Professional Documents

Culture Documents

Style 07 Zero-Flex Rigid Coupling: Product Description

Uploaded by

pca97Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Style 07 Zero-Flex Rigid Coupling: Product Description

Uploaded by

pca97Copyright:

Available Formats

1482 Rev.E 1/02 Registered Trademark of Victaulic Copyright 1999 Victaulic Printed in U.S.A.

R

Victaulic Company of America

Phone: 1- 800- PICK- VIC (1- 800- 742- 5842)

Fax: 610- 250- 8817

e- mai l :pi ckvi c@vi ctaul i c.com

Victaulic Company of Canada

Phone: 416- 675- 5575

Fax: 416- 675- 5565

e- mai l : vi ccanada@vi ctaul i c.com

Victaulic America Latina

Phone: 610- 559- 3300

Fax: 610- 559- 3608

e- mai l : vi cal @vi ctaul i c.com

Victaulic Asia Pacific

Phone: 65- 235- 3035

Fax: 65- 235- 0535

e- mai l : vi cap@vi ctaul i c.com

Victaulic Europe

Phone:32- 9- 381- 1500

Fax: 32- 9- 380- 4438

e- mai l : vi ceuro@vi ctaul i c.be

VICTAULIC

IS AN ISO 9001 CERTIFIED COMPANY

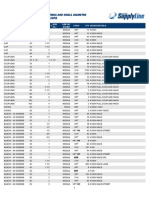

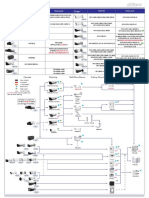

DIMENSIONS

Typical 1 - 12"

Y

X

Z

Nominal

Size

Inches

mm

Diameter

Inches

mm

Max.

Work

Press.

PSI*

kPa

Max.

End

Load

Lbs.*

N

Allow.

Pipe

End #

Sep. In.

mm

@

Bolt/Nut

No. - Size

Inches

mm

Dimensions

Inches/

millimeters

Aprx.

Wgt.

Each

Lbs.

kg

X Y Z

1 1.315 750 650 0.05

2 -

2

2.36 4.22 1.84 1.6

25 33, 7 5175 2890 1, 2 60 107 47 0, 7

1

1.660 750 1, 620 0.05

2 -

2

2.69 4.62 1.84 1.6

32 42, 4 5175 7210 1, 2 68 117 47 0, 7

1

1.900 750 2, 130 0.05

2 -

2

2.94 5.81 1.84 1.6

40 48, 3 5175 9480 1, 2 75 148 47 0, 7

2 2.375 750 3, 320 0.07

2 -

3.35 5.78 1.84 2.3

50 60, 3 5175 14775 1, 7 85 147 47 1, 0

2

2.875 750 4, 875 0.07

2 -

3.88 6.38 1.84 2.6

65 73, 0 5175 21695 1, 7 98 162 47 1, 2

76, 1 mm

3.000 750 5, 300 0.07

2 - 12

70, 0

4.21 6.61 1.84 3.6

76, 1 5175 23585 1, 7 107 168 47 1, 6

3 3.500 750 7, 215 0.07

2 -

4.54 6.81 1.84 3.0

80 88, 9 5175 32105 1, 7 115 173 47 1, 4

4 4.500 750 11, 925 0.16

2 -

5.81 8.21 2.07 5.3

100 114, 3 5175 53065 4, 1 148 209 53 2, 4

108, 0 mm

4.250 750 10, 635 0.16

2 - 12

70, 0

5.56 7.98 2.07 5.2

108, 0 5175 47325 4, 1 141 203 53 2, 4

5 5.563 750 18, 225 0.16

2 -

7.03 9.89 2.07 7.4

125 141, 3 5175 81100 4, 1 179 251 53 3, 4

133, 0 mm

5.250 700 15, 145 0.16

2 - 16

82, 5

6.69 9.60 2.07 7.4

133, 0 4825 67395 4, 1 170 244 53 3, 4

139, 7 mm

5.500 700 16, 625 0.16

2 - 16

82, 5

6.94 9.82 2.07 7.6

139, 7 4825 73980 4, 1 176 249 53 3, 4

6 6.625 700 24, 130 0.16

2 -

8.26 10.83 2.07 8.3

150 168, 3 4825 107380 4, 1 210 275 53 3, 8

159, 0 mm

6.250 700 21, 465 0.16

2 - 16

82, 5

7.84 10.54 2.07 9.2

159, 0 4825 95520 4, 1 199 268 53 4, 2

165, 1 mm

6.500 700 23, 225 0.16

2 -

8.13 10.84 2.07 8.3

165, 1 4825 103305 4, 1 207 275 53 3, 8

Table continued on page 2. * # @ Refer to notes on page 2.

IPS CARBON STEEL PIPE

GROOVED COUPLINGS

06.02

PRODUCT DESCRIPTION

Style 07

Zero-Flex

Rigid Coupling

with Vic-Plus Gasket System

T he uni que angle-pad

desi gn of the Zero-Flex

Style 07 coupli ng adjusts to

standard pi pe and roll or

cut groove tolerances, posi -

ti vely clampi ng the pi pe to

resi st exural and torsi onal

loads. T he wi der key sec-

ti on lls more of the groove

area.

Style 07 coupli ngs are rated

up to 750 psi (5175 kPa),

dependant on si ze, for 1 -

24" (25 - 600 mm) pi pi ng

systems. Style 07 cou-

pli ngs provi de ri gi di ty for

valve connecti ons, machi n-

ery rooms, re mai ns, and

long strai ght runs. Support

and hangi ng requi rements

correspond to A NSI B31.1

Power Pi pi ng Code, A NSI

B31.9 Bui ldi ng Servi ces

Code and NFPA 13 Spri n-

kler Systems. A ngle-pad

desi gn permi ts assembly

by removi ng one nut/bolt

and sci ssori ng housi ng

over gasket. T hi s reduces

the number of components

to handle duri ng assembly,

speeds and eases i nstalla-

ti on.

Vic-Plus Gasket System:

Vi ctauli c

now offers a gas-

ket system whi ch requi res

no eld lubri cati on. T he

Vi c-Plus

T M

System (patent

pendi ng) i s dry, clean, and

non-toxi c. I t reduces

assembly ti me substanti ally

and eli mi nates the mess

and chance of

over-lubri cati on.

Exaggerated for C larity

Patented

U

L

C U

L

FM

See Victaulic

publication 10.01

for details.

06.02 - 2

Housing

: Ducti le i ron conform-

i ng to A ST M A -395, grade 65-

45-15, and A ST M A -536, grade

65-45-12.

Housing Coating

: Orange

enamel.

Optional:

Hot dipped

galvanized and others.

Coupling Gasket

: (speci fy

choi ce*)

Grade E EPDM

Vic-Plus Gasket System

EPDM (Green color code).

Temperature range 30F to

+230F (34C to +110C).

Recommended for cold and

hot water servi ce wi thi n the

speci ed temperature range

plus a vari ety of di lute aci ds,

oi l-free ai r and many chemi -

cal servi ces. UL classi ed i n

accordance wi th A NSI /NSF

61 for cold +86F (+30C) and

hot +180F (+82C) potable

water servi ce. NOT RECOM -

M ENDED FOR PET ROLEUM

SERVI CES.

Grade T nitrile

Vic-Plus Gasket System

Ni tri le (Orange color code).

Temperature range 20F to

+180F (29C to +82C).

Recommended for petroleum

products, ai r wi th oi l vapors,

vegetable and mi neral oi ls

wi thi n the speci ed tempera-

ture range. Not recom-

mended for hot water

servi ces over +150F (+66C)

or for hot dry ai r over +140F

(+60C).

*Servi ces li sted are General Ser-

vi ce Recommendati ons only. I t

should be noted that there are

servi ces for whi ch these gaskets

are not recommended. Refer-

ence should always be made to

the latest Vi ctauli c Gasket

Selecti on Gui de for speci c gas-

ket servi ce recommendati ons

and for a li sti ng of servi ces

whi ch are not recommended.

Bolts/Nuts

: Heat treated car-

bon steel, track-head conform-

i ng to physi cal properti es of

A ST M A -183, mi ni mum tensi le

110,000 PSI (758340 kPa), zi nc

electroplated per A ST M B-633.

Nominal

Size

Inches

mm

Diameter

Inches

mm

Max.

Work

Press.

PSI*

kPa

Max.

End

Load

Lbs.*

N

Allow.

Pipe

End #

Sep. In.

mm

@

Bolt/Nut

No. - Size

Inches

mm

Dimensions

Inches/

millimeters

Aprx.

Wgt.

Each

Lbs.

kg

X Y Z

8 8.625 600 35, 000 0.19

2 -

10.54 13.74 2.51 15.1

200 219, 1 4130 155750 4, 8 268 349 64 6, 8

10 10.750 500 45, 400 0.13

2 -

12.86 16.98 2.56 23.5

250 273, 0 3450 202030 3, 3 327 431 65 10, 7

12 12.750 400 51, 000 0.13

2 -

14.86 18.88 2.56 28.2

300 323, 9 2750 226950 3, 3 377 480 65 12, 8

14 14.000 250 38, 485 0.13

3 -

5

16.06 19.89 2.87 32.8

350 355, 6 1725 171180 3, 2 408 505 73 14, 9

16 16.000 250 50, 265 0.13

3 -

5

18.39 21.84 2.87 41.2

400 406, 4 1725 223580 3, 2 467 555 73 18, 7

18 18.000 250 63, 615 0.13

3 -

5

20.68 23.89 3.00 54.2

450 457, 0 1725 282970 3, 2 525 607 76 24, 6

20 20.000 250 78, 540 0.13

4 - 1

5

22.93 27.47 3.00 67.2

500 508, 0 1725 349345 3, 2 582 698 76 30, 5

24 24.000 250 113, 000 0.09

4 - 1

5

27.05 31.61 3.06 76.2

600 610, 0 1725 502850 2, 3 687 803 78 34, 6

Couplings 8, 10, 12" ( 200, 250, 300 mm) sizes available to JI S standard. Refer to section 06.17 for details.

* # @ See notes below.

DIMENSIONS

MATERIAL SPECIFICATIONS

Typical 14 - 18"

Typical 20 - 24"

NOTES

* Working Pressure and End Load are total, from all internal and external loads, based on standard weight ( ANSI ) steel pipe, standard

roll

or

cut

grooved in accor-

dance with Victaulic

specifications. Contact Victaulic for performance on other pipe.

WARNI NG : FO R O NE TI M E FI ELD TEST O NLY, the M aximum Joint Working Pressure may be increased to 1

times the figures shown.

# For field installation only on roll grooved pipe or cut grooved pipe. Zero-Flex Style 07 couplings are essentially rigid and do not permit expansion/contraction.

@ Number of bolts required equals number of housing segments.

M etric thread size bolts are available ( color coded gold) for all coupling sizes upon request. Contact Victaulic for details.

Style 07 couplings must

not

be used to join PVC pipe.

WARNI NG : Piping systems must always be depressurized and drained before attempting disassembly and removal of any Victaulic piping products.

This product shall be manufactured by Victaulic Company. All products shall be installed in accordance with current Victaulic installation/assembly instructions.

Victaulic reserves the right to change product specifications, designs and standard equipment without notice and without incurring obligations.

X

Y Z

X

Y Z

TORQUE REQUIREMENTS

Nominal Size

inches/

mm

Diameter

Inches/

mm

Recommended Torque

ft. lbs./

Nm

14, 16 & 18 14.000, 16.000, 18.000 250

350, 400, 450 355, 6, 406, 4 & 457, 0 340

20 & 24 20.000, 24.000 300

500, 600 508, 0, 610, 0 407

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Stress AnalysisDocument6 pagesStress Analysisapi-3836286100% (4)

- 24 Ford EE New HollandDocument239 pages24 Ford EE New HollandJohn Mendoza PachecoNo ratings yet

- Air Valves ValmaticDocument28 pagesAir Valves Valmaticnimm1962100% (1)

- Pipe Stress Analysis Using CAESAR IIDocument42 pagesPipe Stress Analysis Using CAESAR IIpca97100% (1)

- Industrial PumpingDocument59 pagesIndustrial Pumpingpca97100% (1)

- Cosmic Freedom: David MolineauxDocument2 pagesCosmic Freedom: David Molineauxsalomon46No ratings yet

- AFT CE Gasflow ReprintDocument8 pagesAFT CE Gasflow ReprintNacho.pNo ratings yet

- Geberit HDPE Piping Systems Catalogue 2011/2012Document83 pagesGeberit HDPE Piping Systems Catalogue 2011/2012IvanSmith100% (1)

- Automax Valve Automation Systems - Pneumatic Actuators and Accessories - FlowserveDocument24 pagesAutomax Valve Automation Systems - Pneumatic Actuators and Accessories - FlowserveKakoDaNo ratings yet

- SSX Diaphragm: Truextent® Replacement Diaphragms For JBL and RADIANDocument2 pagesSSX Diaphragm: Truextent® Replacement Diaphragms For JBL and RADIANIvica IndjinNo ratings yet

- SCFM Vs ACFM Conversion GuideDocument16 pagesSCFM Vs ACFM Conversion GuideFreddy Salvatierra SaavedraNo ratings yet

- FLSMIDTHDocument63 pagesFLSMIDTHJoaquin Jose Abarca Rodriguez86% (7)

- Keystone Fig. AR1-AR2 Butterfly ValveDocument4 pagesKeystone Fig. AR1-AR2 Butterfly Valvepca97No ratings yet

- Hagglunds Viking MK 64 163000 Bo LN 0100Document26 pagesHagglunds Viking MK 64 163000 Bo LN 0100thijssilderhuis100% (1)

- Manual de Partes CascadeDocument18 pagesManual de Partes Cascadejads301179No ratings yet

- Style 997 Transition Coupling HDPE Plastic To Steel: Product DescriptionDocument2 pagesStyle 997 Transition Coupling HDPE Plastic To Steel: Product DescriptionJason MillerNo ratings yet

- Europa Valve Non Slam Check ValvesDocument16 pagesEuropa Valve Non Slam Check ValvesBryan KellyNo ratings yet

- Double Cartridge Mechanical SealsDocument4 pagesDouble Cartridge Mechanical SealsGoran TesicNo ratings yet

- TYCO Keystone F14.Lined - Butterfly.valve enDocument4 pagesTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuNo ratings yet

- Style 808 Duo-Lock High Pressure Coupling: Product DescriptionDocument2 pagesStyle 808 Duo-Lock High Pressure Coupling: Product Descriptionnrd9771No ratings yet

- Super Duplex Stainless Steel Vic-Ball ValveDocument4 pagesSuper Duplex Stainless Steel Vic-Ball Valvemayukhguha88No ratings yet

- FTJ Series Product Guide PDFDocument12 pagesFTJ Series Product Guide PDFJhon SendokNo ratings yet

- Series 774DCDA Specification SheetDocument2 pagesSeries 774DCDA Specification SheetWattsNo ratings yet

- WOT - Tech Data Sheets PDFDocument43 pagesWOT - Tech Data Sheets PDFAmbroise RICHARDNo ratings yet

- Maintenance Arpex enDocument39 pagesMaintenance Arpex enPatrick BaridonNo ratings yet

- 35e PPS A003r1 PDFDocument18 pages35e PPS A003r1 PDFingemexNo ratings yet

- Pig Sig VDocument8 pagesPig Sig VAsemota OghoghoNo ratings yet

- Kvkew 0089 enDocument4 pagesKvkew 0089 enksathishgreenNo ratings yet

- Series 757DCDA, 757NDCDA Specification SheetDocument4 pagesSeries 757DCDA, 757NDCDA Specification SheetWattsNo ratings yet

- Actuator BARDocument16 pagesActuator BARRohit GadekarNo ratings yet

- LOC TechDocument5 pagesLOC Techvx800bikeNo ratings yet

- Rotolok UK Rotary Valves AirlocksDocument6 pagesRotolok UK Rotary Valves AirlocksAngel AlvarezNo ratings yet

- EZstrip BrochureDocument6 pagesEZstrip BrochureDiego FlórezNo ratings yet

- PM GB GearmotorDocument10 pagesPM GB GearmotorMulugeta Kiros GebeyehuNo ratings yet

- Single: GLE Range ofDocument8 pagesSingle: GLE Range ofNghia HuynhNo ratings yet

- Composite Cement Retainer Technical DatasheetDocument2 pagesComposite Cement Retainer Technical DatasheetEvolution Oil ToolsNo ratings yet

- Elem Peltier PF-127!10!13Document12 pagesElem Peltier PF-127!10!13wal1992_20055079No ratings yet

- Vishay Roederstein: L Max. WDocument12 pagesVishay Roederstein: L Max. Wdrs22No ratings yet

- SP Commercial Washer Brochure PDFDocument4 pagesSP Commercial Washer Brochure PDFAl AdcockNo ratings yet

- G61MPV - 09 01 2007Document104 pagesG61MPV - 09 01 2007Baryonyx Troodon100% (1)

- GC Inlet Liners and Glass Inserts GuideDocument4 pagesGC Inlet Liners and Glass Inserts GuidemagicianchemistNo ratings yet

- Technical Data Products 2009 CompletDocument62 pagesTechnical Data Products 2009 CompletRobert NedelcuNo ratings yet

- 210-10-PB - Rev-A (DTA - Dynamic Torque Anchor) PDFDocument5 pages210-10-PB - Rev-A (DTA - Dynamic Torque Anchor) PDFEvolution Oil ToolsNo ratings yet

- Style 77 Standard Flexible Coupling: Product DescriptionDocument0 pagesStyle 77 Standard Flexible Coupling: Product DescriptionAnibal MoralesNo ratings yet

- Imi Cci 860hpcDocument4 pagesImi Cci 860hpcWilliam SukyonoNo ratings yet

- Cable TSJ y TSJ-N PDFDocument4 pagesCable TSJ y TSJ-N PDFmakv12100% (1)

- Mangas PDFDocument14 pagesMangas PDFluisfer811No ratings yet

- Bomba de Lubricação Automatca de MarteloDocument53 pagesBomba de Lubricação Automatca de MarteloDaniel F BarrosNo ratings yet

- Backflow PreventersDocument4 pagesBackflow PreventersSam WeberNo ratings yet

- Shielded High SRF Inductors - 0805PSDocument2 pagesShielded High SRF Inductors - 0805PSnevdullNo ratings yet

- Industrial Penstocks GuideDocument19 pagesIndustrial Penstocks Guidedundee2012No ratings yet

- Style 22 Vic-Ring Coupling: Product DescriptionDocument2 pagesStyle 22 Vic-Ring Coupling: Product DescriptionDante2500No ratings yet

- CATALOUGEDocument3 pagesCATALOUGEdeepthiNo ratings yet

- Manual de Mantenimiento BS2640.180Document28 pagesManual de Mantenimiento BS2640.180Roberto Daniel Sanchez MelgarejoNo ratings yet

- Monolithic Insulating JointsDocument5 pagesMonolithic Insulating JointsTran Thanh TungNo ratings yet

- Robotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icDocument8 pagesRobotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icAsrul Arashi IrdianaNo ratings yet

- Es 775Document2 pagesEs 775WattsNo ratings yet

- Ferraz Shawmut High Voltage Fuses CatalogueDocument93 pagesFerraz Shawmut High Voltage Fuses CataloguerocketvtNo ratings yet

- APV-LLK-2 Ball Valve BrochureDocument13 pagesAPV-LLK-2 Ball Valve BrochureHeri SetyantoNo ratings yet

- Series U009 Specification SheetDocument4 pagesSeries U009 Specification SheetWattsNo ratings yet

- Pneumatic Clamps: DestacoDocument32 pagesPneumatic Clamps: DestacoMarian DunareanuNo ratings yet

- HDP-Victaulic Estilo 995Document4 pagesHDP-Victaulic Estilo 995hugorubenzNo ratings yet

- DLP enDocument15 pagesDLP enpir8s_xNo ratings yet

- SV60 Safety Valves: For Use With Steam, Gas and LiquidsDocument8 pagesSV60 Safety Valves: For Use With Steam, Gas and LiquidscmpuckNo ratings yet

- 5800E Valtek Kit: A.W. Chesterton CoDocument1 page5800E Valtek Kit: A.W. Chesterton CoempswookNo ratings yet

- Construction Shielding (Diffuser) : Type: Catalog#Document2 pagesConstruction Shielding (Diffuser) : Type: Catalog#Alexiz Silva A.No ratings yet

- Max Air PDFDocument8 pagesMax Air PDFKNIGHTHAGENNo ratings yet

- Plastic Pipe - PE - Chapter01Document9 pagesPlastic Pipe - PE - Chapter01garisa1963No ratings yet

- Chapter02-Handbook of Polyethylene PipeDocument27 pagesChapter02-Handbook of Polyethylene Pipepca97No ratings yet

- Plastic Pipe - PE - Chapter01Document9 pagesPlastic Pipe - PE - Chapter01garisa1963No ratings yet

- Chapter03-Handbook of Polyethylene PipeDocument61 pagesChapter03-Handbook of Polyethylene Pipepca97No ratings yet

- AISC Properties ViewerDocument3 pagesAISC Properties Viewerchriscivil12No ratings yet

- SFP'LPFQV: A TutorialDocument15 pagesSFP'LPFQV: A Tutorialcoleiro0% (1)

- Chevron Sae 60Document1 pageChevron Sae 60pca97No ratings yet

- AFT Non Settling Slurry Pumping ProblemsDocument12 pagesAFT Non Settling Slurry Pumping Problemspca97No ratings yet

- CADWorx IP User GuideDocument51 pagesCADWorx IP User Guidepca97No ratings yet

- Forged Fittings and Small Diameter Schedule PipesDocument7 pagesForged Fittings and Small Diameter Schedule Pipespca97No ratings yet

- Modeling Choked Flow Through An Orifice (Aft)Document14 pagesModeling Choked Flow Through An Orifice (Aft)Martín Diego MastandreaNo ratings yet

- Cutting Costs with Pump OptimizationDocument4 pagesCutting Costs with Pump Optimizationpca97No ratings yet

- Choke Flow CVDocument5 pagesChoke Flow CVpca97No ratings yet

- AFT Duke Energy Case StudyDocument2 pagesAFT Duke Energy Case Studypca97No ratings yet

- Combo Air ValvesDocument5 pagesCombo Air Valvespca97No ratings yet

- Diagrama de ModdyDocument1 pageDiagrama de ModdypatoqlNo ratings yet

- General Hammer v8 XMDocument6 pagesGeneral Hammer v8 XMpca97No ratings yet

- Pump InletDocument2 pagesPump Inletpca97No ratings yet

- Valve Sizing TablesDocument5 pagesValve Sizing Tablespca97No ratings yet

- Aft Tme Case StudyDocument2 pagesAft Tme Case Studypca97No ratings yet

- AFT Optimizing Pumping SystemsDocument8 pagesAFT Optimizing Pumping Systemspca97No ratings yet

- AFT Optimizing Pumping SystemsDocument8 pagesAFT Optimizing Pumping Systemspca97No ratings yet

- Overlord - Volume 01 - The Undead KingDocument223 pagesOverlord - Volume 01 - The Undead KingPaulo FordheinzNo ratings yet

- Specifications Sheet ReddyDocument4 pagesSpecifications Sheet ReddyHenry CruzNo ratings yet

- Cars Ger Eu PCDocument157 pagesCars Ger Eu PCsergeyNo ratings yet

- Ub40 LyricsDocument76 pagesUb40 LyricsJose Lucio Flores SantosNo ratings yet

- ARES SC4 Service Manual (HP-300UA)Document20 pagesARES SC4 Service Manual (HP-300UA)mike_net8903No ratings yet

- IotDocument88 pagesIotLalithyaNo ratings yet

- Technote Torsional VibrationDocument2 pagesTechnote Torsional Vibrationrob mooijNo ratings yet

- CBSE Worksheet-01 Class - VI Science (The Living Organisms and Their Surroundings)Document3 pagesCBSE Worksheet-01 Class - VI Science (The Living Organisms and Their Surroundings)Ushma PunatarNo ratings yet

- Mahle KFWA MAIN Data SheetDocument4 pagesMahle KFWA MAIN Data SheetRudnikNo ratings yet

- r05320202 Microprocessors and Micro ControllersDocument7 pagesr05320202 Microprocessors and Micro ControllersSri LalithaNo ratings yet

- Kingspan Spectrum™: Premium Organic Coating SystemDocument4 pagesKingspan Spectrum™: Premium Organic Coating SystemNikolaNo ratings yet

- Ebook Drugs and The Neuroscience of Behavior An Introduction To Psychopharmacology 2Nd Edition Prus Test Bank Full Chapter PDFDocument62 pagesEbook Drugs and The Neuroscience of Behavior An Introduction To Psychopharmacology 2Nd Edition Prus Test Bank Full Chapter PDFeffigiesbuffoonmwve9100% (10)

- Abiotic and Biotic Factors DFDocument2 pagesAbiotic and Biotic Factors DFgiselleNo ratings yet

- Principle Harmony RhythmDocument16 pagesPrinciple Harmony RhythmRosalinda PanopioNo ratings yet

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakNo ratings yet

- Poultry DiseasesDocument5 pagesPoultry DiseasesAnjum IslamNo ratings yet

- A Feature Selection Based On The Farmland Fertility Algorithm For Improved Intrusion Detection SystemsDocument27 pagesA Feature Selection Based On The Farmland Fertility Algorithm For Improved Intrusion Detection SystemsRashed ShakirNo ratings yet

- Chemistry 12: Provincial ExaminationDocument25 pagesChemistry 12: Provincial ExaminationCát TriệuNo ratings yet

- Schroedindiger Eqn and Applications3Document4 pagesSchroedindiger Eqn and Applications3kanchankonwarNo ratings yet

- PPS120 Rev10 0309 PDFDocument2 pagesPPS120 Rev10 0309 PDFArfanAliNo ratings yet

- Mfz-Odv065r15j DS 1-0-0 PDFDocument1 pageMfz-Odv065r15j DS 1-0-0 PDFelxsoonNo ratings yet

- Rincon Dueling RigbyDocument5 pagesRincon Dueling Rigbytootalldean100% (1)

- IIT2019 RIT-1-CPM Chemistry TestDocument15 pagesIIT2019 RIT-1-CPM Chemistry TestPRAKHAR GUPTANo ratings yet

- Myths of Greece and Rome PDFDocument247 pagesMyths of Greece and Rome PDFratheesh1981No ratings yet

- Template EbcrDocument7 pagesTemplate EbcrNoraNo ratings yet

- Blood Group 3Document29 pagesBlood Group 3Hamirie JoshuaNo ratings yet

- Philip Rance EAH Philo of ByzantiumDocument3 pagesPhilip Rance EAH Philo of ByzantiumstoliNo ratings yet

- Knowing Annelida: Earthworms, Leeches and Marine WormsDocument4 pagesKnowing Annelida: Earthworms, Leeches and Marine WormsCherry Mae AdlawonNo ratings yet