Professional Documents

Culture Documents

BatchFurnace Brochure

Uploaded by

julioalexcmOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BatchFurnace Brochure

Uploaded by

julioalexcmCopyright:

Available Formats

UBQ

Universal Batch Quench Furnace

Ultimate in flexibility and versatility

The AFC-Holcroft advantage

AFC-Holcrofts integral quench furnaces are designed for neutral hardening, carburizing, carbonitriding, normalizing, and annealing where a controlled environment is required during the heating and quenching portions of the cycle. An optional atmosphere cooling chamber can be provided in addition to our integral oil, salt, water, or polymer quench systems. The furnaces are designed for a normal operating temperature range of 1450 1750 F with a maximum of 2000 F.

UBQ: Universal Batch Quench Furnace

Objectives

In developing the modularly constructed universal batch system, our objective was to build a system with state-of-the-art technology which is easily serviceable, delivers the highest production as compared to other commercially available systems, delivers consistently high quality with predictable and repeatable results, and is able to perform a large variety of metallurgical processes. After you have examined our brochure, talk to one of our satised customers or visit one of AFC-Holcrofts installations in your area. See for yourself why people call us The First Family of Complete Universal Batch Systems.

IntensiQuench UBQ System. Our quench capacity is approximately 1 gallon of quenchant per pound of quench load. This, coupled with our upow quench agitation system, not only provides uniform quench severity, but also minimizes instantaneous temperature rise of the quench media. automated transfer cars designed for maximum reliability. Our universal batch systems can be fully integrated into production cells with automatic transportation and controls. Over two hundred worldwide successful units in the last ten years are a testimonial to the success of our universal batch systems.

Quality

Universal batch systems are designed to provide excellent temperature uniformity and uniform distribution of atmosphere in the entire work area. Our patented upow quench agitation provides high volume and velocity for uniform quenching of work. Reliability, predictability, and repetitiveness are a trademark of our systems. Our systems produce consistently high-quality product with close metallurgical tolerances, day after day.

Serviceability

Universal batch systems are designed and built to perform reliably for long periods with minimal maintenance. Of course, if any component has to be repaired or replaced, our modular plug-style construction enables quick and easy replacement from outside with minimal downtime.

Innovative features and technologies make the AFC-Holcroft difference

Universal Batch Furnace The AFC-Holcroft universal batch furnace casing is fabricated of 3/16-inch and 1/4-inch steel plates suitably reinforced with structural steel to form a gas-tight chamber. The walls of the furnace are insulated by 9 inches of insulating rebrick backed by 4-1/2 inches of insulating block. Ceramic ber modules are utilized in the roof of the furnace and the oor is lined with insulating rebrick. The hearth consists of two cast alloy roller rail assemblies supported by alloy piers for superior atmosphere circulation under the load. These heavy-duty roller rails are provided in super alloy materials to minimize maintenance. Hearth height is 50 inches above the oor. AFC-Holcroft offers both gas-red and electric heating systems. The gas-red heating system consists of alloy U-tube assemblies mounted vertically in the roof to provide more effective utilization of available

Flexibility

Universal batch systems are developed to provide the exibility of metallurgical processes and layout. Our systems can be arranged close to plant walls to provide the most effective use of oor space. They can be fully automated to minimize operator interaction and installed in line with modern ex production centers.

Productivity

In a typical batch system, productivity is measured in terms of gross load, recovery rates, and ability to quench or uniformly cool these large loads. Our universal batch systems handle gross loads of 1100 to 6000 pounds. In all sizes, we maintain a ratio of 3:1 in internal chamber radiating area to work surface area, and provide larger 8-inch diameter radiant tubes to effectively and uniformly heat the products at a faster heat-up rate than other comparable systems. In our UBQ 36-48-36 system, the 12,650 sq. in. surface area of the radiant tubes delivers a large number of BTUs to the product at an optimal rate.

Companion equipment

AFC-Holcrofts universal batch systems are offered complete with all companion equipment such as tempering furnaces, pre-oxidation furnaces, spraydunk washers, forced air cool stations, scissors lifts, stationary tables, and our complete line of fully

tube heating area. We offer optional high-efficiency recuperators for further energy savings. Our electric heating system consists of vertical tubes containing bayonet-type elements on either side of the work load. This design permits external element maintenance without the necessity of completely cooling the furnace chamber. All of our radiant tubes are bung mounted for easy removal and replacement. A high-capacity recirculating fan is provided in the heating chamber to provide sufficient atmosphere circulation to obtain uniform atmosphere consistency within the furnace chamber. The fan is supplied with an air-cooled insulated bearing housing and is bung mounted so it can be removed as a complete assembly without entering the furnace chamber. No water piping is required to the fan, reducing utility costs. The quench tank is fabricated of 1/4-inch plate and reinforced with structural members to form a rigid, liquid-tight and gas-tight chamber. The AFC-Holcroft quench systems are designed to obtain an upward ow of recirculated quenchant through the work load area. Vertically mounted propeller-type agitators are mounted on the sides of the vestibule. Our spacesaving narrow quench tank design has a capacity of approximately 1 gallon per pound of gross load and requires only a shallow 24-inch pit to obtain the 50-inch hearth height. A double deck elevator system is provided to minimize reloading times. The universal furnace is designed to operate with an external handler to minimize internal furnace mechanisms. The rear handler drive is mounted in the back wall of the furnace to provide for automatic transfer of the work load from the furnace to the quench tank after a completed cycle.

Pioneering Technologies

Austempering UBQA AFC-Holcroft is the clear leader of integral molten salt quench furnace design. Our integral austemper quench systems operate in a temperature range of 350 800 F. Our patented water injection system can provide quench severities equivalent to a water quench and can through harden up to 6-inch-thick cross sections. Our universal batch quench austemper furnaces are designed for neutral hardening, carburizing, carbonitriding, carbo austempering, normalizing, annealing, austempering steel, and austempering ductile irons (ADI). Intensive Quenching UBQI A spin-off of our successful UBQA furnace design, the UBQI was developed for the growing IntensiQuenchSM market. Intensive quenching is a very rapid and uniform cooling of steel parts that causes the simultaneous formation of martensite throughout the whole part surface, creating a rm shell. IntensiQuench martensite is characterized by ner structure with higher dislocation density and improved mechanical properties micro-hammered through higher residual compressive stresses. This strong martensite case or shell minimizes part distortion. RapidGAS atmosphere system AFC-Holcrofts proprietary Rapid GAS atmosphere control system provides the required protective furnace atmosphere without a separate endothermic generator. Rapid GAS controls the generation of the protective atmosphere directly in the furnace chamber. A multi-gas analyzer system and simple oxygen probe are used to control the direct injection of the

required additive gasses. The Rapid GAS system requires approximately 1/10 of the gas ow of a traditional endothermic system and is capable of operating soot-free at higher carbon potentials, reducing carburizing cycles by as much as 50%. The precision control provided by Rapid GAS provides superior metallurgical performance with a nearly 50% reduction of intergranular oxides and a more uniform case depth from root to pitch line. Reduced capital investment and maintenance costs, reduced atmosphere gas consumption, reduced cycle times, and improved quality all add up to increased prots with Rapid GAS. BatchMaster AFC-Holcrofts popular BatchMaster INDIVIDUAL batch furnace management package is based upon a subset of our highly successful ProcessMaster heat-treating supervisory system. The main operator HMI interface is a NEMA 4 industrial panel PC with a 15-inch-wide color LCD touch screen. This HMI communicates directly to the batch furnace PLC controller for complete operational control. A varieties of standard screens are provided for viewing mechanism and recipe status, control loops, process trending and other analog and digital status. All process parameters are read every second and recorded every minute. The built-in disk storage will handle 10 years of process data. The BatchMaster HMI communicates directly with the PLC for temperature and carbon control.

Precision 3D engineered modular UBQ.

Turnkey complete UBQ system installation and integration.

UBQ with BatchMaster PC control system.

Standard UBQ Arrangement and Components

UBW 36 x 48 x 36 SPRAY/DUNK WASHER

UBT 36 x 48 x 36 TEMPER FURNACE

UBTC 36 x 4 TRANSFER C

UBT 36 x 48 x 36 TEMPER FURNACE

UBT 36 x 48 x 36 TEMPER FURNACE

UST 36 x 48 STATIONARY TABLE

USL 36 x 48 SCISSOR LIFT TABLE

Join the next generation today!

UBQ 36 x 48 x 36 BATCH FURNACE

To learn more about how the Universal Batch Quench Furnace can give you the edge over the competition, contact us. Wherever your business is located, AFC-Holcroft can provide you access to an unparalleled level of consultation and support that ensures you get the maximum value from your investment dollar.

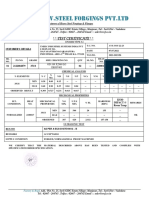

UNIVERSAL BATCH QUENCH (UBQ)

Model UBQ-243624 UBQ-364836 UBQ-367236 Effective Load Size 24 x 36 x 24 36 x 48 x 36 36 x 72 x 36 Gross Load Capacity (pounds) @ 1750 F 1100 3500 6000 Heating Rates (lbs/hr) 1550 F 1700 F 1100 2700 2875 600 2400 2560 Energy Requirements BTU x HP 1000 KW Motors 1000 1200 1800 60 144 216 20 30 40 Atmosphere Quench Tank Required Volume Agitation (CFH) (Gallons) (GPM) 500 750 1000 1100 3500 5950 6750 16000 24000 Dimensions W

H 13 0

16 0 10 0

20 0 13 0 17 11 22 0 13 0 17 11

AFC-HOLCROFT 49630 Pontiac Trail

www.afc-holcroft.com

Wixom, MI 48393 USA Phone: 248.624.8191 Fax: 248.624.3710 sales@afc-holcroft.com

ProcessMaster is a registered trademark of AFC-Holcroft. Bulletin No. UBQ-0604

You might also like

- Preheater Lores PDFDocument8 pagesPreheater Lores PDFamjed_de_enimNo ratings yet

- Fired HeatersDocument20 pagesFired HeatersCal100% (5)

- Ipsen Atmosphere TechnologyDocument5 pagesIpsen Atmosphere TechnologyCarlos SartoriNo ratings yet

- STF Industrial BoilersDocument20 pagesSTF Industrial BoilersDaniellzhangNo ratings yet

- Chromalox Tank Heating System BrochureDocument16 pagesChromalox Tank Heating System BrochuregbgbhagavanNo ratings yet

- Alfa Laval Packinox+ Product Leaflet enDocument5 pagesAlfa Laval Packinox+ Product Leaflet enJavadAminpourNo ratings yet

- Absorption Chillers 07Document52 pagesAbsorption Chillers 07Sujadi Cherbond100% (1)

- Industrial Plants Power Steam GeneratorsDocument20 pagesIndustrial Plants Power Steam GeneratorslosmoscasbrNo ratings yet

- AP Aluminium Annealing Furnaces5Document4 pagesAP Aluminium Annealing Furnaces5Yasin YILDIZNo ratings yet

- Babcox BoilerDocument14 pagesBabcox BoilertoanbtdNo ratings yet

- HVAC Interactive 2015 1Document64 pagesHVAC Interactive 2015 1Prince ChaudharyNo ratings yet

- Depliant Brochure Marine en PDFDocument9 pagesDepliant Brochure Marine en PDFFadzil NorNo ratings yet

- Hydronic Heat System DatasheetDocument2 pagesHydronic Heat System DatasheetthermaltechnologiesNo ratings yet

- ExtruderDocument6 pagesExtruderSamuel AbebawNo ratings yet

- FW Utility Boiler PDFDocument12 pagesFW Utility Boiler PDFChandan AulakhNo ratings yet

- Heat Pipe Heat ExchangerDocument20 pagesHeat Pipe Heat ExchangerrolwinNo ratings yet

- Oil & Gas BurnersDocument8 pagesOil & Gas BurnersgoelamitaNo ratings yet

- GUNTAMATIC Biomass Boiler Heating Range GuideDocument24 pagesGUNTAMATIC Biomass Boiler Heating Range GuideSorin StanNo ratings yet

- CB 8047 4wi Cble BrochureDocument8 pagesCB 8047 4wi Cble Brochurekosmc123No ratings yet

- Pulverized Coal TechnologyDocument7 pagesPulverized Coal TechnologyRi KoNo ratings yet

- E101 3240 Industrial Water Tube Package Boilers Babcock WilcoxDocument12 pagesE101 3240 Industrial Water Tube Package Boilers Babcock Wilcoxa_parratNo ratings yet

- GKMOSS Wood Boiler System BrochureDocument8 pagesGKMOSS Wood Boiler System BrochureJose Lorenzo Toral100% (1)

- Crest Boiler LiteratureDocument6 pagesCrest Boiler LiteratureJohn MoreNo ratings yet

- Kablitz Grate SystemsDocument7 pagesKablitz Grate SystemsrickyNo ratings yet

- McQuay WHS ChillerDocument28 pagesMcQuay WHS ChillerYorkist100% (1)

- Saacke SKV Com MDocument12 pagesSaacke SKV Com MHay ThemNo ratings yet

- SKV Burners for Economic and Environmentally-Friendly CombustionDocument12 pagesSKV Burners for Economic and Environmentally-Friendly CombustionadnanfakharNo ratings yet

- Azanechiller Series 2010 (3) Final VersionDocument12 pagesAzanechiller Series 2010 (3) Final VersionRajkumar GulatiNo ratings yet

- Bringing Efficiency To Heat Transfer: Product LiteratureDocument28 pagesBringing Efficiency To Heat Transfer: Product Literaturescreamingeagle22No ratings yet

- Katalog Per-Eko enDocument13 pagesKatalog Per-Eko enapi-246705026No ratings yet

- Ipsen Vacuum TechnologyDocument6 pagesIpsen Vacuum TechnologyJacques GillesNo ratings yet

- Modul-Plus BrochureDocument8 pagesModul-Plus BrochureiruldarkenNo ratings yet

- Ehandbook Strategize Your Steam SystemDocument18 pagesEhandbook Strategize Your Steam Systemoritas100% (1)

- Ehandbook Strategize Your Steam SystemDocument18 pagesEhandbook Strategize Your Steam SystemMPham100% (1)

- CB HRSG BrochureDocument12 pagesCB HRSG BrochuresaadounNo ratings yet

- Industrial Watertube BrochureDocument12 pagesIndustrial Watertube Brochuregonzaracing84No ratings yet

- Heat Treatment Processes in The Ceramics Industry: Edition 09.09 GBDocument8 pagesHeat Treatment Processes in The Ceramics Industry: Edition 09.09 GBKosphy Arden100% (1)

- Chilled Beam BrochureDocument12 pagesChilled Beam BrochureMahmood EijazNo ratings yet

- Techno-Commercial Offer for 80 MW Biomass Energy PlantDocument31 pagesTechno-Commercial Offer for 80 MW Biomass Energy PlantRahul Patil100% (4)

- Product Manual: Water Cooled Screw ChillersDocument24 pagesProduct Manual: Water Cooled Screw ChillersAnbarasan NagarajanNo ratings yet

- STF Gas&TurbineDocument20 pagesSTF Gas&TurbinepedroanNo ratings yet

- Steam Turbines - A Full Range To Fit Your Needs PDFDocument20 pagesSteam Turbines - A Full Range To Fit Your Needs PDFNitinSoodNo ratings yet

- Chiller - CarrierDocument27 pagesChiller - CarrierJose Francisco Varela CruzNo ratings yet

- Als e Eng 04 - 11 - BDocument56 pagesAls e Eng 04 - 11 - BMICAH JEDAHNo ratings yet

- 50pc 10pdDocument72 pages50pc 10pdm_moreira1974No ratings yet

- Asphalt Batch Type Portable PlantDocument9 pagesAsphalt Batch Type Portable PlantVikas MahajanNo ratings yet

- Alfa Laval Improving Sustainability With Welded Solutions Brochure enDocument30 pagesAlfa Laval Improving Sustainability With Welded Solutions Brochure enhamdy durraNo ratings yet

- Exhausto-Cosuri de Fum SemineeDocument6 pagesExhausto-Cosuri de Fum SemineealanatoraNo ratings yet

- 3s Steam BoilerDocument13 pages3s Steam BoilertahirNo ratings yet

- Thermal Fluid Heaters: Model HHC and VHCDocument4 pagesThermal Fluid Heaters: Model HHC and VHCRexx MexxNo ratings yet

- Windsor Kilns 2021Document8 pagesWindsor Kilns 2021Wai Phyo HlaingNo ratings yet

- AwshcDocument9 pagesAwshcEduardo RivasNo ratings yet

- Sharpen Steam System Best Practices EbookDocument26 pagesSharpen Steam System Best Practices EbookswaminathanNo ratings yet

- ICI Caldaie Catalogue ENGDocument102 pagesICI Caldaie Catalogue ENGaxs00No ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Experimental Investigation On High Performance Concrete Using Silica Fume and SuperplasticizerDocument4 pagesExperimental Investigation On High Performance Concrete Using Silica Fume and SuperplasticizerVipul KalyaniNo ratings yet

- Doss Part 03 - Bolted ConnectionsDocument82 pagesDoss Part 03 - Bolted ConnectionsKaran ThakurNo ratings yet

- Appendix C - Specification For 33kV Cable (v2) PDFDocument15 pagesAppendix C - Specification For 33kV Cable (v2) PDFOGBONNAYA MARTINSNo ratings yet

- TCE Babbitt 18391-2Document2 pagesTCE Babbitt 18391-2paulo cesar hernandez mijangosNo ratings yet

- Mechanical BOQ 130MWDocument72 pagesMechanical BOQ 130MWsaravan1891No ratings yet

- CorrosionDocument79 pagesCorrosionaakash sharma100% (1)

- 2.8 Combustion Air SystemDocument26 pages2.8 Combustion Air SystemDangolNo ratings yet

- Aircraft Material HardwareDocument307 pagesAircraft Material HardwareMorrisNo ratings yet

- Jinan Hensgrand Instrument Co., Ltd. ProfileDocument27 pagesJinan Hensgrand Instrument Co., Ltd. ProfileGMAR ComercializadoraNo ratings yet

- Analysis and Design of FRP Composites For Seismic Retrofit of Infill Walls in Reinforced Concrete FramesDocument9 pagesAnalysis and Design of FRP Composites For Seismic Retrofit of Infill Walls in Reinforced Concrete FramesTAMANA SHAMSINo ratings yet

- Design Manual 7.2 - Foundations and Earth StructuresDocument266 pagesDesign Manual 7.2 - Foundations and Earth StructuresBenny Lin100% (2)

- J6 Series, MS-02-214 R1Document2 pagesJ6 Series, MS-02-214 R1herysyam1980No ratings yet

- Fiber Optic Cable Types ExplainedDocument23 pagesFiber Optic Cable Types ExplainedkoneNo ratings yet

- MTC FormatDocument1 pageMTC FormatNirmit GandhiNo ratings yet

- Solar Cable Halogen FreeDocument2 pagesSolar Cable Halogen FreeGelu BordeaNo ratings yet

- 876JJ6P722 - Partner 200 12-4 (Fini)Document5 pages876JJ6P722 - Partner 200 12-4 (Fini)LefialgaNo ratings yet

- Sarawak - Kuching2019Document14 pagesSarawak - Kuching2019Ruben OhNo ratings yet

- Cast Basalt Division: Steels LTDDocument8 pagesCast Basalt Division: Steels LTDbonat07No ratings yet

- Welded Nickel and Nickel-Cobalt Alloy Tube: Standard Specification ForDocument5 pagesWelded Nickel and Nickel-Cobalt Alloy Tube: Standard Specification ForsamehNo ratings yet

- Thermal Performance Analysis of Earth-Air-Pipe-Heat Exchanger System With Different Backfilling MaterialsDocument5 pagesThermal Performance Analysis of Earth-Air-Pipe-Heat Exchanger System With Different Backfilling MaterialsKamal Kumar AgrawalNo ratings yet

- Smooth Rigid Strip Footing on Elastic Soil VerificationDocument4 pagesSmooth Rigid Strip Footing on Elastic Soil VerificationnishantNo ratings yet

- Tips - Asme b313 Training SeminarDocument382 pagesTips - Asme b313 Training SeminarMarc Abellán EscuraNo ratings yet

- Carrier Debonair 33cs 420 Instructions ManualDocument89 pagesCarrier Debonair 33cs 420 Instructions ManualCDDPPJNo ratings yet

- Elastic Mechanics AssignmentsDocument8 pagesElastic Mechanics AssignmentsEng Bagaragaza Romuald100% (2)

- A Guide To Engineered Wood ProductsDocument12 pagesA Guide To Engineered Wood ProductsCeyanezNo ratings yet

- Aluminium Alloy 3003 Data SheetDocument1 pageAluminium Alloy 3003 Data SheetShyamKhatriNo ratings yet

- A General Tetrakaidecahedron Model For Open-Celled Foams: Roy M. Sullivan, Louis J. Ghosn, Bradley A. LerchDocument12 pagesA General Tetrakaidecahedron Model For Open-Celled Foams: Roy M. Sullivan, Louis J. Ghosn, Bradley A. LerchChitralekha DeyNo ratings yet

- Isolated & Combined Footing Design Bs8110.1985Document6 pagesIsolated & Combined Footing Design Bs8110.1985EdwinNo ratings yet

- TDS - Alumina Aggregates - E - RBT9 - R2Document2 pagesTDS - Alumina Aggregates - E - RBT9 - R2유유재하No ratings yet

- Grounding & Lighting Prot-Grounding BarDocument2 pagesGrounding & Lighting Prot-Grounding BarAlifia AiniNo ratings yet