Professional Documents

Culture Documents

HVAC Commissioning Pharmaceutical Manufacturing

Uploaded by

Sivamalar ThyagarajahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HVAC Commissioning Pharmaceutical Manufacturing

Uploaded by

Sivamalar ThyagarajahCopyright:

Available Formats

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

HVAC Systems and the Pharmaceutical Manufacturing Environment

Part 06: HVAC Commissioning

Mike James, Validation in Partnership

1 1

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 1

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

Definition / Meaning

Commissioning is Part of Good Engineering Practice

Defined as

A A well well planned, planned, documented, documented, and and managed managed engineering engineering approach approach to to the the start-up start-up and and turnover turnover of of facilities, facilities, systems, systems, and equipment to the End-User that results in a safe and equipment to the End-User that results in a safe and and functional functional environment environment that that meets meets established established design design requirements requirements and and stake-holder stake-holder expectations expectations

In other words

Planning, Planning, managing managing and and documenting documenting the the start start up up and and set set up of equipment systems to demonstrate that the user up of equipment systems to demonstrate that the user requirements requirements and and design design requirements requirements have have been been met. met.

2 2

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 2

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

Objectives of Commissioning

Provided Documented Evidence

System correctly installed System correctly set-up and operating properly

Meeting Meeting design design + + user user requirements requirements

Ensure

Engineering documentation present and correct Drawings are accurate and raised to as built status

System ready for validation.

3 3

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 3

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

Importance of Commissioning [1] [1]

Historically HVAC commissioning has been weak

Often found to be poorly documented Resulted in failed validation

Incorrect Incorrect air air balancing balancing (flows (flows + + pressures) pressures) Lack of supporting manufacturers Lack of supporting manufacturers information information Rebalancing Rebalancing and and requalification requalification required required

ISPE baseline guides have helped to change emphasis

GEP incorporating good commissioning essential to support systems impact approach to validation

HEPA HEPA filters filters may may be be the the only only direct direct impact impact equipment equipment items. items.

4 4

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 4

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

Importance of Commissioning [2] [2]

Probably one of the most significant activities in the project life-cycle

Suppliers generally present and can rectify problems there and then Training of clients staff Opportunity to write and test SOPs Set-up activity that provides the environment state for validation Engineering support documentation is compiled and checked Testing that may be used in validation

DOP DOP filter filter testing testing Other??? Other???

5 5

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 5

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

Commissioning and Qualification Certainly need an integrated approach to avoid duplication of effort Very difficult to substitute all qualification testing with commissioning

Air Air and and pressure pressure balancing balancing is is an an iterative iterative process process

Would Would not not meet meet validation validation acceptance acceptance criteria criteria initially initially Require Require flexibility flexibility within within method method to to balance balance and and bring bring conditions conditions within within limits limits

Range of approaches to integration

Carry Carry out out commissioning commissioning to to validation validation documentation*** documentation*** Transpose commissioning data to validation Transpose commissioning data to validation documentation*** documentation*** Carry out validation testing immediately after Carry out validation testing immediately after commissioning commissioning set set up up and and testing testing

*** *** not not recommended recommended

6 6

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 6

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

Commissioning Activities [1] [1]

Installation checks

Equipment correctly installed

All All items items present present and and configured configured correctly correctly Air-breaks Air-breaks for for drains drains

Water Water present present in in drainage drainage loots loots (AHU) (AHU)

Belt Belt tension tension Wiring Wiring Control Control system system installation installation

Drawings correct

Mark-up Mark-up process process

Instruments and loops calibrated Utilities available and connected properly.

7 7

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 7

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

Commissioning Activities [2] [2]

Setting to work

Operation Operation of of fan fan motors motors

Ampage Ampage checks checks Belts and Belts and pulley pulley operation operation Direction Direction of of fans fans

System proving

Duct Duct work work leaks leaks Balancing of Balancing of system system

Return Return air air set-up set-up Volumetric Volumetric air air supply supply Differential Differential pressure pressure (adjusting (adjusting extracts) extracts) Laminar Laminar flow flow velocities velocities

Filter Filter integrity integrity tests tests Filter Filter DPs DPs or or pressure pressure drops drops Facility Facility lighting lighting checks checks Temperature Temperature and and humidity humidity control control set-up set-up and and testing. testing.

8 8

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 8

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

Cleaning Stages

The following slides show the typical stages that are involved in the construction / installation of clean rooms and HVAC through to and including qualification The schematics will pay particular attention to the cleaning stages that are involved.

9 9

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 9

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

1. Construction to Filter Installation

Clean rooms Constructed Clean during early construction, i.e. cleaning visible contamination from ceilings, walls, floors and filter mountings Prepare for air conditioning ductwork installation, i.e. cleaning dust from ductwork sections before installing Clean before mounting all filters into the system, i.e. removing deposited or settled dust from ceilings, walls and floors See Next Slide

10 10

ISO 14644-5 Stage 3 Clean

Install HVAC Systems

Install HVAC Support Systems

ISO ISO 14644-5 14644-5 Stage Stage 4 4 Clean Clean

Introduce Positive Pressure

ISO 14644-5 Stage 5 Clean

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 10

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

2. Filter Installation to Commissioning

Mount HEPA/ULPA Filters

Clean up any contamination caused by the mounting operation

ISO 14644-5 Stage 6 Clean

IQ Clean Rooms

IQ HVAC and IMS Systems (BMS if used for CGMP data)

Certify GEP components of HVAC

Certify GEP HVAC Support Systems

ISO 14644-5 Stage 7 Clean

Adjust Adjust airairconditioning conditioning equipment, equipment, removing removing suspended suspended dust dust from from airflow airflow and and creating creating over over pressure pressure See Next Slide

11 11

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 11

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

3. Commissioning to OQ

Commission BMS and IMS System

Commission HVAC Systems

Commission HVAC Support Systems

OQ IMS System

OQ HVAC Direct Components (if any)

ISO 14644-5 Stage 8 Clean

Upgrade Upgrade room room to to prescribed prescribed Classification Classification

Environmental OQ Testing

12 12

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 12

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

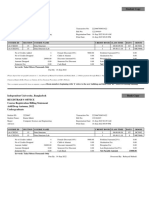

Commissioning Documentation

Normally carried out to detailed method statement

Supported by check/test sheet templates Should be buy in by the client and vendor(s)

Should be a formal report

Approved by vendor and client

Remember

If you wish to use commissioning data for your validation

Commission Commission documentation documentation needs needs to to be be as as for for validation validation

Same Same standards standards Pre-approved Pre-approved acceptance acceptance criteria. criteria.

13 13

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 13

HVAC Systems and the Pharmaceutical Manufacturing Environment

Radisson SAS Hotel - Amsterdam 2008

End of Presentation

Any further questions?

14 14

Validation in Partnership Limited

Part 06 HVAC Commissioning - Page 14

You might also like

- Hvac Testing Adjusting BalancingDocument7 pagesHvac Testing Adjusting Balancingarour.mokraneNo ratings yet

- VRF & DX Split Type ACU Testing MethodologyDocument1 pageVRF & DX Split Type ACU Testing MethodologydamianNo ratings yet

- Sop Hvac 01 Central Chilled Water SystemDocument18 pagesSop Hvac 01 Central Chilled Water SystemRavi ValiyaNo ratings yet

- Plumbing CommissioningDocument5 pagesPlumbing CommissioningZineddine ALICHENo ratings yet

- Hvac Systems Commissioning ProceduresDocument38 pagesHvac Systems Commissioning ProceduresMafe SalazarNo ratings yet

- AHU CHW Coil ConnectionDocument1 pageAHU CHW Coil ConnectionMULTIKARTHI07100% (1)

- Air Handler Check ListDocument3 pagesAir Handler Check Listmnt6176100% (1)

- Quy Trinh T&C BMS Cho MVAC - Tham KhaoDocument79 pagesQuy Trinh T&C BMS Cho MVAC - Tham Khaovin ssNo ratings yet

- Method of Statement For Precommissioning & Commissioning of Chiller Plant ManagerDocument3 pagesMethod of Statement For Precommissioning & Commissioning of Chiller Plant Managervin ssNo ratings yet

- Air Balancing Method StatementDocument1 pageAir Balancing Method StatementmpwasaNo ratings yet

- Ricwil Catalog 10 Final PDFDocument32 pagesRicwil Catalog 10 Final PDFHermanuadi100% (2)

- Ahu Performance 2Document29 pagesAhu Performance 2maddy1667100% (1)

- Method Statement For Air Balancing in HVAC SystemDocument5 pagesMethod Statement For Air Balancing in HVAC SystemNadeem khanNo ratings yet

- Chiller PlantDocument1 pageChiller PlantSudhir KulkarniNo ratings yet

- Sadara Chem-1 HVAC Startup Commissioning GuideDocument20 pagesSadara Chem-1 HVAC Startup Commissioning Guidevasucristal100% (1)

- Installation Report SummaryDocument4 pagesInstallation Report SummaryMohammed IqbalNo ratings yet

- Induction Course for M&E EngineersDocument155 pagesInduction Course for M&E EngineersKHA120096 StudentNo ratings yet

- Neudorfer Sample Tab Report PDFDocument13 pagesNeudorfer Sample Tab Report PDFVin BdsNo ratings yet

- Heating Plant Functional TestDocument81 pagesHeating Plant Functional TestFederico BrigatoNo ratings yet

- Smoke Control Commissioning 9 07Document4 pagesSmoke Control Commissioning 9 07ahmed fouadNo ratings yet

- Method Statement For Air & Water BalancingDocument7 pagesMethod Statement For Air & Water BalancingKidesu Ramadhani100% (1)

- Water Flushing Witnessing and TestDocument3 pagesWater Flushing Witnessing and TestNeguib FarahNo ratings yet

- Double Skin Modular Air Handling Unit: Product CatalogueDocument54 pagesDouble Skin Modular Air Handling Unit: Product CatalogueYasinta Dewi PradinaNo ratings yet

- Dust Collector Service ChecklistDocument1 pageDust Collector Service ChecklistFatemeh AziziNo ratings yet

- Room Noise Level TestDocument3 pagesRoom Noise Level TestNeguib FarahNo ratings yet

- Procedure For Testing & Commissioning of Water Booster Jockey PumpsDocument3 pagesProcedure For Testing & Commissioning of Water Booster Jockey Pumpsvin ssNo ratings yet

- Testing Commisioning Report Cooling Tower: ProjectDocument1 pageTesting Commisioning Report Cooling Tower: Projectagun gunawanNo ratings yet

- QA-F-VN-PCM - T & C Check List For ChillerDocument2 pagesQA-F-VN-PCM - T & C Check List For ChillerKevin TranNo ratings yet

- Prihoda Recycled Fabric Duct SpecificationDocument5 pagesPrihoda Recycled Fabric Duct SpecificationaverentzNo ratings yet

- MEEZA CRAC and Downflow SpecificationDocument57 pagesMEEZA CRAC and Downflow SpecificationSwamy Dhas DhasNo ratings yet

- ADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.Document8 pagesADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.John EvansNo ratings yet

- T&C of Pressurization UnitDocument6 pagesT&C of Pressurization UnitMohamed YousufNo ratings yet

- Ducts and Diffusers Design PDFDocument106 pagesDucts and Diffusers Design PDFsiroliver39No ratings yet

- EAU S1 - Fan SelectionDocument1 pageEAU S1 - Fan SelectionMohsin ShaikhNo ratings yet

- LAWA Basic Commissioning Forms - CompleteDocument53 pagesLAWA Basic Commissioning Forms - Completemohammed_hatem0% (1)

- Install and Maintain Modular AHUDocument35 pagesInstall and Maintain Modular AHUAngga HardiyantomoNo ratings yet

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 pagesProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhNo ratings yet

- Copper Pipes InstallationDocument6 pagesCopper Pipes InstallationrkssNo ratings yet

- Sun Set Mall HVAC Fan SpecsDocument4 pagesSun Set Mall HVAC Fan SpecsMohamed FawzyNo ratings yet

- FAT HVAC Acceptance Requirements PDFDocument120 pagesFAT HVAC Acceptance Requirements PDFshant_mNo ratings yet

- Particle Count SOPDocument2 pagesParticle Count SOPSubodh Murkewar100% (1)

- Fahu - AhuDocument6 pagesFahu - AhuHadi AbdulkaderNo ratings yet

- Installation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreDocument25 pagesInstallation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreScherraine Khrys CastillonNo ratings yet

- Ahu ItpDocument3 pagesAhu ItpMEELMAHDYNo ratings yet

- Testing and Commissioning Catering EquipmentDocument27 pagesTesting and Commissioning Catering EquipmentTrần ChâuNo ratings yet

- Installing Seismic Restraints For Mechanical EquipmentDocument158 pagesInstalling Seismic Restraints For Mechanical EquipmentinitbashNo ratings yet

- HVAC Duct Smoke Test ReportDocument1 pageHVAC Duct Smoke Test ReportSandhyaRamakrishnaNo ratings yet

- Fire Sprinkler Installation MethodDocument3 pagesFire Sprinkler Installation MethodAnkit KumarNo ratings yet

- VAV System Air BalancingDocument3 pagesVAV System Air BalancingShoukat Ali ShaikhNo ratings yet

- HVAC QuestionsDocument27 pagesHVAC QuestionsFaizan KhanNo ratings yet

- Chiller Controls Testing ProcedureDocument2 pagesChiller Controls Testing Procedurerenjithv_4No ratings yet

- HVAC Interview QuestionsDocument3 pagesHVAC Interview Questionsjid00950% (2)

- MVAC Testing & Commissioning Procedure - 2007Document245 pagesMVAC Testing & Commissioning Procedure - 2007spencersiu100% (6)

- Hvac5 0506Document43 pagesHvac5 0506Nadia Fahmi SilabiNo ratings yet

- VMP TheoryDocument34 pagesVMP Theoryparam540No ratings yet

- Commissioning Start UpDocument22 pagesCommissioning Start Upmostafa_1000No ratings yet

- Validation of EquipmentDocument31 pagesValidation of Equipmentjyothisahadevan100% (4)

- Calibration Master Plan LMDocument45 pagesCalibration Master Plan LMTushar Joshi100% (4)

- ISPE - SFCH - TurnOver Packages - FAT - CommissioningDocument36 pagesISPE - SFCH - TurnOver Packages - FAT - CommissioningcoxshulerNo ratings yet

- IGCSEDocument5 pagesIGCSESivamalar ThyagarajahNo ratings yet

- Akilan Aravinthan 1 Genesis Science: Name: Class: SubjectDocument4 pagesAkilan Aravinthan 1 Genesis Science: Name: Class: SubjectSivamalar Thyagarajah100% (1)

- 2019 PT3 Science (Section B + C) : Important UnitsDocument3 pages2019 PT3 Science (Section B + C) : Important UnitsTAARINI THIAGA RAJAN MoeNo ratings yet

- Leo Messi: Name: Akilan Aravinthan Class: 1 Genesis Subject: EnglishDocument3 pagesLeo Messi: Name: Akilan Aravinthan Class: 1 Genesis Subject: EnglishSivamalar ThyagarajahNo ratings yet

- English ScrapbookDocument5 pagesEnglish ScrapbookSivamalar ThyagarajahNo ratings yet

- Solving Quadratics - Formula, Decimals: Name: Class/SetDocument3 pagesSolving Quadratics - Formula, Decimals: Name: Class/SetSivamalar ThyagarajahNo ratings yet

- Solving Quadratics Formula Surd Form WorksheetDocument3 pagesSolving Quadratics Formula Surd Form WorksheetSivamalar ThyagarajahNo ratings yet

- Solving Quadratics - Formula, Surd Form: Name: Class/SetDocument3 pagesSolving Quadratics - Formula, Surd Form: Name: Class/SetSivamalar ThyagarajahNo ratings yet

- Akilan, 1 Genesis, English, Nasi DagangDocument2 pagesAkilan, 1 Genesis, English, Nasi DagangSivamalar ThyagarajahNo ratings yet

- Akilan, 1 Genesis, English, Nasi DagangDocument2 pagesAkilan, 1 Genesis, English, Nasi DagangSivamalar ThyagarajahNo ratings yet

- Solving Quadratics Formula DecimalsDocument3 pagesSolving Quadratics Formula DecimalsSivamalar ThyagarajahNo ratings yet

- EnvironmentDocument1 pageEnvironmentSivamalar ThyagarajahNo ratings yet

- Maths PDFDocument3 pagesMaths PDFSivamalar ThyagarajahNo ratings yet

- Name: Akilan Aravinthan Class: 1 Genesis Subject: EnglishDocument3 pagesName: Akilan Aravinthan Class: 1 Genesis Subject: EnglishSivamalar ThyagarajahNo ratings yet

- Science Project Form 1Document4 pagesScience Project Form 1Sivamalar Thyagarajah100% (3)

- English ScrapbookDocument5 pagesEnglish ScrapbookSivamalar ThyagarajahNo ratings yet

- Pt01 - Introduction To HVAC SystemsDocument20 pagesPt01 - Introduction To HVAC SystemsSivamalar ThyagarajahNo ratings yet

- English ScrapbookDocument5 pagesEnglish ScrapbookSivamalar ThyagarajahNo ratings yet

- Sains RPTDocument7 pagesSains RPTPuLut LePoNo ratings yet

- Pt05 - HVAC System DesignDocument73 pagesPt05 - HVAC System DesignSivamalar ThyagarajahNo ratings yet

- Matematik PT3Document16 pagesMatematik PT3Muhammad Aliff Abdul Rahman91% (23)

- Structured Questions Science Form 2Document12 pagesStructured Questions Science Form 2uminoriah83% (18)

- Kertas Akhir Tahun Tingkatan 2Document18 pagesKertas Akhir Tahun Tingkatan 2uminoriah78% (27)

- Final 2008 Math f2 Paper 1Document19 pagesFinal 2008 Math f2 Paper 1Sivamalar ThyagarajahNo ratings yet

- Trial Math k2 n9 2011Document6 pagesTrial Math k2 n9 2011MHD AMIN OMARNo ratings yet

- Polytechnic University Management Services ExamDocument16 pagesPolytechnic University Management Services ExamBeverlene BatiNo ratings yet

- TheEconomist 2023 04 01Document297 pagesTheEconomist 2023 04 01Sh FNo ratings yet

- C6 RS6 Engine Wiring DiagramsDocument30 pagesC6 RS6 Engine Wiring DiagramsArtur Arturowski100% (3)

- Rubber Chemical Resistance Chart V001MAR17Document27 pagesRubber Chemical Resistance Chart V001MAR17Deepak patilNo ratings yet

- NLL - Elementary - Coursebook 2019 PDFDocument24 pagesNLL - Elementary - Coursebook 2019 PDFgilmolto100% (1)

- Column Array Loudspeaker: Product HighlightsDocument2 pagesColumn Array Loudspeaker: Product HighlightsTricolor GameplayNo ratings yet

- Rohit Patil Black BookDocument19 pagesRohit Patil Black BookNaresh KhutikarNo ratings yet

- If V2 would/wouldn't V1Document2 pagesIf V2 would/wouldn't V1Honey ThinNo ratings yet

- Resume Template & Cover Letter Bu YoDocument4 pagesResume Template & Cover Letter Bu YoRifqi MuttaqinNo ratings yet

- Reg FeeDocument1 pageReg FeeSikder MizanNo ratings yet

- Nursing Care Management of a Client with Multiple Medical ConditionsDocument25 pagesNursing Care Management of a Client with Multiple Medical ConditionsDeannNo ratings yet

- CAS-GEC04 Module11 Food-SecurityDocument6 pagesCAS-GEC04 Module11 Food-SecurityPermalino Borja Rose AnneNo ratings yet

- Dole-Oshc Tower Crane Inspection ReportDocument6 pagesDole-Oshc Tower Crane Inspection ReportDaryl HernandezNo ratings yet

- DMDW Mod3@AzDOCUMENTS - inDocument56 pagesDMDW Mod3@AzDOCUMENTS - inRakesh JainNo ratings yet

- Iq TestDocument9 pagesIq TestAbu-Abdullah SameerNo ratings yet

- AATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsDocument3 pagesAATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsAdrian CNo ratings yet

- Os PPT-1Document12 pagesOs PPT-1Dhanush MudigereNo ratings yet

- DNA Gel Electrophoresis Lab Solves MysteryDocument8 pagesDNA Gel Electrophoresis Lab Solves MysteryAmit KumarNo ratings yet

- Federal Complaint of Molotov Cocktail Construction at Austin ProtestDocument8 pagesFederal Complaint of Molotov Cocktail Construction at Austin ProtestAnonymous Pb39klJNo ratings yet

- Attributes and DialogsDocument29 pagesAttributes and DialogsErdenegombo MunkhbaatarNo ratings yet

- Lifespan Development Canadian 6th Edition Boyd Test BankDocument57 pagesLifespan Development Canadian 6th Edition Boyd Test Bankshamekascoles2528zNo ratings yet

- Pita Cyrel R. Activity 7Document5 pagesPita Cyrel R. Activity 7Lucky Lynn AbreraNo ratings yet

- 621F Ap4405ccgbDocument8 pages621F Ap4405ccgbAlwinNo ratings yet

- Last Clean ExceptionDocument24 pagesLast Clean Exceptionbeom choiNo ratings yet

- Accomplishment Report 2021-2022Document45 pagesAccomplishment Report 2021-2022Emmanuel Ivan GarganeraNo ratings yet

- LM1011 Global ReverseLogDocument4 pagesLM1011 Global ReverseLogJustinus HerdianNo ratings yet

- Krok2 - Medicine - 2010Document27 pagesKrok2 - Medicine - 2010Badriya YussufNo ratings yet

- Quantification of Dell S Competitive AdvantageDocument3 pagesQuantification of Dell S Competitive AdvantageSandeep Yadav50% (2)

- Ir35 For Freelancers by YunojunoDocument17 pagesIr35 For Freelancers by YunojunoOlaf RazzoliNo ratings yet

- Astera Data Integration BootcampDocument4 pagesAstera Data Integration BootcampTalha MehtabNo ratings yet