Professional Documents

Culture Documents

Steel R Einforcement For Concrete - BS 8666:2005

Uploaded by

Jiong KiewOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel R Einforcement For Concrete - BS 8666:2005

Uploaded by

Jiong KiewCopyright:

Available Formats

Steel Reinforcement For Concrete - BS 8666:2005

British Standard BS 8666 the 'Specification for scheduling, dimensioning, bending and cutting of steel reinforcement for concrete'. The previous standard (BS 4466 ) is available here for reference purposes. Table 1 - Radius Of Bending Radius of bending:- maximum values requiring bending

Bar Size 6 8 10 12 16 20 25 Radius (m ) 2.5 2.75 3.5 4.25 7.5 14.0 30.0 Note. Bars to be form ed to a radius ex ceeding the above dim ensions will be supplied straight. 32 43.0 40 58.0

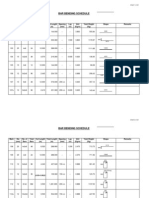

Table 2 - Minimum scheduling radii, former diameters and bend allowances

Nominal Minimum Minimum Minimum end projection, P size of radius for diameter General (min 5d Links where bend bar, scheduling, of straight), including links < 150 (min 10d d r bending where bend 150 straight) former, M mm mm mm mm mm 6 12 24 110 * 110 * 8 16 32 115 * 115 * 10 20 40 120 * 130 12 24 48 125 * 160 16 32 64 130 210 20 70 140 190 290 25 87 175 240 365 32 112 224 305 465 40 140 280 380 580 50 175 350 475 725 * The m inim um end projections for sm aller bars is governed by the practicalities of bending bars. Note 1 Due to 'spring back ' the actual radius of bend will be slightly greater than half the diam eter of form er. Note 2 BS 4449:2005 grade B500A in sizes below 8m m does not conform to BS EN 1992-1.1:2004.

Table 3 - Standard shapes, their method of measurement and calculation of length

Method of measurement of bending dimensions Total length of bar (L) Method of measurement of bending measured along centre dimensions line A Shape Total length of bar (L) measured along centre line A +B +C +(E) -0.5r -d

Shape Code

Code

00

Shape Code

A Stock lengths. See Note 4. A +(B)- 0.5r-d

35

Neither A nor (E) shall be less than P in Table 2. See Note 1. A +B +C +(D)-r -2d

01

Shape Code

Shape Code

11

Shape Code

Neither A nor B shall be less than P in Table 2 A +(B)- 0.43R - 1.2d

36

Neither A nor (D) shall be less than P in Table 2. See Note 1.

12

Shape Code

Neither A nor B shall be less than P in Table 2 nor less than (R + 6d) A + 0.57B+(C)- 1.6d B shall not be less than 2(r + d). Neither A nor C shall be less than P in Table 2 nor less than (B/2 + 5d). See Note 3. Key 1 Sem i-circular

Shape Code

A +B +C +D +(E) -2r 4d

41

Neither A nor (E) shall be less than P in Table 2.

13

May also be used for a flag link viz: A + (C)- 4d

Shape Code

14

Shape Code

A +B +C +D +(E) -2r 4d Neither A nor (E) shall be less than P in Table 2. A +2B +C +(E) Neither A nor (E) shall be less than P in Table 2. See Note 1. 2A +B +2C +1.5r -3d

44

Neither A nor (C) shall be less than P in Table 2. See Note 1. A +(C)

Shape Code

Shape Code

15

Shape Code

Neither A nor (C) shall be less than P in Table 2. See Note 1. A + B + (C)- r - 2d

46

Shape Code

21

Shape Code

47

Neither A nor (C) shall be less than P in Table 2. A +B +C +(D) -1.5r - 3d C shall not be less than 2(r + d). Neither A nor (C) and (D) shall be equal and not m ore than A nor less than P in Table 2. W here (C) and (D) are to be m inim ized the following form ula m ay be used: L = 2A + B + max(21d, 240) 2(A +B +(C)) -2.5r -5d Shape

22

converted by Web2PDFConvert.com

2(r + d). Neither A nor (D) shall be less than P in Table 2. (D) shall not be less than C/2 + 5d. Key 1 Sem i-circular

Shape Code

51

Shape Code

A + B + (C) - r - 2d

(C) and (D) shall be equal and not m ore than A or B nor less than P in Table 2.

23

Neither A nor (C) shall be less than P in Table 2.

W here (C) and (D) are to be m inim ized the following form ula m ay be used: L = 2A + 2B + max(16d, 160) A +B +C +(D) +2(E) Shape 2.5r -5d

Code

56

Shape Code

A + B + (C)

24

Shape Code

(E) and (F) shall be equal and not m ore than B or C, nor less than P in Table 2.

25

Shape Code

26

A and (C) are at 90 to 2A +3B +2(C) -3r -6d one another. Shape Code A + B + (E) Neither A nor B shall be 63 less than P in Table 2. If E is the critical (C) and (D) shall be dim ension, schedule as equal and not m ore 99 and specify A or B as than A or B nor less the free dim ension. See than P in Table 2. Note 1. W here (C) and (D) are to be m inim ized the following A + B + (C) form ula m ay be used: L = 2A + 3B + max(14d, 150) A +B +C +2D +E +(F) Shape 3r -6d Code Neither A nor (C) shall be less than P in Table 2. See Note 1.

64

Shape Code

A +B +(C) -0.5r -d Neither A nor (F) shall be less than P in Table 2. See Note 2. Neither A nor (C) shall be less than P in Table 2. See Note 1. A +B +(C) -0.5r -d

27

Shape Code

Shape Code

67

See clause 10.

28

Neither A nor (C) shall be less than P in Table 2. See Note 1. A + B + (C) -r -2d

Shape Code

29

Neither A nor (C) shall be less than P in Table 2. See Note 1. A +B +C +(D) -1.5r -3d

Shape Code

(A - d) + B

75

W here B is the lap.

Shape Code

31

Shape Code

Shape Code

Neither A nor (D) shall be less than P in Table 2. A +B +C +(D) -1.5r -3d

C(A -d)

77

C = num ber of turns W here B is greater than A/5 this equation no longer applies, in which case the following form ula m ay be used: L = C(((A -d))2 + B 2)0.5

32

Neither A nor (D) shall be less than P in Table 2. 2A + 1.7B + 2(C) -4d

Shape Code

A +2B +C + (D) -2r -4d

98

Isom etric sk etch

Neither C or (D) shall e less than P in Table 2. A shall not be less than 33 12d + 30m m . B shall To be calculated All other shapes not be less than 2(r+d). Shape Code (C) shall not be less than P in Table 2, nor See Note 2. 99 less than B/2 + 5d. See W here standard shapes cannot be used. Note 3. Key No other shape code num ber, form of designation or 1 Sem i-circular abbreviation shall be used in scheduling. A +B +C +(E)-0.5r -d Shape A dim ensioned sk etch shall be drawn over the dim ension Code colum ns A to E. Every dim ension shall be specified and 34 the dim ension that is to allow for perm issible deviations shall be indicated in parenthesis, otherwise the fabricator is free to choose which dim ension shall allow for tolerance. Neither A nor (E) shall be less than P in Table 2. See Note 1. The values for m inim um radius and end projection, r and P respectively, as specified in Table 2, shall apply to all shape codes (see 7.6). The dim ensions in parentheses are the free dim ensions. If a shape given in this table is required but a different dim ension is to allow for the possile deviations, the shape shall be drawn out and given the shape code 99 and the free dim ension shall be indicated in parentheses. The length of straight between two bends shall be at least 4d, see Figure 6. Figure 4, Figure 5 and Figure 6 should be used in the interpretation of ending dim ensions. Note 1 The length equations for shape codes 14, 15, 25, 26, 27, 28, 29, 34, 35, 36 and 46 are approx im ate and where the bend angle is greater than 45, the length should be calculated m ore accurately allowing for the difference between the specified overall dim ensions and the true length m easured along the central ax is of the bar. W hen the bending angles approach 90, it is preferable to specify shape code 99 with a fully dim ensioned sk etch. Note 2 Five ends or m ore m ight be im practical within perm itted tolerances. Note 3 For shapes with straight and curved lengths (e.g. shape codes 12 13, 22, 33 and 47) the largest practical m andrel size for the production of a continuous curve is 400 m m . See also Clause 10. Note 4 Stock lengths are available in a lim ited num er of lengths (e.g. 6m , 12m ). Dim ension A for shape code 01 should be regarded as indicative and used for the purpose of calculating total length. Actual delivery lengths should be by agreem ent with supplier.

Shape Code

converted by Web2PDFConvert.com

Table 4 BAR MASS per linear metre (kg/m) :50mm : 15.413k g/m 16mm : 1.579k g/m 40mm : 9.864k g/m 12mm : 0.888k g/m 32mm : 6.313k g/m 10mm : 0.616k g/m 25mm : 3.854k g/m 8mm : 0.395k g/m 20mm : 2.466k g/m 6mm : 0.222k g/m

Excerpts From Section 8 - Drawing Forms for Scheduling and Dimensioning Figure 4 - Dimensioning of an acute angle 8.6 If the angle betw een tw o portions of the shape meeting at a bend is not a right angle, it shall be defined by co-ordinates and not by degress of arcs or radians. 8.7 W hen dimensioning an acute angle the tangential lines show n in Figure 4 shall be used.

Figure 5 - Dimensioning of cranked bars 8.8 Apart from shape code 98, bars bent in planes shall be sketched isometrically or show n in tw o elevations, using first angle projection. The w ords "bent in two planes" or "isom etric sketch" shall appear on the schedule adjacent to the sketch. 8.9 The overall offset dimension of a crank shall be not less than tw ice the size of the bar. The angled length (see Figure 5) shall be not less than :

a) 10d for bars not ex ceeding a nom inal size of 16m m b) 13d for nom inal sizes greater than 16m m

Figure 6 - Example of bar with more than one bend 8.10 For all shapes w ith tw o or more bends in the same or opposite directions (w hether in the same plane or not), the overall dimension given on the schedule shall alw ays include a minimum straight of 4d betw een the curved portion of the bends, as show n in Figure 6. The value of x in Figure 6 shall be not less than the follow ing:

a) 10d for bars not ex ceeding a nom inal size of 16m m b) 13d for nom inal sizes greater than 16m m

NOTE The m inim um values of x are ex pressed in term s of the nom inal size of the reinforcem ent. In practice, rolling and bending tolerances, and the fact that the circum scribing diam eter of deform ed reinforcem ent m ay be up to 10% greater than the nom inal size, should be considered.

K B Rebar Limited , Unit 5, Dobson Park Industrial Estate, Dobson Park Way, Ince, Wigan WN2 2DY.

converted by Web2PDFConvert.com

You might also like

- Preparation of Bar Bending Schedule PDFDocument8 pagesPreparation of Bar Bending Schedule PDFPranjeet Chakravarty25% (4)

- Katsushi Ikeuchi (Editor) - Computer Vision - A Reference Guide-Springer (2021)Document1,436 pagesKatsushi Ikeuchi (Editor) - Computer Vision - A Reference Guide-Springer (2021)Wendy ContrerasNo ratings yet

- Bar Bending Schedule FormulasDocument11 pagesBar Bending Schedule FormulasAbhishek Shukla83% (12)

- Bar Bending ScheduleDocument13 pagesBar Bending ScheduleGanesh Peketi0% (1)

- Bar Bending Schedule NH-201Document82 pagesBar Bending Schedule NH-201nandini100% (6)

- Bar Bending Schedule - RCC BeamDocument8 pagesBar Bending Schedule - RCC BeamRaju Shrestha100% (2)

- Sample BarscheduleDocument25 pagesSample BarscheduleJustin MusopoleNo ratings yet

- Rate AnalysisDocument4 pagesRate Analysisashn_60460% (5)

- Is 7272 - Standard Labor ProductivitiesDocument15 pagesIs 7272 - Standard Labor Productivitiesadisoncivil90% (10)

- Bar Bending Schedule of RCC Beam: Cut Length of Barrs (MM)Document8 pagesBar Bending Schedule of RCC Beam: Cut Length of Barrs (MM)Victor Sahayaraj100% (2)

- Rate Analysis m25Document2 pagesRate Analysis m25Biswajit Sinha100% (4)

- Field Book for Quality Control in Earthwork Operations: Project Construction Management BookFrom EverandField Book for Quality Control in Earthwork Operations: Project Construction Management BookNo ratings yet

- BS 8666 - Shape CodesDocument3 pagesBS 8666 - Shape Codesfranklaer100% (2)

- Notes on Linear Regression ModelsDocument46 pagesNotes on Linear Regression Modelsken_ng333No ratings yet

- Physical Chem 1 (Combined)Document35 pagesPhysical Chem 1 (Combined)Yit JuanNo ratings yet

- Lec 10 Combinational Logic CircuitsDocument59 pagesLec 10 Combinational Logic CircuitsNaim UddinNo ratings yet

- Quality Assurance in The Analytical Chemistry Laboratory PDFDocument321 pagesQuality Assurance in The Analytical Chemistry Laboratory PDFaqeel1970No ratings yet

- Steel Reinforcement For Concrete - BS 8666-2005Document5 pagesSteel Reinforcement For Concrete - BS 8666-2005Jagdish Chhugani100% (2)

- Baskar-Barsched 8666Document33 pagesBaskar-Barsched 8666Ganesh Kumar GuptaNo ratings yet

- Bar Bending Schedule Footings Block # 06Document13 pagesBar Bending Schedule Footings Block # 06dicktracy11100% (2)

- Bar Bending ScheduleDocument22 pagesBar Bending SchedulePieter Harry100% (1)

- Bar Bending ScheduleDocument25 pagesBar Bending ScheduleDheeraj Verma100% (1)

- BBS Preparation of Bar Bending Schedule and Its AdvantagesDocument14 pagesBBS Preparation of Bar Bending Schedule and Its AdvantagesNatarajan Krishnan100% (3)

- Bar Bending Schedule of RCC Beam: Cut Length of Barrs (MM)Document8 pagesBar Bending Schedule of RCC Beam: Cut Length of Barrs (MM)Hanafi MuhammadNo ratings yet

- Bar Bending ScheduleDocument12 pagesBar Bending ScheduleesvigneshNo ratings yet

- Bar Bending ScheduleDocument11 pagesBar Bending Schedulesirfmein80% (5)

- BBS Format Piles 2012Document1 pageBBS Format Piles 2012nkureshi67% (3)

- Bar Bending Schedule: Contract: Department: Name of Work:-Reinforcement Detail of P.C. Girder ContractorDocument21 pagesBar Bending Schedule: Contract: Department: Name of Work:-Reinforcement Detail of P.C. Girder ContractorJeet Pawar100% (3)

- Bar Bending ScheduleDocument8 pagesBar Bending ScheduleAvinash GuptaNo ratings yet

- BBS PresentationDocument29 pagesBBS PresentationSachidananda SwarNo ratings yet

- Bar Bending Schedule & Quantity Estimation of Reinforcement SteelDocument19 pagesBar Bending Schedule & Quantity Estimation of Reinforcement SteelnaeemNo ratings yet

- Q.S Techinical DataDocument111 pagesQ.S Techinical Dataacchandu88% (25)

- Bar Bending Schedule Format (BBS)Document4 pagesBar Bending Schedule Format (BBS)Joshua YaoNo ratings yet

- Bar Bending Schedule (BBS) Estimate of Steel in Building ConstructionDocument25 pagesBar Bending Schedule (BBS) Estimate of Steel in Building ConstructionYazer Arafath100% (1)

- Bar Bending ScheduleDocument47 pagesBar Bending Scheduleshubash sah godh100% (2)

- Bar Bending Schedule FormatDocument2 pagesBar Bending Schedule Formatanku4frenz100% (2)

- How To Make BBS of Column in Details: L & T - Learning Technology 08:17 Civil NotesDocument16 pagesHow To Make BBS of Column in Details: L & T - Learning Technology 08:17 Civil Notesanon_665535262100% (1)

- Analysis & Rates, Analysis and Rates For Construction Work, Labour For Construction Work, Material Required For ConstructionDocument8 pagesAnalysis & Rates, Analysis and Rates For Construction Work, Labour For Construction Work, Material Required For ConstructionArun Chandra BabuNo ratings yet

- Bar Bending Schedule - RCC Slab NewDocument8 pagesBar Bending Schedule - RCC Slab NewHeris Dogga100% (1)

- C4M Bar Bending Schedule BBS FormatDocument8 pagesC4M Bar Bending Schedule BBS FormatRaja VarshneyNo ratings yet

- Steel Quantity by Thumb RuleDocument15 pagesSteel Quantity by Thumb RuleSheikh Nouman Mohsin RamziNo ratings yet

- BbsDocument72 pagesBbsAkd DeshmukhNo ratings yet

- Reinforcement Calculation for RCC Bridge over Mahi RiverDocument26 pagesReinforcement Calculation for RCC Bridge over Mahi Rivershashirajhans2140100% (1)

- Civil TipsDocument5 pagesCivil Tipssanojev83% (6)

- FormworkDocument16 pagesFormworkabhi arote100% (1)

- Quantity Surveying: Sub-Structure Concrete WorksDocument56 pagesQuantity Surveying: Sub-Structure Concrete WorksrssdpmNo ratings yet

- Analysis For BuildingDocument51 pagesAnalysis For BuildingPerkresht PawarNo ratings yet

- ANALYSISDocument6 pagesANALYSISFahad Zulfiqar100% (1)

- Rate AnalysisDocument8 pagesRate AnalysisSarinNo ratings yet

- Material RequiredDocument2 pagesMaterial RequiredNikhil88% (8)

- BS Code 8666 - 2005 Steel Reinforcement For ConcreteDocument8 pagesBS Code 8666 - 2005 Steel Reinforcement For ConcreteGiridhar Krishna100% (2)

- Steel Reinforcement For Concrete - BS 8666:2005Document3 pagesSteel Reinforcement For Concrete - BS 8666:2005Muhafeez GoolabNo ratings yet

- BS8666 Shape CodesDocument9 pagesBS8666 Shape Codeshema16No ratings yet

- Steel Reinforcement For Concrete - BS 8666:2005: Shape Code Shape CodeDocument6 pagesSteel Reinforcement For Concrete - BS 8666:2005: Shape Code Shape CodeРумен ДрагановNo ratings yet

- BS8666 Bends and Shapes - K B Rebar LimitedDocument6 pagesBS8666 Bends and Shapes - K B Rebar LimitedhenryLYDNo ratings yet

- BS8666 Bends and Shapes GuideDocument6 pagesBS8666 Bends and Shapes GuideShalz JagnarineNo ratings yet

- BS 8666-2005 Scheduling, Dimensioning, Bending and Cutting of Steel Reinforcing For ConcreteDocument8 pagesBS 8666-2005 Scheduling, Dimensioning, Bending and Cutting of Steel Reinforcing For ConcreteapirakqNo ratings yet

- ROM Product GuideDocument40 pagesROM Product Guidefadytm90630% (1)

- Bar Reinforcement - Shapes To BS4466-1989Document5 pagesBar Reinforcement - Shapes To BS4466-1989Jayant LakhlaniNo ratings yet

- BS 4466 - Measurement of bending dimensionsDocument4 pagesBS 4466 - Measurement of bending dimensionsEddy Edmond Mojiun0% (1)

- Method of Measurement of Bending DimensionsDocument6 pagesMethod of Measurement of Bending DimensionsHari HaranNo ratings yet

- Barsched 86662Document29 pagesBarsched 86662Leoven Jef Suzara LorinNo ratings yet

- BS4466 Bends and ShapesDocument5 pagesBS4466 Bends and Shapesprasad perka0% (1)

- Bs 8666 of 2005 Bas Shape CodesDocument5 pagesBs 8666 of 2005 Bas Shape CodesopulitheNo ratings yet

- Cantilever Model for Calculating Minimum Base Plate ThicknessDocument1 pageCantilever Model for Calculating Minimum Base Plate ThicknesspawkomNo ratings yet

- Ec2255 Control SystemsDocument4 pagesEc2255 Control SystemsSree GaneshNo ratings yet

- 5DOF Manipulator Simulation Based On MATLAB-Simulink MethodologyDocument7 pages5DOF Manipulator Simulation Based On MATLAB-Simulink MethodologySasha NarvaezNo ratings yet

- Mechanical Engineering Theory of Machines MCQsDocument24 pagesMechanical Engineering Theory of Machines MCQsSAURABH KUMAR0% (1)

- Resonance: Resonance Describes The Phenomenon of Increased Amplitude That Occurs WhenDocument10 pagesResonance: Resonance Describes The Phenomenon of Increased Amplitude That Occurs WhenLijukrishnanNo ratings yet

- 1D Box ApplicationsDocument2 pages1D Box Applicationsarpan palNo ratings yet

- Basic Review CardDocument6 pagesBasic Review CardSheena LeavittNo ratings yet

- Most Important Questions of OnstructionsDocument9 pagesMost Important Questions of OnstructionsCybeRaviNo ratings yet

- Solution Manual For Advanced Engineering Mathematics 7th Edition Peter OneilDocument35 pagesSolution Manual For Advanced Engineering Mathematics 7th Edition Peter Oneilbraidscanty8unib100% (49)

- LQGDocument64 pagesLQGstephenNo ratings yet

- Data Manipulation Language (DML)Document8 pagesData Manipulation Language (DML)asiflistenNo ratings yet

- MINI Wind TurbineDocument14 pagesMINI Wind TurbineahdabmkNo ratings yet

- Transient Stability Analysis With PowerWorld SimulatorDocument32 pagesTransient Stability Analysis With PowerWorld SimulatorvitaxeNo ratings yet

- Ia Ha 2Document4 pagesIa Ha 2Er Shubham RaksheNo ratings yet

- Q-Learning Based Link Adaptation in 5GDocument6 pagesQ-Learning Based Link Adaptation in 5Gkalyank1No ratings yet

- Chapter 8 Data HandlingDocument84 pagesChapter 8 Data HandlingNanoNo ratings yet

- Network Techniques For Project Management: StructureDocument15 pagesNetwork Techniques For Project Management: StructureManita DhandaNo ratings yet

- HBMT 2103 MeiDocument20 pagesHBMT 2103 MeiNick AnsohNo ratings yet

- Correlation Coefficient DefinitionDocument8 pagesCorrelation Coefficient DefinitionStatistics and Entertainment100% (1)

- Lecture 6-S-Jan29 PDFDocument11 pagesLecture 6-S-Jan29 PDFSankalp PiratlaNo ratings yet

- Measures of Angles Formed Secants and TangentsDocument47 pagesMeasures of Angles Formed Secants and TangentsKhloe CeballosNo ratings yet

- Radiation (Lecture Slides) PDFDocument41 pagesRadiation (Lecture Slides) PDFThe DudeNo ratings yet

- DLL Q4 G5 Math Week 1Document6 pagesDLL Q4 G5 Math Week 1Virgie Anne ConcepcionNo ratings yet

- "Teach A Level Maths" Vol. 1: AS Core Modules: 20: StretchesDocument21 pages"Teach A Level Maths" Vol. 1: AS Core Modules: 20: StretchesTasfia QuaderNo ratings yet

- Mechanics of MachinesDocument8 pagesMechanics of MachinesSachi MensiNo ratings yet

- 3.11 Inequalities: N A A B A A ADocument10 pages3.11 Inequalities: N A A B A A ANethra SasikumarNo ratings yet