Professional Documents

Culture Documents

Burning Zone Ref Failue

Uploaded by

kidcatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Burning Zone Ref Failue

Uploaded by

kidcatCopyright:

Available Formats

Burning zone refractory failure K.P.

PRADEEP KUMAR

The coating is thin and washed away from the brick Surface. Around 9 meter area. High variation in chemistry when OPC clinker is switched over to Oil well cement or sulfate resistant Cement. The second reason is Formation of distorted flame which Eroded the coating and brick. With Petcoke firing the liquid becomes more Viscous and destruct the bricks.

SDCCL

The mag chrome got eroded due to high thermo-chemical load. Some how alumina bricks retain the coating and prolonged condition of this condition would have damaged the alumina bricks too.

Perilex-83

Lofal -70 9 m area

SDCCL

SDCCL

Perilex bricks at 11.5 m. Bricks undergone severe thermal and Thermo chemical srtesses due to variation in clinker Chemistry.Petcoke under reduced conditions further aggravate the situation.

groove formation due to shell deformation Or wrong installation of key bricks. Key bricks must be just fit in .Too much hammering can cause damage. Not more than two Shims must be inserted in a ring with a gap of 3 to 4 bricks.

SDCCL

Severe thermo-chemical ( high liquid % attack on the brick( lava formation)

Crack on the cold face shows that the brick was under severe mechanical stress too Shell distortion at 9 M causes mechanical stresses on the brick.

SDCCL

Grooves on the shell At 9 M length

Bulged portion of the shell at 9.0 m

Mortar application to correct the lining at 9.0 m

About 30 mm it has bulged inwards which is well beyond the toleralance limits. 9.0 m area. Maximum tolrence Limit is +/- 10 mm.

SDCCL

Refractory failure in burning zone SDCCL

Causes Very high variation in clinker chemistry when converted OPC clinker to oil well cement and sulfate resistant cement. Petcoke firing reduces the Viscosity of the liquid and further damage the bricks . Reduced conditions when petcoke is fired is extremely harmful to magchrome bricks. Oil spillage on the refractory bricks and damaged the magchrome bricks. Coal particles was also falling on the bricks while heating. Kiln was rotated in the cold conditions for maintenance purpose Shell was bulged in the burning zone area. Remedies Frequency of change over from OPC clinker to SRC and OWC can be reduced by properly planning. The burner needs replacement. Burner tip was damaged. Oxidised conditions must prevail esp. when petcoke is fired. Kiln shell need replacement at 9 M area No job must be done after the lining is over for kiln rotation.

Melting pit

This happended during start-up , high percentage of liquid forms. The hot aggressive liquid (Lava) attacked the bricks , and washed the brick surface.

GCW

Bricks got soften and eroded due to high liquid formation during kiln start-up ( lava)

GCW

Bricks got softened and eroded. Very high Percentage of melt Formation( lava)

GCW

Thermo chemically attacked magchrome bricks. Sulfur penetrated the bricks.

APCW

APCW

Even the spinel brick is Penetrated by liquid ,in burning Zone, 8 15 M. Calculated liquid % is 33 .

Burning zone refractory failure at GCW

Causes Excessive liquid formation, Lava during startup Thick coating formation due to high liquid % in clinker High thermal loading , >5.8 Gcal/sq M/hr Petcoke was tried for some time. Magchrome bricks with petcoke firing gives less life due to formation of low viscous liquid. Remedies Care must be at the time of start-up. Flame intensity can be reduced in the beginning to avoid over-heating. When thermal load is high the kiln is very sensitive to chemistry variation Hence variation in chemistry esp quartz must be controlled. If Pet coke is used spinel bricks are better choice.

Note: If kiln runs stable with minimum variation in chemistry thermal load does not matter as coating on the bricks protects the bricks. But if the thermal loading is high and coating dislodges due to variation in chemistry or operational instability the consequent thermo-chemical load is more detrimental than the thermal load. .

Refractory failure at 12 m After 4 months of operation. The spinel bricks underwent severe aggressive liquid attack.( 33 % liquid)

APCW

Liquid penetrated the spinel brick

Slice of the spinel brick At 60 mm from the surface.

Hercynite based bricks are senstive to redox conditions. The white coloration is due to redox conditions prevailing In the kiln. Flame needs attention. Picture taken at 7 M area

APCW

Avoid reduced conditions. Shape the flame to get convergent and hot flame Optimize the momentum . Momentum with low % primary and high velocity is always better than Momentum with % primary air and low velocity.

Burning zone refractory failure at APCW

Excessive liquid , > 33% causes liquid penetration deep into the bricks and destroy the texture of the brick , even the conventional spinel bricks. Reduced conditions make the coating very unstable. During coating dislodgement it took away part of the brick.

Remedies Optimise the liquid at around 30 -31 %. Use fused spinel bricks Like Almag AF and Ankral R2 Shape the flame to avoid reduced condition Dislodge the rhino horn by installing proper shock blasters.

Installation Errors

APCW

Installation error

The brick rings are not straight. Though We use pnemato-o-ring this error can occur. Human skill is also needed. This spinel bricks can undergo mechanical stresses and reduce the refractory life. The lining was opened and was corrected.

After correcting the lining

APCW

HCW At 11 M

After starting the kiln within two days hot spot appeared. This V-gap formed due errors in installation. The brick ring must be perpendicular to the axis.

HCW

Thanks for your kind attention K.P.Pradeep Kumar

You might also like

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- Cement Mill: History Materials Ground Temperature Control Ball MillsDocument5 pagesCement Mill: History Materials Ground Temperature Control Ball MillsAli HadiNo ratings yet

- Maintaining Burning Zone Coating for Maximum Kiln Brick LifeDocument2 pagesMaintaining Burning Zone Coating for Maximum Kiln Brick LifeJCSNo ratings yet

- Refractory Thickness in Rotary KilnDocument3 pagesRefractory Thickness in Rotary KilnDileepSaragadamNo ratings yet

- Kiln Slope CalculationDocument4 pagesKiln Slope CalculationSSAC PVT.LTD.No ratings yet

- Modern Cement Grinding Systems ComparedDocument14 pagesModern Cement Grinding Systems ComparedCao Ngoc AnhNo ratings yet

- QUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYDocument8 pagesQUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYVijay BhanNo ratings yet

- Snowman FormationDocument1 pageSnowman FormationKEERTHI INDUSTRIES100% (1)

- Clinker CoolersDocument12 pagesClinker CoolersAkhilesh Pratap SinghNo ratings yet

- The Effects of Oxygen Enrichment On ClinkerDocument9 pagesThe Effects of Oxygen Enrichment On ClinkerNael100% (1)

- By Pass System in The Dry ProcessDocument34 pagesBy Pass System in The Dry Processfaheemqc100% (1)

- Cement IndustryDocument27 pagesCement IndustryAhmed Mahmoud100% (1)

- False Air - Measuerment OverviewDocument11 pagesFalse Air - Measuerment OverviewVijay BhanNo ratings yet

- Increasing cement grinding capacity with vertical roller mill technologyDocument7 pagesIncreasing cement grinding capacity with vertical roller mill technologymahreza189100% (2)

- VRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Document2 pagesVRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Sahadeb Manna100% (1)

- Heat-Up Schedule As Per RequirementDocument1 pageHeat-Up Schedule As Per RequirementVijay BhanNo ratings yet

- Kiln FAQDocument19 pagesKiln FAQKenny RuizNo ratings yet

- Cement Kiln Pyro BalanceDocument45 pagesCement Kiln Pyro BalanceirfanNo ratings yet

- Cement Separator & Ball Mill OptimizationDocument29 pagesCement Separator & Ball Mill OptimizationAdelezzat OmranNo ratings yet

- Hardness of Clinker Due To Usage of Pet CokeDocument1 pageHardness of Clinker Due To Usage of Pet CokeVijay BhanNo ratings yet

- Co2 Emission Per Ton ClinkerDocument5 pagesCo2 Emission Per Ton ClinkerJunaid Mazhar50% (2)

- Rueddenklau Snowman PreventionDocument102 pagesRueddenklau Snowman PreventionIonela Dorobantu100% (2)

- Rotary Kiln Brick CountDocument5 pagesRotary Kiln Brick CountThaigroup CementNo ratings yet

- Clinker. Kiln Design and ProcesDocument7 pagesClinker. Kiln Design and Procesrrvc25100% (1)

- Finish Grinding by Roller PressDocument3 pagesFinish Grinding by Roller PressManish Verma100% (3)

- High VM Coal With 3% SulphurDocument1 pageHigh VM Coal With 3% SulphurIrshad HussainNo ratings yet

- Control Cooler Exit Temperature and IKN Grate RestrictionDocument33 pagesControl Cooler Exit Temperature and IKN Grate Restrictionसागर फुकटNo ratings yet

- What Is A Process ControlDocument17 pagesWhat Is A Process ControlpashaNo ratings yet

- 4 - False Air Profile Dry Preheater KilnDocument1 page4 - False Air Profile Dry Preheater KilnSundara SubramaniyanNo ratings yet

- Burning DashboardDocument3 pagesBurning DashboardMehmet C100% (1)

- Impact of calcium sulfates on cement properties and concrete workabilityDocument10 pagesImpact of calcium sulfates on cement properties and concrete workabilitycemsavantNo ratings yet

- VRM Heat and Mass BalanceDocument1 pageVRM Heat and Mass BalanceRajeshRockNo ratings yet

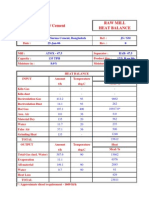

- Raw Mill Heat BalanceDocument1 pageRaw Mill Heat BalanceElwathig Bakhiet100% (1)

- Clinker Production Kiln Surface Heat Loss FactorsDocument2 pagesClinker Production Kiln Surface Heat Loss FactorsvvijaybhanNo ratings yet

- Radiation Calculation For Kiln 1 (From Kiln Outlet)Document32 pagesRadiation Calculation For Kiln 1 (From Kiln Outlet)irfanNo ratings yet

- SOx Emmissions Absortion FLSDocument14 pagesSOx Emmissions Absortion FLSMartha Carolina Gomez MartinezNo ratings yet

- High Efficiency Separators 3Document9 pagesHigh Efficiency Separators 3gldiasNo ratings yet

- Pillard Burners and FlamesDocument21 pagesPillard Burners and FlamesIrshad HussainNo ratings yet

- Cement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Document17 pagesCement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Salah Romdani100% (1)

- Clinker Cooler SystemDocument69 pagesClinker Cooler SystemzementheadNo ratings yet

- Kiln Rotation Procedure Guide for Firing CeramicsDocument1 pageKiln Rotation Procedure Guide for Firing CeramicsVijay BhanNo ratings yet

- Ring Formation in Rotary KilnsDocument30 pagesRing Formation in Rotary Kilnsmohamed ElsayedNo ratings yet

- Cooler Air Flow Vs Kiln FeedDocument2 pagesCooler Air Flow Vs Kiln FeedBùi Hắc HảiNo ratings yet

- Cement KilnDocument2 pagesCement Kilnamir100% (2)

- Rotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationDocument1 pageRotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationVijay Bhan80% (5)

- Common Problems in Cement Plant: One Issue From Each SectionDocument7 pagesCommon Problems in Cement Plant: One Issue From Each SectionYhaneNo ratings yet

- Measurement DDocument37 pagesMeasurement Dgvrr1954100% (2)

- Clinker Cooler OperationDocument5 pagesClinker Cooler OperationJCSNo ratings yet

- Advancement in Refractories used for Cement Rotary kiln(CRKDocument75 pagesAdvancement in Refractories used for Cement Rotary kiln(CRKmahendra sen100% (1)

- Modefied Cooler2Document71 pagesModefied Cooler21977jul100% (2)

- Red RiverDocument16 pagesRed RiverNael100% (1)

- Detailed Study of Burining Problems Caused by Sulphur: Prepared by Suraj Bhaskaran Process EngineerDocument14 pagesDetailed Study of Burining Problems Caused by Sulphur: Prepared by Suraj Bhaskaran Process Engineerbsuraj100% (2)

- Kiln Operator Emergency GuideDocument12 pagesKiln Operator Emergency GuideLe HoangNo ratings yet

- Fan Eff Calculation'Document119 pagesFan Eff Calculation'Durga Prasad100% (1)

- Cement Kiln RefractoryDocument3 pagesCement Kiln Refractoryengr kazamNo ratings yet

- Petcokeforjsw 180403121743Document89 pagesPetcokeforjsw 180403121743Hamed MostafaNo ratings yet

- Firing of Clay Brick and Tiles 2000 - MerschmeyrDocument6 pagesFiring of Clay Brick and Tiles 2000 - Merschmeyrharmal1971No ratings yet

- Types of Cements Guide: Properties and UsesDocument24 pagesTypes of Cements Guide: Properties and UsesHämźã ÃâmïrNo ratings yet

- Ceramic Dec15Document146 pagesCeramic Dec15kidcat0% (2)

- Cause of Materials Accumulation in CycloneDocument3 pagesCause of Materials Accumulation in CyclonekidcatNo ratings yet

- GTZ Holcim Icr Oct 09Document2 pagesGTZ Holcim Icr Oct 09kidcatNo ratings yet

- Conventional Refractory Castables by CastingDocument9 pagesConventional Refractory Castables by Castingkidcat100% (2)

- Kiln Burning SystemsDocument30 pagesKiln Burning SystemsNael100% (8)

- RefractoriesDocument36 pagesRefractorieskidcat100% (1)

- Technology of Cement Production: Bottlenecks and SolutionsDocument256 pagesTechnology of Cement Production: Bottlenecks and SolutionsShashwat OmarNo ratings yet

- Sample Report Kiln Alignment PDFDocument24 pagesSample Report Kiln Alignment PDFWatcharapong PuangthaisongNo ratings yet

- Additives For A Challenging Cement MarketDocument5 pagesAdditives For A Challenging Cement MarketkidcatNo ratings yet

- Slag ItroductionDocument45 pagesSlag ItroductionkidcatNo ratings yet

- Kiln Guide1 Planned MaintenanceDocument9 pagesKiln Guide1 Planned MaintenancekidcatNo ratings yet

- Cement Process ChemistryDocument72 pagesCement Process ChemistryNael100% (2)

- Slag ItroductionDocument45 pagesSlag ItroductionkidcatNo ratings yet

- Types of Cement Explained for Concrete ConstructionDocument11 pagesTypes of Cement Explained for Concrete ConstructionAmmar KimNo ratings yet

- Grindability TestsDocument6 pagesGrindability TestskidcatNo ratings yet

- Burner CalculationDocument29 pagesBurner Calculationjoshuadelapava100% (1)

- How To Ensure Safety For Brick CuttingDocument5 pagesHow To Ensure Safety For Brick CuttingNael67% (3)

- Thesis LiangyuDocument210 pagesThesis LiangyukidcatNo ratings yet

- Burning Zone LengthDocument1 pageBurning Zone LengthkidcatNo ratings yet

- The Influence of Pozzolanic Additions On TheDocument5 pagesThe Influence of Pozzolanic Additions On ThekidcatNo ratings yet

- CombustionDocument26 pagesCombustionkidcatNo ratings yet

- Grinding Aids-A Study On Their Mechanism of ActionDocument10 pagesGrinding Aids-A Study On Their Mechanism of ActionNael100% (1)

- Burning Zone LengthDocument1 pageBurning Zone LengthkidcatNo ratings yet

- Percent Calcination 2Document2 pagesPercent Calcination 2Albar BudimanNo ratings yet

- Sulfur FormationDocument56 pagesSulfur FormationkidcatNo ratings yet

- Pac 06 06Document6 pagesPac 06 06Somnath PalNo ratings yet

- India Coal TechnologyDocument52 pagesIndia Coal TechnologyAjay MenonNo ratings yet

- Cement Kiln Liquid PhaseDocument5 pagesCement Kiln Liquid Phaseمعاوية محمد50% (2)

- SN2651Document20 pagesSN2651phaniraj.kNo ratings yet

- MOL Transol 220 Industrial Gear OilDocument2 pagesMOL Transol 220 Industrial Gear OilMaDa GeoNo ratings yet

- IIT Madras Research Park Substation LayoutDocument13 pagesIIT Madras Research Park Substation Layoutnakul4491_88890127No ratings yet

- SCentre Infra - The Leading Steel Construction Company in IndiaDocument54 pagesSCentre Infra - The Leading Steel Construction Company in Indiaseo2.artistonkNo ratings yet

- Never-Seez® India Call +91-891-6666482Document2 pagesNever-Seez® India Call +91-891-6666482Project Sales CorpNo ratings yet

- Stress and Strain - Axial Loading2Document33 pagesStress and Strain - Axial Loading2Clackfuik12No ratings yet

- Pdvsa: Engineering Design ManualDocument6 pagesPdvsa: Engineering Design Manual20jose12luisNo ratings yet

- Bill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2Document17 pagesBill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2xavierlthNo ratings yet

- Dire-Dawa University Institute of Technology: Construction Technology and Management Chair Course Code: byDocument34 pagesDire-Dawa University Institute of Technology: Construction Technology and Management Chair Course Code: bySemNo ratings yet

- 4190 HPRVDocument12 pages4190 HPRVvadivel415No ratings yet

- Selecting and Measuring Pipe & Fittings: Thread Type CompatibilityDocument1 pageSelecting and Measuring Pipe & Fittings: Thread Type CompatibilityITLHAPNNo ratings yet

- HDPE Tender DocumentDocument4 pagesHDPE Tender Documentabhijithaval100% (1)

- Week 09 MG Answer-FormatDocument7 pagesWeek 09 MG Answer-FormatJohn Carlo BaralNo ratings yet

- Repair Procedure For High Temperature Boiler PipingDocument14 pagesRepair Procedure For High Temperature Boiler PipingEzhil Vendhan PalanisamyNo ratings yet

- Assignment-10 CE39 NOC20Document7 pagesAssignment-10 CE39 NOC20jayadeep ksNo ratings yet

- 12.11 Design Guidelines For Stifflegs and Box CulvertsDocument6 pages12.11 Design Guidelines For Stifflegs and Box CulvertsDave ThompsonNo ratings yet

- FT14 Ball Float Steam Trap (Screwed) : FT14-C (R-L)Document5 pagesFT14 Ball Float Steam Trap (Screwed) : FT14-C (R-L)Quyết Bạch ĐìnhNo ratings yet

- Bondor BondorPanel Insulated Walling Technical DataDocument2 pagesBondor BondorPanel Insulated Walling Technical DataSvan Dxi ArulNo ratings yet

- Design of FootingDocument18 pagesDesign of Footingrumylo f. agustin100% (1)

- 2 NDDocument3 pages2 NDAgnes AsilNo ratings yet

- Machine Design - LDocument2 pagesMachine Design - LNilesh Mistry (Nilesh Sharma)No ratings yet

- Designing A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Document15 pagesDesigning A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Jigar100% (1)

- PMBI WorkflowDocument3 pagesPMBI WorkflowBrian MigueNo ratings yet

- Hashi Complete WD 30.05.2023Document2 pagesHashi Complete WD 30.05.2023tocheckpapershadow01No ratings yet

- Mill Certification: Other Test ResultsDocument1 pageMill Certification: Other Test ResultsAlonso FraireNo ratings yet

- Introduction Portable ToiletsDocument1 pageIntroduction Portable ToiletsShrestha Hem100% (1)

- 12 Point Flange Screws Technical SpecificationsDocument1 page12 Point Flange Screws Technical Specificationsflasher_for_nokiaNo ratings yet

- Conjugate Beam Method SLUDocument41 pagesConjugate Beam Method SLULydia D. GalinganNo ratings yet

- Benfield Conduit Bending Manual PDFDocument68 pagesBenfield Conduit Bending Manual PDFSanMiguelParroquiaDiosesana100% (5)

- Data File PHJDDocument43 pagesData File PHJDtamrinNo ratings yet

- Schedule Q (Quality Requirements)Document86 pagesSchedule Q (Quality Requirements)jeswinNo ratings yet