Professional Documents

Culture Documents

Driver Diaphragm Replacement

Uploaded by

radovanovdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Driver Diaphragm Replacement

Uploaded by

radovanovdCopyright:

Available Formats

7127 N. W.

Third Street Oklahoma City, Oklahoma 73127 (405) 789-0221

TM

D IA PH R A G M /V O IC E C O IL AS SE M B L Y R E P LA C E M E N T F O R A LT EC L AN S IN G 8 0 0 & 9 0 0 S E R IE S H . F . C O M P R E SS IO N D R IV E R S

D IA P H R A G M /V O IC E C O IL A SS E M B L Y R E P L A C E M E N T F O R A LT EC L AN S IN G 8 0 0 & 9 0 0 S E R IE S H . F . C O M P R E SS IO N D R IV E R S

The diaphrag m a nd v oice c oil assem bly in H.F. compression drive rs is extreme ly delicate and must be handled with care. Prior to starting the replacement procedure, select a work area that is clean and free from iron dust or chips. Cover the surface with a few layers of clean paper. The area must be free from drafts to preve nt iron du st particles in the air from being magnetically attracted to and lodged in the voice co il gap of the H.F. compression driver. Replace the diaphragm and voice coil assem bly in accord ance w ith the follow ing pro cedures. 1. Remove leads from external binding posts (see Figure 1). Note electrical phasing (polarity) as leads are removed.

(Figure 3). For mo dels using an acoustical loading cap, set it to one side until read y to re-install. CAUTION! The diaphragm is extremely delicate! Use care to prevent damage. Avoid physical contact with diaphragm. Keep screwdriver away, as strong magnetic field may attract screwdriver into diaphragm. 6. Carefully work diaphragm and voice coil assem bly free. Rem ove assem bly (see Figure 4).

Figure 2. Typical Altec 900-Series H.F. Driver with Acoustical Loading Cap 4. Lift cover from the driver and remove the two leads from their internal binding posts; set cover aside. Please note that som e m ode ls were equipped with an acoustical loading cap (Figure 2), wh ile othe rs we re pro vided w ith an acoustical absorbent felt disc (Figure 3), instead of a loading cap.

Figure 4. Typical Altec 900-Series Diaphragm /Voice C oil Assem bly 7. Clean foreig n m aterial fro m v oice coil gap with a short strip of masking tape one-inch wide. Fold tape back to form a strip with adhesive exposed on both sides. Insert edges of folded tap e into voice coil gap to full depth, and wipe clean com pletely around circular perimeter of ph asing plug and top p late (see Figure 5). Repeat cleaning procedure several times with fresh tape until tape is clean when withdrawn. 8. Carefully place new diaphragm and voice coil assem bly in proper position to align screw holes. Use care to avoid damaging edge and sides of voice coil wh ile positio ning it in voice coil gap. Be sure v oice coil/diaphragm assembly is fully seated.

Figure 1. Typical Altec 900-Series H.F. Com pression Driver 2. As appropriate to th e installation, remove driver loudspeaker and/or horn from enclosure or mounting, and take removed H.F. com pression driver assembly to the prepared work area. P L E A S E N O T E: Where easy access to the driver is available, the replacement procedure may be completed without removing the H.F. compression driver loudspeaker and/or horn. 3. Remove screws securing driver cover (see Figure 1).

Figure 3. Typical 900-Series Altec H.F. Driver without Acoustical Loading Cap 5. Remove three screw s securing acou stical loading cap (F igure 2), or diaphragm and voice coil assem bly

screw -down term inals (u sed o n all Altec 800-series drivers), open the binding post by unscrewing the top, then insert a sm all screwdriver into the opening where the speaker wire usually goes. Using a pair of small, needlenose pliers, turn the nut inside that secures the binding post to the rear cover wh ile app lyin g press ure w ith th e screwdriver in the o ppo site direction. Take care not to damage the small fibre washers that insulate the binding post from th e rear cover. Repeat this process for the sec ond bind ing p ost. C. Install new lead wires on your Altec 800 -series d riv er by connecting the red wire to the L2 external binding post, and the black wire to the L1 external binding post. Tighten securely by using the method given above in Section B. D. Connect the push-on connector of the red lead to the terminal marked + on the diaphragm mounting ring, then connect the push-on connector of the black lead to the terminal marked - on the diaphragm mounting ring. You may now proceed to Step 13. 12. If you have an Altec 900-series driver, and the old diaphragm you replaced utilized screw terminals to attach the leads, you will need an 800-900 Series Leadwire Kit to convert your H.F. compression driver to the new-style push-on terminals used on all diaphragms manufactured since 1983. To replace the old spade-lug type leads with the new, push-on leads provided in the kit, follow these steps: A. Remov e the screws that attach the old leads to the posts. B. Replace old leads with new ones, making sure to maintain proper color coding (red wire to the red

external bind ing p ost, and the black wire to the black external binding post). NO TE: Be sure to align the eyelets of the lead wires onto the binding posts so that they w ill be parallel to the top plate of driver when installed. If this is not done, they mig ht come in contact w ith the metal surface of the driver and short out when the cover is reinstalled. C. Connect the push-on connector of the red lea d to the terminal marked + on the diaphragm mounting ring, then connect the push-on connector of the black lead to the terminal ma rked - on the diaphragm mounting ring. 13. Install cover of H.F. driver, se curin g with screws removed in Step 3. 14. Return driver to service; connect external leads to bind ing p osts. Take care to ma intain electrical phasing (polarity) as originally wired.

Figure 5. Cleaning The Voice Coil Gap 9. For Models without an acoustical loading cap, install screws rem ove d in Step 5. Tighten screws securely. 10. For mo dels with an acoustical loading cap, re-install using screws removed in Step 5. Tighten screws securely. CAUTION! If new screws ar e required to secure the acoustical loading cap and/or the voice coil/diaphragm assem bly, use no n-m agn etic screws (such as stainless steel or brass) only. 11. If you have an Altec 800-series driver, and the old diaphragm you replaced utilized screw term inals to attach the leads, you will need an 800-900 Series Leadwire Kit to convert your H.F. com pression drive r to the new -style push-on terminals used on all diaphragms manufactured since 1983. To replace the old spade-lug type leads with the new, push-on leads provided in the kit, follow these steps: A. Remove the leads from the external bind ing p osts. B. For the old-style nickel plated

M A D E A N D P R I N T E D IN T H E U N I T E D ST A T E S O F A M E R I C A B Y -

7127 N. W. Third Street Oklahoma City, Oklahoma 73127 (405) 789-0221

TM

Great Plains Audio is a trademark of Great Plains Audio, Inc. Altec and Altec Lansing are registered trademarks of Altec Lansing Technologies, Inc.

42-02-035169 10/06/03

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

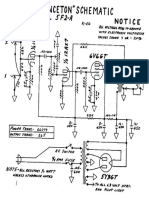

- Fender Princeton 5f2a SCHDocument1 pageFender Princeton 5f2a SCHradovanovdNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- China Menu DecoderDocument1 pageChina Menu DecoderradovanovdNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- How To French Polish Classical Guitars PDFDocument29 pagesHow To French Polish Classical Guitars PDFradovanovdNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- RCF Transducers PDFDocument15 pagesRCF Transducers PDFradovanovdNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Studer A727Document170 pagesStuder A727radovanovdNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- TL Audio 82 SchematicsDocument8 pagesTL Audio 82 Schematicsradovanovd100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- High Stepping Automatic Coil WinderDocument7 pagesHigh Stepping Automatic Coil WinderradovanovdNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- TLA M1 SchematicsDocument6 pagesTLA M1 SchematicsradovanovdNo ratings yet

- Soundcraft B400DDocument12 pagesSoundcraft B400DradovanovdNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Avo Douglas Coil Winding MachineDocument20 pagesAvo Douglas Coil Winding Machineradovanovd50% (2)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Canon PS A550 SM (Part)Document19 pagesCanon PS A550 SM (Part)radovanovdNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Pei Mei's Chinese Cooking Cards - SoupDocument50 pagesPei Mei's Chinese Cooking Cards - Soupradovanovd100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tannoy 1976 BrochureDocument13 pagesTannoy 1976 BrochureradovanovdNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Traktor Kontrol S4 MK2 Manual EnglishDocument233 pagesTraktor Kontrol S4 MK2 Manual Englishradovanovd100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- CHDK v1.3.0Document73 pagesCHDK v1.3.0radovanovdNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Jolpaz Davidov Ranko RisojevicDocument18 pagesJolpaz Davidov Ranko RisojevicradovanovdNo ratings yet

- Pioneer Deh-2950mp 2990mp PDFDocument70 pagesPioneer Deh-2950mp 2990mp PDFAxl Mendoza100% (3)

- Liebert Series 610 UPS: Installation Manual - 500-750kVA, 60Hz, Three Phase Single-ModuleDocument92 pagesLiebert Series 610 UPS: Installation Manual - 500-750kVA, 60Hz, Three Phase Single-ModuleFELIXDEJNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- (NOT Gate) DM7404 PDFDocument5 pages(NOT Gate) DM7404 PDFSai KumarNo ratings yet

- Experiment No. 04: Title Domestic Wiring For Extension Board and Inverter. AimDocument8 pagesExperiment No. 04: Title Domestic Wiring For Extension Board and Inverter. AimStar LordNo ratings yet

- Site Survey For Solar PVDocument4 pagesSite Survey For Solar PVLavancha Renewables100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 9300.97 12-13-19 XFIIRE Models 300B - 1000B Type H & WH IPLDocument7 pages9300.97 12-13-19 XFIIRE Models 300B - 1000B Type H & WH IPLHector FajardoNo ratings yet

- KR - MV S - R410A - 5060Hz - 220V - HP - CSA - MFL67474022 - 0CVM0-01D - Feb.2020 - SpecDocument1 pageKR - MV S - R410A - 5060Hz - 220V - HP - CSA - MFL67474022 - 0CVM0-01D - Feb.2020 - SpecRenzo TrNo ratings yet

- Clap SwitchDocument24 pagesClap Switchbalvendra0350% (2)

- 11-SDMS-03 تلخيصDocument4 pages11-SDMS-03 تلخيصMohammed MadiNo ratings yet

- Láser de CO2 - Bison - FIRE-XEL - Service Training Manual (ENG) Ver 2.2Document26 pagesLáser de CO2 - Bison - FIRE-XEL - Service Training Manual (ENG) Ver 2.2scribdsimh1100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Cathodic Protection For Military ShipsDocument48 pagesCathodic Protection For Military ShipsHitesh MudgilNo ratings yet

- Data SheetDocument13 pagesData SheetbhagvataNo ratings yet

- Manual TDocument36 pagesManual TAnonymous DiBRT8No ratings yet

- KPM Medium Rate: Dimensional and Electrical DataDocument10 pagesKPM Medium Rate: Dimensional and Electrical Datalokesh kumar singhNo ratings yet

- EDEPRO0146 0116 1 en Prospekt Multicond Data SheetDocument10 pagesEDEPRO0146 0116 1 en Prospekt Multicond Data SheetMartín LópezNo ratings yet

- CYMGRD Optimal Design of Substation Grounding GridsDocument5 pagesCYMGRD Optimal Design of Substation Grounding Gridsjaneth lozanoNo ratings yet

- VE026 MECHANICAL MANUAL enDocument33 pagesVE026 MECHANICAL MANUAL enJoséNo ratings yet

- DSO Nano Manual: PCB Version: V1.50 Software Verion: V1.40Document13 pagesDSO Nano Manual: PCB Version: V1.50 Software Verion: V1.40xrs666No ratings yet

- Adjustments For CaterpillarDocument2 pagesAdjustments For CaterpillarsportyjoNo ratings yet

- Pic16f887 MicrocontrollerDocument12 pagesPic16f887 MicrocontrollerShameerNo ratings yet

- Dimetra IP 2006 MTS 2 & MTS 4 Installation, Configuration, Maintenance & TroubleshootingDocument59 pagesDimetra IP 2006 MTS 2 & MTS 4 Installation, Configuration, Maintenance & TroubleshootingMutara Edmond NtareNo ratings yet

- Fanuc 6 Alarm Codes, 6T 6M ..Document8 pagesFanuc 6 Alarm Codes, 6T 6M ..StephanStephanovichNo ratings yet

- Novotechnik LWH 100Document2 pagesNovotechnik LWH 100Jorge Agustin González SaraibaNo ratings yet

- Service Manual Ricoh Mp171 S-C4 Eng FinalDocument512 pagesService Manual Ricoh Mp171 S-C4 Eng FinalVenaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Servo Gun v2.8 (Eng) ObaraDocument63 pagesServo Gun v2.8 (Eng) Obaralogaing13No ratings yet

- EDC LAB Manual PDFDocument110 pagesEDC LAB Manual PDFAbhishek PathakNo ratings yet

- FT Hmi PLCDocument15 pagesFT Hmi PLCLuis VillegasNo ratings yet

- 33kv WTG Switchyard BOMDocument4 pages33kv WTG Switchyard BOMManohar Potnuru100% (1)

- A Study of Different Metal Contact'S With Titanium Dioxide (Tio2)Document3 pagesA Study of Different Metal Contact'S With Titanium Dioxide (Tio2)t19125 t19125No ratings yet

- AP C30KP IM E WebDocument5 pagesAP C30KP IM E Webcr7messiNo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingFrom EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNo ratings yet