Professional Documents

Culture Documents

Operation Manual DB Series VRLA Battery

Uploaded by

Eris Osman RifkiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation Manual DB Series VRLA Battery

Uploaded by

Eris Osman RifkiCopyright:

Available Formats

Operation Manual for DB series

VRLA BATTERY

DB Series

OPERATION MANUAL

Version 1.0

BSB POWER COMPANY LIMITED. Website: www.bsbpower.com

Operation Manual for DB series

Important Safety Instructions Please read this operation manual carefully. It offers very important safety instructions, installation and operation guide, and ensure your equipment with best performance and prolong the service life of your equipment. For the sake of your safety, please do not attempt to remove the components of the battery. The maintenance of the battery can only be carried out by service engineers specially trained by the principal. Considering the potential harm of the lead component to the health and environment, the battery can be replaced only by the service center authorized by the manufacturer. To replace the battery or maintenance equipment, please call the after-sales service hotline for information of the nearest service center. Please check the local regulations on the correct way of dealing with battery disposal or send the battery to the authorized service center for replacement. Battery replacement should be operated or supervised by engineers who are experienced and aware of the preventive measures on the potential harm of the battery. Warning - Do not smoke and refrain having fire near the battery. Warning - Do not use any organic solvent to clean the battery. Warning - Do not have fire near the battery or it may explode. Warning - Do not remove the components of the battery as it contains electrolyte that may cause injury to the human body. Warning - Battery may cause short circuit. Please remove any watches and jewelry during replacement of the battery, and operate with tools with insulated materials.

-2-

Operation Manual for DB series

Chapter One

1. Features

Product Introduction

1.1 Long life � using the polymer gel electrolyte � 4BS paste technology � Special paste technology � Special patent grid alloy 1.2 Wide operational temperature range � Excellent charging and discharging ability at low temperature � Decline the water-loss at high temperature 1.3 Unique rack line dimension and design created by BSB in China � Long and narrow construction design with excellent heat dispersing capability � Both positive and negative posts are along one side of the battery giving ease of monitoring and maintenance � Flexible connectors that can fit according to each clients requirement � Suitable for 19", 23" rack or cabinet � Patented gas collecting system 2. Main Application Fields � Telecom standby and cyclical applications � UPS system � Power system � Solar energy system � Emergency lighting system 3. Types & Dimensions

Table 1-1 Normal Type Voltage V Rated Capacity C10(Ah) BSB DB Series Battery Specification Length Wdith Height Total Height WT (kg)

DB6-100 DB6-150 DB6-180 DB6-200

6 6 6 6

100 150 180 200

194 260 307 321

-3-

170 180 169 176

205 245 220 226

210 250 225 229

15.5 21.5 24.6 29.5

Operation Manual for DB series

DB12-40 DB12-50 DB12-55 DB12-65 DB12-75 DB12-80 DB12-90 DB12-100 DB12-120 DB12-135 DB12-150 DB12-180 DB12-200 DB12-230 DB12-250

12 12 12 12 12 12 12 12 12 12 12 12 12 12 12

40 50 55 65 75 80 90 100 120 135 150 180 200 230 250

197 230 230 350 260 260 306 330 406 342 485 494 522 521 521

165 138 138 166 168 168 169 171 174 172 172 206 238 269 269

170 208 208 179 211 211 211 214 208 280 240 209 218 203 220

170 211 211 179 214 214 214 220 233 285 240 235 221 206 223

13 16.8 17 21 22.8 23 26 30 35.5 41.5 44 54.5 61 62 72

4. Working Principle The chemical reaction taking place in lead acid battery is as follows: Pb+PbO2+2H2SO4

Discharge Charge

2PbSO4+2H2O

Following by-reaction takes place in ordinary lead acid battery: 2H2O 2H2+O2 This by-reaction makes gradual water loss and pure water has to be added regularly to keep the battery operating normally. DB series battery adopts the polymer gel technology and utilizes the AGM separator technology. Thus there is a path existing between the positive and the negative. In addition, the special alloy grid is chosen to increase vent hydrogen over potential gassing on the negative plate, which prevents generation of hydrogen. The oxygen generated from the positive diffuses through the separator to the negative and the oxygen gas reacts quickly and is recombined into water. The chemical reaction is as follows 2Pb +O2 2PbO PbO+ H2SO4 PbSO4 +H2O As such it is possible to build DB series battery in sealed structure.

-4-

Operation Manual for DB series

Chapter Two

1. Charge Performance Curve

Technical Characteristics

Fig 2-1 shows the recharge characteristics of 100% DOD discharge AG12V100F battery with current of 0.1C10A current and limit voltage 14.4V/block (25C).

charge chargcteristisc charge capacity

(%)

charge charge current voltage

(A) (V)

c o n s t a n t a t 0 . 1 C 10- 1 4 . 4 V 2 0

chatge capacity

charge voltage -100%discharge

charge voltage

time hour

2. Internal Resistance and Short Circuit Current The internal resistance of the battery is a dynamic nonlinear parameter that varies continuously with the temperature and discharge state. The internal resistance is at its lowest when the battery is fully charged. Table 2-1 shows the internal resistance and short circuit current of BSB battery in fully charged state according to the IEC60896 standard.

Table 2-1. Type Internal resistance and short circuit current (25C) Internal resistance (m) 3.5 3.3 3.2 3.1 9.5 6.2 5.8 6 Short circuit current (A) 1302 1378 1459 1548 1350 1407 1474 1454

DB6-100 DB6-150 DB6-180 DB6-200 DB12-40 DB12-50 DB12-55 DB12-65

-5-

Operation Manual for DB series

DB12-75 DB12-80 DB12-90 DB12-100 DB12-120 DB12-135 DB12-150 DB12-180 DB12-200 DB12-230 DB12-250

5.5 5.3 5 4.5 4 3.8 3.5 3.5 3 2.8 2.8

1586 1800 1891 1979 2229 2635 2831 2845 2975 3102 3156

Note: Short circuit current will decrease the voltage of the battery to 0V, and damage the internal components of the battery.

-6-

Operation Manual for DB series

Chapter Three

1. Condition

Operation and Maintenance

Ambient Temperature: -40C55 C (Best operation temperture20 C25 C) Ambient Humidity: 95 2. Capacity and Influencing Factors 2.1 The capacity of the battery is the capacity that battery can be discharged under certain conditions, represented by the symbol C. The standard unit of measurement for capacity is ampere-hour (Ah). The capacity can be expressed in Rated Capacity or Actual Capacity. Please refer to Table 1-1 for the Rated Capacity of BSB battery. The Actual Capacity is the product of the discharge current and the discharge time i.e. Ah. 2.2 Factors that influence the Actual Capacity The actual capacity is mainly related to the batterys construction, manufacturing process and operational environment. During operation, the factors that influence the actual capacity are the discharge rate, end voltage, ambient temperature and discharge time. 2.3 Discharge Rate If the discharge rate (hour rate) is lower, the discharge current is larger, and the discharge time is shorter, then the capacity that can be discharged will be lesser. For example, the discharge current of 3 hours rate is larger than that of 10 hours rate; and the capacity of 3 hours rate is smaller than that of 10 hours rate. 2.4 End Voltage The end voltage is the lowest working voltage below which the battery will not be able to discharge further. The end voltage of DB series battery is typically 10.8V per block. Due to the characteristics of lead acid battery, the battery will not be able to discharge even if the end voltage drops. The lower end voltage will harm the battery, especially when the voltage drops to 0V and the battery cannot be recharged in time. This will shorten the life of the battery.

Table 3-1 Discharge End Voltage at Different Current

Discharge current (A) I0.2C 0.2CI0.5C 0.5CI1.0C I1.0C

Discharge end voltage (V/block) 10.8 10.2 9.30 7.80

Operation manual for DB series

3. Ambient Temperature, Capacity and Life 3.1 Relationship between Ambient Temperature and Capacity VRLA batteries can be used in very low or high temperature (below -15C or above 45C). However the battery data such as capacity life and floating voltage are measured with temperature between 20C-25C as a standard. The capacity of the battery will decrease with lower temperature as shown in Fig. 3-1 below.

1.2

1.0 electric Capacity(%) 0.8 0.6

0.4 0.2 0.0

-40

-30

-20

-10

10

20

30

40

50

60

Ambient Tempersture()

Fig.3-1: Ambient Temperature VS Available Capacity

As represented by the graph above, the capacity of the battery will decrease when the temperature is too low. For example, if the temperature decreases by 20C, the capacity will drop by 16%. The battery will be in a less-charged state with lower temperature and this will lead to battery failure in discharging and the active material in the negative plate to saltilize. The capacity of the battery will increase when the temperature rises. For example, the capacity will increase by 6% when the temperature increases by 10C. However the high temperature will accelerate the corrosion of the grid and cause water loss in the battery, thus shortening the battery life. As such it is always important to control the ambient temperature at the customer premises. Please ensure room ventilation and usage of air-condition is recommended in high temperature working environment.

-8-

Operation manual for DB series

3.2 Floating Operation Floating voltage is chosen with the assumption of battery operating under the optimal working condition. If the floating voltage is too high, the battery floating current will get larger and increase the grid eroding speed, thus reducing the service life of the battery. When the floating voltage is too low, the battery will not be able to maintain its fully-charged condition. This will create sulphate and reduces the battery capacity, hence affecting the service life of the battery. The floating voltage of BSB DB series battery is 13.5V/block under 25C. The temperature compensation is at -18mV/C/block. Floating voltage under different temperature is calculated by the following formula: VT=13.5-(T-25)0.0036 VTFloating voltage under T temperature

Table 3-2 Floating Voltage under Different Temperature

Ambient temperature(C) 0 5 10 15 20 25 30 35 40

Floating voltage (V/block) 13.95 13.86 13.77 13.68 13.59 13.50 13.41 13.32 13.23

-9-

Operation manual for DB series

3.3 Equalization Charge VRLA battery needs Equalization Charge regularly to ensure the battery operating under 25C working condition. The equalization voltage of BSB DB series battery is 14.4V/block. The temperature compensation is at -30mV/C/block. Equalization voltage under different temperature is calculated by the following formula: VT=14.4-(T-25)0.0056 VTequalization voltage under T temperature

Table 3-3 Equalization Voltage under Different Temperature

Ambient temperature() 0 5 10 15 20 25 30 35 40 3.4 Ambient Temperature and Life

Equalization voltage (V/block) 15.15 15.00 14.85 14.70 14.55 14.40 14.25 14.10 13.95

High temperature is harmful to the battery and affects its service life. When the ambient temperature exceeds 25Cthe service life reduces by half for every 10C increment in temperature. For example, the battery service life is 10 years under 25C but if the operating temperature is 35C, the service life will become 5 years. The formula to calculate the service life is as follows: t25tT2

T25/10

whereby T : actual ambient temperature tT : design life under T t25: design life under 25C As such the ambient temperature should always be controlled.

- 10 -

Operation manual for DB series

4. Charging Request 4.1 Equalization Charging Equalization charging should be carried out in the following situation: a. There are more than two batteries which voltage is under 13.0V in one group. b. More than three months after floating operation. Equalization charging is recommended as follows: Charge the battery group with constant current not exceeding 0.1C10A till the average voltage increases to 14.4V/block(25C) then change into constant voltage of 14.4V/block charging. The equalization charging time should be 24 hours. 4.2 Battery Charging Battery Charging should be carried out in the following situation: a. The batteries should be recharged in time after discharge. b. After battery system is installed. c. Battery storage period exceeding three months or open circuit voltage lower than 12.6V/block. Battery charging is recommended as follows: The batteries should first be charged on the constant current of 0.15C10A till the average voltage of the batteries increases to 14.1V, then the batteries should be charged with constant voltage of 14.1V till the charging has completed. On some occasions, the batteries have to be fully charged immediately, then fast charging could be adopted. The value of limit current should not be larger than 0.2C10A, and the charge voltage should be 14.4V/block(25C). We can determine if the batteries are fully charged by one of following two conditions: a. After charging 1824hours. The charging time will be lesser if it is not deep discharged. For example at 20% DOD (refer to Table 2-1 for the Depth of Discharge vs Charging Time), the charging time can be shorten to 10 hours. b. Under the condition of constant voltage, the value of charge current has no variation for continuously three hours.

- 11 -

Operation manual for DB series

5. Storage All lead acid batteries experience self-discharge in open circuit. The result is that the voltage of open circuit is decreased, and the capacity also decreases. Please note the following during storage period: 5.1 The self-discharge rate is related to the ambient temperature. The degree of self-discharge is smaller when the ambient temperature is lower, otherwise it will be larger. The required temperature for BSB batteries storage is 5C to 30C. The storage place must be clean, ventilated and dry. 5.2 An important parameter in storage is open circuit voltage, which is related to the density of the electrolyte. In order to avoid permanent damage to the plate caused by self-discharge, the batteries should be recharged if they have been stored for more than three months. The equalization charge method should be adopted. 5.3 During storage, if the open circuit voltage is lower than 12.6V/block, the batteries should be recharged before usage. The equalization charge method should be adopted. 5.4 All batteries should be fully charged before storage. It is recommended to record the storage time in the periodic maintenance record and to note down the time when the next necessary recharge should be carried out. Fig. 3-2 is the curve of DB series batteries storage time vs capacity under different temperature.

Residue Capacity%

100 75

10

50 25

40

30

20

12

15

18

21

24

27

Storage

time month

Fig. 3-2 Self-discharge Curve

- 12 -

Operation manual for DB series

Chapter Four

1. Regulated Maintenance

Maintenance

1.1 Instruments and tools: 1.1.1 Digital Voltage Meter. 1.1.2 Insulated wrench. 1.1.3 Internal resistance, conductive and instant loading experiment instruments. 1.2 Monthly Maintenance Keep the battery-room clean. Measure and record the ambient temperature of the battery-room. Check each batterys cleanliness, check damage and trace of overheating on the terminal, container and lid. Measure and record the total voltage and floating current of the battery system. 1.3 Quarterly Maintenance Repeat monthly inspection. Measure and record floating voltage of every on-line battery. If there is more than one battery with voltage of less than 13.1V after temperature adjustment, the batteries have to go through equalization charged. If the problem persists after adopting the above-mentioned measure, the batteries will require yearly maintenance or even three years maintenance. If all methods are ineffective, please contact the manufacturer. 1.4 Yearly Maintenance Repeat quarterly maintenance and inspection. Check whether the connectors are loose or not annually. Perform a discharge test to check the exact load every year and discharge 30-40% of the rated capacity. 1.5 Three-year Maintenance Perform a capacity test every three years and every year after six years of operation. If the capacity of the battery decreases to lower than 80% of the rated capacity, the battery should be replaced.

- 13 -

Operation manual for DB series

2. Precautions 2.1 Insufficient Charge If the floating voltage is not set correctly i.e. too low or not amend according to the temperature, the battery system will have an insufficient charge state for a long period of time. When the electricity is cut, the battery may not be able to work because the active material is saltilized and the capacity is decreased. 2.2 Over Charge Please ensure the rectifier transfers floating charge to equalization charge. If the rectifier is not able to transfer charge modes, the battery system will always be in an equalization charge state which may cause battery water loss, decrease in service life, overheating and deformation. 2.3 Extreme Temperature Maintain the correct temperature to ensure the performance of the battery. Extremities in temperature will be detrimental to the battery life and performance. 2.4 Low End Voltage The end voltage is an important parameter for battery. The normal end voltage is 10.5V and in some cases 9.6V. The battery will stop discharging when it reaches a certain voltage. If the end voltage is too low, it will be difficult to recharge the battery and decrease the charging efficiency, thus affecting the battery life. 2.5 Charging Battery Immediately after Discharge If the battery is left uncharged for a long period of time i.e. > 2 hours after discharging, it will affect the capacity and battery life. This is due to large size PbSO4 being created in the negative and will be difficult to transfer to active Pb. 3. After-sales Service / Customer Service Hotline BSB POWER COMPANY LIMITED. Tel: +852-26709808 Fax: +852-26701881 Email: enquiry@bsbpower.com Web: www.bsbpower.com

- 14 -

Operation manual for DB series

Annex 1 VRLA Battery Regular Maintenance Record Type Status Total VoltageV Current (A) No. 1 2 3 4 5 6 7 8 9 10 11 12 Check by sight Result VoltageV Place Number of battery Temperature No. 13 14 15 16 17 18 19 20 21 22 23 24 VoltageV

Tester:

Date:

- 15 -

You might also like

- Lean Six Sigma: Vivekananthamoorthy N and Sankar SDocument23 pagesLean Six Sigma: Vivekananthamoorthy N and Sankar SKrito HdezNo ratings yet

- Review of The Literature and StudiesDocument14 pagesReview of The Literature and StudiesbhimraNo ratings yet

- AssignmentDocument13 pagesAssignmentGRACE100% (1)

- Managing ICT Solutions A2Document7 pagesManaging ICT Solutions A2pablo Sandoval100% (1)

- Appendix 1: Case Study - Housefriends Homewares: Business DescriptionDocument13 pagesAppendix 1: Case Study - Housefriends Homewares: Business DescriptionRameez33% (3)

- Blue Scope Steel LimitedDocument90 pagesBlue Scope Steel Limitedtkgoon6349No ratings yet

- Career Investigation Report MetDocument2 pagesCareer Investigation Report Metapi-2693946540% (1)

- RPL Application Form 4Document3 pagesRPL Application Form 4Ruwan Sampath WickramathilakaNo ratings yet

- Certificate IV in Human Resource Management Self-AssessmentDocument20 pagesCertificate IV in Human Resource Management Self-AssessmentKevinaBallaSoupramanienNo ratings yet

- Generoso Pharma Survival StrategiesDocument6 pagesGeneroso Pharma Survival StrategiesEj TorresNo ratings yet

- HI5019 - Group Assignment - EditedDocument14 pagesHI5019 - Group Assignment - EditedbitetNo ratings yet

- Assessment I Team EffectivenessDocument23 pagesAssessment I Team EffectivenessPoochi DougNo ratings yet

- SITXMGT002 - Establish and Conduct BusinessDocument26 pagesSITXMGT002 - Establish and Conduct BusinessRohan ShresthaNo ratings yet

- Faculty of Business and Law Assignment Brief Mode C and Q RegulationsDocument3 pagesFaculty of Business and Law Assignment Brief Mode C and Q RegulationsViệt Nam AriettaNo ratings yet

- Customer Analysis: Customer Service and Research SkillsDocument11 pagesCustomer Analysis: Customer Service and Research SkillsAKRA RACHURINo ratings yet

- Case Study PresentationDocument11 pagesCase Study PresentationAman Sharma100% (1)

- Assessment Brief Law of TortsDocument6 pagesAssessment Brief Law of TortsHossain Ali Al-RaziNo ratings yet

- Discussion Forum Unit 3Document2 pagesDiscussion Forum Unit 3Safwan al ubaied0% (1)

- Hi5019 Strategic Information SystemsDocument9 pagesHi5019 Strategic Information SystemsShivali RS SrivastavaNo ratings yet

- Team Performance Plan and Professional DevelopmentDocument13 pagesTeam Performance Plan and Professional DevelopmentAli ButtNo ratings yet

- BSBHR513 - FORMATIVE ASSESSMENT Activity 12 Q3 PDFDocument1 pageBSBHR513 - FORMATIVE ASSESSMENT Activity 12 Q3 PDFdgerke001No ratings yet

- BSBMGT502 Resources Task 4 - Performance Review AssessmentDocument7 pagesBSBMGT502 Resources Task 4 - Performance Review AssessmentWai Man LeeNo ratings yet

- BSBPMG412 Apply Project Cost Management Techniques: Learner Workbook (Summative V1.1)Document33 pagesBSBPMG412 Apply Project Cost Management Techniques: Learner Workbook (Summative V1.1)Aryan SinglaNo ratings yet

- City of Carmel-By-The-Sea City Council Staff Report: TO: Submit T Ed By: Approved byDocument23 pagesCity of Carmel-By-The-Sea City Council Staff Report: TO: Submit T Ed By: Approved byL. A. PatersonNo ratings yet

- Assessment Cover Sheet: BSB52415 Diploma of Marketing and Communication Student NameDocument11 pagesAssessment Cover Sheet: BSB52415 Diploma of Marketing and Communication Student NameChun Jiang0% (1)

- MN3042QA Assignment Brief 3 With Grading SchemeDocument5 pagesMN3042QA Assignment Brief 3 With Grading SchemeleharNo ratings yet

- MGBBT2HRM U14875 211473 LemboyeDocument22 pagesMGBBT2HRM U14875 211473 Lemboyeremmylemboye2000No ratings yet

- BSBADM405B Organise Meetings Assess7Document6 pagesBSBADM405B Organise Meetings Assess7kajsdkjqwel0% (2)

- Literature Review ProformaDocument13 pagesLiterature Review ProformaShashank Varma100% (1)

- Assig 2Document29 pagesAssig 2vinayNo ratings yet

- NnnBSBLED401A EditedDocument11 pagesNnnBSBLED401A EditedAnonymous d40zNFxdSNo ratings yet

- Human Resource Management in Coca Cola Great BritainDocument9 pagesHuman Resource Management in Coca Cola Great Britainkvbtrb9898No ratings yet

- Lecture Assessment 1 Case Study and Projects-Group ActivitiesDocument25 pagesLecture Assessment 1 Case Study and Projects-Group ActivitiesHimanshuNo ratings yet

- Bsbmkg606 Assessment Tool v2Document23 pagesBsbmkg606 Assessment Tool v2LindaLindy67% (3)

- Vocational Education & Training (Vet) Unit Assessment Pack (Uap) CoversheetDocument49 pagesVocational Education & Training (Vet) Unit Assessment Pack (Uap) CoversheetSandip AgarwalNo ratings yet

- DDC Crash Course HandoutDocument10 pagesDDC Crash Course HandoutAnne She-miNo ratings yet

- Identify and Evaluate Marketing OpportunitiesDocument7 pagesIdentify and Evaluate Marketing Opportunitiesbusiness121984100% (2)

- 2.0 Mentoring!Document7 pages2.0 Mentoring!Seymour Ward100% (1)

- ICTNWK536 PresentationDocument39 pagesICTNWK536 PresentationAhadNo ratings yet

- BSBADM506: Manage Business Document Design and DevelopmentDocument7 pagesBSBADM506: Manage Business Document Design and DevelopmentSaima Asad100% (1)

- Project Template 10118NAT Diploma of Social Media MarketingDocument8 pagesProject Template 10118NAT Diploma of Social Media MarketingKAI JONo ratings yet

- BSBWRT311 Write Simple DocumentsDocument5 pagesBSBWRT311 Write Simple DocumentsPaula Olivares100% (1)

- BSBWHS201 Trainer Manual SampleDocument19 pagesBSBWHS201 Trainer Manual SampleHaroon MirzaNo ratings yet

- MN405 Data and Information ManagementDocument7 pagesMN405 Data and Information ManagementSambhav JainNo ratings yet

- BSBCUS501 Assessment V2.1017Document17 pagesBSBCUS501 Assessment V2.1017Alyne SoaresNo ratings yet

- BSBMGT502 Template Task 2 - Risk Management Plan TemplateDocument3 pagesBSBMGT502 Template Task 2 - Risk Management Plan TemplateWai Man LeeNo ratings yet

- Task 1 - Versão 3Document4 pagesTask 1 - Versão 3Alan Toledo100% (1)

- Cost Concepts: By: Akshat. D. YadavDocument14 pagesCost Concepts: By: Akshat. D. YadavyadavakshatNo ratings yet

- BSBMKG440 Task 1 Version 4 DoneDocument13 pagesBSBMKG440 Task 1 Version 4 DoneMichelle SukamtoNo ratings yet

- Introduction To Information TechnologyDocument19 pagesIntroduction To Information Technologycornel tancoviciNo ratings yet

- RPL Application Guide for Recognition of Prior LearningDocument44 pagesRPL Application Guide for Recognition of Prior LearningKasturie PillayNo ratings yet

- Self-Quiz Unit 5Document4 pagesSelf-Quiz Unit 5DominicNo ratings yet

- Research Methodology: 5. Systematic Literature Review (SLR)Document55 pagesResearch Methodology: 5. Systematic Literature Review (SLR)karimNo ratings yet

- BSBWRT301 Assessment Task 2Document21 pagesBSBWRT301 Assessment Task 2Shah ZeeshanNo ratings yet

- Task 03 Media Plan For EywaDocument27 pagesTask 03 Media Plan For Eywairma suryaniNo ratings yet

- Research Analysis and PresentationDocument32 pagesResearch Analysis and PresentationPaula Martinez100% (1)

- FND3003 Assignment TemplateDocument5 pagesFND3003 Assignment TemplateBogdan GheorghitaNo ratings yet

- Ictict517 MG Pro 2of3Document29 pagesIctict517 MG Pro 2of3Ashutosh Maharaj0% (1)

- Gaston Batt Data SheetDocument23 pagesGaston Batt Data SheetAntony Sifuna WanjalaNo ratings yet

- VRLA Guidelines-OGN-OPS-ELEC-015Document10 pagesVRLA Guidelines-OGN-OPS-ELEC-015Nageswar MakalaNo ratings yet

- Telpo Tps900 Tps900b Driver (Official APK) 2019 - Updated June 2021Document2 pagesTelpo Tps900 Tps900b Driver (Official APK) 2019 - Updated June 2021Eris Osman Rifki50% (2)

- Card Reading Accessories: Tps900 Eft PosDocument2 pagesCard Reading Accessories: Tps900 Eft PosEris Osman RifkiNo ratings yet

- PLTS Offgrid 1 MWPDocument1 pagePLTS Offgrid 1 MWPEris Osman RifkiNo ratings yet

- User Guide Option GlobeSurfer X.1Document30 pagesUser Guide Option GlobeSurfer X.1rebarakazNo ratings yet

- KippZonen Brochure PyranometersDocument4 pagesKippZonen Brochure PyranometerscostpopNo ratings yet

- Acti 9 C60 For DC Circuits - A9N61651Document2 pagesActi 9 C60 For DC Circuits - A9N61651Eris Osman RifkiNo ratings yet

- Solar Inverter Grid PV Array: (C) 2018 - PT. Industri Telekomunikasi Indonesia (Persero)Document3 pagesSolar Inverter Grid PV Array: (C) 2018 - PT. Industri Telekomunikasi Indonesia (Persero)Eris Osman RifkiNo ratings yet

- KippZonen Brochure PyranometersDocument4 pagesKippZonen Brochure PyranometerscostpopNo ratings yet

- BSB Opzv SeriesDocument2 pagesBSB Opzv SeriesEris Osman RifkiNo ratings yet

- Photovoltaic Solar Energy 2Document38 pagesPhotovoltaic Solar Energy 2Eris Osman RifkiNo ratings yet

- Ds Twinmax60cell-30b 6mm Bifacial Eu en 20160509 v04Document2 pagesDs Twinmax60cell-30b 6mm Bifacial Eu en 20160509 v04Eris Osman RifkiNo ratings yet

- BSB DB SeriesDocument2 pagesBSB DB SeriesEris Osman RifkiNo ratings yet

- DS PANDA60Cell-30b 40mm EU EN 20160203 V04Document2 pagesDS PANDA60Cell-30b 40mm EU EN 20160203 V04Eris Osman RifkiNo ratings yet

- Clustbox Den102020Document2 pagesClustbox Den102020Eris Osman RifkiNo ratings yet

- Bat FusesDocument2 pagesBat FusesEris Osman RifkiNo ratings yet

- LV Power Converter ProductsDocument4 pagesLV Power Converter ProductsEris Osman RifkiNo ratings yet

- AWG Wire Gauge Conversion Chart with Diameters and ResistanceDocument2 pagesAWG Wire Gauge Conversion Chart with Diameters and ResistanceAdesina OladayoNo ratings yet

- Vishay Schottky Rectifiers GuideDocument4 pagesVishay Schottky Rectifiers GuideEris Osman RifkiNo ratings yet

- Apogee SP-212 - 215specs PDFDocument2 pagesApogee SP-212 - 215specs PDFEris Osman RifkiNo ratings yet

- 48V DC Axial Fan 480 CFM 63dBDocument4 pages48V DC Axial Fan 480 CFM 63dBEris Osman RifkiNo ratings yet

- Apogee SP-212 - 215specs PDFDocument2 pagesApogee SP-212 - 215specs PDFEris Osman RifkiNo ratings yet

- Elektrikal SystemDocument2 pagesElektrikal SystemEris Osman RifkiNo ratings yet

- Sma Batfuse Ia EngDocument40 pagesSma Batfuse Ia EngEris Osman RifkiNo ratings yet

- FemToCell BasicDocument7 pagesFemToCell BasicEris Osman RifkiNo ratings yet

- Battery Industry Online Buyers GuideDocument78 pagesBattery Industry Online Buyers GuideEris Osman Rifki100% (1)

- Design of EHV SubstationDocument66 pagesDesign of EHV SubstationMadanasekhar Tadimarri100% (1)

- 1 Fuse-LinksDocument102 pages1 Fuse-LinksYoughorta TirNo ratings yet

- DC Motor Load Test Performance AnalysisDocument4 pagesDC Motor Load Test Performance AnalysisTapobroto ChatterjeeNo ratings yet

- Philips SW3660 Service ID4069Document14 pagesPhilips SW3660 Service ID4069sony reseNo ratings yet

- EXD-U00 Universal Driver ModuleDocument1 pageEXD-U00 Universal Driver Moduleron68xNo ratings yet

- Annexure-4 Formula For Calculation of Short Circuit Mechanical Forces NomenclatureDocument3 pagesAnnexure-4 Formula For Calculation of Short Circuit Mechanical Forces NomenclatureShashivendra ShuklaNo ratings yet

- FIITJEE JEE (Main) 2013 Concept Recapitulation Test Physics, Chemistry, MathsDocument10 pagesFIITJEE JEE (Main) 2013 Concept Recapitulation Test Physics, Chemistry, Mathsmail2sgarg_841221144No ratings yet

- Work Practice Manual PDFDocument728 pagesWork Practice Manual PDFMANOLOTEDIAZMURILLO100% (1)

- UDC2500 Universal Digital Controller Product Manual: 51-52-25-135 August 2005Document222 pagesUDC2500 Universal Digital Controller Product Manual: 51-52-25-135 August 2005kmpoulosNo ratings yet

- RF Basics: Martin D. Stoehr PMTS, ISM-RF Strategic ApplicationsDocument55 pagesRF Basics: Martin D. Stoehr PMTS, ISM-RF Strategic ApplicationsmuralikonathamNo ratings yet

- Structure, dielectric tunability, thermal stability and diffuse phase transition behavior of lead free BZT–BCT ceramic capacitorsDocument10 pagesStructure, dielectric tunability, thermal stability and diffuse phase transition behavior of lead free BZT–BCT ceramic capacitorsSamah SamahNo ratings yet

- LG 42pq20 Training ManualDocument123 pagesLG 42pq20 Training ManualLuis SantosNo ratings yet

- Pdce-Cmce Sertec: Electromagnetic Field ProtectorDocument12 pagesPdce-Cmce Sertec: Electromagnetic Field ProtectorRajesh AroraNo ratings yet

- Columbs LawDocument6 pagesColumbs Lawasadaliawanatd1No ratings yet

- Panasonic Car Stereo System CQ-CP134U PDFDocument16 pagesPanasonic Car Stereo System CQ-CP134U PDFJuan Carlos SoHeNo ratings yet

- Dual 3+1 PWM Controller With Current Monitor For Imvp-7/Vr12™ CpusDocument36 pagesDual 3+1 PWM Controller With Current Monitor For Imvp-7/Vr12™ CpusPitarsaNo ratings yet

- 9.2 Electrochemical CellsDocument39 pages9.2 Electrochemical CellsRose ChanNo ratings yet

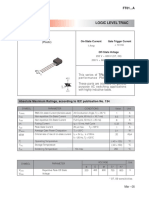

- LOGIC LEVEL TRIAC TECHNICAL SPECIFICATIONSDocument4 pagesLOGIC LEVEL TRIAC TECHNICAL SPECIFICATIONSAnatoly WolkoffNo ratings yet

- Earthing Calculation - Open ElectricalDocument11 pagesEarthing Calculation - Open ElectricalChihiya Fitria NurhayatiNo ratings yet

- Product Information: Toshiba X-Ray Tube D-0712 / D-0712S / D-0712SB Stationary Anode X-Ray TubeDocument8 pagesProduct Information: Toshiba X-Ray Tube D-0712 / D-0712S / D-0712SB Stationary Anode X-Ray TubeKamilNo ratings yet

- 6340Document180 pages6340vikas_vernekarNo ratings yet

- ASSIGNMENT#1 (3rd Oct 2022)Document2 pagesASSIGNMENT#1 (3rd Oct 2022)hamzaNo ratings yet

- Average Cirremt Mode Control of DC To DC Power Converters - Kazimierczuk 2022 WILEYDocument339 pagesAverage Cirremt Mode Control of DC To DC Power Converters - Kazimierczuk 2022 WILEYmelquisedecNo ratings yet

- Introduction To Safety Precautions & Lab Equipment: Power Transmission and Distribution LabDocument16 pagesIntroduction To Safety Precautions & Lab Equipment: Power Transmission and Distribution LabMuhammad Saad AbdullahNo ratings yet

- Magnetic Compass Deviation and CorrectionDocument100 pagesMagnetic Compass Deviation and CorrectionABDUL ALIMNo ratings yet

- Sevcon Powerpak Trouble Shooting Guid 1Document52 pagesSevcon Powerpak Trouble Shooting Guid 1Hector Osorio0% (1)

- Electronic Structure of MatterDocument47 pagesElectronic Structure of MatterMary Rose Lepardo - RosanesNo ratings yet

- PSM FULL CombinedDocument80 pagesPSM FULL CombinedASHUTOSHNo ratings yet

- OPT101 Monolithic Photodiode and Single-Supply Transimpedance AmplifierDocument31 pagesOPT101 Monolithic Photodiode and Single-Supply Transimpedance AmplifierASRANo ratings yet

- Diversity TechniquesDocument37 pagesDiversity TechniquessoumyaNo ratings yet