Professional Documents

Culture Documents

"Responsible Textiles": A Visit To Pratibha Syntex

Uploaded by

ioahSDiouhsdfuohsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

"Responsible Textiles": A Visit To Pratibha Syntex

Uploaded by

ioahSDiouhsdfuohsCopyright:

Available Formats

A Visit to Pratibha Syntex

Responsible Textiles

From its commencement Pratibha Syntex Ltd. has become one of the prominent names in the Indian textile industry. Their profile includes fine quality.

Cotton yarn Open end yarn Organic cotton yarn Polyester yarn Viscose yarn

The learning experience was started from the ware house where we saw the boxes of cotton which were from the different states of India like Orissa, Chattisgarh and Madhya Pradesh etc. They also purchase the raw material from other dealers outside India (Asian continent) First of all I want to share some details about the Company. Company profile: Chief Executive officer -Mr. S k Chaudhary No of employeesWorking hour 1670 8 hours

Process: Now the process of manufracturing the products are stated below:

Yarn The process of making yarn is cleaning, blending, carding and removing the dust from cotton and then mixing, blowing, draw frame and last simpiex means convrting the bobbin into yarn.. Knitting, Dying and garments Yarn was converted into the fabric through the cerculer kneeting machine then quality inspection was made and finally it went for the stichhing. After stiching the dying process was started. They wash the fabrics with chemical in Dye machine for quality inspection and discoloured the fabric for final process. Printing or embroudry and packaging After making the fabric they print or embroudry the logo into the garments and pack the product in big size of carttons which are comes from care and caution company. Now I want to mention the clients of the product. So the Important Clients are NIKE, ADIDAS, WOOLSWORTH, PATAGONIA and WALMART etc.They also export their products to USA, SOUTH AFRICA, CANADA AND CHINA.

Conclusion: The industrial visit is one of the most effective methods of learning. It provides us with an opportunity to learn practically through interaction, working methods and employment practices. The visit to Pratibha Syntex Ltd. was no different as it provided us with a meaningful insight into the day to day workings of a large scale organization. How activities are planned, coordinated and controlled was clearly visible from the way the product was manufactured.

When the whole process was completed we all were shocked and amazed that how can we convert bunch of cottons into a cloth. So at last but not the least I would like to thank Jaipuria Institute of Management to give me such a golden opportunity to enhance my practical learning..

Prajakta Patil Sec-A PGDM 2013-15

You might also like

- Bharat Vijay Mills DocumentDocument62 pagesBharat Vijay Mills DocumentShivangi BhargavaNo ratings yet

- Internship report on textile processes at Khawaja Sons MillsDocument19 pagesInternship report on textile processes at Khawaja Sons MillsMuneeb JavedNo ratings yet

- A Study On Employee's Performance Appraisal Towards Sri Ramco Spinners at RajapalayamDocument81 pagesA Study On Employee's Performance Appraisal Towards Sri Ramco Spinners at RajapalayamJanagar Raja S100% (1)

- Summer Internship On Ankur TextilesDocument47 pagesSummer Internship On Ankur TextilesSarthak Sagar100% (1)

- Internship Report (Saurav Kumar & Kumar Anand Kishor)Document44 pagesInternship Report (Saurav Kumar & Kumar Anand Kishor)kumaranand0646No ratings yet

- Textile Internship at OCM India LTDDocument73 pagesTextile Internship at OCM India LTDHaqiqat Ali100% (4)

- Masood Textile Mill Business Project ReportDocument23 pagesMasood Textile Mill Business Project ReportTariq ArshadNo ratings yet

- Factors Affecting Mayur Suitings SalesDocument88 pagesFactors Affecting Mayur Suitings SalesSwapnil KadamNo ratings yet

- Textile Internship at OCM India LTD PDFDocument73 pagesTextile Internship at OCM India LTD PDFMohit kolliNo ratings yet

- (Head of Textile) : Submitted ToDocument77 pages(Head of Textile) : Submitted ToDivya Thakur100% (1)

- Arvind Textile Internship Report-Final 2015Document44 pagesArvind Textile Internship Report-Final 2015Divyanshu Sagar0% (2)

- Aim of The Project: 210, Nikol Road, Bapu Nagar, Ahmedabad, Gujarat 382352, IndiaDocument4 pagesAim of The Project: 210, Nikol Road, Bapu Nagar, Ahmedabad, Gujarat 382352, IndiahastpatelNo ratings yet

- Abhijith PPT 01Document15 pagesAbhijith PPT 01VENKATESH VNo ratings yet

- Textile Industry in SuratDocument70 pagesTextile Industry in SuratgoswamiakashNo ratings yet

- INDUSTRIAL VISIT TO PRACHIDHI SPINNERS PVT LTDDocument7 pagesINDUSTRIAL VISIT TO PRACHIDHI SPINNERS PVT LTDKirubas KaranNo ratings yet

- Gardan Silk MainDocument134 pagesGardan Silk MainzalaksNo ratings yet

- Sujit ProjectDocument70 pagesSujit ProjectPrashant PatilNo ratings yet

- Operation Management ReportDocument14 pagesOperation Management ReportClaudia SmithNo ratings yet

- Summer Internship Report on Fabric Manufacturing ProcessDocument29 pagesSummer Internship Report on Fabric Manufacturing ProcessSHUBHAM KSHIRSAGARNo ratings yet

- Internship Report On: SR Zohaib Irshad Muhammad Farhan 2017-GCUF-000100 0011223Document16 pagesInternship Report On: SR Zohaib Irshad Muhammad Farhan 2017-GCUF-000100 0011223FASEH GONDALNo ratings yet

- Internship Report On: SR Zohaib Irshad Muhammad Farhan 2017-GCUF-000100 0011223Document16 pagesInternship Report On: SR Zohaib Irshad Muhammad Farhan 2017-GCUF-000100 0011223FASEH GONDALNo ratings yet

- Textile InternshipDocument42 pagesTextile InternshipNutukurthi Venkat RamjiNo ratings yet

- WelspunDocument28 pagesWelspunJinal ShahNo ratings yet

- Sportking NewDocument55 pagesSportking NewPrabhpreet Singh50% (2)

- Technology Management AssignmentDocument9 pagesTechnology Management AssignmentÂįmân ŚhêikhNo ratings yet

- NIFT STUDENT VISITS ALOK INDUSTRIESDocument28 pagesNIFT STUDENT VISITS ALOK INDUSTRIESjyotika kushwahaNo ratings yet

- Vardhman Polytex Report on Working Capital ManagementDocument69 pagesVardhman Polytex Report on Working Capital ManagementRanjeet Brar50% (2)

- Document4 2 Copy Copy 3Document6 pagesDocument4 2 Copy Copy 3mnrwillers0305047No ratings yet

- Presentation 1Document9 pagesPresentation 1Tom DanuNo ratings yet

- KrishnaDocument62 pagesKrishnaAlbert MervinNo ratings yet

- Industry Visit Reveals Ginni International's Supply ChainDocument3 pagesIndustry Visit Reveals Ginni International's Supply ChainNISHA CHANDANI Jaipuria JaipurNo ratings yet

- Internship Report on Textile Mills OperationsDocument11 pagesInternship Report on Textile Mills OperationsMuhammad KhalilNo ratings yet

- STUDENT DECLARATION AaaaaDocument50 pagesSTUDENT DECLARATION AaaaaawadhNo ratings yet

- Chenab Textile Mills FaisalabadDocument27 pagesChenab Textile Mills FaisalabadMubashar100% (2)

- Siyarams RoughDocument38 pagesSiyarams RoughASHISH BHUWANIANo ratings yet

- Production FlowchartDocument58 pagesProduction FlowchartMukes RajakNo ratings yet

- Textile Internship ReportDocument134 pagesTextile Internship Reportmeezan_alam91% (23)

- Laxmi Cotspin PVT - Ltd. Jalna: Study of Inventory ManagementDocument27 pagesLaxmi Cotspin PVT - Ltd. Jalna: Study of Inventory Managementsatu20No ratings yet

- Ojt ReportDocument33 pagesOjt Reportpandim6477No ratings yet

- Internship Report (Decent Textiles FSD)Document47 pagesInternship Report (Decent Textiles FSD)Waqas AhmedNo ratings yet

- Nitesh PariharDocument142 pagesNitesh Pariharnitesh pariharNo ratings yet

- Roll No 5, 10, 11, 20 Case StudyDocument16 pagesRoll No 5, 10, 11, 20 Case StudyPrabhat Kiran ChaulagainNo ratings yet

- Final Report - Envoy LastDocument88 pagesFinal Report - Envoy LastMd Motaleb50% (4)

- Sitara Textile Industries Industrial Visit ReportDocument8 pagesSitara Textile Industries Industrial Visit Reportwajeeha ramzanNo ratings yet

- Research (RVS IMSR), Were Scheduled To Undergo An Organizational Study For A PeriodDocument28 pagesResearch (RVS IMSR), Were Scheduled To Undergo An Organizational Study For A PeriodParthi PartiNo ratings yet

- SIP FinalDocument47 pagesSIP FinalAnkit SinghNo ratings yet

- Textile Internship - Usha YarnsDocument49 pagesTextile Internship - Usha YarnsROHAN GIREESHNo ratings yet

- Introduction to Knitting IndustryDocument29 pagesIntroduction to Knitting IndustryJustin RahulNo ratings yet

- Textile Mill ProjectDocument85 pagesTextile Mill ProjectTehmina NaqviNo ratings yet

- Financial Analysis of RSWM Limited1Document88 pagesFinancial Analysis of RSWM Limited1Jitendra VirahyasNo ratings yet

- Textile ProjectDocument38 pagesTextile Projectsathyamoorthisasu75% (4)

- Siddiq Leather Works Pvt Ltd Internship ReportDocument51 pagesSiddiq Leather Works Pvt Ltd Internship ReportMajid AliNo ratings yet

- Internship ProjectDocument25 pagesInternship ProjectMithra SubramaniamNo ratings yet

- Experiential Learning at Textile Giant Ginni InternationalDocument3 pagesExperiential Learning at Textile Giant Ginni InternationalNISHA CHANDANI Jaipuria JaipurNo ratings yet

- GP Report QC 1Document50 pagesGP Report QC 1Rohan JetlingNo ratings yet

- INTERNSHIP A.S. FashionDocument52 pagesINTERNSHIP A.S. FashionanupmasarojNo ratings yet

- Industrial Training ReportDocument32 pagesIndustrial Training Reportজহিরুলইসলামশোভন100% (1)

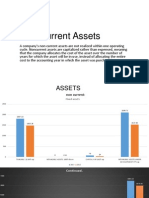

- AssetsDocument5 pagesAssetsioahSDiouhsdfuohsNo ratings yet

- AssetsDocument5 pagesAssetsioahSDiouhsdfuohsNo ratings yet

- Listening Skills: The Importance of Active ListeningDocument28 pagesListening Skills: The Importance of Active ListeningioahSDiouhsdfuohsNo ratings yet

- Listening Skills: The Importance of Active ListeningDocument28 pagesListening Skills: The Importance of Active ListeningioahSDiouhsdfuohsNo ratings yet

- Project Report Mother DairyDocument54 pagesProject Report Mother DairyRavinder Kasana67% (9)

- An overview of microeconomics theory in fast food marketingDocument13 pagesAn overview of microeconomics theory in fast food marketingioahSDiouhsdfuohsNo ratings yet

- An overview of microeconomics theory in fast food marketingDocument13 pagesAn overview of microeconomics theory in fast food marketingioahSDiouhsdfuohsNo ratings yet

- Snacks & NamkeensDocument33 pagesSnacks & NamkeensNavjot SinghNo ratings yet

- Coffee in The Philippines: Euromonitor International June 2012Document9 pagesCoffee in The Philippines: Euromonitor International June 2012Miguel LucenaNo ratings yet

- Etrma Imds Vulcanised Rubber Pseudo Susbtances Tyres Guidance 2Document9 pagesEtrma Imds Vulcanised Rubber Pseudo Susbtances Tyres Guidance 2rockraghav100% (1)

- Packaging ManualDocument127 pagesPackaging ManualShruti JainNo ratings yet

- 1628Document16 pages1628mballeza19No ratings yet

- Textiles AnnualReport2018 2019 (English) PDFDocument263 pagesTextiles AnnualReport2018 2019 (English) PDFPallavi IngaleNo ratings yet

- Sample IKEA Assignment Part 3Document6 pagesSample IKEA Assignment Part 3scholarsassistNo ratings yet

- HarisDocument13 pagesHarisanandsivNo ratings yet

- Digital Patterns: Designed by Steve GoodDocument35 pagesDigital Patterns: Designed by Steve GoodSerban GeorgianaNo ratings yet

- Miele W1712 Operating InstructionsDocument60 pagesMiele W1712 Operating InstructionsJeremy Moore50% (2)

- Easyfit ™ Business Idea: Executive SummaryDocument5 pagesEasyfit ™ Business Idea: Executive SummaryJackie AsherNo ratings yet

- Dewan TextileDocument3 pagesDewan TextileAdnan FarooquiNo ratings yet

- Astm E11-16Document11 pagesAstm E11-16Said MohamedNo ratings yet

- Niir Complete Technology Book On Dyes Dye IntermediatesDocument9 pagesNiir Complete Technology Book On Dyes Dye IntermediatesAmit Kanani100% (1)

- Wheat MillingDocument18 pagesWheat MillingNatalia Shpak100% (1)

- Metal Inclusion, Haccp FDA Seafood Ch20Document10 pagesMetal Inclusion, Haccp FDA Seafood Ch20thanhtl_hugolata100% (1)

- Material Passage Diagram of Bale Opener MachineDocument4 pagesMaterial Passage Diagram of Bale Opener MachineMaruf Uddin Ahmed100% (4)

- Aero BrochureDocument4 pagesAero BrochureMilind KhandweNo ratings yet

- CRAB RatingDocument62 pagesCRAB RatingRashed MahmudNo ratings yet

- Methods of ProductionDocument5 pagesMethods of ProductionOshane BaileyNo ratings yet

- Apresentação The Melting PotDocument15 pagesApresentação The Melting PotGlobal FranchiseNo ratings yet

- Jidoka SampleDocument8 pagesJidoka SampleHai Dai Nguyen MinhNo ratings yet

- 4aa5 9733enwDocument4 pages4aa5 9733enwعبداللهأحمدNo ratings yet

- CatalogDocument100 pagesCatalogandygraficoNo ratings yet

- Report SipDocument37 pagesReport SipAmit Rewatkar50% (2)

- Coca Cola Sales and DistributionDocument58 pagesCoca Cola Sales and DistributionkarthikaNo ratings yet

- Better Cotton Chain of Custody v1.3 Summary of Changes 2018Document23 pagesBetter Cotton Chain of Custody v1.3 Summary of Changes 2018AtifKhanNo ratings yet

- PCM at NestleDocument16 pagesPCM at NestlenasirenamNo ratings yet

- An Application of DMAIC Methodology For Increasing The Yarn Quality in Textile IndustryDocument16 pagesAn Application of DMAIC Methodology For Increasing The Yarn Quality in Textile IndustryVarunNo ratings yet

- Project On BingoDocument28 pagesProject On BingoViPul50% (2)

- $100M Leads: How to Get Strangers to Want to Buy Your StuffFrom Everand$100M Leads: How to Get Strangers to Want to Buy Your StuffRating: 5 out of 5 stars5/5 (12)

- To Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryFrom EverandTo Pixar and Beyond: My Unlikely Journey with Steve Jobs to Make Entertainment HistoryRating: 4 out of 5 stars4/5 (26)

- Bare Bones: I'm Not Lonely If You're Reading This BookFrom EverandBare Bones: I'm Not Lonely If You're Reading This BookRating: 4 out of 5 stars4/5 (11)

- They Can't Kill Us Until They Kill UsFrom EverandThey Can't Kill Us Until They Kill UsRating: 4.5 out of 5 stars4.5/5 (36)

- Summary: Greenlights: by Matthew McConaughey: Key Takeaways, Summary & AnalysisFrom EverandSummary: Greenlights: by Matthew McConaughey: Key Takeaways, Summary & AnalysisRating: 4 out of 5 stars4/5 (6)

- The Black Star of Kingston: Tales of Old Natalia 1From EverandThe Black Star of Kingston: Tales of Old Natalia 1Rating: 5 out of 5 stars5/5 (152)

- Designing Brand Identity: A Comprehensive Guide to the World of Brands and BrandingFrom EverandDesigning Brand Identity: A Comprehensive Guide to the World of Brands and BrandingNo ratings yet

- I Didn't Come Here to Make Friends: Confessions of a Reality Show VillainFrom EverandI Didn't Come Here to Make Friends: Confessions of a Reality Show VillainRating: 3 out of 5 stars3/5 (47)

- Storyworthy: Engage, Teach, Persuade, and Change Your Life through the Power of StorytellingFrom EverandStoryworthy: Engage, Teach, Persuade, and Change Your Life through the Power of StorytellingRating: 4.5 out of 5 stars4.5/5 (152)

- No Lifeguard on Duty: The Accidental Life of the World's First SupermodelFrom EverandNo Lifeguard on Duty: The Accidental Life of the World's First SupermodelRating: 3.5 out of 5 stars3.5/5 (42)