Professional Documents

Culture Documents

Cimenterie Nationale PDF

Uploaded by

bulentbulutOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cimenterie Nationale PDF

Uploaded by

bulentbulutCopyright:

Available Formats

Case Study

Cimenterie Nationale Cement Plant

Fact file Date: Location: Product: Principal: Problem: April 4th 2008 Fond Mombin,Caberet, Haiti - Cimenterie Nationale Primasonics Acoustic Cleaning System Primasonics International Ltd (UK) Build up on the side of his 6000 tonne cement silo

Client Background Ricardo Corrales, Mec. Eng, Assistant to the Maintenance Manager at the Cimenterie Nationale cement plant in Haiti (jointly owned by Holcim, Colombian Group Argos, local investors and Haitian government) does not have a lot of spare time. However, in August last year whilst reading through World Cement Journal he saw an article about Primasonics Cleaners. Material build up on the side of his 6000 tonne cement silos was continuing to be a serious problem, especially in the adverse local weather conditions ranging from monsoon to extremely dry. THE APPROACH Ricardo visited the Primasonics website and discovered that Primasonics Cleaners had been successfully employed to eliminate material build up on silo walls on a global basis. As requested, Ricardo supplied Primasonics with a dimensional drawing and completed a questionnaire which enabled them to select the most appropriate Primasonics Cleaner solution. THE RESULT At the end of the trial period Ricardo was delighted to report that the Primasonics cleaning system was operating very well and the General Manager of the Technical Department based in Colombia was also equally impressed with the performance of the Primasonics Cleaners during his visit to site. In February this year Primasonics received the following e-mail from Ricardo "Greetings from Haiti - for me it is a pleasure to communicate with you to inform you that because of the Primasonics Cleaners we have been able to withdraw an additional 1000 tonnes of cement which we could not do before we installed your cleaners.

Case Study

Cimenterie Nationale Cement Plant

This has all meant that choosing your technology was a good decision and it is the kind of success that we can show to the other companies within our group." THE SOLUTION The equipment was despatched on an agreed trial basis and installed on an existing inspection hatch on top of the silo and the trial commenced using the recommended sounding pattern.

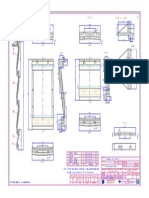

TECHNICAL DETAILS Material: Material Particle Size Range: Silo Construction: Silo Dimensions: Silo Discharge: 45 micron sieve Portland Cement 82-85% through Concrete Height 25m Diameter 15m Flat Bottom with Air Slides

You might also like

- ContentDocument11 pagesContentberihu tesfayNo ratings yet

- Advertising and Sales Promotion at Acc CemenDocument92 pagesAdvertising and Sales Promotion at Acc CemenshaikameermalikNo ratings yet

- Advertising and Sales Promotion at Acc CemenDocument92 pagesAdvertising and Sales Promotion at Acc CemenAyush JatpuriyaNo ratings yet

- Christiaens B2 EngDocument8 pagesChristiaens B2 EngRabindranath Hendy TagoreNo ratings yet

- David, Kimberly Joyce Illuscupides, Dianne Mallari, Rose Marie Padilla, Raisa Sih, Allen JamesDocument34 pagesDavid, Kimberly Joyce Illuscupides, Dianne Mallari, Rose Marie Padilla, Raisa Sih, Allen JamesxpthatsmeNo ratings yet

- Kroenert Sets New StandardsDocument4 pagesKroenert Sets New Standardsjuergen.blum2743No ratings yet

- Paperworks in Acdc - PCPIDocument15 pagesPaperworks in Acdc - PCPIClariza CaponesNo ratings yet

- Diamond Cement Products EnterprisesDocument15 pagesDiamond Cement Products EnterprisessamrudhrsarikarNo ratings yet

- Global Strategy of CEMEXDocument29 pagesGlobal Strategy of CEMEXAbhishek Jain100% (1)

- All RubberDocument157 pagesAll RubberIvan MaciasNo ratings yet

- Form Cementos Mexicanos S.A., Acquired Cementos Maya's Plant in MeridaDocument6 pagesForm Cementos Mexicanos S.A., Acquired Cementos Maya's Plant in Meridakristine contrerasNo ratings yet

- 15.00 Paolo Bossi, MD, Sinai White CementDocument38 pages15.00 Paolo Bossi, MD, Sinai White CementMohd AliNo ratings yet

- Job-Report AyrtonSennaHighway enDocument8 pagesJob-Report AyrtonSennaHighway enproject listNo ratings yet

- Address: Quirino, Bacnotan, La Union: I. Introuction A. VissionDocument21 pagesAddress: Quirino, Bacnotan, La Union: I. Introuction A. VissionJose Paulo DiazNo ratings yet

- White Cement Prospect ICR 2008-12Document3 pagesWhite Cement Prospect ICR 2008-12jsabovik33No ratings yet

- Channel of DistributionDocument122 pagesChannel of Distributioncursorkkd100% (1)

- Eyu Internship ReportDocument12 pagesEyu Internship ReportAbel Lema100% (2)

- Market Audit and Competitive Market Analysis of SHAH Cement in PhilippinesDocument23 pagesMarket Audit and Competitive Market Analysis of SHAH Cement in PhilippinesAshraful IslamNo ratings yet

- COMPANYINFODocument32 pagesCOMPANYINFOwan22839448No ratings yet

- Boldrocchi CatalogueDocument19 pagesBoldrocchi Catalogueamitjoshi2002No ratings yet

- Lafarge - Transcript of - Cement Manufacturing ProcessDocument4 pagesLafarge - Transcript of - Cement Manufacturing ProcessBaguma Grace Gariyo100% (1)

- Waste Energy Plastic 3Document3 pagesWaste Energy Plastic 3Jorge Alejandro DelaVega Lozano100% (2)

- Daliform Group Creating and Manufacturing Plastic Products For The Construction Industry.Document8 pagesDaliform Group Creating and Manufacturing Plastic Products For The Construction Industry.Daliform GroupNo ratings yet

- POM Assignment Part 1Document3 pagesPOM Assignment Part 1Dhruv KapoorNo ratings yet

- Wti/Environan Photo-Catalytic Tarmac SolutionsDocument25 pagesWti/Environan Photo-Catalytic Tarmac SolutionsMichaelCoffeeBNo ratings yet

- WorldCement May 2013 PreviewDocument23 pagesWorldCement May 2013 Previewnsprasad88No ratings yet

- Compounding World May 2011Document56 pagesCompounding World May 2011Ercan Ubay100% (1)

- Air BlastersDocument3 pagesAir BlastersVenkatesha HebbarNo ratings yet

- Sustainable Develompent in Cement IndustryDocument9 pagesSustainable Develompent in Cement IndustrylintangnurNo ratings yet

- Company ProfilesDocument14 pagesCompany ProfilesKeiser MonteroNo ratings yet

- Magazine 66 EnglishPartDocument179 pagesMagazine 66 EnglishPartAli AwamiNo ratings yet

- Free Mba Reports: AcknowledgementDocument32 pagesFree Mba Reports: AcknowledgementFarhan Ali SiddiqiNo ratings yet

- Usa Catalog 2012Document51 pagesUsa Catalog 2012Pisos PorcelánicosNo ratings yet

- Socotherm BrochureDocument9 pagesSocotherm Brochuremaruc08No ratings yet

- Factsheet: Membrane Filtration TechnologyDocument2 pagesFactsheet: Membrane Filtration TechnologyDheeraj ShuklaNo ratings yet

- 2008 Bullentin Rel. 2-DataDocument5 pages2008 Bullentin Rel. 2-DataKalai SelvanNo ratings yet

- Refineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyDocument3 pagesRefineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyGjorgeluisNo ratings yet

- Operation Management ReportDocument31 pagesOperation Management ReportFarhan Ali SiddiqiNo ratings yet

- Technical Appraisal of An Industrial ProjectDocument8 pagesTechnical Appraisal of An Industrial ProjectVivek SavaliyaNo ratings yet

- Daliform Group Corporate ImageDocument8 pagesDaliform Group Corporate ImageDaliform GroupNo ratings yet

- Foam Bitumen RecyclingDocument65 pagesFoam Bitumen Recyclingkemas100% (7)

- Environment Scanning ON Indian Cement IndustryDocument64 pagesEnvironment Scanning ON Indian Cement IndustryMuskaan ChauhanNo ratings yet

- Report 3 - CDP307B - 216716973Document19 pagesReport 3 - CDP307B - 216716973Gerhard vd WesthuizenNo ratings yet

- NylonDocument2 pagesNylonHarsh GuptaNo ratings yet

- Construction Materials HandoutDocument6 pagesConstruction Materials HandoutKeith Anshilo DiazNo ratings yet

- A Local Partner With A Global Reach: The Premier Tech Chronos WorldDocument8 pagesA Local Partner With A Global Reach: The Premier Tech Chronos WorldNaeemSiddiquiNo ratings yet

- Explosion Protection in Sugar HandlingDocument6 pagesExplosion Protection in Sugar HandlingMartinNo ratings yet

- In Plant Training Report in Ultratech Cement Limited: Submitted By: P.Bharath Kumar ReddyDocument40 pagesIn Plant Training Report in Ultratech Cement Limited: Submitted By: P.Bharath Kumar ReddyPeram Bharath Kumar Reddy100% (1)

- Northern Cement CorporationDocument26 pagesNorthern Cement CorporationJHuvieCLaireNo ratings yet

- Fine Rubber Powders From Rubber Crumb & Buffings: Anne & Russ EvansDocument8 pagesFine Rubber Powders From Rubber Crumb & Buffings: Anne & Russ EvansPeter Jake PatriarcaNo ratings yet

- Vidal Terra ArmeDocument5 pagesVidal Terra Armegrga piticNo ratings yet

- Dear Sir: Basekrete MD/HD Polyurethane Mortar FlooringDocument3 pagesDear Sir: Basekrete MD/HD Polyurethane Mortar FlooringBlind SpotNo ratings yet

- Ogr-Portfolio-19 6 19Document19 pagesOgr-Portfolio-19 6 19OMAR MUKTHAR JAMAL MOHAMEDNo ratings yet

- Industrial ReportDocument9 pagesIndustrial ReportAhasan RidoyNo ratings yet

- Unique Processes and Best Practices: Cement Manufacturing Operations Holcim Philippines, IncDocument5 pagesUnique Processes and Best Practices: Cement Manufacturing Operations Holcim Philippines, IncAndro MedaNo ratings yet

- Internship Report Fauji Cement FinalDocument53 pagesInternship Report Fauji Cement FinalSHAHEER HASHMINo ratings yet

- Chap 1Document9 pagesChap 1kri009No ratings yet

- Zydex Corporate Profile - RoadsDocument14 pagesZydex Corporate Profile - RoadsSiti Hanila BowhaniNo ratings yet

- How Are Supercars Made? Technology Book for Kids 4th Grade | Children's How Things Work BooksFrom EverandHow Are Supercars Made? Technology Book for Kids 4th Grade | Children's How Things Work BooksNo ratings yet

- Flo Way PresentationDocument33 pagesFlo Way PresentationbbulutmmNo ratings yet

- Bu Coalpsa en v011Document2 pagesBu Coalpsa en v011bulentbulutNo ratings yet

- Open Gears: Lubrication + Maintenance + ServiceDocument16 pagesOpen Gears: Lubrication + Maintenance + ServicebulentbulutNo ratings yet

- Nansulate For Energy Efficient WindowsDocument5 pagesNansulate For Energy Efficient WindowsbulentbulutNo ratings yet

- EN21004243A Roller StationsDocument51 pagesEN21004243A Roller StationsbulentbulutNo ratings yet

- SUPERTHERM To Replace HouseWrapDocument1 pageSUPERTHERM To Replace HouseWrapbulentbulutNo ratings yet

- High-Pressure Grinding 2MB PDFDocument0 pagesHigh-Pressure Grinding 2MB PDFbulentbulutNo ratings yet

- Loesche Classifiers Modification Report at MCLDocument42 pagesLoesche Classifiers Modification Report at MCLnsprasad88No ratings yet

- Çap3668 X L 1777-ModelDocument1 pageÇap3668 X L 1777-ModelbulentbulutNo ratings yet

- WEBBH009 - Baghouse Maintenance GuideDocument1 pageWEBBH009 - Baghouse Maintenance GuidebulentbulutNo ratings yet

- SUPERTHERM Over Tanks JapanDocument2 pagesSUPERTHERM Over Tanks JapanbulentbulutNo ratings yet

- Dustex Overview For DustexTurkey TrainingDocument69 pagesDustex Overview For DustexTurkey TrainingbulentbulutNo ratings yet

- Dustex Turkey - Power Industry 12-16-13Document37 pagesDustex Turkey - Power Industry 12-16-13bulentbulutNo ratings yet

- Without ATEX Permission: LED-cap Lamp With 2-Step Illumination (Emergency Light, Main Light)Document29 pagesWithout ATEX Permission: LED-cap Lamp With 2-Step Illumination (Emergency Light, Main Light)bulentbulutNo ratings yet

- CompAir L23 - 26A 50Hz Compressor Performance Data PDFDocument1 pageCompAir L23 - 26A 50Hz Compressor Performance Data PDFbulentbulut100% (1)

- CompAir L23 - L29 - RS Compressor Brochure PDFDocument8 pagesCompAir L23 - L29 - RS Compressor Brochure PDFbulentbulutNo ratings yet

- PSP Kırma Eleme Genel Katalog PDFDocument40 pagesPSP Kırma Eleme Genel Katalog PDFbulentbulutNo ratings yet

- Pre Alignment PDFDocument38 pagesPre Alignment PDFbulentbulutNo ratings yet

- Toh MFS8B 98B 003-11114-3AG1 PDFDocument92 pagesToh MFS8B 98B 003-11114-3AG1 PDFDmitry NemtsoffNo ratings yet

- Data Sheet Eldar Void SpinnerDocument1 pageData Sheet Eldar Void SpinnerAlex PolleyNo ratings yet

- Derebe TekesteDocument75 pagesDerebe TekesteAbinet AdemaNo ratings yet

- What Is Universe?Document19 pagesWhat Is Universe?Ruben M. VerdidaNo ratings yet

- Upes School of Law Lac & Adr Association: PresentsDocument7 pagesUpes School of Law Lac & Adr Association: PresentsSuvedhya ReddyNo ratings yet

- Current Concepts in Elbow Fracture Dislocation: Adam C Watts, Jagwant Singh, Michael Elvey and Zaid HamoodiDocument8 pagesCurrent Concepts in Elbow Fracture Dislocation: Adam C Watts, Jagwant Singh, Michael Elvey and Zaid HamoodiJoão Artur BonadimanNo ratings yet

- EdisDocument227 pagesEdisThong Chan100% (1)

- Shelly e CommerceDocument13 pagesShelly e CommerceVarun_Arya_8382No ratings yet

- HFE0106 TraskPart2Document5 pagesHFE0106 TraskPart2arunkr1No ratings yet

- Low Budget Music Promotion and PublicityDocument41 pagesLow Budget Music Promotion and PublicityFola Folayan100% (3)

- Mahesh R Pujar: (Volume3, Issue2)Document6 pagesMahesh R Pujar: (Volume3, Issue2)Ignited MindsNo ratings yet

- SyncopeDocument105 pagesSyncopeJohn DasNo ratings yet

- Midi Pro Adapter ManualDocument34 pagesMidi Pro Adapter ManualUli ZukowskiNo ratings yet

- E-Versuri Ro - Rihana - UmbrelaDocument2 pagesE-Versuri Ro - Rihana - Umbrelaanon-821253100% (1)

- ALE Manual For LaserScope Arc Lamp Power SupplyDocument34 pagesALE Manual For LaserScope Arc Lamp Power SupplyKen DizzeruNo ratings yet

- Final Selection Criteria Tunnel Cons TraDocument32 pagesFinal Selection Criteria Tunnel Cons TraMd Mobshshir NayeemNo ratings yet

- Moquerio - Defense Mechanism ActivityDocument3 pagesMoquerio - Defense Mechanism ActivityRoxan MoquerioNo ratings yet

- Battery Guide - 2021Document27 pagesBattery Guide - 2021Mario LaurieNo ratings yet

- CSE 202.04 Inspection of Concrete StructuresDocument67 pagesCSE 202.04 Inspection of Concrete StructuresJellyn BaseNo ratings yet

- Research 093502Document8 pagesResearch 093502Chrlszjhon Sales SuguitanNo ratings yet

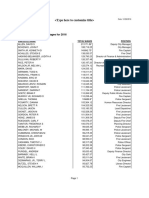

- 2016 W-2 Gross Wages CityDocument16 pages2016 W-2 Gross Wages CityportsmouthheraldNo ratings yet

- Chapter 2Document8 pagesChapter 2Fahmia MidtimbangNo ratings yet

- Math 9 Quiz 4Document3 pagesMath 9 Quiz 4Lin SisombounNo ratings yet

- Bajaj Vs Hero HondaDocument63 pagesBajaj Vs Hero HondaHansini Premi100% (1)

- Trade MarkDocument2 pagesTrade MarkRohit ThoratNo ratings yet

- RMC 102-2017 HighlightsDocument3 pagesRMC 102-2017 HighlightsmmeeeowwNo ratings yet

- BARUDocument53 pagesBARUhueuaNo ratings yet

- EKRP311 Vc-Jun2022Document3 pagesEKRP311 Vc-Jun2022dfmosesi78No ratings yet

- Phylogeny Practice ProblemsDocument3 pagesPhylogeny Practice ProblemsSusan Johnson100% (1)

- List of Iconic CPG Projects in SingaporeDocument2 pagesList of Iconic CPG Projects in SingaporeKS LeeNo ratings yet