Professional Documents

Culture Documents

B404

Uploaded by

t_syamprasadOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B404

Uploaded by

t_syamprasadCopyright:

Available Formats

EFFECTS OF URBANIZATION ON SUBSTATIONS AND CONSTRAINTS IN PROVIDING SUBSTATION GROUND GRID RAJENDRA S.

BHATT* KAHRAMAA QATAR SREEJIT DEV DIVAKARAN ENERGOPROJEKT-ENTEL QATAR

I.

SUMMARY

II.

KEYWORDS

Due to very rapid development in Qatar, the expansion of power transmission system has necessitated establishment of the transmission substations within the commercial areas with high rising and densely populated areas. But with swift urbanization owing to economic growth, availability and acquiring of land has become a major constraint in development of conventional substations. This constraint is overcome with the introduction of unconventional substations like fully-underground and sub-underground substations, which need special consideration and pose many technical challenges as compared to conventional substations. The foremost and one of the many technical challenges in development of such unconventional substations is the substation grounding grid which requires minimal usage of land. The grounding grid is designed and determined by various factors including current distribution of earth-fault by split factor and ground potential rise (GPR) evaluations. Due to optimization of available land, the grounding grid is placed below the foundation of substations with depth of the substation well below the summer water table, where the resistance of the soil is negligible. Since unconventional substations are built in multi-levels, connection of earthing risers from the grounding grid to the equipment also have drastic effect on the design of the grounding grid. This paper presents design of such grounding grid, where usage of land for laying the grid is limited. The constraints in establishing this grounding design is also discussed in the paper with a real time example of Dohaland-1 66/11kV primary substation, which was designed with fault on conservative basis.

Ground grid, ground potential rise, ground resistance, ground resistivity, unconventional substation III. INTRODUCTION

The Mshereib development is located in the centre of Doha. It will be a mixed use development providing in excess of 750,000 sqmm of above ground accommodation including residential, commercial, retail and leisure and providing basement services to support the above ground facilities. To meet the electrical power demand of the development, KAHRAMAA has identified a requirement for two primary substations within the development cartilage. The two primary substations are multi-leveled located underground accessed by the main service tunnels. Of the two substations, 66/11kV Dohaland-1 primary substation has the lowest level, B4 will be cable basement. Above it will be level B3 consisting of transformer cells, service yard for transformers, fire suppression plant room, 66kV and 11kV switchgear rooms, battery room, access and escape routes. Level B2 comprises control and relay room, telecommunication room, LV power supply system and HVAC plant room. Additionally Dohaland-1 substation has staff facilities on level B2 and level B1 is spared for other services. On ground level above Dohaland-1 substation the Eid prayer ground is located. Major challenges were observed during design of earthing grid for Dohaland-1 substation. In accordance to the challenges, solutions were derived and are discussed accordingly.

KAHRAMAA, PO BOX 41, DOHA, QATAR

Page 1 of 6

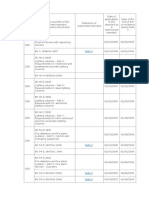

EID PRAYER GROUND

FIELD DATA

LEVEL

B1

LEVEL

ADDITIONAL AND OTHER SERVICES CONTROL AND RELAY ROOM, LVAC AND TELECOM ROOM, HVAC PLANT ROOM TRANSFORMERS, 66kV AND 11kV SWITCHGEAR, BATTERY ROOM. CONDUCTOR SIZE

B2

LEVEL

B3

LEVEL

INTIAL DESIGN

B4

CABLE BASEMENT

MODIFY DESIGN

GRID RESISTANCE

Figure 1: Arrangement of 66/11kV Dohaland-1 substation IV. EARTH GRID DESIGN

GRID CURRENT

IV.I. GENERAL For every substation, design of earth grid for the substation is the first major step towards design of a substation. A safe grounding design consists of two grounding system; the intentional ground consisting of ground electrodes buried at some depth below the earths surface and the accidental ground temporarily established by a person exposed to a potential gradient in the vicinity of a grounded facility. Factors which influence the substation ground design are soil resistivity, level of water table, fault current, fault clearance time, substation configuration, equipment rating, Local authorities rules/ regulations etc. The general approach for ground grid design starts with measurement of soil resistivity from proposed substation site. Soil resistivity is measured by different methods. With an exposure to soil resistivity, a two layer or multi layer soil model is built along with calculation of tolerable touch and step potentials. With result of soil resistivity and depth of summer water table, earthing conductors are laid along with vertical earth rods to form a grid at adequate depth as necessary to enhance safe grounding system for the substation. The contribution of fault current flowing to the grid is formulated after deriving the fault current division factor. The grid is evaluated for grid resistance though the amount of fault current flowing through the grid. Ground potential rise (GPR) is calculated as product of grid resistance and fault current flowing through the grid. The ground grid design is considered safe if GPR is lower than the tolerable touch potential.

NO

GPR<TOLERA BLE TOUCH POTENTIAL

YES

MESH TOUCH POTENTIAL < TOLERABLE TOUCH POTENIAL

NO

MESH STEP POTENTIAL < TOLERABLE STEP POTENIAL

DETAIL DESIGN

Figure 2: Flowchart for design of substation earth grid

Page 2 of 6

IV.II. DOHALAND-1 SUBSTATION The soil resistivity values were obtained from geotechnical investigation report. The measurement at site was carried out using 4-electrode Wenner method, with electrode spacing 3m, 6m, 9m, 15m, 20m and 25m at each test locations. The measurements of soil resistivity were performed at ground level at dewatering condition. The in-situ borehole details for the substation showed water table at about 6m from the ground level. Based on the inputs of soil resistivity and the depth of water, a two layer soil model was chosen. The selected soil model has upper layer resistivity of 27.56m having thickness of 9.13m and lower layer resistivity of 0.0014m. of infinite thickness. From the soil model, the tolerable touch and step potentials were obtained as 169V and 207.91V respectively. Conductor size for the earthing conductors was calculated and as per KAHRAMAA practice 1Cx240sqmm lead sheathed copper cables were proposed. The grid model was constructed based on the soil model and conductor sizing calculation. Since the basements were 6m below the finished ground floor level and no space available outside the substation area, the grid was placed 8m below finished ground floor level along with four vertical earth rods.

Figure 4: Sectional view of Dohaland-1 substation earth grid The substation was considered conservative with the full fault current of 31.5kA flowing through the ground grid for 1sec, following which the grid resistance was calculated, resulting in 0.00033 and value of ground potential rise was derived as 10.6, hence ground grid design for Dohaland-1 primary substation is safe.

Figure 3: Grid layout of 66/11kV Dohaland-1 substation

Figure 5: Contour plot for touch potential

Page 3 of 6

Figure 6: Potential contour plot V. MAJOR CONSTRAINTS IN PROVIDING EARTH GRID FOR DOHALAND-1 SUBSTATION

Figure 7: Placement of earth grid in Dohaland-1 substation The floor B4 level of the substation was 6m below the finished ground floor level. With raft foundations below the B4 level, the substation ground grid was placed 8m below the finished ground level for effective dissipation of fault currents. Constant dewatering was required for laying of the earth conductors. The substation earth grid would be below water table during substations service which would enhance the conductivity of fault currents through low resistive path. The surface layer for the earth grid was wet concrete of the raft foundation which is a low resistive layer compared to higher resistive layers like crushed gravel.

V.I. LAYING OF EARTH GRID Earth grid is the most important component of a safe grounding method. The earth grid consists of earthing conductors that are laid with adequate spacing between them from 3m-15m and joined together. The earth grid also consists of vertical earth rods that are connected to earthing conductors through earth pit. For conventional substations, the earth grid is placed by laying continuous conductor outside the periphery of substation site typically at a distance of 1.5m to 2m from the boundary at a depth of 0.5m 1.5 below the ground level. The exact positioning of the perimeter conductor and the depth of burial is determined during the design process taking into account external step and touch potentials. According to the practice in Qatar, cable basement is provided wherein indoor earthing grid is fixed at a 1.5m below the ground level. In case of underground/ semi-underground substations this type of earthing grid formation is not feasible. Dohaland-1 substation, being an unconventional multi-level substation, no land was available on any direction of substation due to raft foundations for building of other new facilities as part of Dohaland project. Hence due to these limitations, substation earth grid was placed below the substation.

Figure 8: Earthing conductors laid in Dohaland-1 substation before Raft construction

Page 4 of 6

V.II. EARTH PIT LOCATION AND CONNECTION TO EARTH GRID Vertical earth rods are used to increase the conductivity of earth grid and reduce the overall resistance of the grid. Hence the vertical earth rods need to be placed below 2m of the summer water of the substation plot. The vertical earth rods are accessed for maintenance and testing through concrete structure known as the earth pit. It is through the earth pit that the vertical earth rod is connected to the earthing conductor to form the substation earth grid.

Figure 9: Typical earth pit For maintenance and test purpose access to earth pit is required and accordingly earth pit should be located in open areas at the periphery of the substation. However, in case of Dohaland-1 substation, there are no open areas as such, for accessibility of earth pit for maintenance. Solution was made to place earth pits inside the substation in cable basement at level B4. By placing earth pit at level B4, vertical earth rods needs to pass through the waterproofing membrane and the basement slab. Since the basement B4 level is well below the water table, any piercing of basement slab and waterproofing would lead to water logging in basement. In this context a special arrangement is required for the vertical earth rod to negate water logging in the basement. An earth vertical rod configuration was proposed with single flange earth rod seal that restricts open passage with coating of water proof membrane around the vertical earth rods, which restricts movement of water to the basement. Figure 10: Proposed earth pit configuration V.III. EARTHING RISERS The connection from the outdoor earth grid to auxiliary earth mat in equipment rooms and directly to the equipment, which forms the indoor earthing system is done through earthing risers/spur connections. Since the earthing risers have to transfer the high fault current from the equipment/auxiliary earth mat to the earthing conductors in earth grid, the size of earthing riser is larger than the earthing conductors in earthing grid. As per KAHRAMAA practice, the size of the earthing riser should not be less than 400 sqmm lead sheathed cable.

Page 5 of 6

In case of conventional substations, the earthing risers are taken through the wall to the substation and connected to the indoor earthing system of the substation through conduits. For multilevel substations, such as Dohaland-1 substation, the earthing risers have to reach four basement levels to achieve connectivity between the ground grid and indoor earthing system. Further the risers cannot be taken through the wall due to basement slab of the other adjacent structures are made in close proximity of the underground substation. Hence the solution was made to take the risers through the pile structure, which leads to column of the substation.

In case of earthing risers also the same problem was faced as it was faced for placement of earth pit. If the earthing risers were to pierce through the basement slab, it would have to pass through the water proofing laid to check that no water would enter the substation leading to water logging of basements. Also the number of earthing risers had to be reduced due to its passing through the water membrane and the basement slab. The piercing of water membrane was eliminated by making a special arrangement with conduits placed and a thick water proofing membrane made around the risers, same arrangement in line with vertical earth rods. With this special arrangement, the number of risers was optimized to 28 numbers and complies with the minimum criterion for safe earthing system as well. VI. CONCLUSION

Grounding grid design for a conventional substation is one of the simplest routine. However an unconventional substation poses many technical challenges due to optimization of land. The above study introduces the major constraints in provision of substation earth grid for unconventional underground substation. The challenges faced during design of earthing grid for 66/11kV Dohaland-1 substation were discussed which includes laying of earth grid, location of earth pit and path of risers. Adequate solutions were provided for overcoming the constraints in the earthing grid design for unconventional substations. VII. 1. 2. Figure 11: Path of riser through column REFERENCES IEEE Guide for Safety in AC Substation Grounding, Greg Kohn, IEEE80-2000 Ma J, Dawalibi F P, Southey R D. Effects of Changes in IEEE Std. 80 on the Design and Analysis of Power System Grounding (PowerCon 2002 page 974-979 vol 2)

Page 6 of 6

You might also like

- QuotationDocument3 pagesQuotationt_syamprasadNo ratings yet

- Tamil Nadu Coke-24 V DC - r1Document14 pagesTamil Nadu Coke-24 V DC - r1t_syamprasadNo ratings yet

- 36 KV, 1250a VCB GTP - r1Document3 pages36 KV, 1250a VCB GTP - r1t_syamprasadNo ratings yet

- B Ðéæý :: 6 Bvýsçü$T 2017: Ólyýl$ (Òœ Yšlíù Yól Çü Ýlæý  V ..Document40 pagesB Ðéæý :: 6 Bvýsçü$T 2017: Ólyýl$ (Òœ Yšlíù Yól Çü Ýlæý  V ..t_syamprasadNo ratings yet

- Navya Daily - 18.11.2017Document3 pagesNavya Daily - 18.11.2017t_syamprasadNo ratings yet

- Cleaning Mounting and Removal of BearingDocument23 pagesCleaning Mounting and Removal of Bearingt_syamprasadNo ratings yet

- Bearing Handbook For Electric MotorsDocument34 pagesBearing Handbook For Electric Motorst_syamprasad0% (1)

- 33KV CB DrawingDocument1 page33KV CB Drawingt_syamprasadNo ratings yet

- Ball and Roller BearingsDocument105 pagesBall and Roller Bearingssamurai7_77No ratings yet

- SF6 Circuit Breaker Instruction ManualDocument386 pagesSF6 Circuit Breaker Instruction ManualiraqnewNo ratings yet

- Lan Details0122Document1 pageLan Details0122t_syamprasadNo ratings yet

- Owners Manual KwidDocument130 pagesOwners Manual Kwidt_syamprasad100% (2)

- Offer124033 Bom R0Document2 pagesOffer124033 Bom R0t_syamprasad100% (1)

- Ñ ) L-Ç - Yýl-° Òœ Çù Byýl-Í - Ëï - Ól A° ™ðlë$ - Çü$-Mø Yìl!Document40 pagesÑ ) L-Ç - Yýl-° Òœ Çù Byýl-Í - Ëï - Ól A° ™ðlë$ - Çü$-Mø Yìl!t_syamprasadNo ratings yet

- D81-1 2013 EnglishDocument236 pagesD81-1 2013 EnglishCady StantonNo ratings yet

- General KnowlwdgeDocument115 pagesGeneral KnowlwdgeMUDASSAR IDRIS98% (44)

- Axis Multicap Fund (NFO)Document2 pagesAxis Multicap Fund (NFO)t_syamprasadNo ratings yet

- Axis Multicap Fund (NFO)Document2 pagesAxis Multicap Fund (NFO)t_syamprasadNo ratings yet

- Ms. BCEL - Hookup DrawingDocument13 pagesMs. BCEL - Hookup Drawingt_syamprasadNo ratings yet

- IFB 25BC3 User ManualDocument22 pagesIFB 25BC3 User Manualt_syamprasad50% (2)

- CIEG Coke OvenDocument3 pagesCIEG Coke Ovent_syamprasadNo ratings yet

- CKYC Form Fillable FormDocument4 pagesCKYC Form Fillable Formt_syamprasadNo ratings yet

- MBA IUS CurriculumDocument45 pagesMBA IUS Curriculumt_syamprasadNo ratings yet

- Vendor ListDocument2 pagesVendor Listt_syamprasadNo ratings yet

- 3.approvl Bom - 00031 - 1415 - 37 KWDocument1 page3.approvl Bom - 00031 - 1415 - 37 KWt_syamprasadNo ratings yet

- 8BK80 O&M ManualDocument32 pages8BK80 O&M Manualt_syamprasad78% (9)

- Apfc Panel 2Document1 pageApfc Panel 2t_syamprasadNo ratings yet

- 8BK88 O&M ManualDocument36 pages8BK88 O&M Manualt_syamprasadNo ratings yet

- Renewal AMC Offer of 2x10KVA UPS System To Bhatia Coke at Gummipoondi For 2014-15 Dtd. 28.09.2013Document2 pagesRenewal AMC Offer of 2x10KVA UPS System To Bhatia Coke at Gummipoondi For 2014-15 Dtd. 28.09.2013t_syamprasadNo ratings yet

- Compressor DRWDocument2 pagesCompressor DRWt_syamprasadNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Studio Mumbai. The Practice of MakingDocument8 pagesStudio Mumbai. The Practice of Makingfsrom3No ratings yet

- 2 3 9 A SR ResidentialplumbingcoderequirementsDocument4 pages2 3 9 A SR Residentialplumbingcoderequirementsapi-348618361No ratings yet

- Form 6 (Daily Accomplishment)Document4 pagesForm 6 (Daily Accomplishment)Bendaña KHayeNo ratings yet

- Osian ChlorophyllDocument34 pagesOsian ChlorophyllSupriya Ganesh KumarNo ratings yet

- Architectural Project Forest VillaDocument9 pagesArchitectural Project Forest VillakapingaofficialNo ratings yet

- Residence PH72 111W57 2022Document3 pagesResidence PH72 111W57 2022mmmNo ratings yet

- Palestine Building CodesDocument20 pagesPalestine Building Codesrami zughayar100% (1)

- Guidelines GFADocument107 pagesGuidelines GFAJamesNo ratings yet

- F2280 BoltsDocument2 pagesF2280 Boltsm.bizama100% (1)

- Mountain Park Brochure FinalDocument77 pagesMountain Park Brochure FinalMostafa ElghifaryNo ratings yet

- Transverse Longitudinal SectionDocument1 pageTransverse Longitudinal SectionDucusin Renzo JoshuaNo ratings yet

- Fire BOQ Mapsko Tower ADocument20 pagesFire BOQ Mapsko Tower AankurNo ratings yet

- 2000 Fire Resistance Design ManualDocument139 pages2000 Fire Resistance Design ManualKrista Undeberg Mercer100% (1)

- How To Build A Brick BBQDocument2 pagesHow To Build A Brick BBQnt01dannyNo ratings yet

- 2017 Updated Virtual Catalog SUPER INDUSTRIAL ONLINEDocument163 pages2017 Updated Virtual Catalog SUPER INDUSTRIAL ONLINESUPER INDUSTRIAL ONLINENo ratings yet

- Hubli Bye LawsDocument17 pagesHubli Bye LawsShrinivas Sonnad100% (3)

- 0one Games Battlemaps Corridors and Hallways Vol IIDocument46 pages0one Games Battlemaps Corridors and Hallways Vol IIteam_moNo ratings yet

- Standards VNA WarehouseDocument1 pageStandards VNA WarehouseAnonymous FZs3yBHh7No ratings yet

- Limit State DesignDocument85 pagesLimit State Designkeshav1980No ratings yet

- 9.2 Seven-Story Office Building, Los Angeles, CaliforniaDocument35 pages9.2 Seven-Story Office Building, Los Angeles, CaliforniadanielvillagrapNo ratings yet

- Analysis of Thermal BridgesDocument64 pagesAnalysis of Thermal BridgesGuillermo Durán Moro100% (2)

- Revit NotesDocument5 pagesRevit NotesmageshNo ratings yet

- Pricelist 2017Document133 pagesPricelist 2017Ramkumar GunaNo ratings yet

- 12 Lowry Close, Sandhurst - Steelwork DesignDocument8 pages12 Lowry Close, Sandhurst - Steelwork DesignInoshan Madushika JayawickramaNo ratings yet

- External Finishes Assessment FormsDocument1 pageExternal Finishes Assessment FormsMarkjue14 AzizulNo ratings yet

- En 1991Document95 pagesEn 1991basilscript100% (2)

- Manual for Barrier Sensor with 8m Range and Relay OutputDocument2 pagesManual for Barrier Sensor with 8m Range and Relay OutputJeffrey BaldwinNo ratings yet

- Sos VillageDocument70 pagesSos VillageRidhima Sharma100% (2)

- En Standards For Construction MaterialsDocument50 pagesEn Standards For Construction MaterialsAnonymous xqokgZ3GNo ratings yet

- Add A Wall Light PDFDocument5 pagesAdd A Wall Light PDFisland14No ratings yet