Professional Documents

Culture Documents

FMEA

Uploaded by

Navnath TamhaneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FMEA

Uploaded by

Navnath TamhaneCopyright:

Available Formats

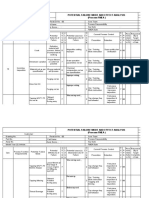

Item :Hinge Key Date: 15/6/2004

Page: 01 of 03

Process Responsibility: Quality / Production FMEA Date (Orignal): 12/04/2004

FMEA No.: 03 Rev. No. 00

Prepared By: D.S Wilkhoo

Core Team: D. S Wilkhoo(Systems), Raman Kr. / Raman Kr. / Rakesh Gill(Quality), Navdeep Mitalia(T/Room), Ved Prakash(Casting), Janak Dev(Machining) Occurrence Action Results Responsible Recommended / Target R.P.N Actions Completion Action Taken Date Occurrence 80 Severity

1. Raw material Inspection

Composition Of Material

In-adequate physical strength

10

Cr.

Chemical components is not as per requirement

Comparision of material test certificate with required composition Aluminium Treatment in every Two Hrs. Air cleaning of die after each shot Vent cleaning after every shot

2. Casting

Blow Holes Poursity

Less Strength

Cr.

1.Improper Aluminium Treatment 2.Improper cleanning of Die /Tool 3. Improper Vents / Overflow or closed Vents

64

80

80

Non-Filling

Appearance

Mj.

Under Heat Molten Metal Improper Aluminium treatment

Check Temp. of the Molten Metal after every Hour & 100% Visual Inspection

48

60

Detection

Process Potential Function Failure Mode requirements

Potential Effect(s) of Failure

Potential cause(s) / Class Mechanism of failure

Current Process Control

Detection

Severity

.: 03

00

lts

R.P.N

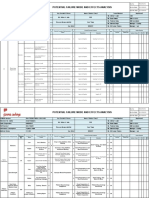

Item :

Hinge

Page: 02 of 03 Prepared By: D.S Wilkhoo

Process Responsibility: Quality / Production FMEA Date (Orignal): 12/04/2004

FMEA No.: 03 Rev. No.00

Key Date: 15/6/04

Core Team: D.S Wilkhoo(Systems), Raman Kr. / Rakesh Gill(Quality), Navdeep Mitalia(T/Room), Ved Prakash(Casting), Janak Dev(Machining) Occurrence Action Results Responsible Recommended / Target R.P.N Actions Completion Action Taken Date Occurrence Severity 84

Detection

Process Potential Function Failure Mode requirements 2.Casting Non-Filling

Potential Effect(s) of Failure Appearance

Potential cause(s) / Class Mechanism of failure Mj. 2nd & 3rd Phase Pressure of machine not Adequate

Current Process Control Check the parameters after every two hours & 100% Visual Inspection Approximate Weight Manually Spraying of Die coat & Air Cleaning & 100% visual inspection Weight of component after every hour Check the parameters after every two hours Weight of component after every hour

Detection

Severity

R.P.N

7 Oil Mark 6

Mj. Mi.

Less Aluminum Improper Die Coat & Cleaning

3 5

4 3

84 90

Less / Excess Weight

Mj.

Loose Die

98

Mj.

3rd Phase or intensification Pressure of Machine is excess Improper Matching of Die / Tools

70

Mj.

70

Item : Hinge Key Date: 15/06/2004

Page: 01 of 03 Prepared By: D.S Wilkhoo

Process Responsibility: Quality / Production FMEA Date (Orignal): 12/04/2004

FMEA No.: 03 Rev. No.00

Core Team: D.S Wilkhoo(Systems), Raman Kr. /Rakesh Gill(Quality), Navdeep Mitalia(T/Room), Ved Prakash(Casting), Janak Dev(Machining) Occurrence Action Results Responsible / Recommended Target R.P.N Actions Completion Action Taken Date Occurrence Severity 72

Detection

Process Potential Function Failure Mode requirements 2.Casting Dimensions

Potential Effect(s) of Failure Not fit for purpose

Potential cause(s) / Class Mechanism of failure Cr. Improper Die Matching

Current Process Control Match the die at startup & Check the critical dimensions after every hour & 100% Visual Inspection 100% Visual Inspection Check the critical dimensions after every two hours 100% Visual Inspection

Detection

Severity

R.P.N

Cr.

Broken hole forming Pins Improper Movement of Slides or hole forming pins Low workmanship & Un-skilled labour Low workmanship & Un-skilled labour

81

Cr.

72

Fettling

Un-Even Filling Of component

Poor appearance

Mi.

42

Changed Dimensions

Cr.

100% Visual Inspection

80

You might also like

- DFMEADocument2 pagesDFMEASumeet SainiNo ratings yet

- Process Validation ReportDocument4 pagesProcess Validation ReportSUBODHHNo ratings yet

- Customer:: Potential Failure Mode and Effect Analysis (Process FMEA)Document8 pagesCustomer:: Potential Failure Mode and Effect Analysis (Process FMEA)Rajnish PotdarNo ratings yet

- Change Management Matrix for Vendor Updates in May 2022Document1 pageChange Management Matrix for Vendor Updates in May 2022nitin rathoreNo ratings yet

- Control PlanDocument6 pagesControl PlanFahmy Khoerul HudaNo ratings yet

- Design Fmea 1 ST Pipe Teflon HoseDocument11 pagesDesign Fmea 1 ST Pipe Teflon HoseSandeep PandeyNo ratings yet

- 8 D Report FormatDocument9 pages8 D Report FormatAlok MehtaNo ratings yet

- Sampling Plan for Laxmi IndustriesDocument2 pagesSampling Plan for Laxmi IndustriesAbhay KarandeNo ratings yet

- MTTR & MTBF TrendDocument2 pagesMTTR & MTBF TrendMASU BRAKE PADS QANo ratings yet

- Design Fmea ExampleDocument2 pagesDesign Fmea ExampleSenthil_KNo ratings yet

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDocument9 pagesGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikNo ratings yet

- Process Flow Chart Ext. RotorDocument6 pagesProcess Flow Chart Ext. RotorVasile MarculescuNo ratings yet

- Aspect & ImpactDocument79 pagesAspect & ImpactMuneendra SharmaNo ratings yet

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNo ratings yet

- DRBFM Worksheet AnalysisDocument1 pageDRBFM Worksheet AnalysisHareth MRAIDINo ratings yet

- Ppap Spacer TubeDocument37 pagesPpap Spacer TubeSeenivasagam SeenuNo ratings yet

- GM Machining CP REV 03Document17 pagesGM Machining CP REV 03Suraj RawatNo ratings yet

- Pages From Cinematography-Theory and PracticeDocument74 pagesPages From Cinematography-Theory and PracticeSalazar SliterinNo ratings yet

- Failure Mode and Effects Analysis (Process Fmea) : PotentialDocument2 pagesFailure Mode and Effects Analysis (Process Fmea) : Potentialjavier ortizNo ratings yet

- Optimize Company Control PlanDocument6 pagesOptimize Company Control Planazadsingh1No ratings yet

- Fmea Sfe47.005 WeldingDocument8 pagesFmea Sfe47.005 Weldingkumaraswamy.kNo ratings yet

- APQP TemplateDocument7 pagesAPQP TemplateBob ZepfelNo ratings yet

- Quality Control PlanDocument1 pageQuality Control PlanScha Affin100% (1)

- Quality Manual Template: WWW - Iso-9001-Checklist - Co.ukDocument10 pagesQuality Manual Template: WWW - Iso-9001-Checklist - Co.ukNavnath TamhaneNo ratings yet

- Company Process Flow and FMEA DiagramsDocument12 pagesCompany Process Flow and FMEA DiagramsDINESH SHARMA100% (1)

- Exedy India Ltd. APQP Process DocumentsDocument3 pagesExedy India Ltd. APQP Process Documentssam1hi5No ratings yet

- Guidelines For Making PFMEA - A PDFDocument10 pagesGuidelines For Making PFMEA - A PDFKalimuthu PsNo ratings yet

- Fmea CastingDocument8 pagesFmea CastingSuraj RawatNo ratings yet

- GS-0002D, Design FMEADocument26 pagesGS-0002D, Design FMEAmesa142100% (1)

- Measurement System Analysis LabDocument32 pagesMeasurement System Analysis LabAnonymous 3tOWlL6L0U100% (1)

- Control plan optimizationDocument11 pagesControl plan optimizationRadhika GuptaNo ratings yet

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- 3 3bb0aDocument7 pages3 3bb0aEleandro JoaquimNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- Training in MSA PQ Systems Training Material PDFDocument109 pagesTraining in MSA PQ Systems Training Material PDFsaby aroraNo ratings yet

- CLAUSE 8.5 Production and Service ProvisionDocument10 pagesCLAUSE 8.5 Production and Service ProvisionNavnath TamhaneNo ratings yet

- Copy of APQP Check List - Ford (Blank)Document9 pagesCopy of APQP Check List - Ford (Blank)feiraluremaNo ratings yet

- Clause Map - IATF 16949:2016 To ISO/TS 16949:2009Document5 pagesClause Map - IATF 16949:2016 To ISO/TS 16949:2009Navnath TamhaneNo ratings yet

- Apqp FormsDocument32 pagesApqp FormsAnonymous A2jnZ5MNPxNo ratings yet

- Apqp FormsDocument25 pagesApqp FormsgkspNo ratings yet

- Tutorial Chapter 1 2018Document3 pagesTutorial Chapter 1 2018Ain Syahira0% (1)

- Repair and Modification of Printed Boards and Electronic AssembliesDocument6 pagesRepair and Modification of Printed Boards and Electronic AssembliesArvind NangareNo ratings yet

- FMEA PDocument6 pagesFMEA Pparu1982No ratings yet

- Shop Floor Review AuditDocument10 pagesShop Floor Review AuditSead ZejnilovicNo ratings yet

- System Modelling and SimulationDocument260 pagesSystem Modelling and SimulationArvind Kumar100% (13)

- Wi SPCDocument4 pagesWi SPCSujeet Kumar100% (1)

- Vda FmeaDocument30 pagesVda Fmealalit GuptaNo ratings yet

- Partial Differential Equations Formula SheetDocument3 pagesPartial Differential Equations Formula SheetnewyorkstudyNo ratings yet

- Soal Bahasa InggrisDocument7 pagesSoal Bahasa InggrisPelkeh Prianda25% (16)

- What Happens When Warm Air RisesDocument30 pagesWhat Happens When Warm Air RisesCriselAlamag100% (1)

- Fmea WorksheetDocument3 pagesFmea WorksheetatathodNo ratings yet

- PFEMA Attachment B Rev 16fe15Document1 pagePFEMA Attachment B Rev 16fe15Saulo TrejoNo ratings yet

- PPAP PriruckaDocument10 pagesPPAP PriruckaKin MattNo ratings yet

- Setup & Inprocess Inspection Report CaseDocument19 pagesSetup & Inprocess Inspection Report CaseMURALIDHRANo ratings yet

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- Samples Inspection ReportDocument5 pagesSamples Inspection ReportArun GuptaNo ratings yet

- Xfmea Pfmea PDFDocument8 pagesXfmea Pfmea PDFvinidesoNo ratings yet

- Controls:: Measuring Instruments in ImteDocument5 pagesControls:: Measuring Instruments in ImteDhinakaranNo ratings yet

- DFMEADocument1 pageDFMEAPrabh GarchaNo ratings yet

- Technical Devices Validation ProtocolDocument19 pagesTechnical Devices Validation ProtocolarumNo ratings yet

- Control Plan: Process InformationDocument20 pagesControl Plan: Process InformationGeovanni calderonNo ratings yet

- FMEA SampleDocument94 pagesFMEA SampleKaran MalhiNo ratings yet

- Malati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDocument1 pageMalati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDhananjay PatilNo ratings yet

- Non-Conformity Report & Corrective Action: Description of Non-ConformanceDocument1 pageNon-Conformity Report & Corrective Action: Description of Non-Conformanceazadsingh1No ratings yet

- Sterility Test Failure Investigation FormDocument9 pagesSterility Test Failure Investigation FormmishannakNo ratings yet

- Env Data Sheet For Ip54Document3 pagesEnv Data Sheet For Ip54Er. Kuldeep GangwarNo ratings yet

- Quality Management System Principle 3 Engagement of PeopleDocument4 pagesQuality Management System Principle 3 Engagement of PeopleNavnath TamhaneNo ratings yet

- ISO 9001 Leadership PrinciplesDocument3 pagesISO 9001 Leadership PrinciplesNavnath TamhaneNo ratings yet

- 8.1 Operational Planning and ControlDocument6 pages8.1 Operational Planning and ControlNavnath TamhaneNo ratings yet

- Summary of Each Section of ISO 90012015 RequirementsDocument4 pagesSummary of Each Section of ISO 90012015 RequirementsShailesh GuptaNo ratings yet

- Clause 7.5 of ISO 9001 Documented InformationDocument3 pagesClause 7.5 of ISO 9001 Documented InformationNavnath TamhaneNo ratings yet

- 21 148Document1 page21 148Navnath TamhaneNo ratings yet

- ISO 9001 - Clause 7 Support ExplainedDocument5 pagesISO 9001 - Clause 7 Support ExplainedNavnath TamhaneNo ratings yet

- Mplement A QMS and Achieve ISO 9001 Certification With Customer FocusDocument2 pagesMplement A QMS and Achieve ISO 9001 Certification With Customer FocusNavnath TamhaneNo ratings yet

- 8.7 Control of Nonconforming Process Outputs, Products, and ServiceDocument2 pages8.7 Control of Nonconforming Process Outputs, Products, and ServiceNavnath TamhaneNo ratings yet

- Why A New Version of ISO 9001 2015Document5 pagesWhy A New Version of ISO 9001 2015Navnath TamhaneNo ratings yet

- 4 Main Differences Between ISO 90012008 and ISO 90012015Document4 pages4 Main Differences Between ISO 90012008 and ISO 90012015Navnath TamhaneNo ratings yet

- ISO 9001 Requirements and StructureDocument4 pagesISO 9001 Requirements and StructureNavnath TamhaneNo ratings yet

- DeskRef9K1 2015 Transition0 10Document89 pagesDeskRef9K1 2015 Transition0 10Navnath TamhaneNo ratings yet

- IATF 16949:2016 Clause 4 Context of The Organization: FD-440-001 Flow Diagram Process InteractionsDocument1 pageIATF 16949:2016 Clause 4 Context of The Organization: FD-440-001 Flow Diagram Process InteractionsNavnath TamhaneNo ratings yet

- Iso 9001 CRMDocument6 pagesIso 9001 CRMNavnath TamhaneNo ratings yet

- 05 Guidance On Outsourced ProcessesDocument4 pages05 Guidance On Outsourced ProcessesNavnath TamhaneNo ratings yet

- Documented InformationDocument5 pagesDocumented InformationbkssdgNo ratings yet

- 9 Ncert Solutions Social Science Pol CH 4Document7 pages9 Ncert Solutions Social Science Pol CH 4Navnath TamhaneNo ratings yet

- 9 Ncert Solutions Social Science Pol CH 4Document7 pages9 Ncert Solutions Social Science Pol CH 4Navnath TamhaneNo ratings yet

- 9 Social His Ch1 1Document6 pages9 Social His Ch1 1Navnath TamhaneNo ratings yet

- 9 Ncert Solutions Soc Sci Eco The Story of Village PalampurDocument5 pages9 Ncert Solutions Soc Sci Eco The Story of Village PalampurNavnath TamhaneNo ratings yet

- 9 Ncert Solutions Soc Sci Eco The Story of Village PalampurDocument5 pages9 Ncert Solutions Soc Sci Eco The Story of Village PalampurVaibhav ChouhanNo ratings yet

- Mycbseguide: Class 09 - Social Science Term 1 - His The French Revolution - 01Document6 pagesMycbseguide: Class 09 - Social Science Term 1 - His The French Revolution - 01Navnath TamhaneNo ratings yet

- Mycbseguide: Class 09 - Social Science Term 1 - His The French Revolution - 01Document6 pagesMycbseguide: Class 09 - Social Science Term 1 - His The French Revolution - 01Navnath TamhaneNo ratings yet

- 9 Ncert Solutions Social Science Pol CH 4Document7 pages9 Ncert Solutions Social Science Pol CH 4Navnath TamhaneNo ratings yet

- RTN Connect Pfmea PDFDocument23 pagesRTN Connect Pfmea PDFNavnath TamhaneNo ratings yet

- Quality ManualDocument22 pagesQuality ManualRajeeb MohammedNo ratings yet

- CFD and Experimental Study of Wetting of Structured Packing ElementsDocument139 pagesCFD and Experimental Study of Wetting of Structured Packing ElementsahmedsalemyNo ratings yet

- Literature SurveyDocument6 pagesLiterature SurveyAnonymous j0aO95fgNo ratings yet

- Submodular Set Function - WikipediaDocument5 pagesSubmodular Set Function - WikipedianmahsevNo ratings yet

- Molykote Greases For Subsea ApplicationsDocument1 pageMolykote Greases For Subsea ApplicationsProject Sales CorpNo ratings yet

- A+A Diagnostics: Chemray 420Document2 pagesA+A Diagnostics: Chemray 420Saleh HamadanyNo ratings yet

- Norma Japonesa Aij-Rlb-1996Document36 pagesNorma Japonesa Aij-Rlb-1996AnaApcarianNo ratings yet

- Maximum Material Boundary (MMB) and Its Advantages in GD&T Analysis PDFDocument6 pagesMaximum Material Boundary (MMB) and Its Advantages in GD&T Analysis PDFSangeethaNo ratings yet

- Slide Micro Teaching 5.3Document18 pagesSlide Micro Teaching 5.3Mastura MohamadNo ratings yet

- Cati Pakistan Training Course - MechanicalDocument13 pagesCati Pakistan Training Course - MechanicalImam Haryadi WibowoNo ratings yet

- Heat Exchangers Types & Applications, LMTD Derivation & ProblemsDocument11 pagesHeat Exchangers Types & Applications, LMTD Derivation & Problemsananth2012No ratings yet

- Notesch # 18Document11 pagesNotesch # 18ZeeshanMahdiNo ratings yet

- PEGN 419 / GPGN 419 Spring 2017: Manika Prasad Mansur Ermila Expert Resource: Robert LieberDocument30 pagesPEGN 419 / GPGN 419 Spring 2017: Manika Prasad Mansur Ermila Expert Resource: Robert LiebertahermohNo ratings yet

- 960 Physics (PPU) Semester 2 Topics-SyllabusDocument7 pages960 Physics (PPU) Semester 2 Topics-SyllabusJosh, LRT0% (1)

- Refractive Index of A Liquid (Theory) : Class 12: PhysicsDocument4 pagesRefractive Index of A Liquid (Theory) : Class 12: PhysicsAmartya AnshumanNo ratings yet

- Adjoint Rans With Filtered Shape Derivatives For Hydrodynamic OptimisationDocument11 pagesAdjoint Rans With Filtered Shape Derivatives For Hydrodynamic Optimisationvolo87No ratings yet

- Filter Vessel Calculations Per As Me Viii 1Document40 pagesFilter Vessel Calculations Per As Me Viii 1Anonymous J1vjrU2No ratings yet

- Solar System and Astronomy FactsDocument535 pagesSolar System and Astronomy FactsKavita KrishnamorthiNo ratings yet

- MIT Feedback Linearization LectureDocument5 pagesMIT Feedback Linearization LectureJosé Ignacio Fierro TravoNo ratings yet

- Cooling Tower Pumping and Piping: LegendDocument46 pagesCooling Tower Pumping and Piping: LegendDenise Koh Chin HuiNo ratings yet

- On Errors of Fit and Accuracy in Matching Synthetic Seismograms and Seismic TracesDocument21 pagesOn Errors of Fit and Accuracy in Matching Synthetic Seismograms and Seismic TracesBSSNo ratings yet

- Cementing EquipDocument12 pagesCementing Equipzbhdzp100% (1)

- Concrete Technology Internal Assessment QuestionsDocument2 pagesConcrete Technology Internal Assessment QuestionsSubodh AdhikariNo ratings yet

- Thesis MainDocument144 pagesThesis MainIvan GrkajacNo ratings yet