifiedDocument13 pages1 e 13 Modifiedelbrujo135No ratings yet

- DSA1Document10 pagesDSA1Viswajeet RayNo ratings yet

- Turing Machines: A Fundamental Model of ComputationDocument13 pagesTuring Machines: A Fundamental Model of ComputationBilo BiloNo ratings yet

- Introduction To Power Flow Analysis Toolbox: Chao LeiDocument79 pagesIntroduction To Power Flow Analysis Toolbox: Chao LeiHarshith GowdaNo ratings yet

- English For Computer Use: Program DesignDocument9 pagesEnglish For Computer Use: Program DesignSally LuNo ratings yet

- Algorithms: Philip W. L. FongDocument24 pagesAlgorithms: Philip W. L. FongMatthew ScottNo ratings yet

- An Overview of Computational Thinking PDFDocument11 pagesAn Overview of Computational Thinking PDFmramininiNo ratings yet

- 480-484 Rrijm190403109Document5 pages480-484 Rrijm190403109Hema KumbharNo ratings yet

- Algorithm and basic concepts of C programmingDocument65 pagesAlgorithm and basic concepts of C programmingPranay ReddyNo ratings yet

- 1040 L Scheme EceDocument201 pages1040 L Scheme EceEng Abdulkadir MahamedNo ratings yet

- ResearchPaper DAADocument5 pagesResearchPaper DAAAleeza AhmedNo ratings yet

- Lec Week 2Document8 pagesLec Week 2Alisher KazhmukhanovNo ratings yet

- Chapter 1 (Philoid-In)Document19 pagesChapter 1 (Philoid-In)govindNo ratings yet

- DAA Question Bank-10CS43Document7 pagesDAA Question Bank-10CS43CHANDAN JOSHINo ratings yet

- Advanced Data StructuresDocument2 pagesAdvanced Data StructuresThamaraiselvi CSENo ratings yet

- Thesis Writing PDFDocument35 pagesThesis Writing PDFBrian Quintero ArboledaNo ratings yet

- Poster of Team JalshanDocument1 pagePoster of Team JalshanArchita GogoiNo ratings yet

- Subject: Algorithm Analysis and Design: Question BankDocument10 pagesSubject: Algorithm Analysis and Design: Question BanksunilaswiniNo ratings yet

- Algorithms For Portfolio Management Based On The Newton MethodDocument8 pagesAlgorithms For Portfolio Management Based On The Newton MethodthyagosmesmeNo ratings yet

- Research Interact With Human Statement 3Document12 pagesResearch Interact With Human Statement 3Alexander Waiganjo MachariaNo ratings yet

- Chapter 3Document81 pagesChapter 3Aditya PandeyNo ratings yet

- Problemset RPC04Document18 pagesProblemset RPC04Teno notztliNo ratings yet