Professional Documents

Culture Documents

Fungal Pretreatment of Lignocellulosic Biomass

Uploaded by

Riki MandolCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fungal Pretreatment of Lignocellulosic Biomass

Uploaded by

Riki MandolCopyright:

Available Formats

Biotechnology Advances 30 (2012) 14471457

Contents lists available at SciVerse ScienceDirect

Biotechnology Advances

journal homepage: www.elsevier.com/locate/biotechadv

Research review paper

Fungal pretreatment of lignocellulosic biomass

Caixia Wan, Yebo Li

Department of Food, Agricultural, and Biological Engineering, The Ohio State University/Ohio Agricultural Research and Development Center, 1680 Madison Ave, Wooster, OH 44691-4096, USA

a r t i c l e

i n f o

a b s t r a c t

Pretreatment is a crucial step in the conversion of lignocellulosic biomass to fermentable sugars and biofuels. Compared to thermal/chemical pretreatment, fungal pretreatment reduces the recalcitrance of lignocellulosic biomass by lignin-degrading microorganisms and thus potentially provides an environmentally-friendly and energy-efcient pretreatment technology for biofuel production. This paper provides an overview of the current state of fungal pretreatment by white rot fungi for biofuel production. The specic topics discussed are: 1) enzymes involved in biodegradation during the fungal pretreatment; 2) operating parameters governing performance of the fungal pretreatment; 3) the effect of fungal pretreatment on enzymatic hydrolysis and ethanol production; 4) efforts for improving enzymatic hydrolysis and ethanol production through combinations of fungal pretreatment and physical/chemical pretreatment; 5) the treatment of lignocellulosic biomass with lignin-degrading enzymes isolated from fungal pretreatment, with a comparison to fungal pretreatment; 6) modeling, reactor design, and scale-up of solid state fungal pretreatment; and 7) the limitations and future perspective of this technology. 2012 Elsevier Inc. All rights reserved.

Available online 10 March 2012 Keywords: Fungal Pretreatment White rot fungi Biodelignication Biomass Biofuel

Contents Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Lignin-degrading microorganisms and degrading enzymes . . . . . . . . Lignin-degrading microorganisms . . . . . . . . . . . . . . . . . Degrading enzymes . . . . . . . . . . . . . . . . . . . . . . . . Ligninolytic enzymes . . . . . . . . . . . . . . . . . . . . Hydrolytic enzymes . . . . . . . . . . . . . . . . . . . . Gene expression of ligninolytic enzymes . . . . . . . . . . . . . . Solid state fungal pretreatment process . . . . . . . . . . . . . . . . . Inoculum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Moisture content . . . . . . . . . . . . . . . . . . . . . . . . . Particle size . . . . . . . . . . . . . . . . . . . . . . . . . . . Supplements . . . . . . . . . . . . . . . . . . . . . . . . . . . Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . Aeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Decontamination . . . . . . . . . . . . . . . . . . . . . . . . . Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Enzymatic hydrolysis . . . . . . . . . . . . . . . . . . . . . . . . . Non-selective lignin degrading fungi . . . . . . . . . . . . . . . . Selective lignin degrading fungi . . . . . . . . . . . . . . . . . . Combination of fungal pretreatment and physical/chemical pretreatments Enzymatic treatment . . . . . . . . . . . . . . . . . . . . . . . . . Modeling and scale-up . . . . . . . . . . . . . . . . . . . . . . . . Limitations and potentials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1448 1448 1448 1449 1449 1449 1450 1450 1450 1451 1451 1451 1451 1451 1451 1452 1452 1452 1452 1453 1454 1454 1455

Corresponding author. Tel.: + 1 330 263 3855; fax: + 1 330 263 3670. E-mail address: li.851@osu.edu (Y. Li). 0734-9750/$ see front matter 2012 Elsevier Inc. All rights reserved. doi:10.1016/j.biotechadv.2012.03.003

1448

C. Wan, Y. Li / Biotechnology Advances 30 (2012) 14471457

Conclusions and future perspectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Acknowledgments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1455 1455 1455

Introduction In order to reduce dependence on fossil fuels and thus alleviate associated economic and environmental concerns, biofuels derived from renewable and domestic sources have received extensive interest for displacement of fossil transportation fuels in many countries. Lignocellulosic biomass, mostly from agricultural and forestry sources, is rich in carbohydrates (5575% dry basis) and widely available, thus providing attractive feedstocks for ethanol production. To maximally utilize carbohydrates in the biomass, a pretreatment process is needed to overcome the biomass recalcitrance and subsequently improve its accessibility to hydrolytic enzymes (Mosier et al., 2005). Thermal/ chemical pretreatment methods have been regarded as the current leading pretreatment technologies; however, they usually need expensive corrosion resistant reactors, processing large volumes of the waste stream, extensive washing of treated solids, and detoxication of compounds inhibitory to ethanol-fermenting microorganisms. Thus, pretreatment still remains one of the most costly steps in cellulosic ethanol production and is a signicant barrier to its commercialization (Mosier et al., 2005). From both economic and environmental perspectives, fungal pretreatment with lignin-degrading microorganisms, preliminary white rot fungi, has received renewed interest as an alternative to thermal/chemical pretreatment for cellulosic ethanol production. The feasibility of fungal pretreatment for improving enzymatic digestibility of various biomass feedstocks, such as corn stover (Keller et al., 2003; Xu et al., 2010), wheat straw (Dias et al., 2010), rice straw (Bak et al., 2009), cotton stalks (Shi et al., 2009), and woody biomass (Yu et al., 2009a), has been reported. Moreover, most researchers are interested in solid state fungal pretreatment as limitations of liquid state cultivation are apparent, mainly due to a considerably low substrate loading (b 5%). The advantages of this technology over thermo-chemical pretreatments include simple techniques, low energy requirements, no or

reduced output of waste streams, reduced downstream processing costs, and no or reduced inhibitors to ethanol fermentation (Keller et al., 2003; Nigam and Pandey, 2009). Despite the advantages, substantial holocellulose (cellulose and hemicellulose) loss and long pretreatment time are the major issues associated with fungal pretreatment. To ensure a cellulose-rich but highly delignied biomass for biofuel production, white rot fungi, highly selective in lignin degradation, are preferred for fungal pretreatment. In addition, cultivation parameters also affect the pretreatment performance. Scale-up related issues like decontamination and reactor design also need to be addressed for industrial applications. This review provides an overview of recent studies on solid state fungal pretreatment with white rot fungi for biofuels production, focusing on critical pretreatment parameters affecting the effectiveness of fungal pretreatment, enzymes involved in the degradation of biomass feedstocks, and sugar and ethanol yields resulting from fungal pretreatment. An overall comparison of the effectiveness of fungal and enzymatic pretreatments, synergistic effects of combined fungal and physical/chemical pretreatment, and feasibility and limitations of scale-up of fungal pretreatment for biofuels production are also discussed. Lignin-degrading microorganisms and degrading enzymes Lignin-degrading microorganisms Microorganisms, including white-, brown-, and soft-rot fungi, and some ruminant bacteria, are capable of degrading lignocellulosic biomass. Among them, white rot fungi are most effective for delignication due to their unique ligninolytic systems (Eriksson et al., 1990). Traditionally, white rot fungi have been employed for biopulping, forage upgrading, and bioremediation of soil and wastewater by oxidizing lignin and a wide range of lignin analogous compounds (Sanchez, 2009;

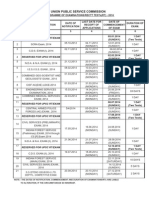

Table 1 The effect of fungal pretreatment on enzymatic hydrolysis and ethanol production. Fungus Phaerochaete chrysosporium Phaerochaete chrysosporium Phaerochaete chrysosporium Phaerochaete chrysosporium Phaerochaete chrysosporium Pleurotus ostreatus Pleurotus ostreatus Pleurotus ostreatus, Pycnoporus cinnabarinus 115 Euc-1 Cyathus stercoeus Irpex lactues Ceriporiopsis subvermispora Pheblia tremellosus Polyporus giganteus Stereum hirsutum Echinodontium taxodii 2538 Echinodontium taxodii 2538, Coriolus versicolor

a b c d e f

Substrate Cotton stalk Corn stover Rice straw Beechwood Corn ber Rice straw Rice hull Wheat straw Wheat straw Corn stover Corn stover Corn stover Aspenwood Aspenwood Japanese red pine Chinese willow, China-r Bamboo culm

Sugar/ethanol yielda Reduced glucose yield No improvement on glucose yield 50% glucose yield b 50% ethanol yield b 9.5% total sugar yield c Reduced sugar yield or no signicant improvement 33% glucose yield 38.9% glucose yield 2728% glucose yield d 22.5% total sugar yield c 36% glucose yield 66.4% total sugar yield e 5666% glucose yield and 57.8% ethanol yield 11.6% glucose yieldc 55.2% glucose yield 13.7% glucose yieldc 535% glucose yield 37% total sugar yield f

References Shi et al. (2009) Keller et al. (2003) Bak et al. (2009) Sawada et al. (1995) Shrestha et al. (2008) Taniguchi et al. (2005) Yu et al. (2009b) Hatakka (1983) Dias et al. (2010) Keller et al. (2003) Xu et al. (2010) Wan and Li (2010b) Mes-Hartree et al. (1987) Kirk and Moore (1972) Lee et al. (2007) Yu et al. (2009a) Zhang et al. (2007a, 2007b)

% of theoretical yield of glucan in the original material, unless stated otherwise. Results were obtained from submerged fungal pretreatment. % of dry mass of the treated material. % of dry mass of the original material. % of theoretical yield of holocellulose in the original material. % of theoretical yield of holocellulose in the treated material.

C. Wan, Y. Li / Biotechnology Advances 30 (2012) 14471457

1449

Wesenberg et al., 2003; Winquist et al., 2008). As listed in Table 1, several white rot fungi, such as Phanerochaete chrysosporium, Pleurotus ostreatus, Coriolus versicolor, Cyathus stercoreus, and Ceriporiopsis subvermispora, have been studied for pretreatment of a wide range of biomass feedstocks. Although delignication is of signicance to reduce the biomass recalcitrance, white rot fungi with a high selectivity for lignin degradation over cellulose loss, as aforementioned and discussed in the later sections, are most important to fungal pretreatment for biofuel production. Analysis of white rot-degraded wood indicates that lignin degradation by these microorganisms is highly oxidative and may involve chemical oxidants such as singlet oxygen and hydroxyl radicals (Eriksson et al., 1990). The following reactions are generally involved: (i) oxidative, (ii) demethylation (or demethoxylation), (iii) sidechain oxidation, and (iv) propyl side-chain cleavage. In contrast to white rot fungi, brown rot fungi are able to circumvent the lignin barrier, remove the hemicellulose and cellulose with only minor modications to the lignin (Eriksson et al., 1990). Consequently, lignin remains a major component of the degraded plant cell wall. The remaining lignin is demethylated on arylmethoxy groups and contains a greater number of ring hydroxyl groups. Degrading enzymes Ligninolytic enzymes It is well known that lignin peroxidase (LiP), manganese peroxidase (MnP), and laccase are the three major oxidative enzymes secreted by white rot fungi (Eriksson et al., 1990). They are responsible for oxidation of lignin and a wide range of lignin analogous compounds (Winquist et al., 2008). However, not all of these enzymes are detected from fungal cultures. For example, P. chrysoporium produced LiP and MnP, but no laccase (Ruttimann-Johnson et al., 1993). C. subvermispora only produced MnP and laccase whereas LiP was not detected, although a lip-like gene was revealed in this fungus by a southern-blot hybridization technique using the same probe coding as lip (Rajakumar et al., 1996). Lignin peroxidase (also ligninase, EC 1.11.1.14) is a hemeprotein, involving in the oxidative cleavage of non-phenolic aromatic lignin moieties and similar compounds. Manganese peroxidase (EC 1.11.1.13) is an enzyme secreted to aid lignin degradation, catalyzing the chemical reaction that oxidizes numerous phenolic compounds, especially syringyl (3, 5-dimethoxy-4-hydroxyphenyl) and vinyl side-chain substituted substrates in the presence of Mn 2 +. Laccases (EC 1.10.3.2) are copper-containing oxidase enzymes that act on phenols and similar molecules, performing one-electron oxidations. Ligninolytic enzymes may be non-specic on different lignin substrates and have similar degradation reactions. For example, both LiP and MnP were found to degrade non-phenolic lignin by oneelectron oxidation of the aromatic ring (Kirk et al., 1986; Srebotnik et al., 1997). Versatile peroxidase (VP) isolated from Pleurotus and Bjerkandera species is regarded as the third peroxidase, a LiP-MnP hybrid as it shows Mn2 + independent activity but is capable of degrading phenolic and non-phenolic compounds (Martinez et al., 1996; Mester and Field, 1998). However, due to the complicated and heterogeneous nature of lignocellulosic biomass, the role of ligninolytic enzymes on the early stage decay of biomass feedstocks still remains unclear. A study conducted by Guerra et al. (2002) showed no evidence for a correlation between oxidative enzymes and lignin degradation by C. subvermispora. Moreover, the mineralization of lignin occurred after the lignin modication, which was indicative of a series of reactions involved in lignin depolymerization. Studies with immunocytochemical techniques revealed that lignindegrading enzymes did not diffuse into sound and unaltered cell walls due to their large molecular weight (Blanchette et al., 1997; Flournoy et al., 1993; Srebotnik et al., 1988). However, the oxidative enzymes could be active at the surface of the cell wall and induce the formation of low molecular mass agents such as radicals and oxalic

acids (Enoki et al., 1999; Kapich et al., 1999). These low molecular compounds are diffusible and could initiate wood decay and facilitate the penetration of lignin-degrading enzymes (Galkin et al., 1998). For instance, C. subvermispora produces a variety of low molecular compounds including glyoxylic acids (Urzua et al., 1998), oxalic acid (Galkin et al., 1998; Urzua et al., 1998), and several unsaturated fatty acids (Enoki et al., 1999; Gutierrez et al., 2002) in liquid or solid state culture. Radical agents (e.g., peroxyl and acyl radicals), generated from MnP-dependent peroxidation of white rot fungi, have been suggested as playing an important role in non-phenolic lignin oxidation (Kapich et al., 1999; Watanabe et al., 2000). Hydrolytic enzymes Hydrolytic enzymes play important roles by providing easily digestible carbon sources to fungal growth and metabolism. However, non-selective white rot fungi, due to their high cellulolytic and hemicellulolytic activity, cause substantial cellulose loss. In contrast, selective white rot fungi mainly secrete hemicellulolytic enzymes and utilize hemicellulose-derived sugars as the main carbon sources for selfgrowth and metabolism. Cellulase-decient mutants developed from fast-growing but non-selective white rot fungi, such as P. chrysosporium, were also evaluated for lignin degradation. Although some P. chrysosporium mutants can act effectively in lignin and lignin model compounds (Eriksson et al., 1983), no degradation on lignocellulosic biomass by the mutants was ever reported relative to wild species (Akin et al., 1993). Due to the low permeability of sound wood cells, it is difcult for such large molecule hydrolytic enzymes to penetrate. Similar to ligninolytic enzymes, low molecular mass agents have also been suggested as a mechanism to induce cellulose depolymerization. The Fenton system (Fe 2 + and H2O2), known to depolymerize cellulose, can be generated by the action of some enzymes such as cellobiohydranase and MnP in white rot fungal cultures (Dumonceaux et al., 2001; Henriksson et al., 2000; Xu et al., 2009). In contrast to cellulase and peroxidase, hemicellulases, such as xylanase, did not act in the synergism of low molecular compounds (Ferraz et al., 2003). Therefore, diffusion of xylanase into the plant cell wall is suggested to be facilitated by lignin degradation which increases cell wall permeability (Machuca and Ferraz, 2001; Vicentim and Ferraz, 2007). Due to the lack of a complete cellulolytic enzyme complex, C. subvermispora has become well known as a selective white rot fungus that preserves most cellulose during fungal decay (Ferraz et al., 2003). In the study of Ferraz et al. (2003), no signicant glucose loss was detected from C. subvermispora culture on the wood species Eucalyptus grandis until 60 d. Maximum glucan loss of 7.3% was observed after 90 d. Low cellulase activity revealed by lter paper activity explained the low glucan loss caused by this fungus. Another wood species, Pinus taeda, cultured with this fungus was observed with only 2% glucan loss after 90 d (Guerra et al., 2003). During 42-d fungal pretreatment of corn stover by this fungus, there were no detectable lter paper and carboxymethylcellulose activities and the cellulose loss was less than 5% (Wan and Li, 2010a). However, cellulose degradation up to 26% was observed in Pinus radiate during 200-d pretreatment by C. subvermispora, probably due to slowly induced cellulolytic activity (Ferraz et al., 2001). Unlike C. subvermispora, P. ostreatus is a widely studied white rot fungus that is able to produce a hydrolytic enzyme complex in different lignocellulosic biomass or under different fermentation strategies (Elisashvili et al., 2008; Snchez, 2009). Several studies have focused on hydrolytic enzyme production by this fungus and detected multiple cellulolytic enzymes, including cellulases, endoglucanase, and cellobiohydrolase, from its culture on agricultural residues (Elisashvili et al., 2008; Garzillo et al., 1994; Marnyye et al., 2002; Okamoto et al., 2002). Similar results were also reported for other Pleutorus strains (Elisashvili et al., 2008). With high hydrolytic and ligninolytic activities, P. ostreatus has been widely used for upgrading crop residues, such as wheat straw, for animal feed (Cohen et al., 2002a). However, as

1450

C. Wan, Y. Li / Biotechnology Advances 30 (2012) 14471457

discussed in the enzymatic hydrolysis section, based on the effectiveness of fungal pretreatments, P. ostreatus is regarded as a moderately selective lignin degrader, due to its substantial consumption of cellulose in lignocellulosic substrates, especially with prolonged pretreatment time. Gene expression of ligninolytic enzymes Numerous studies have demonstrated that expression of white rot fungi genes encoding ligninolytic enzymes is differentially regulated at the transcriptional level by the culture conditions as reviewed in the solid state fungal pretreatment process section. Expression of LiP isoenzyme genes of P. chrysosporium is strongly inuenced by nitrogen or carbon limitation. Holzbaur and Tien (1988) reported that lipA transcripts of P. chrysosporium were relatively abundant in nitrogen-starved media while lipD transcripts were dominant in carbon-starved cultures. Both lipC and lipJ gene transcripts were dramatically upregulated under nitrogen-decient conditions (Stewart et al., 1992). In contrast, lipE transcript levels were not affected by either carbon or nitrogen deciency in the culture media (Reiser et al., 1993). Culture substrates such as soil and wood also largely affect transcript patterns and levels. For example, lipF transcripts were absent in soil culture but were abundant in aspen culture (Bogan et al., 1996; Janse et al., 1998). lipD and lipE transcripts showed almost the opposite expression, being highly expressed in soil but not in aspen wood. Mn 2 + also had an indirect effect on LiP gene expression of white rot fungi Bjerkandera sp. Strain BOS 55 and P.chrysosporium BKM-F-1767 by its regulation of veratryl alcohol levels in culture media (Mester et al., 1995). Relative to LiP gene expression, more complex regulation by culture conditions, such as nutrient limitation, Mn 2 +, H2O2 concentration, and other physiological factors (e.g. temperature, agitation, moisture), has been observed with MnP gene expression (Janse et al., 1998). mnp1 and mnp2 of P. chrysosporium were strongly dependent on Mn2 + and also differentially regulated by culture agitation while mnp3 had no response to Mn2 + (Gettemy et al., 1998). Similarly, mnp2 isolated from P. ostreatus grown on saw dust appeared not to be regulated by Mn2 + (Giardina et al., 2000). Mn2 + amendment also affected MnP and VP expression of P. ostreatus. Unlike multiple lip genes, all three mnp genes were detected in both wood and soil cultures (Janse et al., 1998). Laccase encoding genes were also studied for constitutive expression and inducible expression. Mansur et al. (1998) studied expression patterns of the laccase gene family from Basidomycete I-62 (CECT 20197) and reported that lcc1 and lcc2 were induced by veratryl alcohol at different stages of growth while lcc3 was non-induced by veratryl alcohol. RT-PCR demonstrated that lcc transcription in Trametes versicolor was activated by copper, nitrogen and certain aromatic compounds tested (i.e. c2,5-xylidine and 1-hydroxybenzotriazole) (Collins and Dobson, 1997). Several regulatory elements in promoter regions of genes encoding ligninolytic enzymes have been postulated to be responsible for transcriptional activation (Collins and Dobson, 1997; Have and Teunissen, 2001). Putative metal response elements (MREs) have been identied as target sequence for transcription factors responding to heavy metals (e.g. Mn 2+, Cu 2+, Ag 2+). High dependence of expression of certain mnp genes on Mn 2 + reveals MREs regulation at the transcription level (Cohen et al., 2001, 2002b). Activation protein of cup1 expression (ACE) elements provide specic binding sites for the ACE1-like transcription factor which activates transcription of target genes especially in response to copper (Manubens et al., 2007). As P. chrysosporium does not produce laccase, ACE1 identied in this fungus activated expression of mco1 gene encoding a different type of multicopper oxidase (Canessa et al., 2008). Alvarez et al. (2009) rst isolated and characterized an ACE1-like copper-st transcription factor from genes encoding laccase and MnP in basidiomycetes. Receptors or binding proteins of putative xenobiotic responsive elements (XREs) are associated with transcription activation of genes in response to nonpolar carbon compounds (Collins and Dobson, 1997).

Putative XREs have been identied in the promoter of lip genes and lcc genes in a number of white rot fungi (e.g., T. versicolor, P. ostreatus), which explains inducible expression of these genes by aromatic compounds. Activator protein-2-binding sequence identied in upstream regulatory region of lip and mnp genes of white rot fungi has been proposed to be involved in differential regulation of these gene families by nitrogen (Dhawale, 1993). cAMP response elements (CRE) could also play a role in inducing gene expression during carbon or nitrogen limitation (Have and Teunissen, 2001). Other regulatory elements identied, such as cis-regulatory elements, are proposed to respond to physiological factors, in this case to heat shock. More research is ongoing to provide insight into the mechanism involved in differential regulation of gene expression at transcription levels. Most studies reported that transcription levels are collinear to enzyme activity proles in the culture media (Cohen et al., 2001; Collins and Dobson, 1997). However, it should be noted that some genes encoding ligninolytic enzymes have not yet been cloned or need some posttranslational modication to be active (Morgenstern et al., 2010). Unidentied factors hindering free secretion of expressed genes to the surrounding media could also cause the discrepancy between enzymatic activity and transcription levels. Not readily demonstrable enzyme activities have also been observed for white rot fungi with putative ligninolytic genes. For example, Phanerochaete sordida and C. subvermispora were detected with lip-like genes but not Lip activities (Rajakumar et al., 1996). It is also widely quoted that P. chrysosporium lacks laccase even with putative lcc genes. However, Srinivasan et al. (1995) rst reported that a low level laccase was produced by P. chrysosporium BKM-F1767 in a dened culture medium containing cellulose (10 g/l) and either 2.4 or 24 mM ammonium tartrate. Heterologous expression of active lignin and Mn peroxidases was studied with isolation of cDNA encoding many peroxidases isoenzymes. Baculovirus systems have been successfully used for expression of MnP isozymes H4 (Pease et al., 1991), LiP isozymes H2 (Johnson et al., 1992), and LiP H8 of P. chrysosporium H2 (Johnson et al., 1992). lcc1 of T. versicolor was also expressed by Pichia pastoris (Jnsson et al., 1997). Although properties and activity of these heterologously expressed genes are similar to that of native enzymes, yields obtained are mostly too low to be feasible for large scale production or convenient for biochemical characterization. Fermentation strategies have been reported to markedly enhance expression levels (Hong et al., 2002). Solid state fungal pretreatment process Inoculum Inoculum for solid state fungal pretreatment can be prepared by different methods, e.g., mycelium grown in liquid or agar medium, spawn grown in cereal grains, or fungal-precolonized substrate (Reid, 1989b). Phanerochaete chrysosporium yields spores which enable convenient inoculum preparation and mixing with the substrate. In contrast, most white rot basidiomycetes do not produce spores. Instead, the precolonized lignocellulosic biomass is generally used for inoculation. Similar to liquid fermentation, fermented materials in solid state reactors can also serve as inoculum and the fresh substrate can be fed to partially replace fermented materials. A minimum level of inoculum is generally required for effective colonization and subsequent delignication (Reid, 1989a). However, a further increase in inoculum level may only have a marginal effect on the fungal colonization rate and subsequent growth. Akhtar et al. (1998) tested different levels of inoculum using precolonized wood chips by P. chrysosporium for the decay of aspen wood as alternatives to mechanical pulping. The results showed that a 25% inoculation level gave good performance and energy savings while increasing the inoculation level to 20% did not correspondingly increase energy savings for mechanical pulping.

C. Wan, Y. Li / Biotechnology Advances 30 (2012) 14471457

1451

Moisture content Initial moisture content of the substrate is important to the fungal establishment and growth and affects secondary metabolism in fungal pretreatment (Reid, 1989b). Previous studies suggested that initial moisture ranging from 70 to 80% was the optimal level for lignin degradation and ligninolytic activities of most white rot fungi. Shi et al. (2008) observed that after 14-d cultivation of cotton stalks by P. chrysosporium, lignin degradation of 27.6% was obtained at 75% moisture content in the substrate, which was approximately 7% higher than that at 65% moisture content but was not signicantly different from that at 80% moisture content. Asgher et al. (2006) investigated the solid state cultivation of P. chrysosporium on corn cobs with a moisture content ranging from 40% to 90%. The highest ligninase activity was obtained at 70% moisture content. During fungal pretreatment of corn stover with C. subvermispora, no fungal growth and degradation occurred at 45% moisture content while lignin degradation reached 19.48%, 29.54%, and 31.33% when the moisture contents increased to 60%, 75%, and 85%, respectively (Wan and Li, 2010b). In general, high moisture content is favorable for formation of fungal mycelia but not necessarily for increased delignication (Zadrazil and Brunnert, 1981). Another side effect of high moisture content is a reduced solid loading for fungal pretreatment. On the other hand, too low a moisture content could hamper fungal delignication without providing sufcient water to fungal growth. Particle size Particle size of the substrate is also a major factor affecting the performance of solid state fungal pretreatment. Large particle size can hamper the penetration of fungi into cellulosic biomass and also prevent the diffusion of air, water, and metabolite intermediates into the particles. However, the reduced particle size with a decreased size of interparticle channel may adversely affect interparticle gas circulation (Reid, 1989a; Zadrazil and Puniya, 1995), thus not necessarily giving an enhanced delignication rate. Reid (1989a) found that during the cultivation of Phlebia tremellosa with active aeration, 40mesh aspen wood had similar lignin degradation and subsequent enzymatic digestibility to 10-mesh aspen, while the least effectiveness was observed with aspen chips. Membrillo et al. (2008) also reported the highest level of lignocellulolytic enzyme production on sugar cane bagasse at 2.9 mm particle size among the three particle sizes tested (0.92, 1.68, and 2.9 mm). Sarikaya and Ladisch (1999) reported that a ne particle size of less than 0.42 mm caused less lignin degradation compared to 0.420.82 mm during 32-d treatment of rapeseed with P. ostreatus. Substantially lower lignin degradation (12.8324.90%) was obtained with 15 mm corn stover compared to that with particle sizes of 5 and 10 mm (19.4831.59%) while there was no signicant difference between the lignin degradation of 5 and 10 mm corn stover (Wan and Li, 2010b). Supplements Supplementation of inducers, such as Mn 2 +, H2O2, and aromatic compounds, can potentially stimulate secretion of ligninolytic enzymes and lignin degradation on biomass feedstock. Shrestha et al. (2008) tested effects of Mn 2 +, H2O2, and veratryl alcohol on lignin degradation of corn ber by P. chrysosporium and found Mn 2 + addition resulted in the highest lignin degradation. Some studies, however, showed the addition of Mn 2 + did not improve lignin degradation on cotton stalk by P. chrysosporium (Shi et al., 2008). The addition of nutrients generally increased formation of the fungal biomass and also facilitated fungal colonization in the deeper areas of feedstocks (Messner et al., 1998). As a low cost carbon/nitrogen source, corn steep liquor has been used for biopulping to increase fungal biomass

production and reduce energy consumption of mechanical pulping (Messner et al., 1998). For most white rot fungi, the depolymerization of lignin is induced under nitrogen starvation (Akhtar et al., 1998; Ruttimann-Johnson et al., 1993). In other words, addition of supplemental nitrogen may inhibit lignin degradation while stimulating growth of white rot fungi and consumption of carbohydrates (Reid, 1985). Temperature In general, white rot ascodiomycetes grow well around 39 C while white rot basidiomycetes can grow between 15 and 35 C and their high delignication rate is generally obtained within an optimal temperature range between 25 and 30 C (Reid, 1985; Reid, 1989b). Wan and Li (2010b) tested a wide range of temperature (437 C) for its effect on pretreatment of corn stover with C. subvermispora in 250-ml asks and the results showed that 28 C was the optimal temperature for improving enzymatic digestibility of corn stover. The metabolism of white rot fungi generates heat and causes temperature gradients in solid state cultivation. The accumulated heat can kill or inhibit the fungal growth and metabolism. Therefore, in the scaleup of solid state cultivation, heat dissipation is one of the key factors to be taken into account in bioreactor design. Aeration Aeration is known to markedly affect the performance of solid state fermentation. Since lignin degradation is an oxidative process, oxygen availability is important for ligninolytic enzyme activity of white rot fungi. In ask reactors (b 500 ml), passive air diffusion through cotton plugs was as sufcient as forced air circulation for the delignication process (Reid, 1989a). However, for reactors containing packed feedstock, active aeration was necessary to provide uniform air diffusion throughout the substrate. Messner et al. (1998) tested air aeration (0.001, 0.022, 0.1 v v 1 min 1) for P. chrysosporium treatment of aspen chips for biopulping and concluded that the ow rate of 0.022 v v 1 min 1 was enough to achieve good fungal performance. Hatakka (1983) reported that ushing with oxygen 3 times per week shortened pretreatment time by approximately 1 week during pretreatment of wheat straw by the fungi Pycnoporus cinnabarinus 115 and Phanerochaete sorodida 37. As reviewed by Reid (1989a), high oxygen could increase the delignication rate but it did not increase delignication selectivity. Thus, aeration needs to be controlled to ensure the performance of fungal pretreatment. Decontamination Decontamination of feedstocks (e.g., gas, steam, chemicals) can effectively kill or inhibit indigenous microorganisms in the feedstock and is generally required prior to fungal pretreatment, especially with white rot basidiomycetes. P. chrysosporium was found to be efciently competitive against fungal and bacterial infection while C. subvermispora was more vulnerable to contaminates (Srebotnik and Messner, 1994). Akin et al. (1995) tested the inuence of contamination on activity of two white rot fungi (C. subvermispora and C. steroreus). The results showed that abundant bacteria and unknown fungi were prevalent on both control and contaminated Bermuda grass stems. However, contamination did not affect either fungal performance or the resulting digestibility of pretreated materials. It indicated that activities of white rot fungi were not suppressed by fungal and bacterial infection. However, in scaled up applications, decontamination poses one of the major costs for fungal pretreatment. In the study of Akhtar et al. (1998), it was found that complete sterilization was not necessary and short atmospheric steaming (~ 15 s) was sufcient to allow the establishment of white rot fungi and to outcompete indigenous fungi and bacteria. Instead of decontamination by

1452

C. Wan, Y. Li / Biotechnology Advances 30 (2012) 14471457

atmospheric steam or autoclave, inexpensive chemicals such as sodium biosulte, sodium meta-bisulte, and sodium hydrosulte were also reported to be effective at concentrations of 6001200 ppm for decontamination of wood chips for their pretreatment by the biopulping fungi such as P. chrysosporium and C. subvermispora (Akhtar et al., 1998). Time Long pretreatment time, due to low delignication rates, is one of the major barriers to large scale application of fungal pretreatment. Generally, several weeks to months are needed to obtain a high degree of lignin degradation. P. chrysosporium is a fast-growing white rot fungus, only requiring a few days to weeks for vigorous degradation; however, it degrades lignin and holocellulose unselectively, which is undesirable for biofuel production (Keller et al., 2003; Sawada et al., 1995; Shi et al., 2009). In contrast, for P. ostreatus, one of the widely studied white rot fungi, a few weeks only resulted in 10.3% lignin degradation in beechwood (Itoh et al., 2003). After 72 d of cultivation with P. ostreatus, 32% of the carbohydrates in rice straw were converted to soluble sugars (Taniguchi et al., 2005). Locci et al. (2008) observed that substantial degradation in wheat bran occurred during 62 d of fungal treatment by P. ostreatus. For pretreatment time as long as 90 d, 51% lignin was degraded from wheat straw by this fungus (Lindenfelser et al., 1979). For the feedstocks resistant to fungal attack, such as softwood and bamboo, even longer pretreatment time is needed. Zhang et al. (2007a, 2007b) reported that 60120 d was required for pretreatment of bamboo with Echinodontium taxodii and C. versicolor to obtain signicant improvement on sugar yields. Enzymatic hydrolysis Non-selective lignin degrading fungi As summarized in Table 1, cellulose digestibility of different biomass feedstocks resulting from fungal pretreatment has been reported in the past. P. chrysosporium, a well-known non-selective lignin-degrading fungus, had little or no effect on improvement on enzymatic hydrolysis. The fungus itself consumes a large amount of readily accessible carbohydrates due to the simultaneous degradation of cellulose, hemicellulose, and lignin. The remaining cellulose might be less digestible and thus resistant to the subsequent hydrolysis. Moreover, the reduced cellulose content after fungal pretreatment also contributes to the reduced glucose yield. The longer time the biomass feedstock is pretreated by P. chrysosporium, the lower the expected saccharication yield compared to that from the non-treated feedstock. This expectation was observed during a 100-d pretreatment of aspen wood by this fungus, where the maximum saccharication yield was reached on day 28 and thereafter the saccharication yield decreased (Sawada et al., 1995). The lignin degradation was increased from 42% to 50% as pretreatment time increased from 28 to 100 d while the corresponding holocellulose loss was increased from 17% to 50%. Although the degradation selectivity was high on day 28, the fungal pretreatment was not sufcient to increase the saccharication yield of aspen wood. Pretreatment time beyond 2 weeks also resulted in a reduced saccharication yield of corn ber compared to that of the control (Shrestha et al., 2008). Keller et al. (2003) reported that pretreatment of corn stover with P. chrysosporium for 29 d did not signicantly increase saccharication yield compared to the control, probably due to too long a pretreatment time. Even for a 14-d fungal pretreatment of cotton stalk by P. chrysosporium, a reduced saccharication yield was obtained with both submerged and solid state fungal-treated cotton stalks (Shi et al., 2009). The cellulose loss from both methods was as high as 40.49%, while lignin degradation was in the range of 19.3835.53%. Hot water washing, for removal of fungal biomass/protein and lignin derivatives, improved the saccharication yield of solid state treated

stalks but not the submerged-treated stalks. Nevertheless, the saccharication yield was not signicantly different from that of non-treated. There was an exception for P.chrysosporium with respect to the degree to which saccharication yield was improved. Bak et al. (2009) serially optimized the culture media for submerged pretreatment of rice straw with P. chrysosporium in order to achieve high ligninolytic enzymes. It was found that glucose yield was improved by at least 2 times during a 30-d pretreatment, reaching a maximum glucose yield of 64.9% (equivalent to 50% of glucose yield of the raw feedstock) when cellulase and -glucosidase (Novozyme 188) loadings were 60 FPU and 30 CBU per gram glucan, respectively. Similar improvement was also reported for ethanol yield from their study. However, taking into consideration both considerable cellulose loss and low solid loading of submerged cultivation, such non-selective fungus may not be effective for fungal pretreatment to improve the saccharication yield of biomass feedstocks. Selective lignin degrading fungi Selective lignin-degrading white rot fungi degrade larger amounts of lignin relative to cellulose. However, fungal selectivity varies among species and with pretreatment time. In addition, fungal performance on degradation and the resulting digestibility varies with different feedstocks. For agricultural residue, Keller et al. (2003) reported that a saccharication yield of 36% was obtained from corn stover pretreated with C. stercoreus for 29 d when the enzymatic hydrolysis was conducted at 60 FPU/g glucan for 136 h, which was about 4 times that of the untreated. In contrast, the saccharication yield of 66.4% was obtained with 25-d Irpex lacteus CD2 treated corn stover at a cellulase loading of 20 FPU/g solid for enzymatic hydrolysis (Xu et al., 2010). In their study, the saccharication yield of fungal-treated corn stover decreased slightly during 2560 d of pretreatment and then decreased dramatically due to holocellulose loss. It was found that holocellulose degradation, especially hemicellulose degradation, was dominant during the early stage (05 d) while no lignin degradation was observed during this period. Thereafter, active lignin degradation was observed on days 5 to 10 with a rate higher than that of holocellulose degradation. In contrast, glucose yield as high as 67% was obtained from corn stover pretreated with C. subvermispora as a result of 35.81% lignin degradation when cellulase loading for enzymatic hydrolysis was 10 FPU/g solid (Wan and Li, 2010b). These studies indicated that delignication of corn stover was fungus-specic. P. ostreatus was reported to be more effective with straw materials than other fungi (Taniguchi et al., 2005). Wheat straw pretreated with this fungus gave 2733% cellulose digestibility during 72-h enzymatic hydrolysis with cellulase loading of about 10 FPU/g solid (Hatakka, 1983; Taniguchi et al., 2005). It should be noted that this fungus was less selective in lignin and cellulose degradation when pretreatment time was extended to several weeks. Thus, the cellulose digestibility tended to level off during the later stage of cultivation (Taniguchi et al., 2005; Yu et al., 2009b). Fungal pretreatment also greatly improved the digestibility of hardwoods such as aspen and birch but with a longer pretreatment time. A desirable polysaccharide digestibility of aspen wood (5055%) was obtained after pretreatment with Polyporus giganteus, Polyporus berkeleyi, or Polyporus resinosus for 6399 d while the digestibility of birch wood was not substantially improved with these fungi (Kirk and Moore, 1972). For Chinese willow after pretreatment with E. taxodii 2538 for 120 d, about 37% of the polysaccharides were converted when enzymatic hydrolysis was conducted at a cellulase loading of 20 FPU/g solid. Similar saccharication yield was also observed with bamboo residues under the same pretreatment and enzymatic hydrolysis conditions (Zhang et al., 2007b). Compared to other types of feedstocks, softwood generally required a longer pretreatment but its resulting saccharication rate appeared to be unattractive. Yu et al. (2009a) reported that the saccharication yield of China r was 17% after

C. Wan, Y. Li / Biotechnology Advances 30 (2012) 14471457

1453

pretreatment with E. taxodii for 120 d. Lee et al. (2007) also reported a 21% sugar yield from Japanese red pine pretreated with Stereum hirsutum for 8 weeks, of which 14% was glucose. As a result, it is suggested that thermo-chemical pretreatment be used rather than fungal pretreatment for softwood. Combination of fungal pretreatment and physical/chemical pretreatments Fungal pretreatment of wood with white rote fungi has been widely applied in the pulp industry. This so-called biopulping process can potentially overcome the problems associated with mechanical and chemical pulping methods (e.g., intensive energy input for mechanical pulping, high chemical loadings for chemical pulping). The advantages include signicant energy savings in mechanical pulping, low severity for subsequent chemical pulping, improved paper strength properties, and reduced toxicity of pulping waste (Akhtar et al., 1998; Kang et al., 2003). Messner et al. (1998) observed that a relatively short incubation time substantially favored the chemical pulping process due to appreciable pre-modication of lignin. Similar to benets of biopulping, fungal pretreatment combined with mild mechanical or physical/chemical pretreatment has been of interest to improve the digestibility of lignocellulosic biomass. Fungal pretreatment followed by physical/chemical pretreatment is summarized in Table 2. Similar to biopulping, fungal pretreatment improved the performance of the subsequent non-fungal pretreatment. Yu et al. (2010) reported that the 15-d fungal pretreatment of corn stalks with I. lacteus modied the lignin structure and signicantly facilitated lignin degradation and xylan removal during mild alkaline pretreatment (1.5% NaOH, 3075 C for 15120 min). The synergic effect largely depended on the severity of alkaline pretreatment. The less the severity of the alkaline pretreatment, the more the cellulose digestibility was improved by fungal pretreatment. In other words, the fungal pretreatment reduced the required severity of alkaline pretreatment. For example, at the enzyme loading of 30 FPU/g solid, an 80% glucose yield was obtained with corn stalk pretreated by alkaline solution at 60 C for 120 min, while, with

Table 2 Combined white rot fungal pretreatment and physical/chemical pretreatment. Fungal pretreatment Physical/chemical pretreatment Prior Prior Prior

a

fungal pretreatment for 15 d, the similar yield was obtained by less severe alkaline pretreatment conditions (60 C for 30 min or 30 C for 120 min). Similar results were also reported by Ma et al. (2010), who observed that acid pretreatment (0.25% H2SO4, 28100 C for 15 60 min) following 15-d fungal pretreatment improved enzymatic hydrolysis and ethanol yields of water hyacinth by 12 times over acid pretreatment alone. Ethanol yields of woody biomass such as Japanese cedar and beech wood resulting from combined C. subvermispora pretreatment and ethanolysis were about 12 fold higher than that without fungal pretreatment (Baba et al., 2011; Itoh et al., 2003). Fungal pretreatment of beech wood meal with P. chrysosporium and then steam explosion also increased saccharication yield compared to a single pretreatment (Sawada et al., 1995). However, the effectiveness of combined pretreatment depended on the operational conditions of steam explosion. A severe steam explosion at a higher pretreatment temperature and time could cause condensation of Klason lignin with carbohydrate oligomers and methanol soluble lignin (Sawada et al., 1995). As a result, these newly formed compounds can lower the susceptibility of the co-treated substrate to hydrolytic enzymes. Therefore, regardless of chemical or physical pretreatment following fungal pretreatment, a moderate subsequent pretreatment method is suggested to achieve a more synergic effect exerted by fungal pretreatment. Fungal pretreatment as the second step of combined pretreatment is also summarized in Table 2. As one physical pretreatment method, ultrasonic pretreatment has been applied to degrade -O-4 and -O-4 linkages in lignin (Seino et al., 2001), oxidize hydroxyl groups by radicals and H2O2 formed during ultrasonic cavitation (Tan et al., 1985), and increase ber wall porosity (Laine and Goring, 1977). The synergistic effect of ultrasonic pretreatment on the subsequent fungal pretreatment was evident. As reported in the study of Kadimaliev et al. (2003), prior ultrasonic pretreatment (22 kHz, 10 min) improved fungal delignication of beech and pine sawdust with Panus (Lentinus) tigrinus. Yu et al. (2008) combined more powerful ultrasonic pretreatment (250 w, 40 kHz, 30 min) with fungal pretreatment and found that during 18-d fungal pretreatment with P. ostreatus, lignin degradation on ultrasonic-modied rice hull was much higher than that of raw hull. The substrate resulting from combined pretreatment had

Substrate Corn stalk

Effectiveness

References Yu et al. (2010) Ma et al. (2010) Itoh et al. (2003)

Alkaline (NaOH) Diluted acid Ethanolysis

Prior Prior Post b Post

Ethanolysis Steam explosion Alkaline (NaOH) H2O2

Post Post Post Post

Acid (Sulfuric acid) Alkaline (Ammonia) Ultrasound Ultrasound

Post Post

a b

Hot water extraction Liquid hot water pretreatment

Fungal pretreatment improved delignication and xylan removal during mild alkaline pretreatment Water hyacinth Combined pretreatment increased sugar and ethanol yields by 12 folds over single acid pretreatment Beech wood chips Combined pretreatment saved 15% electricity and increased the ethanol yield by up to 1.6 times over ethanolysis alone. Japanese cedar wood Combined pretreatment increased the sugar yield by 7 times over ethanolysis alone Beech wood meal Combined pretreatment improved overall sugar yield Wheat straw Strong alkaline pretreatment masked the synergistic effect of fungal pretreatment on the combined process Rice hull H2O2 enhanced fungal delignication, resulting in a sugar yield that is comparable to that obtained from a long-term sole fungal pretreatment. Beechwood and pine sawdust Acid pretreatment reduced lignin degradation on fungal pretreatment Beechwood and pine sawdust Alkaline pretreatment reduced lignin degradation on fungal pretreatment Beechwood and pine sawdust Ultrasound accelerated fungal lignin degradation Rice hull Ultrasound accelerated fungal delignication while slightly increased cellulose and hemicellulose loss, resulting in a higher sugar yield compared to the fungal pretreatment alone. wheat straw Hot water extraction improved delignication and the resulting sugar yield Soybean straw Liquid hot water pretreatment improved delignication and the resulting sugar yield

Baba et al. (2011) Sawada et al. (1995) Hatakka (1983) Yu et al. (2009b)

Kadimaliev et al. (2003) Kadimaliev et al. (2003) Kadimaliev et al. (2003) Yu et al. (2009b)

Wan and Li (2011) Wan and Li (2011)

Prior indicates that fungal pretreatment is the rst step of combined pretreatment. Post indicates that fungal pretreatment is the subsequent step of combined pretreatment.

1454

C. Wan, Y. Li / Biotechnology Advances 30 (2012) 14471457

a 20% higher glucose yield than the sole fungal-pretreated material. Moreover, this glucose yield was comparable to that obtained with 42-d fungal-pretreated, which indicated that pre-modication of the feedstock by ultrasound led to a shortened fungal pretreatment time. In the same study, H2O2 pretreatment (2% w/v, 48 h) performed better on the following fungal delignication than ultrasound pretreatment. Hydrothermal treatment improved the fungal degradation of wheat straw and soybean straw that appeared to be strongly resistant to C. subvermispora degradation (Wan and Li, 2011). The hot water extraction (85 C for 10 min at atmospheric pressure) facilitated fungal pretreatment of wheat straw by removing water soluble extractives but not of soybean straw. A pressurized hot water treatment (170 C for 3 min at 110 psi), altering rather than degrading the cell wall structure, nally facilitated the fungal degradation of soybean straw, and the glucose yield of the combined liquid hot water and fungal pretreatment reached about 65% when the cellulase loading for enzymatic hydrolysis was 10 FPU/g solid (Wan and Li, 2011) . In contrast to the effectiveness of mild chemical pretreatment, severe prior chemical pretreatment could mask the effect of fungal pretreatment and result in no or less improvement on lignin degradation and saccharication yield. Ammonia (5%, 165 C for 10 min) and sulfuric acid (2.5%, 165 C for 10 min) before fungal pretreatment resulted in negative impacts on lignin degradation of both beech and pine sawdust (Kadimaliev et al., 2003). This problem was presumed to be due to partial degradation of polysaccharides caused by chemical pretreatment, which provided more easily accessible compounds for the fungal growth; thus, more carbohydrates were consumed during fungal pretreatment while fungal lignin degradation activity was probably also depressed. Similarly, NaOH pretreatment (0.4 g NaOH/g straw, 115 C for 10 min) prior to fungal pretreatment did not improve sugar yields of wheat straw (Hatakka, 1983) due to degradation caused by severe alkaline pretreatment. Therefore, it can be concluded that the severity of physical or chemical pretreatment strongly affects the performance of the combined pretreatment and a mild prior pretreatment resulting in sufcient modication on biomass could favor fungal pretreatment. Enzymatic treatment As mentioned in the above section, ligninolytic enzymes, mainly lignin peroxidase (LiP), manganese peroxidase (MnP), and laccase, are responsible for delignication by white rot fungi. However, the slow fungal growth (several weeks to months) and holocellulose loss are the major problems related to fungal pretreatment. The use of ligninolytic enzymes for direct treatment of lignocellulose, which only takes several hours to days (Ramos et al., 2004), has the potential to overcome the problems of fungal pretreatment. Ligninolytic enzymes were shown to cleave lignin model compounds oxidatively in vitro (Tuor et al., 1992). The oxidation by peroxidase is highly dependent on oxygen as the nal electron acceptor (Ibarra et al., 2006) and H2O2 is usually used as a source of O2 (Khazaal et al., 1993). For oxidation of lignin by laccase, chemical mediators, such as 1-hydroxybenzotrizole (HBT) and N-hydroxy-Nphenylacetamide (NHA), are extensively used for radical formation during enzyme oxidation (Palonen and Viikari, 2004). These radicals can react with aromatic acid compounds of lignin. Therefore, the ligninolytic enzyme-based treatment can be considered as an enzymecatalyzed oxidative treatment (Ibarra et al., 2006). Temperature, pH, and enzyme concentration are important factors for enzyme treatment. Ramos et al. (2004) tested the effect of treatment of debrated sugarcane bagasse with crude enzyme extract from P. chrysosporium on the production of mechanical pulps. It was found that 36-hour enzymatic treatment with the addition of H2O2 resulted in higher pulp yield than the 2-week fungal pretreatment. The treatment with enzymatic extract isolated from white rot fungi also improved in vitro digestibility of wheat straw as reported by Rodrigues et al.

(2008). However, this effect seemed strongly dependent on synergistic effects between extracted enzymes. For enzymatic treatment of diluted acid-pretreated wheat straw, laccase had a synergistic effect on cellulase for enhancing glucose yield but was less effective than xylanse and feruloyl esterase (Tabka et al., 2006). A maximal increase of 21% in the saccharication rate of steam-treated softwood was obtained from sequential combination of laccase-mediator treatment and commercial cellulase hydrolysis (Palonen and Viikari, 2004). White rot fungi may serve as a good producer of extracellular enzymes including oxidative enzymes and polysaccharide-degrading enzymes. The isolated enzyme complex has the potential to replace fungal pretreatment to avoid long pretreatment and the possible concomitant degradation of lignin and holocellulose. However, enzymatic treatment is immature and the efciency of oxidative enzymes largely relies on chemical mediators. On the other hand, the fungalpretreated substrate containing the enzyme complex could be directly used for the subsequent digestion and fermentation if it acts on the synergism between commercial enzymes. Modeling and scale-up Solid state fungal pretreatment involves the degradation of the substrate taking place in absence (or near absence) of free water, due to release of extracellular enzymes or cell bound enzymes to the external environment. Both interparticle and intraparticle mass transfer occurs in solid state fungal pretreatment. The intraparticle mass transfer refers to the transfer of nutrients and enzymes within the substrate solids. However, in aerobic digestion, the transfer of oxygen to the growing microorganisms is the major interparticle mass transfer. Modeling of microscale phenomena, such as the microorganism growth behavior, mass diffusion, and particle size reductions, can describe how microscale processes inuence growth kinetics of microorganisms. The growth kinetics models, such as linear, exponential, logistic, and Monod equation, have been used to describe microorganism growth. The logistic model, which is most commonly used, assumes the growth rate () is independent of substrate concentration (Saucedo-Castaneda et al., 1990). Some studies have proposed to express the growth rate as a function of temperature, which varies during growth (Fanaei and Vaziri, 2009; SaucedoCastaneda et al., 1990). Due to the difculty in separating the lamentous fungal biomass from the substrate, various indirect measurements, such as dry mass loss, oxygen consumption/CO2 production, and cell specic compounds, have been proposed as fungal biomass indicators (Mitchell et al., 2006). Cell specic compounds such as glutamate or ergosterol content are often used for indirect measurements of fungal biomass (Joergensen, 2000; Mitchell et al., 2006). Due to lack of free water and low conductivity of solid particles, heat generation related to metabolic activities of the microorganism growth causes temperature gradients in solid state fungal pretreatment; thus, modeling of temperature gradient and optimizing heat removal are the major considerations in the design of solid state bioreactors. Various bioreactors have been developed for solid state fermentation, including tray reactors, packed-bed, rotating drums, and stirred bioreactors (Mitchell et al., 2006). Although mixing can improve heat dissipation, it is only useful for solid state fungal pretreatment in which the fungus does not bind the solid particles together. For fungal fermentation with the interparticle hyphal bridges across the substrate, mixing is deleterious to bioreactor performance because of disruption of the hyphae between particles and the shear force resulting from mixing (Fanaei and Vaziri, 2009; Mitchell et al., 2000). Instead, static operation is preferred for binding the substrate bed with fungi that does not tolerate mixing. Two types of reactors, tray and packed-bed bioreactors, are commonly used for this operation. The tray reactors are simple but suitable for low volume production due to a limited loading capacity. In packed-bed reactors, modeling is mostly focused on temperature gradients and heat transfer while

C. Wan, Y. Li / Biotechnology Advances 30 (2012) 14471457

1455

neglecting oxygen transfer because heat transfer has a greater impact on microorganism growth than oxygen transfer (Mitchell et al., 2000). Heat transfer with a water jacket is impractical for a large bioreactor as it requires a large diameter water jacket. Instead, convective heat transfer, such as forced humid air, is more practical to remove the heat and also prevents the substrate bed from drying out. The traditional packed-bed bioreactor has the problem of axial temperature gradients. It causes signicant water evaporation and high temperature at the outlet of the bed even if saturated air is supplied. In contrast, the Zymotis packed-bed bioreactor has internal heat transfer plates, which has advantages over traditional packedbed bioreactors, including a decrease in axial temperature gradients and evaporation rates (Mitchell et al., 2006). However, the substrate loading and unloading is difcult in the Zymotis bioreactor due to the presence of the heat transfer plates. Also, the water condensation on the exposed surface limits oxygen on the top of the bed. Scott et al. (1998) tested both the tubular reactor and chip piles for the scale-up of fungal pretreatment of wood chips for biopulps. The tubular reactors such as PVC tubes and silos were used as packed-bed reactors. The larger scale-up trial of up to 40 t was done in an outdoor wood chip pile; however, the heat gradient was still a problem. Compared to the tubular reactors, the chip piles are more difcult to control due to 2- to 3-dimensional airow. In addition, the surface of the chip piles is more exposed to undesirable fungal species, and air ow and weather changes. Less controlled chip piles could also lead to reduction and variation of pulp quality due to more degradation of cellulose which was caused by undesirable fungi and bacteria. Limitations and potentials Generally speaking, fungal pretreatment with selective lignindegrading white rot fungi has been shown to have a signicant impact on degradation and digestibility improvement for a wide range of feedstocks. Lignin in biomass is one of the major barriers to enzymatic hydrolysis, and lignin removal can increase pore size in the substrate and provide more accessible surface area to cellulase (Taniguchi et al., 2005; Yu et al., 2009a). Therefore, lignin degradation is the key indicator to the performance of fungal pretreatment, and good correlations between extent of lignin and polysaccharide digestibility were reported in many studies (Sawada et al., 1995; Taniguchi et al., 2005; Zhang et al., 2007b). However, fungal degradation may occur slowly and thus long pretreatment time is required to achieve a relatively high lignin removal and cellulose saccharication. Concerns have been raised about increased costs and contamination due to very long pretreatment time. Combined fungal pretreatment with other pretreatment methods has been shown to synergistically improve enzymatic digestibility and thus has the potential to shorten the fungal pretreatment time. Fungal pretreatment as an application of on-farm wet storage is a promising direction that addresses both the long pretreatment time and biomass storage concerns. Currently, wet storage (>45% moisture) is receiving interest for on-farm storage of biomass, and has advantages over dry storage including low risk of re, reduced weather related delay during harvest, reduced harvesting costs, and improved feedstock uniformity (Atchison and Hettenhaus, 2003; Digman et al., 2007; Shinners et al., 2007). Chen et al. (2007) studied ensiling agricultural residues (barley straw, triticale straw, wheat straw, cotton straw, and triticale hay) for bioethanol production. The ensilage was conducted in sealed jars at room temperatures for 96 d. It was found that holocellulose loss ranged from 1.31% to 9.93% as a result of ensiling while no lignin degradation was observed. About 510% increase in sugar yield over untreated feedstocks was observed with ensiled feedstocks. In contrast, enzymatic digestibility resulting from fungal pretreatment was much higher as a result of substantial lignin degradation (Table 1). For example, the overall glucose yield

of corn stover after 35-d fungal pretreatment reached 67%, which was more than 45% higher than the untreated (Wan and Li, 2010b). The glucose yield obtained from optimized enzymatic hydrolysis is comparable to that from thermo-chemical pretreatment (Wan and Li, 2010a). Conclusions and future perspectives Compared to current leading thermal or chemical pretreatment processes, fungal pretreatment with white rot fungi is an environmentalfriendly and energy-efcient process. White rot fungi with a high selectivity of lignin degradation over cellulose loss are important for fungal pretreatment. Moisture and particle size of the feedstock, aeration, and pretreatment time are critical for fungal growth and metabolism to achieve good performance. Complete decontamination may not be necessary since white rot fungi can survive in contamination and actively act on degradation. Fungal pretreatment prior to mild physical and chemical pretreatment has shown synergism on the improvement of cellulose digestibility with advantages similar to that of the biopulping process. Long pretreatment time is a major and common barrier for the application of fungal pretreatment. Using fungal treatment concurrently with on-farm wet storage is a promising option to solve the long pretreatment time issue. Another option is to apply fungal pretreatment prior to physical or thermo-chemical pretreatment. As short-term fungal pretreatment can modify the cell walls before evident degradation takes place, the required pretreatment severity of thermo-chemical pretreatment can be substantially reduced. Acknowledgments This work was supported by funding from North Central Sun Grant Program (No. GRT00013735), USDA NIFA 1890 Capacity Building Program, and Ohio Agricultural Research and Development Center Seeds Program. The authors wish to thank Mrs. Mary Wicks and Dr. Jian Shi in the Department of Food, Agricultural and Biological Engineering of the Ohio State University for reading through the manuscript and providing useful suggestions. References

Akhtar M, Blanchette RA, Myers G, Kirk TK. An overview of biochemical pulping research. In: Young RA, Akhtar M, editors. Environmental friendly technologies for the pulp and paper industry. New York: Wiley, Inc.; 1998. p. 30940. Akin DE, Sethuraman A, Morrison III WH, Martin SA, Eriksson KEL. Microbial delignication with white rot fungi improves forage digestibility. Appl Environ Microbiol 1993;59:427482. Akin DE, Rigsby LL, Sethuraman A, Morrison WH, Gamble GR, Eriksson KEL. Alterations in structure, chemistry, and biodegradability of grass lignocellulose treated with the white-rot fungi Ceriporiopsis subvermispora and Cyathus stercoreus. Appl Environ Microbiol 1995;61:1591-8. Alvarez JM, Canessa P, Mancilla RA, Polanco R, Santibez PA, Vicua R. Expression of genes encoding laccase and manganese-dependent peroxidase in the fungus Ceriporiopsis subvermispora is mediated by an ACE1-like copper-st transcription factor. Fungal Genet Biol 2009;46:10411. Asgher M, Asad MJ, Legge RL. Enhanced lignin peroxidase synthesis by Phanerochaete chrysosporium in solid state bioprocessing of a lignocellulosic substrate. World J Microb Biotechnol 2006;22:44953. Atchison JE, Hettenhaus JR. Innovative methods for corn stover collecting, handling, storing and transportation. NREL/SR-510-33893. Golden, CO, USA: National Renewable Energy laboratory; 2003. Baba Y, Tanabe T, Shirai N, Watanabe T, Honda Y, Watanabe T. Pretreatment of Japanese cedar wood by white rot fungi and ethanolysis for bioethanol production. Biomass Bioenerg 2011;35:3204. Bak JS, Ko JK, Choi IG, Park YC, Seo JH, Kim KH. Fungal pretreatment of lignocellulose by Phanerochaete chrysosporium to produce ethanol from rice straw. Biotechnol Bioeng 2009;104:47182. Blanchette RA, Krueger EW, Haight JE, Akhtar M, Akin DE. Cell wall alterations in loblolly pine wood decayed by the white-rot fungus, Ceriporiopsis subvermispora. J Biotechnol 1997;53:20313. Bogan BW, Schoenike B, Lamar RT, Cullen D. Expression of lip genes during growth in soil and oxidation of anthracene by Phanerochaete chrysosporium. Appl Environ Microbiol 1996;62:3697703.

1456

C. Wan, Y. Li / Biotechnology Advances 30 (2012) 14471457 Joergensen RG. Ergosterol and microbial biomass in the rhizosphere of grassland soils. Soil Biol Biochem 2000;32:64752. Johnson TM, Li JKK. Heterologous expression and characterization of an active lignin peroxidase from Phanerochaete chrysosporium using recombinant baculovirus. Arch Biochem Biophys 1991;291:3718. Jnsson LJ, Saloheimo M, Penttil M. Laccase from the white-rot fungus Trametes versicolor: cDNA cloning of lcc1 and expression in Pichia pastoris. Curr Genet 1997;32:42530. Kadimaliev DA, Revin VV, Atykyan NA, Samuilov VD. Effect of wood modication on lignin consumption and synthesis of lignolytic enzymes by the fungus Panus (Lentinus) tigrinus. Appl Biochem Micro 2003;39:48892. Kang KY, Jo BM, Oh JS, Manseld SD. The effects of biopulping on chemical and energy consumption during kraft pulping of hybrid poplar. Wood Fiber Sci 2003;35:594600. Kapich AN, Jensen KA, Hammel KE. Peroxyl radicals are potential agents of lignin biodegradation. FEBS Lett 1999;461:1159. Keller F, Hamilton J, Nguyen Q. Microbial pretreatment of biomass. Appl Biochem Biotechnol 2003;105:2741. Khazaal KA, Owen E, Dodson AP, Palmer J, Harvey P. Treatment of barley straw with ligninaseeffect on activity and fate of the enzyme shortly after being added to straw. Anim Feed Sci Technol 1993;41:1521. Kirk T, Moore W. Removing lignin from wood with white-rot fungi and digestibility of resulting wood. Wood Fiber Sci 1972;4:729. Kirk TK, Tien M, Kersten PJ, Mozuch MD, Kalyanaraman B. Ligninase of Phanerochaete chrysosporiummechanism of its degradation of the nonphenolic arylglycerol beta-aryl ether substructure of lignin. Biochem J 1986;236:27987. Laine JE, Goring DAI. Inuence of ultrasonic irradiation on the properties of cellulosic bers. Cell Chem Technol 1977;11:5617. Lee JW, Gwak KS, Park JY, Park MJ, Choi DH, Kwon M, et al. Biological pretreatment of softwood Pinus densiora by three white rot fungi. J Microbiol 2007;45:48591. Lindenfelser LA, Detroy RW, Ramstack JM, Worden KA. Biological modication of the lignin and cellulose components of wheat straw by Pleurotus ostreatus. Dev Ind Microbiol 1979;20:54151. Locci E, Laconi S, Pompei R, Scano P, Lai A, Marincola FC. Wheat bran biodegradation by Pleurotus ostreatus: a solid-state Carbon-13 NMR study. Bioresour Technol 2008;99: 427984. Ma F, Yang N, Xu C, Yu H, Wu J, Zhang X. Combination of biological pretreatment with mild acid pretreatment for enzymatic hydrolysis and ethanol production from water hyacinth. Bioresour Technol 2010;101:96004. Machuca A, Ferraz A. Hydrolytic and oxidative enzymes produced by white- and brown-rot fungi during Eucalyptus grandis decay in solid medium. Enzyme Microb Technol 2001;29:38691. Mansur M, Suarez T, Gonzalez AE. Differential gene expression in the laccase gene family from basidiomycete I-62 (CECT 20197). Arch Biochem Biophys 1998;64: 7714. Manubens A, Canessa P, Folch C, Avila M, Salas L, Vicuna R. Manganese affects the production of laccase in the basidiomycete Ceriporiopsis subvermispora. FEMS Microbiol Lett 2007;275:13945. Marnyye A, Velsquez C, Mata G, Michel SJ. Waste-reducing cultivation of Pleurotus ostreatus and Pleurotus pulmonarius on coffee pulp: changes in the production of some lignocellulolytic enzymes. World J Microb Biotechnol 2002;18:2017. Martinez MJ, RuizDuenas FJ, Guillen F, Martinez AT. Purication and catalytic properties of two manganese peroxidase isoenzymes from Pleurotus eryngii. Eur J Biochem 1996;237:42432. Membrillo I, Sanchez C, Meneses M, Favela E, Loera O. Effect of substrate particle size and additional nitrogen source on production of lignocellulolytic enzymes by Pleurotus ostreatus strains. Bioresour Technol 2008;99:78427. Mes-Hartree M, Yu EKC, Reid ID, Saddler JN. Suitability of aspenwood biologically delignied with Pheblia tremellosus for fermentation to ethanol or butanediol. Appl Microbiol Biotechnol 1987;26:1205. Messner K, Koller K, Wall MB, Akhtar M, Scott GM. Fungal treatment or wood chips for chemical pulping. In: Young RA, Akhtar M, editors. Environmental friendly technologies for the pulp and paper industry. New York: Wiley, Inc.; 1998. p. 385419. Mester T, Field JA. Characterization of a novel manganese peroxidase-lignin peroxidase hybrid isozyme produced by Bjerkandera species strain BOS55 in the absence of manganese. J Biol Chem 1998;273:154127. Mester T, Dejong E, Field JA. Manganese regulation of veratryl alcohol in white-rot fungi and its indirect effect on lignin peroxidase. Appl Environ Microbiol 1995;61: 18817. Mitchell DA, Krieger N, Stuart DM, Pandey A. New developments in solid-state fermentation: II. Rational approaches to the design, operation and scale-up of bioreactors. Process Biochem 2000;35:121125. Mitchell DA, Krieger N, Berovic M. Solid-state fermentation bioreactors: fundamentals of design and operation. New York: Springer-Verlag; 2006. Morgenstern I, Robertson DL, Hibbett DS. Characterization of three mnp genes of Fomitiporia mediterranea and report of additional class II peroxidases in the order Hymenochaetales. Appl Environ Microbiol 2010;76:643140. Mosier N, Wyman CE, Dale B, Elander R, Lee YY, Holtzapple M, et al. Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 2005;96:67386. Nigam P, Pandey A. Solid-state fermentation technology for bioconversion of biomass and agricultural residues. In: Nigam P, Pandey A, editors. Biotechnology for agro-industrial residues utilisation. Netherlands: Springer; 2009. p. 197221. Okamoto K, Narayama S, Katsuo A, Shigematsui I, Yanase H. Biosynthesis of p-anisaldehyde by the white-rot basidiomycete Pleurotus ostreatus. J Biosci Bioeng 2002;93:20710. Palonen H, Viikari L. Role of oxidative enzymatic treatments on enzymatic hydrolysis of softwood. Biotechnol Bioeng 2004;86:5507.