Professional Documents

Culture Documents

Neural Fuzzy DC

Uploaded by

Ahmed AlostazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Neural Fuzzy DC

Uploaded by

Ahmed AlostazCopyright:

Available Formats

Available online at www.uofk.edu/uofkej UofKEJ Vol. 3 Issue 1 pp.

7-11(February 2013)

UNIVERSITY of KHARTOUM ENGINEERING JOURNAL (UofKEJ)

Neuro-Fuzzy Controller Design for a DC Motor Drive

Ghazally Y. Mustafa1, A. Taifour Ali2, Eisa Bashier2, Mirghani Fateh Elrahman3

Damazin Technical College (E-mail: Ghazally120@gmail.com) College of Engineering, Sudan University of Science and Technology 3 Department of Electrical and Electronics Engineering, Faculty of Engineering, University of Khartoum, Khartoum, Sudan

2 1

Abstract: This paper presents a neuro-fuzzy controller design for speed control of DC motor. The most commonly used controller for the speed control of dc motor is the conventional Proportional-Integral-Derivative (PID) controller. The PID controller has some disadvantages like: high overshoot, sensitivity to controller gains and slow response. Fuzzy control and neuro-fuzzy control are proposed in this study. The performances of the two controllers are compared with PID controller performance. In this paper, neural networks are used in a novel way to solve the problem of tuning a fuzzy logic controller. The neuro fuzzy controller uses neural network learning techniques to tune membership functions. For the speed control of dc motor drives, it is observed that neuro-fuzzy controller gives a better response compared to other controllers. Keywords: DC motor; PID controller; Fuzzy logic controller; Neuro-fuzzy control

1.

INTRODUCTION

2.

CONTROLLERS STRUCTURE

Direct Current motor drives have been widely used where accurate speed control is required. The development of high performance motor drives is very important in industrial as well as other applications [1]. The DC motors are used in various applications such as defence, industries, robotics etc. Due to their simplicity, ease of application; reliability and favorable cost DC motors have long been a backbone of industrial applications. DC drives are less complex with a single power conversion from AC to DC. DC motors have a long tradition of use as adjustable speed machines and a wide range of options have evolved for this purpose. The PID controller is one of the conventional controllers and it has been widely used for the speed control of DC motor drive [2][4]. The values of proportional (P), integral (I) and derivative (D), can be interpreted in terms of time, P depends on the present error, I on the accumulation of past errors, and D is a prediction of future errors based on current rate of change. The weighted sum of these three actions is used to adjust the process via a control element such as the position of a control valve, or the power supplied to a heating element. Fuzzy logic is one of the popular new technologies in intelligent control, which is defined as a combination of control theory, operations research, and artificial intelligence (AI). Since the announcement of the first fuzzy chips in 1987, fuzzy logic is still perhaps the most popular area in AI [5].

A. PID Controller Block diagram of the drive with PID controller is shown in Fig. 1. The speed error e(t) between the reference speed u(t) and the actual speed N of the motor is fed to the P-I-D controller. The Kp, Ki and Kd are the proportional, integral and derivative gains of the P-I-D controller The transfer function of a PID controller is given by

n C(s)=Kp+ i +Kds=Kd s S 2 2wn = Kp / Kd, wn =Ki / Kd

S 2 +2 w S+w n 2

(1) (2)

where and wn, are damping ratio and undamped natural frequency [6].

Fig. 1. PID controller structure 7

Ghazally Y. Mustafa, et al. / UofKEJ Vol. 3 Issue 1, pp.7-11(February 2013)

B. Fuzzy Controller Fuzzy control provides a formal methodology for representing, manipulating and implementing a humans heuristic knowledge of how to control a system. Fuzzy controller block diagram is given in Fig. 2, where we show a fuzzy controller embedded in a closed-loop control system. The plant outputs are denoted by y(t), its inputs are denoted by u(t), and the reference input to the fuzzy controller is denoted by r(t). The fuzzy controller has four main components: (1) The rule-base holds the knowledge, in the form of a set of rules, of how best to control the system. (2) The inference mechanism evaluates which control rules are relevant at the current time and then decides what the input to the plant should be. (3) The fuzzification interface simply modifies the inputs so that they can be interpreted and compared to the rules in the rule-base. (4) Defuzzification converts the conclusions reached by the inference mechanism into plant inputs [9]. Neuro-fuzzy system shown in Fig. 3 combines neural networks and fuzzy logic. It has recently gained a lot of interest in research and application [7], [8].

Table 1: Rule base for 5 membership functions dE N NL NS ZE PS EN

dt

PL ZE PS PL PL PL

NL NS ZE PS PL

NL NL NL NS ZE

NL NS NS ZE PS

NL NS ZE PS PL

NS ZE PS PS PL

C.

Neuro-Fuzzy Controller

The adaptive neuro-fuzzy inference system (ANFIS) uses a feed forward network to search for fuzzy decision rules that perform well in a given task. Using a given input/output data set ANFIS creates a fuzzy inference system for which membership function parameters are adjusted using a combination of a back propagation and least square method [9]. ANFIS estimator design consists of two parts: constructing and training. In the constructing part, structure parameters are determined. These are type and number of input Membership Functions (MFs), and type of output MF. Effective partition of the input space is important and it can decrease the rule number and thus increase the speed in both learning and application phase. Output MFs can be either a constant or in linear form. Both of the two forms are used for the output MF in this study. Having described the number and type of input MFs, the estimator rule base is constituted. Since, there is no standard method to utilize the expert knowledge; automatic rule generation method is usually preferred. According to this method, for instance, an ANFIS model with two inputs and five MFs on each input would result in 52 = 25 TakagiSugeno fuzzy if-then rules automatically. Although this method may requires much computational knowledge, especially in systems that have to be defined with many inputs. It is used in this study due to the advantage of MATLAB software. Therefore, rule bases of estimators are formed automatically with the number of inputs and number of MFs. After the ANFIS structure is constructed, learning algorithm and training parameters are chosed. As mentioned earlier in this paper, back propagation or hybrid learning can be used as a learning algorithm. Therefore, hybrid learning algorithm is adopted in this study. Parameters in the algorithm are epoch size (presentation of the entire data set), error tolerance, initial step size, step size decrease rate, and step size increase rate. Since there is no exact method in the literature to find the optimum of these parameters a trial and error procedure is used. MATLAB fuzzy logic toolbox is used to design ANFIS estimators structures. Using the given training data set, the toolbox constructs an ANFIS structure using either a back propagation algorithm alone, or in combination with least squares type of method (hybrid algorithm). ANFIS model can be generated either from the command line, or through the ANFIS editor GUI. In this study, ANFIS Editor graphical user interface (GUI) is used to generate ANFIS models with the chosen

Fig. 2. Fuzzy controller architecture

Fig. 3. Neuro Fuzzy control scheme

Ghazally Y. Mustafa, et al. / UofKEJ Vol. 3 Issue 1, pp.7-11(February 2013)

design parameters in the construction phase. MATLAB code is used to train the ANFIS structure in the training step. The three steps of ANFIS estimator design are as follows: 1. Generated training data is loaded to the Editor GUI. 2. Design parameters, number and type of input and output MFs, are chosen. Thus, initial ANFIS structure is formed. 3. The code for training is run with an initial structure. 4. ANFIS structure constituted after training is saved. 3. SIMULATION RESULTS AND DISCUSSION In order to validate the control strategies as described above, digital simulation are carried out on a converter dc motor drive system (see Appendix). The MATLAB/SIMULINK model of the system under study with all three controllers is shown in Figs. 4-6.

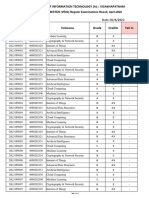

The response of motor speed with PID controller is shown in Fig. 7. Figure 8 shows response of motor speed to a unit step input with a fuzzy controller. Figure 9 shows the response of the motor speed to a unit step input with a neuro-fuzzy controller. Figure 10 shows the response of motor speed to a unit step input with three different controllers A comparison has been made between maximums overshoot (MP), rise times (rt) and settling times (ts) of system with three different controllers as illustrated in Table (2). Table 2. A comparison of maximum overshoot, rise time, settles time for three different controllers Controller MP (%) Tr(Sec.) Ts (Sec.) PID Fuzzy Neuro-Fuzzy 7.93 1.5 4.78 0.2577 0.3909 0.2748 0.9465 1.3 0.8531

Fig. 4. PID controller for speed control of DC motor

Fig. 5. Fuzzy controller for speed control of DC motor

Ghazally Y. Mustafa, et al. / UofKEJ Vol. 3 Issue 1, pp.7-11(February 2013)

Fig. 6. Neuro-Fuzzy controller for speed control of DC motor

1.4

1.4 1.2 1

Amplitute

1.2

Amplitude

0.8

0.8 0.6 0.4 0.2 0

0.6

0.4

0.2

0.5

1.5

2 2.5 3 Time (Second)

3.5

4.5

0.5

1.5

2.5 Time (sec)

3.5

4.5

Fig. 7. Motor speed response with PID controller

1.4 1.2 1 0.8 0.6 0.4 0.2 0

Amplitute

Amplitute

Fig. 9. Motor speed response with neuro fuzzy controller

1.4 1.2 1 0.8 Neuro-Fuzzy controller 0.6 0.4 0.2 0 Fuzzy controller PID controller

0.5

1.5

2.5 Time sec

3.5

4.5

0.5

1.5

2.5 Time(sec)

3.5

4.5

Fig. 8. Motor speed response with fuzzy controller

Fig. 10. Motor speed response with three different controllers

10

Ghazally Y. Mustafa, et al. / UofKEJ Vol. 3 Issue 1, pp.7-11(February 2013)

4. CONCLUSIONS In this paper, the DC motor has been reviewed from control theory perspective. PID controller and intelligent techniques such as Fuzzy logic controllers and their hybrid (ANFIS) are used for DC motor speed control. In the Design with PID controller, lots of attempts are needed to choose the right term, which gives a good response. Design with fuzzy controller gives perfect results, but also a trial-and-error method is needed to find the required parameters. Design with neuro-fuzzy controller reached a very good response and was very fast. The advantages of the NeuroFuzzy controller are that it determines the number of rules automatically, reduces computational time, learns faster and produces lower errors than other methods. With proper design a Neuro-Fuzzy controllers can replace PID and Fuzzy controllers for the speed control of dc motor drives. From simulations, it is concluded that the use of ANFIS reduces design efforts and gives better results. REFERENCES 1 S.R. Khuntia, K.B. Mohanty and S. Panda and C. Ardil A Comparative Study of PI, I-P, Fuzzy and Neuro-Fuzzy Controllers for Speed Control of DC Motor Drive International Journal of Electrical Systems Science and Engineering vol-1 (1), Jul2009, pp: 1-5. A.Taifour Ali, Eisa Bashier M. Tayeb and Omar Busati alzain Mohd. Adaptive PID Controller for Dc Motor Speed Control International Journal of Engineering Inventions, Volume 1, Issue 5 (September2012) PP: 26-30. Mehdi Ghazavi Dozein, Amin Gholami, Mohsen Kalantar Speed Control of DC Motor Using Different Optimization Techniques Based on PID Controller Journal of Basic and Applied Scientific Research, 2(7) 2012, pp: 6488-6494. Guoshing Huang PC-based PID Speed Control in DC Motor International Conference on ALIP 2008, pp 400-407. Thrishantha Nanayakkara and Mo Jamshidi Intelligent Control Systems with an Introduction to System of Systems Engineering Taylor & Francis Group-2010. M. Sam Fadali Digital Control Engineering Analysis and Design Elsevier Inc- Copyright 2009. Mohammad-Reza Mosavi, Abdoreza Rahmati, Alireza Khoshsaadat Design of Efficient Adaptive Neuro-Fuzzy Controller Based on Supervisory Learning Capable for Speed and Torque Control of BLDC Motor PRZEGLD ELEKTROTECHNICZNY (Electrical Review), R. 88 NR 1a/2012, pp238-246. G. Qin, W. Yao and W. Zhang Design of Nonlinear Optimization PID Controller for BLDCM Based on Neuro- Fuzzy Proceedings of the 8th International Conference on Electrical 11

Machines and Systems, Vol.2, pp.15241527,September 2006. 9 Hung T. Nguyen - Nadipuram R. Prasad - Carol L. Walker - Elbert A. Walker A First course in Fuzzy and Neural Control CHAPMAN & HALL/CRC, 2003. 10 R. Sivakumar and K. Balu Paper on ANFIS based Distillation Column Control Josephs College of Engineering, 2010. APPENDIX Motors Parameters The motor used in this experiment is dc separately excited, rating 2.5hp at rated voltage 110 V, and the motors parameters are as follows [1]: Armature resistance (Ra) = 0.6 Armature inductance (La) = 8 mH Back e.m.f constant (K) = 0.55 V/rad/s Mechanical inertia (J) = 0.0465 kg.m2 Friction coefficient (B) = 0.004 N.m/rad/s Rated armature current (Ia) = 20 A

4 5

6 7

You might also like

- NL Proj 216982Document17 pagesNL Proj 216982Ahmed AlostazNo ratings yet

- OptimalControl 1Document41 pagesOptimalControl 1Alfa BetaNo ratings yet

- Lecture 1Document33 pagesLecture 1sandeepbabu28No ratings yet

- 586 ProblemsDocument46 pages586 ProblemsAhmed AlostazNo ratings yet

- Novel Clamping Force Control For Electric Parking Brake SystemsDocument6 pagesNovel Clamping Force Control For Electric Parking Brake SystemsAhmed AlostazNo ratings yet

- Stability Analysis of An Electric Parking Brake (EPB) SystemDocument7 pagesStability Analysis of An Electric Parking Brake (EPB) SystemAhmed AlostazNo ratings yet

- InTech-Adaptive Neuro Fuzzy SystemsDocument27 pagesInTech-Adaptive Neuro Fuzzy SystemsAhmed AlostazNo ratings yet

- Neuro-Fuzzy Methods For Nonlinear System IdentificationDocument13 pagesNeuro-Fuzzy Methods For Nonlinear System IdentificationboopsubhaNo ratings yet

- A Robotic Eye Controller Based On Cooperative Neural AgentsDocument6 pagesA Robotic Eye Controller Based On Cooperative Neural AgentsAhmed AlostazNo ratings yet

- Neuro FuzzyDocument106 pagesNeuro FuzzyAhmed AlostazNo ratings yet

- Fuzzy Pid With GimbalDocument8 pagesFuzzy Pid With GimbalAhmed AlostazNo ratings yet

- A Robotic Eye Controller Based On Cooperative Neural AgentsDocument6 pagesA Robotic Eye Controller Based On Cooperative Neural AgentsAhmed AlostazNo ratings yet

- Real Time Object Tracking Using Image Based Visual ServoDocument6 pagesReal Time Object Tracking Using Image Based Visual ServoAhmed AlostazNo ratings yet

- Paper For CIS Feb20132Document8 pagesPaper For CIS Feb20132Ahmed AlostazNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Approaching Rules Induction CN2 Algorithm in Categorizing of BiodiversityDocument4 pagesApproaching Rules Induction CN2 Algorithm in Categorizing of BiodiversityEditor IJTSRDNo ratings yet

- Article Segmentation ClientsDocument6 pagesArticle Segmentation ClientsAbdoulayeNo ratings yet

- Aruksha ResumeDocument2 pagesAruksha Resumeapi-304262732No ratings yet

- Lec 1,2Document69 pagesLec 1,2ABHIRAJ ENo ratings yet

- Seminar ReportDocument18 pagesSeminar ReportAll About Youtuber'sNo ratings yet

- Unit I-AI-KCS071Document32 pagesUnit I-AI-KCS071Sv tuberNo ratings yet

- ML Lab Manual TE 2021-22Document43 pagesML Lab Manual TE 2021-22FD04 Alok KaduNo ratings yet

- Artificial Intelligence and Internet of Things For Autonomous VehiclesDocument31 pagesArtificial Intelligence and Internet of Things For Autonomous VehiclesРусские ТрейлерыNo ratings yet

- Data Scientist Resume SummaryDocument5 pagesData Scientist Resume SummaryQuantico Smith100% (1)

- Analytical Study of Diagnosis For Angioplasty and Stents Patients Using Improved Classification TechniqueDocument4 pagesAnalytical Study of Diagnosis For Angioplasty and Stents Patients Using Improved Classification TechniqueEditor IJTSRDNo ratings yet

- Unit IvDocument34 pagesUnit Ivdanmanworld443No ratings yet

- Seminar Report FormatDocument29 pagesSeminar Report FormatJeeshma Krishnan KNo ratings yet

- B 9781509963379Document379 pagesB 9781509963379enazifiNo ratings yet

- What's Next For ML & You: Emily Fox & Carlos GuestrinDocument38 pagesWhat's Next For ML & You: Emily Fox & Carlos GuestrinPranavNo ratings yet

- Build Your Trust Advantage: Leadership in The Era of Data and AI EverywhereDocument50 pagesBuild Your Trust Advantage: Leadership in The Era of Data and AI Everywherecheryl bryersNo ratings yet

- Machine Learning With Random Forests and Decision Trees - A Visual Guide For Beginners by Scott HartshornDocument73 pagesMachine Learning With Random Forests and Decision Trees - A Visual Guide For Beginners by Scott HartshornIvaylo KrustevNo ratings yet

- Machine Learning Snap Card GameDocument1 pageMachine Learning Snap Card GameSamer MaaraouiNo ratings yet

- DS Resume Template by Emma DingDocument2 pagesDS Resume Template by Emma DingJalal LhachmiNo ratings yet

- Face Mask Detection by Using Optimistic Convolutional Neural NetworkDocument6 pagesFace Mask Detection by Using Optimistic Convolutional Neural NetworkTrung Huynh KienNo ratings yet

- Building Ethics Into Artificial IntelligenceDocument7 pagesBuilding Ethics Into Artificial IntelligencecrazysttrikerNo ratings yet

- A Comparative Study On Machine Learning For Computational Learning TheoryDocument5 pagesA Comparative Study On Machine Learning For Computational Learning TheoryijsretNo ratings yet

- UNIDIR AI-international-security Understanding Risks Paving The Path For Confidence Building MeasuresDocument65 pagesUNIDIR AI-international-security Understanding Risks Paving The Path For Confidence Building MeasuresGjoko IvanoskiNo ratings yet

- ANN Models ExplainedDocument42 pagesANN Models ExplainedAakansh ShrivastavaNo ratings yet

- VR20 - 2-1 - MCA-Reg - Result - APR - 22Document9 pagesVR20 - 2-1 - MCA-Reg - Result - APR - 22Lovely VasanthNo ratings yet

- A Blockchain Future To Internet of Things Security A Position PaperDocument4 pagesA Blockchain Future To Internet of Things Security A Position PaperLong VỹNo ratings yet

- Digital Twin Development: Frank U. Rückert Michael Sauer Tuomo Liimatainen Dirk HübnerDocument129 pagesDigital Twin Development: Frank U. Rückert Michael Sauer Tuomo Liimatainen Dirk HübnerTeknNo ratings yet

- Machine Learning: Bilal KhanDocument20 pagesMachine Learning: Bilal KhanOsama Inayat100% (1)

- Examining Technological Innovation of Apple Using Patent AnalysisDocument20 pagesExamining Technological Innovation of Apple Using Patent AnalysisAlexandru BalanNo ratings yet

- fishes-08-00516-v2Document19 pagesfishes-08-00516-v2Walter Sullivan Felipe GasparNo ratings yet