Professional Documents

Culture Documents

F 85154

Uploaded by

nazar750Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F 85154

Uploaded by

nazar750Copyright:

Available Formats

FOAM CHAMBERS

Data/Specifications

FEATURES Choice of four foam chamber sizes for various foam solution flow rate requirements Hinged inspection hatch with captive bolt securement for ease of inspection and maintenance Choice of primed or standard red finish; or polyamide CR epoxy for marine and other corrosive environments Teflon vapor seal allows unrestricted flow of expanded foam Convenient vapor seal replacement without removal of retaining bolts UL Listed

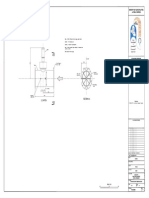

HINGED INSPECTION HATCH CHAMBER BODY OUTLET FLANGE

GASKETS TANK WALL

SPLIT DEFLECTOR

INLET FLANGE

APPLICATION ANSUL foam chambers are air-aspirating foam discharge devices that are used to protect various types of flammable liquid storage tanks including open top floating roof tanks and cone roof tanks with or without internal floaters. Additional applications include most types of open tanks where flammable liquid products are involved. Foam chambers are defined by NFPA 11 as Type II discharge outlets for delivering foam to the surface of a flammable liquid. They are commonly used with bladder tanks, balanced pressure pump proportioning systems, line proportioners, or foam trucks. These foam chambers can be used with ANSUL low expansion foam agents as determined suitable for the flammable liquid being protected.

ORIFICE PLATE

GASKETS

001257

MOUNTING PAD

SPECIFICATIONS The foam chamber assembly shall consist of a chamber body with integral foam maker and orifice plate. A foam deflector and foam chamber mounting pad shall be included with the assembly as required. The foam chamber body shall be of steel construction with a choice of primed, standard red, or CR epoxy finish. The discharge outlet shall be of the flat-faced flange design that may be welded or bolted to the storage tank. For ease of access to the vapor seal, the chamber body shall contain a hinged inspection hatch secured with stainless steel captive bolts. The hatch shall also contain a lifting handle designed to support the weight of the chamber for hoisting. The foam maker shall contain a stainless steel screen that is cylindrically shaped to conform to the air inlet surface to help prevent damage. The vapor seal shall be of teflon construction to allow an unrestricted flow. The teflon vapor seal shall be designed of a thickness to meet the UL required burst pressure range of 10 to 25 psi (0.69 to 1.72 bar). The vapor seal retainer shall be designed with slotted keyholes to eliminate bolt removal during replacement. The inlet to the foam maker shall be a raised-faced flange with an orifice sized to allow the required flow rate of foam solution at the available pressure. A split foam deflector shall be provided for either bolting or welding to the mounting surface, or for installation from the outside wall of the storage tank. For bolting applications, a mounting pad shall be available with a stud pattern compatible with the flat-faced flange of the foam chamber body and the foam deflector. A stainless steel data nameplate shall be attached to the foam chamber hatch. The plate shall specify manufacturer, model number, and part number.

DESCRIPTION The ANSUL foam chambers consist of a foam expansion chamber and an integral foam maker with a stainless steel screened air inlet. A removable orifice plate located at the flanged inlet to the foam maker is sized to deliver the required flow rate of foam solution at a specified inlet pressure. A frangible teflon vapor seal is burst upon entry of foam solution allowing an unrestricted flow of expanded foam into the chamber body. From the chamber body, the foam flows through the foam deflector which disperses the foam into the storage tank. The chamber vapor seal is accessible for inspection and service through a hinged inspection hatch that is secured with captive bolts. The hatch also contains a lifting handle that is designed to support the weight of the foam chamber. The foam deflector directs the foam stream down the tank sidewall to lessen the submergence of the foam and agitation of the fuel surface (Type II application). The foam deflector is a split (two-piece) style. The split deflector allows for either bolting or welding to storage tanks when installation may be performed from both sides of the tank wall as with newly constructed tanks. The split deflector also allows for insertion of the deflector through the flange opening from the outside wall as is often required with tanks already in service. The foam chamber and deflector can be bolted to the storage tank using a mounting pad. The pad contains mounting studs to fit standard flange holes.

FLOW RANGE The flow rate of the foam chamber is determined by the orifice size and the inlet pressure. The flow ranges listed in the following table are based on 40 psi (2.76 bar) using the smallest orifice for the minimum flow and 100 psi (6.9 bar) using the largest orifice for the maximum flow. Model _____ AFC-90 AFC-170 AFC-330 AFC-550 Flow Range __________ 49 to 151 gpm (185 to 572 Lpm) 94 to 279 gpm (356 to 1033 Lpm) 183 to 610 gpm (693 to 2309 Lpm) 350 to 980 gpm (1325 to 3709 Lpm) K-Factor Range ______ 7.8 to 15.1 14.9 to 27.9 28.9 to 61.0 55.3 to 98.0

DIMENSION TABLE Dimension A B C D E F G H I J K L M N O P Q R AFC-90 26 1/16 in (66.2 cm) 15 5/16 in (38.9 cm) 8 1/2 in (21.6 cm) 8 3/8 in (21.2 cm) 7 in (17.8 cm) 2 1/2 in (6.4 cm) 3 1/4 in (8.3 cm) 5 5/16 in (13.5 cm) 8 in (20.3 cm) 4 5/8 in (11.7 cm) 8 in (20.3 cm) 12 in (30.5 cm) 4 1/2 in (11.4 cm) 7 1/2 in (19.1 cm) 3/4 in (1.9 cm) 2 7/8 in (7.3 cm) 5 1/2 in (13.9 cm) 3/4 in (1.9 cm) AFC-170 31 7/8 in (81.0 cm) 19 5/8 in (49.8 cm) 10 in (25.4 cm) 10 3/8 in (26.4 cm) 9 in (22.9 cm) 3 in (7.6 cm) 4 1/16 in (10.3 cm) 7 3/8 in (18.7 cm) 9 1/2 in (24.1 cm) 6 1/8 in (15.6 cm) 12 in (30.5 cm) 18 in (45.7 cm) 6 5/8 in (16.8 cm) 9 1/2 in (24.1 cm) 7/8 in (2.2 cm) 3 1/2 in (8.9 cm) 6 in (15.2 cm) 3/4 in (1.9 cm) AFC-330 35 3/8 in (89.9 cm) 20 5/8 in (52.4 cm) 11 1/8 in (28.3 cm) 12 3/8 in (31.4 cm) 10 in (25.4 cm) 4 in (10.2 cm) 5 in (12.7 cm) 9 1/8 in (23.1 cm) 11 in (27.9 cm) 7 3/4 in (19.7 cm) 16 in (40.6 cm) 24 in (61.0 cm) 8 5/8 in (21.9 cm) 11 3/4 in (29.8 cm) 7/8 in (2.2 cm) 4 1/2 in (11.4 cm) 7 1/2 in (19.1 cm) 3/4 in (1.9 cm) AFC-550 42 in (106.7 cm) 24 3/4 in (62.9 cm) 12 3/8 in (31.4 cm) 15 in (38.1 cm) 12 in (30.5 cm) 6 in (15.2 cm) 6 7/8 in (17.5 cm) 9 3/4 in (24.8 cm) 12 in (30.5 cm) 8 1/4 in (20.9 cm) 20 in (50.8 cm) 30 in (76.2 cm) 10 3/4 in (27.3 cm) 14 1/4 in (36.2 cm) 1 in (2.5 cm) 6 5/8 in (16.8 cm) 9 1/2 in (24.1 cm) 7/8 in (2.2 cm)

To determine flow rates for specific applications and proper orifice sizing, consult Ansul Incorporated, Technical Services, Marinette, WI 541432542.

OUTLET FLANGE

OUTLET FLANGE

O AFC-550 O AFC-90, 170, 330

E D

C H

G B

BOLTING WITH SPLIT DEFLECTOR F INLET FLANGE

WELDING WITH SPLIT DEFLECTOR

BOLTING WITH PAD AND SPLIT DEFLECTOR

001259

INLET FLANGE (F DETAIL)

INLET FLANGE (F DETAIL)

R AFC-90, 170 AFC-330, 550

001260

ORDERING INFORMATION Approximate Shipping Weight lb (kg) _________ 60 60 60 5 5 100 100 100 10 10 145 145 145 20 20 270 270 270 30 30 (27.2) (27.2) (27.2) (2.3) (2.3) (45.4) (45.4) (45.4) (4.5) (4.5) (65.8) (65.8) (65.8) (9.1) (9.1) (122.5) (122.5) (122.5) (13.6) (13.6)

Part No. Description _________ _______ Foam Chambers 75887 Foam Chamber/Maker, AFC-90, Primed 75883 Foam Chamber/Maker, AFC-90, Standard Red 75879 Foam Chamber/Maker, AFC-90, CR EpoxyRed 74376 Split Deflector, AFC-90, Primed 428637 Shallow Deflector, AFC-90, Primed 75888 Foam Chamber/Maker, AFC-170, Primed 75884 Foam Chamber/Maker, AFC-170, Standard Red 75880 Foam Chamber/Maker, AFC-170, CR Epoxy Red 74380 Split Deflector, AFC-170, Primed 428638 Shallow Deflector, AFC-170, Primed 75889 Foam Chamber/Maker, AFC-330, Primed 75885 Foam Chamber/Maker, AFC-330, Standard Red 75881 Foam Chamber/Maker, AFC-330, CR Epoxy Red 74384 Split Deflector, AFC-330, Primed 428639 Shallow Deflector, AFC-330, Primed 75890 Foam Chamber/Maker, AFC-550, Primed 75886 Foam Chamber/Maker, AFC-550, Standard Red 75882 Foam Chamber/Maker, AFC-550, CR Epoxy Red 74388 Split Deflector, AFC-550, Primed 428640 Shallow Deflector, AFC-550, Primed

Note: Shallow deflectors are a lower protrusion option than the standard split deflectors illustrated on Page 3. Shallow deflectors may be required for cone roof tanks with internal floaters where the protrusion of a split deflector interferes with the internal floater operation.

Foam Chamber Accessories 74392 Foam Chamber AFC-90 Mounting Pad, Primed 74390 Foam Chamber AFC-90 Mounting Pad, CR Epoxy Red 74396 Foam Chamber AFC-170 Mounting Pad, Primed 74394 Foam Chamber AFC-170 Mounting Pad, CR Epoxy Red 74400 Foam Chamber AFC-330 Mounting Pad, Primed 74398 Foam Chamber AFC-330 Mounting Pad, CR Epoxy Red 74404 Foam Chamber AFC-550 Mounting Pad, Primed 74402 Foam Chamber AFC-550 Mounting Pad, CR Epoxy Red 418581 Foam Chamber AFC-90 Vapor Seal Assembly 418582 Foam Chamber AFC-170 Vapor Seal Assembly 418583 Foam Chamber AFC-330 Vapor Seal Assembly 418584 Foam Chamber AFC-550 Vapor Seal Assembly 75985 Foam Chamber AFC-90 Cover Gasket 75986 Foam Chamber AFC-170 Cover Gasket Foam Chamber AFC-330 Cover Gasket 75987 75988 Foam Chamber AFC-550 Cover Gasket 74610 Foam Chamber AFC-90 Orifice Plate 74611 Foam Chamber AFC-170 Orifice Plate 74612 Foam Chamber AFC-330 Orifice Plate Foam Chamber AFC-550 Orifice Plate 74613 74408 Foam Chamber AFC-90 Foam Diverter Test Tube 74412 Foam Chamber AFC-170 Foam Diverter Test Tube 74416 Foam Chamber AFC-330 Foam Diverter Test Tube Foam Chamber AFC-550 Foam Diverter Test Tube 74420 75968 Foam Chamber Cover Screw, All Models

15 15 20 20 35 35 50 50 0.5 0.5 0.5 0.5 0.3 0.3 0.3 0.3 1 1 1 1 15 20 40 65 0.3

(6.8) (6.8) (9.1) (9.1) (15.9) (15.9) (22.7) (22.7) (0.23) (0.23) (0.23) (0.23) (0.14) (0.14) (0.14) (0.14) (0.45) (0.45) (0.45) (0.45) (6.8) (9.1) (18.1) (29.5) (0.14)

Note: Foam chambers, mounting pads, foam deflectors are available constructed of 304 stainless steel. Contact Ansul Technical Services for pricing and availability.

ANSUL is a trademark of Ansul Incorporated or its affiliates.

Ansul Incorporated Marinette, WI 54143-2542

715-735-7411 www.ansul.com

Copyright 2007 Ansul Incorporated Form No. F-85154-6

You might also like

- Foam CHamberDocument4 pagesFoam CHamberempacao1No ratings yet

- Foam ChamberrDocument4 pagesFoam ChamberrFauziAidilSukmaNo ratings yet

- Foam ChambersDocument4 pagesFoam ChambersIvo KovachevNo ratings yet

- Camara AnsulDocument4 pagesCamara AnsulLuis del BarcoNo ratings yet

- Camara de Espuma ANSUL AFC 170 PDFDocument6 pagesCamara de Espuma ANSUL AFC 170 PDFfercho`sNo ratings yet

- HD 254 Foam Chamer Model-FCADocument6 pagesHD 254 Foam Chamer Model-FCAktc8120No ratings yet

- CG 2015238 01 Foam ChambersDocument6 pagesCG 2015238 01 Foam ChambersDavid TjNo ratings yet

- Spesifikasi Foam Chamber - Ansul - Ru-3-2018Document2 pagesSpesifikasi Foam Chamber - Ansul - Ru-3-2018Monalisa DoskiNo ratings yet

- Foam Chamber F-85154Document4 pagesFoam Chamber F-85154Juan VillavicencioNo ratings yet

- Pqs BC 150 Lbs Con Ruedas MODELO 150-CDocument4 pagesPqs BC 150 Lbs Con Ruedas MODELO 150-CtremendousNo ratings yet

- Pqs BC 150 Lbs Con Ruedas MODELO 150-C PDFDocument4 pagesPqs BC 150 Lbs Con Ruedas MODELO 150-C PDFtremendousNo ratings yet

- Foam ChambersDocument3 pagesFoam ChambersAhmed HassanNo ratings yet

- Foam Chamber AnsulDocument4 pagesFoam Chamber AnsulenolNo ratings yet

- Foam Chamber Model FDocument6 pagesFoam Chamber Model FMaulia SabrinaNo ratings yet

- Line ProportionerDocument2 pagesLine ProportionerpsycopaulNo ratings yet

- Series LF909 Specification SheetDocument4 pagesSeries LF909 Specification SheetWattsNo ratings yet

- Apco Airvacuum Valves Avv Sales 601Document8 pagesApco Airvacuum Valves Avv Sales 601Jhony MedranoNo ratings yet

- Formed-Cylinders 2007-04 LoDocument14 pagesFormed-Cylinders 2007-04 LomartinvandoornNo ratings yet

- Foam ChamberFCADocument6 pagesFoam ChamberFCAarachman297988No ratings yet

- Worcester Controls C44 Series Cryogenic 3-Piece Ball Valve BrochureDocument8 pagesWorcester Controls C44 Series Cryogenic 3-Piece Ball Valve BrochureKakoDaNo ratings yet

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoNo ratings yet

- Series 909 Specification SheetDocument4 pagesSeries 909 Specification SheetWattsNo ratings yet

- Catalogs Proporcionadores EspumaDocument10 pagesCatalogs Proporcionadores EspumaPoncho RmzNo ratings yet

- CEMENT FLOAT COLLAR & SHOE WITH ALUMINUM PLUNGER VALVEDocument9 pagesCEMENT FLOAT COLLAR & SHOE WITH ALUMINUM PLUNGER VALVEkaveh-bahiraeeNo ratings yet

- AV-C Butterfly ValveDocument20 pagesAV-C Butterfly ValveSopon SrirattanapiboonNo ratings yet

- Double Block Bleed TOSVDocument8 pagesDouble Block Bleed TOSVplanet123No ratings yet

- Foam Chamber PDFDocument6 pagesFoam Chamber PDFAinur RohmanNo ratings yet

- Technical Installation Guide Above Below Ground DrainageDocument44 pagesTechnical Installation Guide Above Below Ground DrainageChamara Chinthaka RanasingheNo ratings yet

- Valve0114 PDFDocument14 pagesValve0114 PDFbinhjukiNo ratings yet

- 3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsDocument4 pages3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsrodrurenNo ratings yet

- 15 Foam MakerDocument8 pages15 Foam MakerMatthew BennettNo ratings yet

- Catálogo Master FloDocument12 pagesCatálogo Master FloclaudioandrevalverdeNo ratings yet

- Adjustable Choke Valves PDFDocument2 pagesAdjustable Choke Valves PDFMilena Lemus FonsecaNo ratings yet

- Sewage Air ValveDocument10 pagesSewage Air ValveAhmed TalaatNo ratings yet

- Choke E Series MasterFloDocument14 pagesChoke E Series MasterFloianherzogNo ratings yet

- 'C' Series Control ValvesDocument12 pages'C' Series Control Valvesابزار دقیق100% (1)

- Apco Air Release Valves Arv Arv Air Release Valves Sales 600Document4 pagesApco Air Release Valves Arv Arv Air Release Valves Sales 600RashedNo ratings yet

- ANSUL Between Flanged ProportionersDocument2 pagesANSUL Between Flanged ProportionersAngel Mendieta100% (1)

- Bombas Dosificadoras Milton Roy Lmi CDocument2 pagesBombas Dosificadoras Milton Roy Lmi CErikLjNo ratings yet

- 07 ValvesDocument33 pages07 Valvesshiva_ssk17No ratings yet

- Virgo Welded Valve BrochureDocument8 pagesVirgo Welded Valve BrochureHerrera Jorge AgustínNo ratings yet

- Series 909 Specification SheetDocument4 pagesSeries 909 Specification SheetWattsNo ratings yet

- FlygtDocument4 pagesFlygtToby Hopkins-AllanNo ratings yet

- VALVULAS - Series2200, NORRISEALDocument8 pagesVALVULAS - Series2200, NORRISEALAndrea Hernández CarreñoNo ratings yet

- Burst Plug Tubing Drain - Technical DatasheetDocument8 pagesBurst Plug Tubing Drain - Technical DatasheetEvolution Oil ToolsNo ratings yet

- Air Foam Chamber: Fire Fighting Equipment Data SheetDocument8 pagesAir Foam Chamber: Fire Fighting Equipment Data SheetMihir JhaNo ratings yet

- CI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsDocument12 pagesCI Close-Coupled End Suction Pumps: Water Circulation Pumps & CirculatorsAndre Gazali MalikNo ratings yet

- Master Flo Choke Valve CatalogueDocument28 pagesMaster Flo Choke Valve Cataloguegladwyn_hallatu100% (2)

- Danfoss Price List For 2012Document40 pagesDanfoss Price List For 2012Arbee AquinoNo ratings yet

- Awwa c900 y c905Document4 pagesAwwa c900 y c905Angel LopezNo ratings yet

- Fire HydrantDocument6 pagesFire HydrantdileepsiddiNo ratings yet

- Quality Blowout Preventer SpecificationsDocument12 pagesQuality Blowout Preventer SpecificationsLeonardo Alvarez100% (1)

- ETL Pressure Relief Valves Datasheet PDFDocument6 pagesETL Pressure Relief Valves Datasheet PDFNanasaheb PatilNo ratings yet

- Fire Tender SpecificationsDocument13 pagesFire Tender Specificationskaranbhadu50% (2)

- Series 800 Specification SheetDocument2 pagesSeries 800 Specification SheetFEBCONo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- String: "String".title "String".upper : "String".lower F" Sring (String) (String) String"Document16 pagesString: "String".title "String".upper : "String".lower F" Sring (String) (String) String"nazar750No ratings yet

- Python Tutorial PDFDocument155 pagesPython Tutorial PDFDiana RusuNo ratings yet

- Helical Static Mixer Data SheetDocument5 pagesHelical Static Mixer Data Sheetnazar750No ratings yet

- LPG Storage VesselsDocument14 pagesLPG Storage Vesselsthanhphucbr87No ratings yet

- Tank Api650Document11 pagesTank Api650nazar750No ratings yet

- The Mathematics of Pumping Water PDFDocument9 pagesThe Mathematics of Pumping Water PDFOualid LamraouiNo ratings yet

- English Grammar in English EnglizecomDocument102 pagesEnglish Grammar in English Englizecomnazar750100% (1)

- Static Mixer Designing QuestionnairesDocument1 pageStatic Mixer Designing Questionnairesnazar750No ratings yet

- Static Mixer User ManualDocument9 pagesStatic Mixer User Manualnazar750No ratings yet

- Conversion Gate01Document1 pageConversion Gate01nazar750No ratings yet

- Tank Api650Document6 pagesTank Api650nazar750No ratings yet

- Tank Api650Document11 pagesTank Api650nazar750No ratings yet

- BoooDocument1 pageBooonazar750No ratings yet

- Bump Case FPC58-2745-01 RBDocument8 pagesBump Case FPC58-2745-01 RBnazar750No ratings yet

- SolidWorks Motion Tutorial 2013Document32 pagesSolidWorks Motion Tutorial 2013bhumijayaNo ratings yet

- Sewer AppDocument27 pagesSewer AppEr Harsh MahajanNo ratings yet

- 1279 Gauge ManualDocument2 pages1279 Gauge Manualmasood1369No ratings yet

- ElectricalDocument46 pagesElectricalRobert Columbine100% (2)

- Jonshon ScreenDocument25 pagesJonshon Screennazar750No ratings yet

- MINISTRY MUNICIPALITIES PUBLIC WORKS TWST COMPARTMENTS PUMPING STATIONDocument4 pagesMINISTRY MUNICIPALITIES PUBLIC WORKS TWST COMPARTMENTS PUMPING STATIONnazar750No ratings yet

- 01-203 RW Mechanical DrawingsDocument6 pages01-203 RW Mechanical Drawingsnazar750No ratings yet

- Horizontal ScrubberDocument8 pagesHorizontal Scrubbernazar750No ratings yet

- 01-217 CLB Mechanical DrawingsDocument5 pages01-217 CLB Mechanical Drawingsnazar750No ratings yet

- 01-212 FB Mechanical DrawingsDocument7 pages01-212 FB Mechanical Drawingsnazar750No ratings yet

- 01-203 RW Mechanical DrawingsDocument6 pages01-203 RW Mechanical Drawingsnazar750No ratings yet

- 01-203 RW Mechanical DrawingsDocument6 pages01-203 RW Mechanical Drawingsnazar750No ratings yet

- 01-207 CLAR Mechanical DrawingsDocument5 pages01-207 CLAR Mechanical Drawingsnazar750No ratings yet

- 01-206 CD Mechanical DrawingDocument1 page01-206 CD Mechanical Drawingnazar750No ratings yet

- Dosing PumpDocument6 pagesDosing Pumpnazar750No ratings yet

- Sluice Gate DenizDocument1 pageSluice Gate Deniznazar750No ratings yet

- Airbase 13671Document6 pagesAirbase 13671ssarangNo ratings yet

- MTF - CSSDocument14 pagesMTF - CSSEdmar SamortinNo ratings yet

- Poultry House Heat GainDocument1 pagePoultry House Heat GainPrestoneKNo ratings yet

- The Iron Carbon Phase DiagramDocument2 pagesThe Iron Carbon Phase Diagramsinha.subhasis1417No ratings yet

- 9/11 FAA Transcript Mentioning Hijacked Airliners, in Particular United 175Document12 pages9/11 FAA Transcript Mentioning Hijacked Airliners, in Particular United 1759/11 Document ArchiveNo ratings yet

- As 1815.3-2007 Metallic Materials - Rockwell Hardness Test Calibration of Reference Blocks (Scales A B C D EDocument3 pagesAs 1815.3-2007 Metallic Materials - Rockwell Hardness Test Calibration of Reference Blocks (Scales A B C D ESAI Global - APACNo ratings yet

- JSS - Reshaping Data with the reshape PackageDocument20 pagesJSS - Reshaping Data with the reshape PackagewhyawhaNo ratings yet

- Buok Chapter 2Document15 pagesBuok Chapter 2Edmil Jhon AriquezNo ratings yet

- Manual Operación Balanza Génesis PDFDocument24 pagesManual Operación Balanza Génesis PDFCarolinaOrdóñezBalcázarNo ratings yet

- Cs1254 Operating SystemDocument10 pagesCs1254 Operating SystemSathish KrishnaNo ratings yet

- RFQ 3894-21Document9 pagesRFQ 3894-21ZewduErkyhunNo ratings yet

- LCA Training PackageDocument57 pagesLCA Training PackageSilvia PolliniNo ratings yet

- Foundations For Transmission LineDocument73 pagesFoundations For Transmission LineDato Azariani100% (2)

- ColumnShearCapacity 1Document4 pagesColumnShearCapacity 1Azhar PLNo ratings yet

- CN398 - Dual ESSP Interface To Both Smart Payout and HopperDocument1 pageCN398 - Dual ESSP Interface To Both Smart Payout and HopperAymen CheffiNo ratings yet

- Glycol Dehydration UnitDocument11 pagesGlycol Dehydration UnitarispriyatmonoNo ratings yet

- 76 5500 1 I1Document152 pages76 5500 1 I1shawn allen100% (4)

- Folded PlateDocument14 pagesFolded PlateTanvi Yadav100% (3)

- Information Framework (SID) Suite Release Notes Release 13-5 v3-5-4Document15 pagesInformation Framework (SID) Suite Release Notes Release 13-5 v3-5-4birenderNo ratings yet

- Temporary Horizontal Lifeline Rope A6Document3 pagesTemporary Horizontal Lifeline Rope A6tanu00No ratings yet

- Study of Tig WeldingDocument11 pagesStudy of Tig WeldingChandan Srivastava100% (1)

- Aquarius XT CT LT Cts-Owner's-Manual v05 Aqsum01Document294 pagesAquarius XT CT LT Cts-Owner's-Manual v05 Aqsum01leongf6467100% (2)

- ARL-TR-3760 - Mortar Simulation With Interior Propellant CanisterDocument73 pagesARL-TR-3760 - Mortar Simulation With Interior Propellant CanisterRick GainesNo ratings yet

- UM4730 Integration GuideDocument0 pagesUM4730 Integration Guidenarse8488No ratings yet

- Programming a Synth for Wind Control (part 1Document3 pagesProgramming a Synth for Wind Control (part 1CirrusStratusNo ratings yet

- Purchasing and Supply ManagementDocument78 pagesPurchasing and Supply Managementbilm100% (2)

- CPA Process GuideDocument58 pagesCPA Process GuideUtkarsh RaiNo ratings yet

- DS0000087 - Programmer's Manual - of X-LIB Software LibraryDocument175 pagesDS0000087 - Programmer's Manual - of X-LIB Software LibraryAmir Nazem zadeh100% (1)

- Wing Twist and DihedralDocument4 pagesWing Twist and DihedralchiragNo ratings yet

- Revision of existing site plan for residential propertyDocument1 pageRevision of existing site plan for residential propertyAndrew BydderNo ratings yet