Professional Documents

Culture Documents

Strengthening of RC Beams With Timber-Frp Composite System

Uploaded by

Diana VînagaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strengthening of RC Beams With Timber-Frp Composite System

Uploaded by

Diana VînagaCopyright:

Available Formats

Mechanics of Composite Materials, Vol. 44, No.

3, 2008

STRENGTHENING OF RC BEAMS WITH AN INNOVATIVE TIMBER-FRP COMPOSITE SYSTEM

N. Mazzon,* M. Guadagnini,** and M. R. Valluzzi***

Keywords: beam, FRP, timber, strengthening, serviceability limit state, deflection, crack width, flexural behaviour The results of a theoretical and experimental research project on the use of an innovative technique for strengthening concrete beams are presented. A spacer element is inserted between the tension side of a beam and the composite material to increase its lever arm and to enhance the overall stiffness of the strengthened beam. The main aim of this exploratory project was to increase the ultimate failure load of strengthened beam specimens, whilst guaranteeing acceptable overall deflections at the serviceability limit states. This resulted into a significant reduction in the amount of FPR required and in a better utilization of the materials employed. A preliminary theoretical study was carried out to investigate the effect of Youngs modulus, failure strain, and thickness of the element to be used as a spacer in order to determine the best possible candidate material. Three tests on 2.5-m-long beams were carried out, and different anchorage techniques were used to try and prevent the debonding of the strengthening system. The results from this pilot study are very promising, as the strengthening system ensures an adequate initial stiffness along with an improved ultimate flexural capacity.

Introduction The flexural strengthening of RC structures by externally bonding a FRP reinforcement to their tension side has become a well-established procedure, and it is often preferred to more conventional strengthening techniques. Several performance issues, especially concerning serviceability conditions, however, require the use of large amounts of external reinforcement to ensure that deflection and cracking requirements are met. Thin can often result in an uneconomical use of strengthening materials and yield an undesired, or unintentional, large increase in the ultimate capacity of an element or structure, which needs to be considered carefully, because it might affect or alter its ultimate failure mode. The new strengthening technique discussed in this paper attempts to address the above-mentioned issues by using a combination of purposely chosen materials, so as to optimally exploit their mechanical properties. A spacer is positioned between the beam and the external reinforcement to provide the necessary stiffness at the serviceability limit state (SLS) and to improve the performance at the ultimate limit state (ULS), owing mainly to the resulting increased lever arm of internal forces. The effects of mechanical properties of the material to be used as a spacer were investigated in a preliminary feasibility study. The cost and availability of candidate materials were

*Department of Civil Engineering, University of Padua, Italy. **Department of Civil and Structural Engineering, University of Sheffield, UK. ***Department of Civil Engineering, University of Padua, Italy. Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 44, No. 3, pp. 403-416, May-June, 2008. Original article submitted August 20, 2007; revision submitted April 4, 2008.

0191-5665/08/4403-0279 2008 Springer Science+Business Media, Inc.

279

also taken into account. The spacer material must be stiff enough to control the deflection of the strengthened beam and light enough to limit the amount of the additional weight. Timber was selected for this project and was used as a spacer material for the beams tested during the experimental programme reported here. Although the system investigated differs from those used in other applications, important insights can be gained by examining the available literature on the use of FRPs in combination with timber and concrete. One of the main concerns when combining different layers of structural materials is guaranteeing the development of an adequate composite action. Thus, the magnitude of the shear stresses developed at the interface layers, as well as within the materials, needs to be controlled. Brody et al. [1] conducted a study on the strengthening of glulam beams with concrete and FRP and reported that the ability of the glulam beam to transfer shear stresses was critical in guaranteeing a successful application of this technique. A theoretical increase of about 500% in the bending moment capacity of the strengthened beam was estimated if full composite actions could be ensured. Craig et al. [2] studied the behaviour of FRP-glulam-concrete bridge girders. The gain in the service load was estimated to be about 500% over that of conventional noncomposite timber beams. Although a relative slip between the materials used, leading to a strain discontinuity at the timber-concrete interface, was noticed due to the fatigue damage, no significant loss in the ultimate capacity or ductility was observed. Results of the two studies mentioned above have shown that the use of a combination of concrete, timber, and FRPs can significantly enhance the overall structural performance of an element. Brunner [3] studied the influence of various types of timber-concrete connections and concluded that adhesive connections allow a better distribution of shear stresses over a larger surface, whilst the use of mechanical connectors may result in the development of critical stress concentrations. Moreover, if the relative slip of concrete-timber is eliminated by using adhesive connections, the bending stiffness of the element increases, and smaller overall deflections are observed. Theoretical Investigation A preliminary analysis was conducted to investigate the influence of various parameters that can affect the overall behaviour of a reinforced concrete beam strengthened with the timber-FRP system proposed here. As the primary objective of this simple analysis was to determine the required stiffness provided by a spacer to effectively control deflections under service loads, a linear elastic analysis was considered to be appropriate. In addition, a nonlinear finite-element analysis was carried out to gain additional insights into the ultimate behaviour of the strengthened element and to investigate the effect of spacer geometry on the distribution of stresses along the end anchorage regions. Sectional analysis. The geometrical and mechanical properties of the strengthening system investigated through the implementation of a sectional analysis were the spacer thickness, Youngs modulus, the ultimate strain of the spacer material, and the amount of FRP. Figure 1 shows the momentcurvature diagram for a cross-section of a beam strengthened with a timber-FRP element. For low levels of applied load, the overall behaviour of the beam is controlled mainly by the nature of the spacer material, which must provide a sufficient stiffness and effectively limit the curvature and deflections. When the maximum strain in the spacer reaches its ultimate value, the material, which was modelled according to a brittle elastic formulation, fails, and the internal bending moment is resisted only by the compressed concrete and the stretched FRP. The transition between the two stages is marked by a sudden drop in the resisted moment, along with a rapid increase in the curvature of the section. An appropriate combination of the geometry and mechanical properties of the spacer with the amount of FRP reinforcement can result in the development of a pseudo-ductile behaviour of the beam, for which the ultimate load is similar to the load that induces failure of the spacer, yet allowing much greater deflections. A stiffer spacer material would allow a greater control of deflections under service conditions, but would result in a brittle-like behaviour (see Fig. 2), as the FRP cannot accommodate higher values of moment before the crushing of concrete. After the rupture of spacer, the increase in the ultimate moment can be attributed only to the higher lever arm. The effect of the level of strain that can be developed in the spacer material before failure was also examined, and the results obtained are summarized in Fig. 3. The higher the ultimate strains mobilized in the spacer, the higher bending moments

280

140 120 100 80 60 40 20 0

Mrd, kN.m

6 5 4 3 2 1 - no spacer

k, 10-5.mm -1

1 2 3 4

Fig. 1. Momentcurvature diagrams M rd k at different spacer thicknesses s: 0 (1); 25 (2); 50 (3); 75 (4); 100 (5); 125 mm (6).

150

Mrd, kN.m

E = 20 GPa 15

100

10 5

50

k, 10-5. mm-1

0 0.5 1.5 2.5 3.5

Fig. 2. The same at different Young's modulus E of the spacer: 0 (1); 5.0 (2); 10.0 (3); 15.0 (4); 20.0 GPa (5). can be sustained by the strengthened element. The optimum value of ultimate strain that can be developed in the spacer should allow an adequate control of deflections within the service range and lead to a smaller area of FRP needed to achieve a predetermined level of strengthening. If Youngs modulus of the spacer is relatively high, the failure strain yields a better performance, and a pseudo-ductile behaviour can be achieved by ensuring a sufficient capacity of the beam after the rupture of the spacer. The amount of FRP was optimized by analysing various combinations of the amount and type of FRP (see Fig. 4) and spacer thickness. The results of this study show that the amount and type of FRP significantly affect the behaviour of a strengthened element only beyond its serviceability range. The FRP reinforcement can thus be designed primarily to meet requirements for the ultimate limit state. On the basis of the parametric study mentioned above, a 10-cm-high timber spacer (softwood C16) was selected for use in a combination with three layers of CFRP. Finite-element analysis. The efficiency of a strengthening used is generally limited by the onset of end-debonding phenomena, which, in turn, can be affected by the geometry of the strengthening system and the quality of its connection to the existing RC element. The effect of spacer shape on the stress distribution in structural materials (concrete, timber, and FRP) was investigated by means of a nonlinear finite-element analysis. The performance of systems using spacers with a constant thickness was assessed and compared with that of systems using spacers with a variable thickness. Figures 5 and 6, for example, show stress distributions for two different spacer geometries at a load that induced a stress state along the end zones of the strengthening

281

140 120 100 80 60 40 20 0

Mrd, kN.m

eu = 0.004

0.003

0.002

k, 10-5. mm-1

1 2 3 4

Fig. 3. The same at different values of the ultimate strain e u : 0.003 (s = 0) (1); 0.001 (2); 0.002 (3); 0.003 (4); 0.004 (5).

90 70 50 30 10 0

Mrd, kN.m

n=5 4 3 2 1

k, 10-5. mm-1

1 2 3 4 5

Fig. 4. The same at different numbers n of FRP layers: 0 (1); 1 (2); 2 (3); 3 (4); 5 (6). (- - -) without FRP. TABLE 1. Mechanical Characteristics of the Materials Employed

Youngs modulus, GPa Concrete FRP Timber Adhesive 32 240 8 Strength, MPa Failure strain, % Compressive 30 2.2 85 Tensile 1.14 3.720 10 17 0.35 (compression) 1.6 (tension) 0.125 (tension)

systems that was considered critical for the ripe-off failure. These critical states developed at 90.5 and 124.5 N for the systems with spacers of constant and variable thickness, respectively. The reduction in the stiffness of the strengthening systems towards the supports allowed a better distribution of stresses in the element and the development of a load 40% higher than that in the case of the spacer of conctant thickness. Therefore, a spacer of variable thickness was used in the experimental programme described in the following.

282

Fig. 5. Distribution of stresses s 22 in an element strengthened with a spacer of constant thickness and FRP (95.5kN, a), and with spacer of variable thickness and FRP (124.5kN, b). Experimental Investigation Two RC beams with a rectangular cross-section 150 mm wide and 250 mm high and a total length of 2500 mm (Fig. 6) were subjected to two consecutive phases of testing. Both the beams were pre-cracked during the initial phase and then repaired by attaching a timber-FRP system to their tension side. The strengthening comprised a spacer (timber class C16), shaped as shown in Fig. 6, along with three layers of CFRP reinforcement. The mechanical characteristics of all the structural materials used during the experimental phase of this project are presented in Table 1. The beams were tested in four-point bending. The strains in the internal and external reinforcement were monitored using electric strain gauges, whilst linear variable differential transducers (LVDTs) were employed to measure deflections at different locations along the beam. The loaddeflection response of beam SB6a was linear up to failure, which occurred at about 124 kN (Fig. 7) by concrete rip-off (Fig. 11). The experimental deflections of the strengthened beam were by about 60% smaller than those of the unstrengthened one. An analysis of strain gauge readings showed that a full composite action was guaranteed up to about 80 kN. The maximum strain measured in the CFRP at failure was about 0.15%, which corresponded to only a fraction of the strain that could be taken up in the composite material. Although, as expected, the performance of the strengthening solution was limited

283

1 8 4 3 5 9 2

Fig. 6. Specimen geometry, test set-up, and lay-out of the instrumentation (all dimensions in mm): 1-9 LVDT; strain gauge. 1 timber spacer; 2 FRP reinforcement.

250 200

P, kN

SB6b SB6a-r

150 100 50

SB6 (pre-cracking)

D, mm

0 5 10 15 20 25 30

Fig. 7. Loaddisplacement diagrams PD of tested specimens: 5 concrete rip-off and l slip of the strengthening system. by the occurrence of debonding, the results of the first test provided evidence that the strengthening system can control the deflections at the SLS efficiently. After this testing phase, vertical CFRP strips were attached to the end of the timber spacer of beam SB6a to restore its integrity and to avoid the rip-of failure mode. Beam SB6a was then redesigned as SB6a-r and subjected to an additional testing phase. Debonding of the strengthening system of the beam initiated at about 150 kN. At this level of load, the strengthening system started to slip, resulting in a sudden drop in the sustained load. The CFRP straps located along the end zone of the strengthening element prevented the progression of the rip-off failure and allowed the test specimen to carry an additional load, up to 190 kN, giving an ample warning of incipient failure (Figs. 8 and 12). At failure, a strain level of 0.3% was measured in the CFRP reinforcement. On the basis of the preliminary theoretical analysis, a maximum strain of 0.38% would have been reached if full composite action had developed up to failure. The vertical CFRP strips prevented the cracks from extending towards the upper face of the concrete beam. After the debonding initiated, deflections increased very rapidly, resulting in large deformations at the ultimate state. The failure of beam SB6a-r occurred through the crushing of concrete. Based on the results of the previous tests, pre-tensioned steel strips were used to strengthen beam SB6b in shear and to ensure adequate anchorage for the flexural strengthening element. The strips were positioned along the shear spans, as detailed in Fig. 13. The loaddeflection behaviour of beam SB6b is shown in Fig. 8. The deflection at the midspan increased linearly up

284

250 200

P, kN

SB6b CB0 SB6b SLS CB0 SLS

150 100 50

D, mm

0 5 10 15 20 25 30

Fig. 8. The same for beam SB6a (strengthened with timber-FRP) and CB0 (plate- bonded).

250 200

P, kN

SB6b CB0

150 100 50

me

0 1000 2000 3000 4000 5000 6000

Fig. 9. Development the strain e in the external FRP reinforcement for beams SB6b (strengthened with timber-FRP) and CB0 (plate-bonded).

to about 170 kN. As in the previous tests, the loss of composite action was observed at a load of about 80 kN, when cracks started to occur at both ends of the strengthening element. At loads of about 170 and 185 kN, some debonding occurred, causing a sudden increase in deflection, accompanied by a decrease in the strain transferred along the CFRP. The metal straps, however, were mobilized adequately, and the local debonding of the external element did not compromise the efficiency of the strengthening applied. Beam SB6b failed at 210 kN (an increase of about 40% over the theoretical ultimate capacity of the unstrengthened beam) by crushing of concrete (Fig. 13). The use of the timber-FRP system examined in this study assisted successfully in controlling the overall deflections under serviceability loads, and when an adequate anchorage was provided at the end zones, it ensured a sufficient increase in the load-carrying capacity, along with a ductile deformation behaviour. Comparison with the Conventional Plate Bonding Figure 9 shows a comparison between the loaddisplacement behavior of beams SB6b and CB0, the latter being an equivalent RC beam strengthened in flexure with a CFRP plate bonded to its soffit [4]. The plate used for strengthening beam CB0 was 100 mm wide and 1.4 mm thick and had an elastic modulus of 200 GPa, thus yielding an equivalent area of CFRP more than three times larger than that used to strengthen beam SB6b.

285

Fig. 10. Concrete rip-off failure of beam SB6a.

Fig. 11. Debonding of the timber-FRP strengthening system in beam SB6a-r at the ultimate load (194 kN). Both the beams failed owing to crushing of concrete in compression, after their flexural capacity was reached. An analysis of Fig. 9 shows that the timber-FRP strengthening system resulted in a better performance within the service range. In addition, the service load of beam SB6b was about 16% higher than that of beam CB0. A comparison of the strain developed in the external reinforcement of both the beams provides additional evidence that the use of the timber spacer allowed us to take advantage of the superior mechanical properties of the CFRP reinforcement. Figure 10, for example, illustrates the development of strain in the composite reinforcement of the two beams measured at the section under one of the point loads. As for the measured deflections, the values of strain measured at corresponding load levels along the FRP reinforcement of beam SB6b were generally lower than those of beam CB0. Higher strain values (up to 40%) were eventually mobilized in the CFRP reinforcement of beam SB6b, allowing the specimen to develop a more ductile behaviour and achieve a higher ultimate load than that recorded for beam CB0. Performance of the New Strenghtening System at the SLS The performance of beam SB6b under service conditions was assessed against the current recommendations for the design of RC elements with an externally bonded FRP reinforcement to verify the ability of the timber-FRP system proposed to control the overall deflections. The design recommendations considered in this analysis included: CNR-DT 200/2004 [5]; fib bulletin 14 [6]; Design manual no. 4, prepared by ISIS Canada [7]; Technical Report 55 of the Concrete Society [8]; and ACI 440.2R-02 [9].

286

Fig. 12. Compression failure of beam SB6b (210 kN).

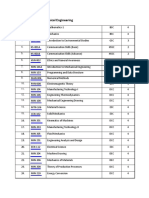

TABLE 2. Limiting Values at the Serviceability Limit State According to Different Design Recommendations

Deflection, mm 5.2 9.2 9.2 9.2 9.2 9.2 Stress limit, MPa Crack width, mm Steel 184 322 368 368 368 368 Concrete 17.6 18 18 18 18 18 FRP 480 2.976 2.976 1.860 2.418 0.30 0.40 0.30 0.30 0.30 0.41

Service Tests CNR [5] fib [6] ISIS [7] TR55 [8] ACI [9]

The service load was 1.5 times smaller than the ultimate load recorded during the test, yielding a value of about 140 kN. The value of 1.5 was chosen as a representative load factor, which is in line with the average of the load factors adopted by the design recommendations reviewed here. Table 2 summarizes the design limit values, as well as the experimental ones, in terms of midspan deflection, crack width, and service stresses. As can be seen from an analysis of the values reported in this table, all serviceability requirements are met when the strengthening system proposed is used. Conclusions This study was focused on the development, design, and verification of a new strengthening system. Based on an analysis of the theoretical and experimental investigations discussed above, the following conclusions can be drawn. Timber can be used very effectively in combination with FRP to increase the stiffness of strengthened RC elements within the service range and to ensure that all serviceability requirements are met. The strengthening solution proposed allows a better utilization of the mechanical properties of both the external FRP reinforcement and the existing RC beam at the ultimate limit state. The use of a spacer and the resulting increase in the lever arm of internal forces can lead to a significant reduction in the amount of FRP required to satisfy the strengthening requirements desired.

287

Although methods to avoid premature debonding of the strengthening system were employed successfully in this work, the bond-related phenomena are always of primary concern, and effective anchorage solutions have to be devised to optimize the use of any strengthening solution. Aknowledgements. The authors wish to acknowledge the European Commission for their European Community Action Scheme for the Mobility of University Students (ERASMUS) and for their financial assistance to the Marie Curie Research Training Network En-Core.

REFERENCES 1. J. Brody, A. Richard, K. Sebesta, K. Wallace, Yong Hong, R. L. Anido, W. Davids, and E. Landis, FRP-wood-concrete composite bridge girders, Structures 2000-103, 189, Advanced Engineered Wood Composites Center, University of Maine, Orono, ME (2000). 2. A. W. Craig, C. D. William, and J. D. Habib, Testing and analysis of partially composite fiber-reinforced polymer-glulam-concrete bridge girders, J. Bridge Eng., 9, Iss. 4, 316-325 (2004). 3. M. Brunner, C. Gerber, Holz-Beton-Verbundelemente durch die Anwendung von Klebesystemen, KTI Projekt 3953.1, interim report, SWOOD, Biel-Bienne (July, 1999). 4. V. Nardini, Anchorage strength models for end debonding prediction in RC beams strengthened with FRP composites, Tesi di laurea, Department of Civil Engineering, University of Padova (September, 2006). 5. Comitato Nazionale di Ricerca (CNR), Istruzioni per la Progettazione, lEsecuzione ed il Controllo di Interventi di Consolidamento Statico mediante lutilizzo di Compositi Fibrorinforzati, CNR-DT 200/2004, Roma (luglio 2004). 6. International Federation for Structural Concrete (fib), Technical Report on the Design and Use of Externally Bonded Fibre-Reinforced Polymer Reinforcement (FRP EBR) for Reinforced Concrete Structures, Task Group 9.3 FRP Reinforcement for Concrete Structures, Bulletin 14 (July, 2001). 7. ISIS Canada, Design Manual No. 4 Strengthening Reinforced Concrete Structures with Externally-Bonded Fibre-Reinforced Polymers, The Canadian Network of Centres of Excellence on Intelligent Sensing for Innovative Structures (2001). 8. The Concrete Society, Design Guidance for Strengthened Concrete Structures Using Fibre Composite Materials, Technical Report No. 55 (2000). 9. American Concrete Institute (ACI), Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures ACI.440.2R-02, ACI Committee 440 (2002). 10. B. H. Ahmadi, and M. P. Saka, Behaviour of composite timber-concrete floors, J. Struct. Eng., 119, No. 10, 3111-3130 (1993). 11. R. Capozucca, Bond stress system of composite concrete-timber beams, Mater. Struct., 3, No. 1, 634-640 (1998). 12. M. Demarzo and M. Tacitano, Semirigid Wood-Concrete T-Beams, M.S. Dissertation Fac. de Eng. Civil, UNICAMP, Campinas, Sao Paulo, Brasil (2002). 13. A. W. Craig, Behaviour of FRP-Reinforced Glulam-Concrete Bridge Girders, Thesis for a Degree in MSc in Civil Engineering, University of Maine (May, 2002). 14. G. D. William, Non-linear analysis of FRP-glulam-concrete beams with partial composite action, J. Struct. Eng., 127, Iss. 8, 967-971 (2001).

288

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- AISC - Verification Examples: 1 Bolted Flange Plate Moment Connection - LRFDDocument35 pagesAISC - Verification Examples: 1 Bolted Flange Plate Moment Connection - LRFDPablo García Peña100% (1)

- Design of RCC Building G+4Document39 pagesDesign of RCC Building G+4D.V.Srinivasa Rao0% (2)

- FULL REPORT ConsolidationDocument29 pagesFULL REPORT ConsolidationFatin Nabihah86% (21)

- Introduction To Finite Element MethodDocument202 pagesIntroduction To Finite Element MethodPrithviraj Daga80% (15)

- Gas/Liquids Separators - Part 3: Quantifying Separation PerformanceDocument14 pagesGas/Liquids Separators - Part 3: Quantifying Separation PerformanceWendellReeceFrankNo ratings yet

- Sph3Ui: Unit 2: KinematicsDocument26 pagesSph3Ui: Unit 2: KinematicsPOONAM MONDAL100% (1)

- Detail Praxis - Timber ConstructionDocument55 pagesDetail Praxis - Timber Constructionaajz88% (16)

- MDSP T17Document100 pagesMDSP T17Jd Magtibay100% (1)

- Norme Deviz RPC - Reparatii ConstructiiDocument1,059 pagesNorme Deviz RPC - Reparatii ConstructiiDeea Vodarici100% (1)

- Physical Science Module 4 EditedDocument13 pagesPhysical Science Module 4 EditedLj kim100% (2)

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- Dimensionare Si Armare Diafragma DT3: Montant 3Document5 pagesDimensionare Si Armare Diafragma DT3: Montant 3Eliseo JohnsonNo ratings yet

- Caracter Is Tic I LeDocument2 pagesCaracter Is Tic I LeDiana VînagaNo ratings yet

- Dimensionare Si Armare Diafragma DT3: Montant 3Document5 pagesDimensionare Si Armare Diafragma DT3: Montant 3Eliseo JohnsonNo ratings yet

- Dimensionare Si Armare Diafragma DT3: Montant 3Document5 pagesDimensionare Si Armare Diafragma DT3: Montant 3Eliseo JohnsonNo ratings yet

- Antiseismic Structural EngineeringDocument11 pagesAntiseismic Structural EngineeringDiana VînagaNo ratings yet

- IncarcariDocument2 pagesIncarcariDiana VînagaNo ratings yet

- Paving Specs ListDocument1 pagePaving Specs ListDiana VînagaNo ratings yet

- Norme Deviz W3 - Semnalizari Si Centralizari FeroviareDocument270 pagesNorme Deviz W3 - Semnalizari Si Centralizari Feroviarebabuliu100% (1)

- 202 - Topsoil SalvagingDocument2 pages202 - Topsoil SalvagingDiana VînagaNo ratings yet

- (Architecture Ebook) Richard Meier Red BookDocument417 pages(Architecture Ebook) Richard Meier Red Bookdiego_vasquez_65100% (6)

- Design Guidance For Strengthening Concrete Structures Using Fiber Composite Materials (2000)Document71 pagesDesign Guidance For Strengthening Concrete Structures Using Fiber Composite Materials (2000)Diana VînagaNo ratings yet

- Caier Sarcini - Structura MetalicaDocument48 pagesCaier Sarcini - Structura MetalicaDiana VînagaNo ratings yet

- Proiect SaveDocument32 pagesProiect SaveDiana VînagaNo ratings yet

- N. M. Belyaev - Strength of Materials - MirDocument650 pagesN. M. Belyaev - Strength of Materials - Mircentscoup1No ratings yet

- Laser Plasma Accelerators For Charged Particles PDFDocument105 pagesLaser Plasma Accelerators For Charged Particles PDFAjit UpadhyayNo ratings yet

- HWCH 12 BDocument3 pagesHWCH 12 BfcordNo ratings yet

- Bsen 13334Document13 pagesBsen 13334Zaido Al HalabiNo ratings yet

- Homework #11 (Phy 112) SolutionsDocument28 pagesHomework #11 (Phy 112) SolutionsKvn4N6No ratings yet

- HFSS-High Frequency Structure SimulatorDocument38 pagesHFSS-High Frequency Structure SimulatorSanchita BasakNo ratings yet

- Collapse Dynamics of Super-Gaussian Beams: Taylor D. Grow, Amiel A. Ishaaya, Luat T. Vuong and Alexander L. GaetaDocument8 pagesCollapse Dynamics of Super-Gaussian Beams: Taylor D. Grow, Amiel A. Ishaaya, Luat T. Vuong and Alexander L. GaetaVijay SinghNo ratings yet

- ALL ConcreteDocument261 pagesALL ConcreteSaman AdelNo ratings yet

- 17-01-SEP-New Integral End Bent Pile Design ProcedureDocument17 pages17-01-SEP-New Integral End Bent Pile Design ProcedureMainulNo ratings yet

- M7500 Ultra HPHT Rheometer BrochureDocument1 pageM7500 Ultra HPHT Rheometer Brochuremega87_2000No ratings yet

- Coherence (Statistical Optics)Document54 pagesCoherence (Statistical Optics)Jae-Wook KimNo ratings yet

- Me PDFDocument340 pagesMe PDFShyam ChoudharyNo ratings yet

- 2.3 Temperature Conversions: Chapter 2 Energy and MatterDocument18 pages2.3 Temperature Conversions: Chapter 2 Energy and MatterBeverly PamanNo ratings yet

- BCHCT-133 (Eng) 2020Document4 pagesBCHCT-133 (Eng) 2020vdefbv daefNo ratings yet

- Commensurability, Comparability, Communicability Thomas KuhnDocument21 pagesCommensurability, Comparability, Communicability Thomas KuhnPablo MelognoNo ratings yet

- Cable and ArchesDocument15 pagesCable and Archess k sharmaNo ratings yet

- Guide 08Document40 pagesGuide 08Christopher ThaiNo ratings yet

- MasteringPhysics - Assignment 4 - Forces Part OneDocument7 pagesMasteringPhysics - Assignment 4 - Forces Part OneStrange Sht100% (2)

- Multiple Choice Questions (MODULE 4 & 5) Mechanics of SolidsDocument67 pagesMultiple Choice Questions (MODULE 4 & 5) Mechanics of SolidsA22 Tekale AdityaNo ratings yet

- Warp Drive PaperDocument14 pagesWarp Drive PapercarsongbakerNo ratings yet

- Lecture 03Document27 pagesLecture 03nghaNo ratings yet