Professional Documents

Culture Documents

AHM060 2 Ramp Handling PDF

Uploaded by

Narablues IndonesiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AHM060 2 Ramp Handling PDF

Uploaded by

Narablues IndonesiaCopyright:

Available Formats

2.

RAMP HANDLING AND GROUND SUPPORT EQUIPMENT

Station: Date: Handling Company:

2.1 Services

2.1.1 Services Provided

Services FOD inspection other: Aircraft marshalling other: Placing of wheel chocks other: Checking for aircraft damage other: Opening/closing aircraft compartment doors other: Aircraft loading/off-loading other: Stowing/securing of load in the aircraft cargo compartments other: Checking aircraft in-plane loading systems and reporting of missing locks and serviceability other: Reporting of loading irregularities other: Physical checking of dangerous goods other: Checking of NOTOC against actual load other: Cross check and reporting of Last Minute Changes other: Providing fire fighting equipment other: Handling Company Carrier Not Provided

Services Providing passenger stairs/jetways

Handling Company

Carrier

Not Provided

other: Providing pallet/container dollies/bulk carts other: Toilet servicing other: Potable water servicing other: GPU/Air start services other: Catering services other: Fuel services other: Anti/De-icing Services other: Aircraft push back other: Walk out assistance other: Aircraft towing other:

2.1.2 Experience

The Handling Company has experience in handling following Carriers and Aircraft Types: Name of Carrier Aircraft Types

Comments:

Legend: = safety relevant complaint = complaint; not safety relevant = no complaint; in accordance with carriers standards fulfilled = not applicable; not checked

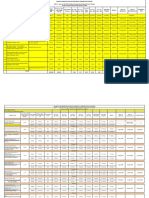

2.1.3 Ground Support Equipment

Condition GSE Ground Power Unit (GPU) Toilet Service Truck Aircraft Cooling Unit Portable Water Truck Airstart Unit (ASU) Container/Pallet Loader Main Deck Loader Conveyor Belt Fork Lift Pallet Transporter Container Transporter Catering Lift Truck Container Dollies Pallet Dollies ULD-Storage racks Baggage/cargo carts Tugs Passenger steps Maintenance steps Jet bridges Aircraft Tow tractors Tow bars De-icing unit De-icing fluid Snow Plow Range of height: Range of height: Operable height: Max. capacity: A/C types: Range of height: Type of name: Size: Range of height: Quantity Type/Make Specifications Output KVA: Capacity: Capacity: Capacity: Lbs/min: Lift Capacity: Lift Capacity: Range of height: Lift Capacity:

Comments:

2.2 Training and Qualification of Aircraft Loading/Servicing Staff

Several different functions are involved in the Aircraft loading and servicing process. Consequently, the training and qualification may differ per function. To have a proper overview, the training and qualification aspects shall be indicated for each function.

2.2.1 Basic Training

A. Basic training must be completed by a written test (Yes/No) B. Minimum passing rate for test (in %) C. A Licence is issued (Yes/No) Duration (days) Function General loader Loading Supervisor Operator Passenger boarding equipment Operator aircraft loading equipment GSE operator (GPU, ASU, ACU) Push Back operator Towing operator Walk out assistance Water servicing Toilet Servicing Catering Truck operator Anti/de-icing operator Classroom On the Job CBT Selfstudy Provider Yes A No % B Yes C No

Comments on Basic Training:

2.2.2 Recurrent Training

A. Recurrent training must be completed by a written test (Yes/No) B. Minimum passing rate for test (in %) C. A Licence is issued/updated (Yes/No) Duration (days)/Intervals (months) Function General loader Loading Supervisor Operator Passenger boarding equipment Operator aircraft loading equipment GSE operator (GPU, ASU, ACU) Push Back operator Towing operator Walk out assistance Water Servicing Toilet Servicing Catering Truck operator Anti/de-icing operator Classroom On the Job CBT Selfstudy Provider Yes A No B % Yes C No

Comments on Basic Training:

2.2.3 Dangerous Goods Training

Dangerous Goods training is given according to: Carriers regulations IATA Dangerous Goods Regulations Dangerous Goods Training is Certified by: A. Dangerous Goods Training must be completed by a written test B. Minimum passing rate for test (in %) C. A Licence is issued (Yes/No) Duration (days) Function General loader Loading Supervisor Operator aircraft loading equipment Classroom On the Job CBT Selfstudy Provider Yes A No B % Yes (Yes/No)

C No

Comments on Dangerous Goods Training:

2.2.4 Dangerous Goods Recurrent Training

Dangerous Goods Recurrent Training is Certified by: A. Dangerous Goods Recurrent Training must be completed by a written test (Yes/No) B. Minimum passing rate for test (in %) C. A Licence is issued/updated (Yes/No) Duration (days)/Interval (months) Function General loader Loading Supervisor Operator Passenger boarding equipment Classroom On the Job CBT Selfstudy Provider Yes A No B % Yes C No

Comments on Dangerous Goods Recurrent Training:

2.2.5 Airside Safety Awareness Training

Note: A comprehensive airside safety performance audit is published under AHM 612 Recommendations for Airside Safety Performance Audits. A. Airside Safety Training must be completed by a written test (Yes/No) B. Minimum passing rate for test (in %) C. A Licence is issued (Yes/No) Duration (days) Function Operator Passenger boarding equipment Operator aircraft loading equipment GSE operator (GPU, ASU, ACU) Push Back operator Towing operator Walk out assistance Water Servicing Toilet Servicing Catering Truck operator Anti/de-icing operator Classroom On the Job CBT Selfstudy Provider Yes A No B % Yes C No

Comments on Airside Safety Awareness Training:

2.2.6 Additional Training

(Please state below, if, what type and for which ramp handling staff/function additional training is given) Duration (days) Type of Training Staff/Function Classroom On the Job CBT Self-study

2.2.7 Training and Qualification Records

Training and qualification records are: kept on file Type of Training Basic Training Recurrent Training Dangerous Goods Training Dangerous Goods Recurrent Training Airside Safety Awareness Training No Yes by No checked for validity Yes by

Comments on Training and Qualification Records:

2.2.8 General Comments on Training

2.3 Procedures and Organisation Assessment

2.3.1 General

2.3.1.1 Safety and Health Policy

Safety and Health policy available and known by handling staff Yes No

2.3.1.2 Quality Assurance

A Quality Assurance Program has been implemented Yes No

2.3.1.3 Emergency Procedures Available at Ramp Handling Control Office

Carriers emergency procedures Carriers list of contacts in case of emergency Handling agents emergency procedures Handling agents list of contacts in case of emergency Airport authoritys list of contacts in case of emergency Other (specify): Other (specify):

2.3.1.4 Discipline on the Ramp

Applicable regulations are in place concerning: Smoking on the Ramp Horseplay Maltreatment of GSE/Loading aids/ULDs Observation of Danger Areas/Hazards on the ramp

2.3.1.5 Danger Areas and Hazards

Danger areas/hazards clearly marked, known and understood by ramp staff Yes No

2.3.1.6 IATA Guide Man Hand Signals

IATA Guide man hand signals are known and used Yes No

2.3.1.7 Manuals Available at Ramp Handling Control Office

Handling Companys Manual is known and being used Y Y X X Y Y Y Y Y N N N N N N N Y Y Y Y Y Y Y

Manual Aircraft Handling Manual Dangerous Goods Regulations IATA Dangerous Goods Regulations IATA Airport Handling Manual Other (specify): Other (specify): Other (specify):

Carrier

Valid N N N N N N N

2.3.2 Preparation for Handling on the Ramp

2.3.2.1 FOD-Inspection

FOD-Inspections are performed by: Airport Authority Handling Company Carrier Other (Specify): At which intervals are FOD-Inspections performed:

2.3.2.2 Ground Support Equipment GSE

GSE is planned and dispatched to the ramp position Yes No By: Availability of Fire Fighting Equipment checked Yes No By: Supervision that GSE is parked within safety perimeters at the ramp is performed Yes No By:

2.3.2.3 Briefing of Aircraft Loading Staff

The loading staff handling the particular flight is briefed by: at: by means of: Comments on Preparation for handling on the ramp:

2.3.3 Inspection of the Onload

2.3.3.1 Comparison Between Onload and Loading Instruction

Comparison between the onload positioned on the ramp and the loading instruction is performed: Yes No By:

2.3.3.2 Check of the Onload

Correct ULD build-up as contour, tie down, load spreading is checked Yes No By: Visible damage to load is checked and reported Yes No By: Attachment of ULD-tags and proper completion is checked Yes No By: Comments on Inspection of the Onload:

2.3.4 Aircraft Acceptance

2.3.4.1 Aircraft Marshalling

Aircraft marshalling is performed Yes No By: ICAO standards are followed Yes No

2.3.4.2 Aircraft Acceptance

Aircraft acceptance is performed Headset Hand signals Other (specify): Yes No by using:

and is performed by: Aircraft wheel chocks are placed Yes No By: A visual check for aircraft exterior damage (walk around) and reporting is performed: Yes No By: Comments on Aircraft Acceptance:

2.3.5 Passenger Disembarkation

2.3.5.1 Positioning of Passenger Stairs and/or Jetways

Safe and correct positioning and manoeuvering of Passenger stairs and/or jetways is performed Yes No By:

2.3.5.2 Safeguarding of Passenger Disembarkation

The Safeguarding of passenger ways and supervision of passenger disembarkation process is performed Yes No By: Comments on Passenger Disembarkation:

2.3.6 Positioning of Ground Support Equipment (GSE)

Safe and correct positioning and manoeuvering of GSE at the aircraft is co-ordinated and supervised Yes No By: Guide person is used during positioning of GSE Comments on Positioning of Ground Support Equipment: Yes No

2.3.7 Fuelling Operation

Fuelling Operation is supervised Yes No By: Load Control Office is informed about the final fuel data Yes No By: By means of: Comments on Fuelling Operation:

2.3.8 Off-loading Operation

Aircraft compartment doors are opened by: The off-loading principles and logistics (incl. aircraft ground stability tail tipping) are known Yes No and followed by: Action is taken if compartments are contaminated Yes No By: A visual check on loading and restraint system, damage etc. of all cargo compartments after off loading is performed and reported Yes No By: Comments on Off-loading Operation:

2.3.9 Loading Operation

2.3.9.1 Responsibility and Supervision of Loading Operation

Overall responsibility for and supervision of the entire loading operation (catering, fuelling, GSE-positioning, loading etc.) is performed Yes No By:

2.3.9.2 Loading Principles/Logistics

Loading principles and logistics (incl. ground stability tail tipping) are known and followed Yes No By: Comments on loading Operation:

2.3.10 Loading Instruction/Report

2.3.10.1 Loading According to Loading Instruction/Report

Loading and positioning of the load at the aircraft is performed according to the Loading Instruction Report Yes No By: Loading and positioning of the load at the aircraft according to the Loading Instruction Report is supervised Yes No By:

2.3.10.2 Notations on the Loading Instruction Report

ULD-numbers are recorded and amendments to weights and figures on the Loading Instruction Report are performed Yes No By:

2.3.10.3 Signature on the Loading Instruction Report

The loading instruction is signed by: Comments on loading Instruction/Report:

2.3.11 Dangerous Goods, Special Load, ULD Restraint and Loading

2.3.11.1 Dangerous Goods and Special Load

The loading of dangerous goods and special loads in accordance with carriers and international regulations is performed Yes No By: The actual dangerous goods and special load is checked against the NOTOC and/or the Loading Instruction Report Yes No By:

2.3.11.2 Restraining of Load

Restraining of bulk load and ULDs is performed by: Restraining of bulk load and ULDs is supervised by: The missing lock procedure is known and missing or unserviceable locks are reported by: to: by means of: Comments on Special load, ULD restraint and loading:

2.3.12 Loading Irregularities and Reporting

by: by means of: to:

Loading irregularities including damage to onload, leaking packages and aircraft loading system defects are reported

Deviation from the loading instructions are reported to the Load Control office by: to: by means of: Comments on Loading irregularities and reporting:

2.3.13 Passenger Embarkation Process

2.3.13.1 Passenger Embarkation Clearance

Clearance to start passenger embarkation is obtained from the crew Yes No By: The Safeguarding of passenger ways and supervision of the passenger embarkation process is performed Yes No By: Comments on Passenger embarkation process:

2.3.14 Actions Immediately Performed Prior To Departure

2.3.14.1 Last Minute Changes (LMC)

Last Minute Changes (LMCs) are checked and reported to the Load Control Office by: by means of: = safety relevant complaint = complaint; not safety relevant = no complaint; in accordance with carriers standards fulfilled = not applicable; not checked

2.3.14.2 Flight Documentation, e.g. Load Sheet, Passenger Manifest etc.

Flight documents are presented to the cockpit crew by:

2.3.14.3 Aircraft Doors, Service Panels and Aircraft Damage

Proper closing of all aircraft doors and service panels is checked by: A visual check for aircraft damage (walk around) and reporting is performed by: to: by means of: Comments on Actions immediately performed prior to departure:

2.3.15 Push Back and Walk-out Assistance

2.3.15.1 Push Back

Push back is performed by:

2.3.15.2 Walk-out Assistance

Walk-out assistance is performed by:

2.3.15.3 Ground to Cockpit Communication

The Ground to Cockpit communication is performed by:

2.3.15.4 Safety Zones

Safety zones are clear and adhered to Yes Wing walkers are used during push back Yes Comments on Push back and walk-out assistance: No No

2.4 Summary

You might also like

- AC 00-65 Towbar and Towbarless Movement PDFDocument15 pagesAC 00-65 Towbar and Towbarless Movement PDFKaung MyatToeNo ratings yet

- Global Megatrends and Aviation: The Path to Future-Wise OrganizationsFrom EverandGlobal Megatrends and Aviation: The Path to Future-Wise OrganizationsNo ratings yet

- IATA ManualDocument44 pagesIATA ManualjasdsbNo ratings yet

- Hand PDFDocument45 pagesHand PDFledelgado.tacv323350% (2)

- Airside Drivers Handbook APRIL 2016Document67 pagesAirside Drivers Handbook APRIL 2016Mahmood Mushtaq100% (1)

- Day01 04 IATA AcostaDocument58 pagesDay01 04 IATA AcostaManuel ReyesNo ratings yet

- SOP 001.WI-5.Ramp Arrivals ActivityDocument4 pagesSOP 001.WI-5.Ramp Arrivals ActivityTony RandersonNo ratings yet

- New Ramp Safety Handout - May 2017 PDFDocument63 pagesNew Ramp Safety Handout - May 2017 PDFameetsharma100% (1)

- Annex 17 SummaryDocument10 pagesAnnex 17 SummaryAmit Kumar PudaruthNo ratings yet

- Load Control CourseDocument11 pagesLoad Control CourseRamyAbdullahNo ratings yet

- Ahm 810Document45 pagesAhm 810FERRACHI SamiraNo ratings yet

- Ch4 MCQ PDFDocument2 pagesCh4 MCQ PDFGhazanfar AliNo ratings yet

- Ramp HandlingDocument20 pagesRamp HandlingHtetMyetKo100% (2)

- Iat ADocument81 pagesIat ARafael GM Grosser0% (1)

- Dnata Cargo - Study MaterialDocument47 pagesDnata Cargo - Study MaterialKishore Khatri86% (7)

- Ahm 804 Iata (Sla)Document37 pagesAhm 804 Iata (Sla)Luciano Romero100% (1)

- Ahm TocDocument18 pagesAhm TocMik Aeil50% (2)

- Cargo Webinar IATADocument35 pagesCargo Webinar IATAMik AeilNo ratings yet

- Guidance On Unruly Passenger Prevention and ManagementDocument70 pagesGuidance On Unruly Passenger Prevention and ManagementMedTaïebBenTekayaNo ratings yet

- V13 D03 1 PDFDocument45 pagesV13 D03 1 PDFFredy Camayo De La CruzNo ratings yet

- Ramp and CargoDocument17 pagesRamp and Cargonimmymathewpkkthl100% (2)

- Ground Operations TrainingDocument46 pagesGround Operations TrainingRizal Asri100% (2)

- AHM IGOM Feb2012 PDFDocument130 pagesAHM IGOM Feb2012 PDFgoodtimesdeccan4267100% (1)

- The ICAO Aviation Security Programme The ICAO Aviation Security ProgrammeDocument35 pagesThe ICAO Aviation Security Programme The ICAO Aviation Security ProgrammeTc Adfo100% (1)

- ICAO WCO Moving Air Cargo enDocument36 pagesICAO WCO Moving Air Cargo enManmohan RawatNo ratings yet

- Diploma in Airport OperationsDocument5 pagesDiploma in Airport OperationsMartin NadarNo ratings yet

- ISM 9th Edition Sept2015Document419 pagesISM 9th Edition Sept2015sakashefNo ratings yet

- Security ProgrammeDocument96 pagesSecurity ProgrammeAmalNo ratings yet

- IATA Updates at ULD CARE PDFDocument75 pagesIATA Updates at ULD CARE PDFali4957270No ratings yet

- 01-CPD-8, Civil Aviation Procedure Document On Airworthiness-MinDocument884 pages01-CPD-8, Civil Aviation Procedure Document On Airworthiness-Minnishat529100% (1)

- ICAO & Aviation SecurityDocument36 pagesICAO & Aviation SecurityFrancisco Ashley Acedillo100% (3)

- Human Factors Training ManualDocument297 pagesHuman Factors Training ManualAna_Stancescu_4778No ratings yet

- Rfid For Baggage Business Case 21Document72 pagesRfid For Baggage Business Case 21Mohd Fikry100% (2)

- BCAS SoP For Screening of Passengers With Special Needs and Medical ConditionsDocument6 pagesBCAS SoP For Screening of Passengers With Special Needs and Medical ConditionsDisability Rights Alliance100% (2)

- MessagesDocument25 pagesMessagesAdmon del GrupoNo ratings yet

- Aviation Ramp Safety How Much DamageDocument13 pagesAviation Ramp Safety How Much DamageDung Rwang Pam100% (4)

- Ahm TocDocument19 pagesAhm TocFouad RatemeNo ratings yet

- Egom 2019 v8.0 PublicDocument402 pagesEgom 2019 v8.0 PublicPavan SoniNo ratings yet

- SGHADocument124 pagesSGHAPro Tector100% (1)

- Travel Agent Handbook EngDocument150 pagesTravel Agent Handbook EngAnaBaicu50% (2)

- Load Planning and Load Control ManualDocument70 pagesLoad Planning and Load Control Manualhermanhermaszewski100% (2)

- AVSEC RegulationsDocument51 pagesAVSEC RegulationsWorawat Wongratanamajcha100% (1)

- Arffs Inspection Checklist PDFDocument19 pagesArffs Inspection Checklist PDFSHERIEFNo ratings yet

- Airport Operations Manual: August 20, 2020Document73 pagesAirport Operations Manual: August 20, 2020hakan özcanNo ratings yet

- Aircraft HandlingDocument46 pagesAircraft HandlingAmrino Giogio100% (7)

- Dnata - SGHA 2008Document202 pagesDnata - SGHA 2008chaouch.najehNo ratings yet

- Cabin PresentationDocument29 pagesCabin PresentationGeorge Menchaca100% (1)

- Webinar 10 Integrated Ops Control Centre v1 0 2010.06.09Document26 pagesWebinar 10 Integrated Ops Control Centre v1 0 2010.06.09AndriantsalamaNo ratings yet

- DGR Exam 2 Cat 16 2020Document5 pagesDGR Exam 2 Cat 16 2020Kelvin100% (1)

- Dangerous Goods Training ProgrammeDocument96 pagesDangerous Goods Training ProgrammebabrulhasantaponbabulNo ratings yet

- 1 Air Transport .TDocument160 pages1 Air Transport .TWondwosen TirunehNo ratings yet

- Ahs SghaDocument68 pagesAhs SghaIlkay GultasNo ratings yet

- Ground Handling SafetyDocument46 pagesGround Handling SafetyamvitaNo ratings yet

- AEA Deicing v27Document50 pagesAEA Deicing v27Miroslav StoyanovNo ratings yet

- AHM060 1 Load ControlDocument16 pagesAHM060 1 Load ControlhermanNo ratings yet

- Airline Transport Pilot Licence Aeroplane - Flight Test ReportDocument4 pagesAirline Transport Pilot Licence Aeroplane - Flight Test Reportsd_hosseini_88No ratings yet

- CAP Form 5 - Jan 2009Document3 pagesCAP Form 5 - Jan 2009CAP History LibraryNo ratings yet

- OC06 2018 (R1 Feb2023)Document39 pagesOC06 2018 (R1 Feb2023)chandraNo ratings yet

- ChromiumDocument18 pagesChromiumNarablues IndonesiaNo ratings yet

- Young's Modulus - Wikipedia, The Free EncyclopediaDocument6 pagesYoung's Modulus - Wikipedia, The Free EncyclopediaNarablues IndonesiaNo ratings yet

- Work (Physics) - WikDocument12 pagesWork (Physics) - WikNarablues IndonesiaNo ratings yet

- AHM640 Ramp Error Codes PDFDocument9 pagesAHM640 Ramp Error Codes PDFNarablues IndonesiaNo ratings yet

- AHM650 Ground Incident Damage Report Sheet 01-02 PDFDocument4 pagesAHM650 Ground Incident Damage Report Sheet 01-02 PDFNarablues IndonesiaNo ratings yet

- AHM381 Special Load Notification To Captain General PDFDocument5 pagesAHM381 Special Load Notification To Captain General PDFNarablues Indonesia100% (1)

- Flight Management ComputerDocument19 pagesFlight Management ComputerNarablues IndonesiaNo ratings yet

- Safety Around Helicopters-IndustryDocument1 pageSafety Around Helicopters-IndustryNarablues IndonesiaNo ratings yet

- 004 Contingency Planning - English VersionDocument20 pages004 Contingency Planning - English VersionNarablues IndonesiaNo ratings yet

- Threat OverviewDocument16 pagesThreat OverviewNarablues IndonesiaNo ratings yet

- Heliport DesignDocument17 pagesHeliport DesignNarablues IndonesiaNo ratings yet

- Helicopter Flight Training ManualDocument20 pagesHelicopter Flight Training ManualNarablues Indonesia100% (1)

- Checkballbook: Import Volume IIIDocument10 pagesCheckballbook: Import Volume IIIFS TRANSMISSÕESNo ratings yet

- A Guide On Good Practice To Boost Energy Efficiency in Central and South Eastern Europe-EUDocument92 pagesA Guide On Good Practice To Boost Energy Efficiency in Central and South Eastern Europe-EUOner AltınsoyNo ratings yet

- Final Tdfs Dimts Rites+StudyDocument144 pagesFinal Tdfs Dimts Rites+StudyNidhi MalhotraNo ratings yet

- CV Roby Eka P BARU2Document1 pageCV Roby Eka P BARU2delfad robyekaputraNo ratings yet

- Parts Manual Keeway Fact 50 2tDocument61 pagesParts Manual Keeway Fact 50 2tSimon Albert100% (1)

- Bobcat 320 Excavator Parts Catalogue Manual SN 562313001 and Above PDFDocument29 pagesBobcat 320 Excavator Parts Catalogue Manual SN 562313001 and Above PDFjnfksmemms0% (1)

- Consulting ServicesDocument1 pageConsulting ServicesTimu OvidiuNo ratings yet

- System PracticesDocument27 pagesSystem PracticesMechanicalNo ratings yet

- Driven Machinery RegulationsDocument16 pagesDriven Machinery RegulationsSangeevNo ratings yet

- Catalogo Motoniveladora GD655-5 PDFDocument444 pagesCatalogo Motoniveladora GD655-5 PDFNilton Junior Kern100% (3)

- Arada VS CaDocument6 pagesArada VS CaNFNLNo ratings yet

- Seoul Autumn ItineraryDocument2 pagesSeoul Autumn ItineraryvgparceNo ratings yet

- Kotak I3s Report 01.12.2019Document122 pagesKotak I3s Report 01.12.2019Darshan PhadkeNo ratings yet

- Owner'S Manual: Read This Manual Carefully Before Operating This VehicleDocument100 pagesOwner'S Manual: Read This Manual Carefully Before Operating This Vehicleigor petrovskiNo ratings yet

- Safety Gram 16Document6 pagesSafety Gram 16bigpow6560No ratings yet

- Guascor F SF 480 Diesel Engines - 2Document9 pagesGuascor F SF 480 Diesel Engines - 2Xmenxs XmenxsNo ratings yet

- Computer Data Lines (Information Bus) - ALLDATA RepairDocument2 pagesComputer Data Lines (Information Bus) - ALLDATA RepairMarco ChanNo ratings yet

- Intercity Trains Schedule ChittagongDocument1 pageIntercity Trains Schedule ChittagongWjwjiwwiNo ratings yet

- Police Log July 22, 2016Document20 pagesPolice Log July 22, 2016MansfieldMAPoliceNo ratings yet

- Tailift FD (G) 15 35 Artison Series Parts ManualDocument308 pagesTailift FD (G) 15 35 Artison Series Parts ManualJose Pereira0% (1)

- Ch14 Case Study Company Case Volvo TrucksDocument2 pagesCh14 Case Study Company Case Volvo TrucksМөнхтөр ЭнхжаргалNo ratings yet

- Flight Plan 2030: An Air Traffic Management Concept For Urban Air MobilityDocument48 pagesFlight Plan 2030: An Air Traffic Management Concept For Urban Air MobilityTOMNo ratings yet

- 2012 40' Azimut 40S - Sample Survey ReportDocument53 pages2012 40' Azimut 40S - Sample Survey ReportSuenos Azules67% (3)

- Tutorial 2 ConcreteDocument1 pageTutorial 2 ConcretepangkaiyunNo ratings yet

- Week WiseDocument89 pagesWeek Wiseanon_282986602No ratings yet

- Gujarat Setco Annual Report 2011Document104 pagesGujarat Setco Annual Report 2011HitechSoft HitsoftNo ratings yet

- Ata 52 DoorsDocument106 pagesAta 52 DoorsOmar Khan100% (1)

- Construction Opportunities - February 2018Document152 pagesConstruction Opportunities - February 2018Adriano BelucoNo ratings yet

- Letter of IntentDocument5 pagesLetter of IntentTokimemoto Lustre ReidNo ratings yet

- Twi Industries VSMDocument12 pagesTwi Industries VSMChe CruzNo ratings yet