Professional Documents

Culture Documents

Design of Cooling Tower

Uploaded by

Mohan VarkeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Cooling Tower

Uploaded by

Mohan VarkeyCopyright:

Available Formats

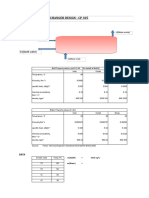

DESIGN OF COOLING TOWER

DESIGN CONDITIONS:

Cooling Tower Type COUNTER FLOW INDUCED DRAFT

Water Temperature

Leaving C 25

Entering C 30

Air Condition

Leaving WB C DB C 98 , 38

Entering RH DB C % 65 , 26

Make-up Water

Temperature C 26

Barometric Pressure kPa 325 . 101

Note:

(1) The practical cooling range

2 1

t t is C 7 . 16 6 . 5 (Morse, 1990)

p 122

(2) For cooling towers the rating conditions are C 35 entering water, C 4 . 29

leaving water, and C 9 . 23 wet bulb of the outdoor air (Wang, 2001)

p 10.50

(3) In most cases, the temperature of the water leaving the tower will be F to 10 7

above wet bulb temperature of the entering air (Dossat, 1978)

p 333

Calculation Procedure:

Amount of water to be handled by the cooling tower, m

cw

( ) ( )

( )

sec 74 . 13

sec

78 . 10 96 . 2

kg m

kg

m

m m m

cw

cw

condenser cw compressor cw cw

=

+ =

+ =

Air Properties Using Psychometrics Chart

At RH and C % 65 26

air dry of kg

moisture of kg

HR

kg

KJ

h

0136 . 0

;

61

4 4

= =

At RH and C % 98 32

air dry of kg

moisture of kg

HR

kg

KJ

h

0297 . 0

;

108

5 5

= =

Mass of Air,

, a

m

Energy Balance on the cooling tower

( ) ( )

3 4 2 1

4 3 2 1

&

h h m t Cp m t t Cp m

m m m m m m

a mw w mw cw cw

a cw

= +

= = = =

( ) ( )

mw w

cw cw a

mw

t Cp

t t Cp m h h m

m

2 1 3 4

=

( ) ( )

( )

1 . 642 . 2 43174 . 0

26 187 . 4

25 30 187 . 4

sec

74 . 13 61 108

0

0

0

0

eq m m

C

C kg

KJ

C

C kg

KJ

kg

kg

KJ

m

m

a mw

a

mw

=

|

.

|

\

|

|

.

|

\

|

=

Mass Balance

Mass entering = Mass leaving

2 . 0161 . 0

) 0136 . 0 0297 . 0 ( ) . . (

. .

3 4

4 3

eq m m

m R H R H m m

R H m m R H m m m

a mw

a a mw

a w a w mw

=

= =

+ = + +

Substituting eq.1 to eq.2

642 . 2 43174 . 0 0161 . 0 =

a a

m m

a a

m m 0161 . 0 4317 . 0 642 . 2 =

sec

36 . 6

kg

m

a

=

Mass of Make-up water,

5 w

m

From Equation 2

water of

kg kg

m

m m

w

a w

sec

1023 . 0

sec

36 . 6 0161 . 0

0161 . 0

5

5

=

|

.

|

\

|

=

=

Volume flow rate of air,

a

V

( ) ( ) KPa KPa Psat RH Ps

KPa Psat RH and C At

18595 . 2 363 . 3 65 . 0

363 . 3 , % 65 26

= = =

=

MRT PV =

( )

( )

( )

3

0

0

18595 . 2 325 . 101

273 26

2871 . 0

sec

36 . 6

m

KN

or KPa

K

K kg

KJ

kg

P P

T R m

V

S B

a a a

a

+

|

.

|

\

|

|

.

|

\

|

=

=

sec

507 . 5

3

m

V

a

=

Where: R.H= relative humidity

vapor water of pressure partial P

C at pressure saturation P

V

Sat

=

= 26

Volume flow rate of air,

w

V

From Refrigeration Engineering by Mc Intire P. 495. cross-sectional area of

induced draft fan is found by allowing gpm/ft 3.0

2

t =

2

30 25+

= 27.5 C @ 27.5 C

3

512 . 996

m

kg

w

=

Therefore,

Volume flow rate (

w

v ) =

3

512 . 996

sec

74 . 13

m

kg

kg

M

w

w

=

=

min 1

sec 60

003785 . 0

1

sec

0138 . 0

3

3

x

m

gal

x

m

= 218.57 gpm

Cooling tower range, C.T.R.

C.T.R. = C t t

o

5

2 1

=

Cooling tower approach, C.T.A.

At 26 C

o

and 65% RH ; C t

o

wb

75 . 18 =

C.T.A. = C t t

o

wb

25 . 6 75 . 18 25

1

= =

Cooling tower efficiency, C.T.E.

C.T.R. =

% 100

75 . 18 30

25 30

% 100

1

2 1

x x

t t

t t

wb

= 44.4 %

PIPING SYSTEM FOR COOLING TOWER

Design Condition:

Mass flow rate cooling water

Compressor sec 96 . 2 kg

Condenser sec 78 . 10 kg

water

v = 996.512 kg/

3

m ;

f

v v = @ C t

o

ave

5 . 27 =

Water Velocity, v = 1.83 m/sec (range: 1.5 to 2.1m/sec)

Solving for the total amount of cooling water,

Tcw

Q

sec / 10 97 . 2

/ 512 . 996

sec / 96 . 2

3 3

3

m x

m kg

kg

Q

compressor

= =

sec / 10 82 . 10

/ 512 . 996

sec / 78 . 10

3 3

3

m x

m kg

kg

Q

condenser

= =

condenser compressor Tcw

Q Q Q + =

sec / ) 10 82 . 10 10 97 . 2 (

3 3 3

m x x Q

Tcw

+ =

sec / 01379 . 0

3

m Q

Tcw

=

PIPE SIZE FOR THE SUPPLY AND RETURN PIPES

From cooling tower pool to tee-run

v D Q

Tcw

2

4

t

=

|

.

|

\

|

=

sec

83 . 1

4 sec

01379 . 0

2

3

m

D

m t

D = 0.0979 m = 97.9 mm

USE: 100 mm NPS schedule 40 (from Table 7-2 Dimensions of steel pipe by

Wilbert F. Stoeker, P 136)

OD = 114.3 mm ID = 102.3 mm

From tee-run to condenser inlet

v D Q

condenser

2

4

t

=

|

.

|

\

|

=

sec

83 . 1

4 sec

10 82 . 10

2

3

3

m

D

m

x

t

D = 0.08676 m = 86.76 mm

USE: 100 mm NPS schedule 40 (from Table 7-2 Dimensions of steel pipe by

Wilbert F. Stoeker, P 136)

OD = 114.3 mm ID = 102.3 mm

From tee-run to compressor inlet

v D Q

compressor

2

4

t

=

|

.

|

\

|

=

sec

83 . 1

4 sec

10 97 . 2

2

3

3

m

D

m

x

t

D = 0.04545 m = 45.45 mm

USE: 50 mm NPS schedule 40 (from M.E.T.C. Steel Pipe Dimensions, P 114.)

OD = 73.03 mm ID = 62.65 mm

COOLING WATER PUMP

Design Data:

Type Centrifugal

Capacity, Q

P

0.01379 m

3

/sec

Average water temperature, t

ave

27.5

0

C

Water density, 996.4129 kg/m

3

Main pipe 100 mm NPS

Capacity, Q

T

0.01379 m

3

/sec

Condenser pipe 100 mm NPS

Capacity, Q

cond

0.01082 m

3

/sec

Compressor pipe 50 mm NPS

Capacity, Q

comp

0.00297 m

3

/sec

Static head, h

S

2 m

Friction Heads, h

f

( ) ( ) ( ) ( ) ( ) ( ) k p L factor correction e Temperatur drop essure length equivalent Total h

e f

A = = Pr

For the main line, 100 mm NPS, Schedule 40, from cooling tower to Tee of

condenser

Straight Pipe ------------------------------------------------------------ 6.42 m

2 90

0

elbow ------------------------------------------------------------ 6 m

1 Standard tee ------------------------------------------------------------ 4.16 m

1 Gate valve ------------------------------------------------------------ 0.52 m

1 Check valve ------------------------------------------------------------ 9.15 m

__________

Total length 26.25 m

For the condenser line, 100 mm NPS, Schedule 40, from condenser tee to

condenser inlet

Straight Pipe ------------------------------------------------------------ 2.23 m

1 Standard tee ------------------------------------------------------------ 5.18 m

1 gate valve (open) --------------------------------------------------- 0.52 m

1 90

0

elbow ------------------------------------------------------------ 3.0 m

____________

Total length 10.93 m

For the condenser tubes, 25 mm NPS, Schedule 40

Straight Pipe ------------------------------------------------------ 279 m

3 Close return bend --------------------------------------------- 49.41 m

____________

Total length 328.41 m

For the compressor line, 50 mm NPS, Schedule 40, from condenser tee to

compressor tee

Straight Pipe ------------------------------------------------------------ 3.8 m

1 Standard tee ------------------------------------------------------------ 0.9 m

1 gate valve (open) --------------------------------------------------- 0.09 m

1 90

0

elbow ------------------------------------------------------------ 0.6 m

____________

Total length 5.39 m

From Compressor Tee to compressor inlet, 50 mm NPS, Schedule 40

Straight Pipe ------------------------------------------------------------ 3.0 m

1 Standard tee ------------------------------------------------------------ 0.9 m

1 gate valve (open) --------------------------------------------------- 0.09 m

____________

Total length 3.99 m

For the compressor jacket water line, assume equivalent length of 2 m inside

the compressor cooling water system.

From Figure 7 6, Pressure drop for water flowing in schedule 40 steel pipes,

Refrigeration and Air-conditioning by Stoecker & J ones, page 138.

For 100 mm pipe & 7.89 L/sec, p = 220 Pa / m

For 100 mm pipe & 7.65 L/sec, p = 370 Pa / m

For 50 mm pipe & 2.97 L/sec, p = 400 Pa / m

For 25 mm pipe & 0.24 L/sec, p = 1300 Pa / m

From Figure 7 7, Multiplying factors for pressure drops to correct for

temperature, Refrigeration and Air-conditioning by Stoecker & J ones, page 139.

For t

ave

of 27.5

0

C & 1.52 m/sec water velocity, k = 0.98

Therefore the friction heads h

f

, are equal to,

O H of m

kPa

O H of m

x kPa Pa x

m

Pa

x m h

f 2

2

1

5756 . 0 1017 . 0 6595 . 5 5 . 659 , 5 98 . 0

220

25 . 26 = = = =

O H of m

kPa

O H of m

x kPa Pa x

m

Pa

x m h

f 2

2

2

403 . 0 1017 . 0 963 . 3 218 . 963 , 3 98 . 0

370

93 . 10 = = = =

O H of m

kPa

O H of m

x kPa Pa x

m

Pa

x m h

f 2

2

3

55 . 42 1017 . 0 39 . 418 4 . 394 , 418 98 . 0

1300

41 . 328 = = = =

O H of m

kPa

O H of m

x kPa Pa x

m

Pa

x m h

f 2

2

4

2148 . 0 1017 . 0 112 . 2 88 . 2112 98 . 0

400

39 . 5 = = = =

O H of m

kPa

O H of m

x kPa Pa x

m

Pa

x m h

f 2

2

5

159 . 0 1017 . 0 564 . 1 08 . 1564 98 . 0

400

99 . 3 = = = =

O H of m

kPa

O H of m

x kPa Pa x

m

Pa

x m h

f 2

2

6

3 . 0 1017 . 0 98 . 2 2989 98 . 0

1525

2 = = = =

Also the total friction head h

fT

,

is equal to,

O H of m h h h h h h h

f f f f f f S f 2 6 5 4 3 2 1

2 . 44 3 . 0 159 . 0 2148 . 0 55 . 42 403 . 0 5756 . 0 = + + + + + = + + + + + =

Total friction head, h

fT

Assuming the supply line equal to the discharge line,

( )

S f T f

h h 2 =

Therefore,

( ) O H of m O H of m h

T f 2 2

4 . 88 2 . 44 2 = =

Total Pumping Head, H

T

O H of m h h H

S fT T 2

4 . 90 2 4 . 88 = + = + =

Water Horsepower, W

hp

( )( )( )

hp

hp kW

m m kN m H Q

W

T water P

hp

4 . 16

746 . 0

4 . 90 81 . 9 sec 01379 . 0

746 . 0

3 3

= = =

Motor Power, P

m

p

hp

m

m

hp

p

W

P

P

W

q

q = = ;

Using 75 % pump efficiency,

hp

hp

P

m

86 . 21

75 . 0

4 . 16

= =

For standard motor sizes, use 25 hp electric motor for the cooling water pump.

You might also like

- Cooling TowerDocument27 pagesCooling Towerjogedhayal100% (1)

- Cooling Tower-CalculatorDocument7 pagesCooling Tower-CalculatorparykoochakNo ratings yet

- Cooling Tower DesignDocument36 pagesCooling Tower DesignJewel Fe Olangco100% (2)

- Cooling Tower Design Part I PDFDocument9 pagesCooling Tower Design Part I PDFVictor AugelloNo ratings yet

- Cooling TowerDocument50 pagesCooling TowerKM100% (2)

- Cooling Tower Fill EfficiencyDocument11 pagesCooling Tower Fill EfficiencyMubarik Ali100% (1)

- Cooling Tower Formulae-ImpDocument4 pagesCooling Tower Formulae-ImptpplantNo ratings yet

- Cooling Tower Workshop PETDocument2 pagesCooling Tower Workshop PETruk1921No ratings yet

- Calculation of Scrubber DiameterDocument44 pagesCalculation of Scrubber DiameterRamakrishna SomuNo ratings yet

- Calculate water and chemical usage for cooling towersDocument11 pagesCalculate water and chemical usage for cooling towersياسر نديمNo ratings yet

- Download Industrial Cooling Tower PDFDocument5 pagesDownload Industrial Cooling Tower PDFAsif Sadar0% (1)

- Cooling Tower CalculationDocument4 pagesCooling Tower CalculationAnonymous 7CnrWpzZf1No ratings yet

- Cooling Water CalculationDocument20 pagesCooling Water CalculationShahzaibUsman100% (1)

- Design Calc - Cooling Tower Sizing - Rev 0Document1 pageDesign Calc - Cooling Tower Sizing - Rev 0Paijo TejoNo ratings yet

- Cooling tower design parameters and heat balance calculationDocument47 pagesCooling tower design parameters and heat balance calculationDavid LambertNo ratings yet

- Condenser & EvaporatorDocument21 pagesCondenser & EvaporatorfitratulqadriNo ratings yet

- Compressed Air Drying PDFDocument29 pagesCompressed Air Drying PDFmaddukuri jagadeesh babu100% (1)

- Cooling Tower Fundamentals PDFDocument27 pagesCooling Tower Fundamentals PDFDarshan Raghunath100% (3)

- Optimization of Cooling TowersDocument49 pagesOptimization of Cooling TowersKhalil LasferNo ratings yet

- Deaerator Venting Capacity CalculationsDocument2 pagesDeaerator Venting Capacity CalculationsEng Alf100% (1)

- Evaporator (D-1) Design ExcelDocument7 pagesEvaporator (D-1) Design ExceldiRkdARyLNo ratings yet

- FAD CALCULATION FOR AIR DELIVERYDocument4 pagesFAD CALCULATION FOR AIR DELIVERYAnonymous JZK84WzfKNo ratings yet

- Cooling Tower Water CalculationsDocument11 pagesCooling Tower Water CalculationsShesadri ChakrabartyNo ratings yet

- Cooling Tower PracticalDocument17 pagesCooling Tower PracticalRichardt LootsNo ratings yet

- Cooling Tower CalculationsDocument10 pagesCooling Tower CalculationsRadu ReluNo ratings yet

- Heat Exchanger Design 1Document9 pagesHeat Exchanger Design 1Rajeev SaxenaNo ratings yet

- IA Compressor & SystemDocument51 pagesIA Compressor & SystemKazi Irfan100% (1)

- Heat Exchanger Design CalculationsDocument8 pagesHeat Exchanger Design Calculationskikokiko KarimNo ratings yet

- Hybrid Cooling TowerDocument12 pagesHybrid Cooling TowerEka SafitriNo ratings yet

- Line Sizing and Pressure Drop Calculations for Sanstar Bio-Polymers Ltd Steam LinesDocument11 pagesLine Sizing and Pressure Drop Calculations for Sanstar Bio-Polymers Ltd Steam Linessantosh_raju0% (1)

- Dedusting Cyclone Sizing and Pressure DropDocument1 pageDedusting Cyclone Sizing and Pressure DropVijay BhanNo ratings yet

- Wet Scrubbers PDFDocument225 pagesWet Scrubbers PDFnacer zidi100% (6)

- Process Design of Spray Chamber or Spray Tower Type AbsorberDocument12 pagesProcess Design of Spray Chamber or Spray Tower Type Absorbersatish_shah_1592% (26)

- Steam Calculation 2008 0326Document53 pagesSteam Calculation 2008 0326Myungkwan HaNo ratings yet

- Wet Cooling Towers: Rule-of-Thumb Design and SimulationDocument32 pagesWet Cooling Towers: Rule-of-Thumb Design and SimulationMohammed Alnefayei100% (10)

- Cooling Tower Basic Calculation PDFDocument45 pagesCooling Tower Basic Calculation PDFFredie Unabia92% (39)

- Boiler CalculationDocument37 pagesBoiler CalculationFmJoy Dioko100% (2)

- Wet Scrubber Application Guide: Impingement Plate Scrubbers Venturi Scrubbers Eductor Venturi ScrubbersDocument17 pagesWet Scrubber Application Guide: Impingement Plate Scrubbers Venturi Scrubbers Eductor Venturi ScrubbersAlvaro MathisonNo ratings yet

- Multi-Stage Centrifugal Blower Design Pressure ConsiderationsDocument5 pagesMulti-Stage Centrifugal Blower Design Pressure ConsiderationsSATYA20091100% (1)

- Cooling Tower Heat and MassDocument18 pagesCooling Tower Heat and MassChris Mark100% (2)

- Effective Thermal Design of Cooling TowersDocument13 pagesEffective Thermal Design of Cooling TowersKarthick VelayuthamNo ratings yet

- CBE 417 FlashDrumSizing WankatDocument7 pagesCBE 417 FlashDrumSizing WankatRahmansyah GaekNo ratings yet

- Cooling Tower FinalDocument10 pagesCooling Tower Finalmkha87100% (4)

- Calculating Cooling Tower Makeup WaterDocument2 pagesCalculating Cooling Tower Makeup WaterSiLan Subramaniam100% (1)

- Condenser CalculationDocument6 pagesCondenser Calculationgreenenergykolkata100% (2)

- Cooling Tower Fan CalculationDocument6 pagesCooling Tower Fan Calculationanup_nair50% (2)

- Calculating Centrifugal Chiller Condenser LoadsDocument49 pagesCalculating Centrifugal Chiller Condenser Loadseka resmana100% (1)

- Cooling Tower Calc Efficiency Under 40Document4 pagesCooling Tower Calc Efficiency Under 40Maman HakimNo ratings yet

- Heat Transfer through a Glass WindowDocument4 pagesHeat Transfer through a Glass WindowAlexander Yauri Gomez50% (2)

- Duct DesignDocument35 pagesDuct DesignAnonymous 8LOtly9100% (5)

- ME3122E - Tutorial Solution 3Document8 pagesME3122E - Tutorial Solution 3LinShaodun100% (3)

- Fire Calculation1Document7 pagesFire Calculation1Jesús Yarleque RamosNo ratings yet

- Tank Venting According API 2000Document34 pagesTank Venting According API 2000Youssef Lagrini50% (2)

- Heat Chap08 053Document10 pagesHeat Chap08 053Kerem GönceNo ratings yet

- FLUMECHDocument4 pagesFLUMECHniel senNo ratings yet

- Fluid Flow Measurement Devices and CalculationsDocument31 pagesFluid Flow Measurement Devices and CalculationsCamille LardizabalNo ratings yet

- PNEUMATIC PRINCIPLESDocument10 pagesPNEUMATIC PRINCIPLESSomhiNo ratings yet

- Xi - Cooling Tower - CheckDocument11 pagesXi - Cooling Tower - CheckJanine Glaiza Jaspe GallerosNo ratings yet

- CEE 345 Spring 2002 problem set solutions pump efficiency discharge headDocument10 pagesCEE 345 Spring 2002 problem set solutions pump efficiency discharge headAdrian Antonio TorresNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Introduction To Lean Six Sigma: A Course Overview: Jorge Luis Romeu, Ph.D. Quanterion Solutions IncDocument26 pagesIntroduction To Lean Six Sigma: A Course Overview: Jorge Luis Romeu, Ph.D. Quanterion Solutions IncMohan VarkeyNo ratings yet

- Blood Transfusion During Pregnancy - Birth - Jan13Document6 pagesBlood Transfusion During Pregnancy - Birth - Jan13Mohan VarkeyNo ratings yet

- Cost Centre ExpensesDocument173 pagesCost Centre ExpensesMohan VarkeyNo ratings yet

- Presentation PipingDocument3 pagesPresentation PipingMohan VarkeyNo ratings yet

- GoldsmithDocument12 pagesGoldsmithMohan VarkeyNo ratings yet

- Inspection Monitoring ReportDocument2 pagesInspection Monitoring ReportMohan VarkeyNo ratings yet

- CCH TeamMate EWP RR ReplicationDocument2 pagesCCH TeamMate EWP RR ReplicationMohan VarkeyNo ratings yet

- Airtel Screen ShotDocument1 pageAirtel Screen ShotMohan VarkeyNo ratings yet

- General PipingDocument1 pageGeneral PipingMohan VarkeyNo ratings yet

- 6767-00-La-Vd-4060 Rev A Vendor Data RequrmntsDocument4 pages6767-00-La-Vd-4060 Rev A Vendor Data RequrmntsMohan VarkeyNo ratings yet

- NEFT Mandate Form - Effective From Aug 2012Document1 pageNEFT Mandate Form - Effective From Aug 2012Mohan VarkeyNo ratings yet

- Standard Estimate of PumpDocument60 pagesStandard Estimate of PumpMohan VarkeyNo ratings yet

- Route To MunnarDocument6 pagesRoute To MunnarMohan VarkeyNo ratings yet

- Compressor DetailsDocument32 pagesCompressor DetailsMohan VarkeyNo ratings yet

- Awake To FreedomDocument1 pageAwake To FreedomIsabelleMoscovitzNo ratings yet

- ANSULDocument4 pagesANSULMohan Varkey100% (1)

- Orthographic ProjectionDocument9 pagesOrthographic ProjectionMohan VarkeyNo ratings yet

- Cavitational Cause Due To Pump SpeedDocument1 pageCavitational Cause Due To Pump SpeedMohan VarkeyNo ratings yet

- SWG To MM ChartDocument1 pageSWG To MM ChartMohan VarkeyNo ratings yet

- Awake To FreedomDocument1 pageAwake To FreedomIsabelleMoscovitzNo ratings yet

- Venting Aboveground TanksDocument15 pagesVenting Aboveground TanksMohan Varkey100% (2)

- Water Cooled Chiller Package Data SheetDocument9 pagesWater Cooled Chiller Package Data SheetMohan VarkeyNo ratings yet

- File 2 - Chapter 1 and 2 - GaASKETSDocument13 pagesFile 2 - Chapter 1 and 2 - GaASKETSMohan VarkeyNo ratings yet

- Expansion JointsDocument4 pagesExpansion JointsMohan VarkeyNo ratings yet

- DisciplineDocument2 pagesDisciplineMohan VarkeyNo ratings yet

- List of BS CodesDocument33 pagesList of BS Codesnavaneethsparkwest100% (8)

- 4Document1 page4Mohan VarkeyNo ratings yet

- Spec For Jet Type Cooling TowerDocument5 pagesSpec For Jet Type Cooling TowerMohan VarkeyNo ratings yet

- Heat Load FormatDocument5 pagesHeat Load FormatMohan VarkeyNo ratings yet

- Steam TurbineDocument9 pagesSteam TurbineMohan VarkeyNo ratings yet

- Electricity Distribution Companies by Country - Wikipedia, The Free EncyclopediaDocument24 pagesElectricity Distribution Companies by Country - Wikipedia, The Free EncyclopediahemantNo ratings yet

- Sulfuric Acid Tank - APIDocument4 pagesSulfuric Acid Tank - APISakthi VelNo ratings yet

- DM0565RDocument20 pagesDM0565RSURESH CHANDRA ROUTNo ratings yet

- Manual Og Maxi Sl1ws v3 060307Document90 pagesManual Og Maxi Sl1ws v3 060307Cezar GabrielNo ratings yet

- COP26 and PakistanDocument16 pagesCOP26 and PakistanBilal KhalidNo ratings yet

- 5PADPAO Updated Watchlist 2019 (MAY 8, 2019)Document30 pages5PADPAO Updated Watchlist 2019 (MAY 8, 2019)PATRICK SARMIENTONo ratings yet

- Calculation Wind LoadDocument50 pagesCalculation Wind Loadnoorggggg100% (2)

- PHD, Thesis-Abdullah AbuhabayaDocument184 pagesPHD, Thesis-Abdullah AbuhabayaYlm PtanaNo ratings yet

- The Problem and Its BackgroundDocument4 pagesThe Problem and Its BackgroundNoxian TelicNo ratings yet

- Guidelines for REEM Registration and Energy Efficiency ReportingDocument61 pagesGuidelines for REEM Registration and Energy Efficiency ReportingYing Yi TanNo ratings yet

- ADT SOLAR (Going Solar 101)Document18 pagesADT SOLAR (Going Solar 101)Tommy HectorNo ratings yet

- Energy (R) Evolution: A Sustainable Energy Outlook For CanadaDocument120 pagesEnergy (R) Evolution: A Sustainable Energy Outlook For Canadarto2951100% (1)

- Sulzer Running Direction Fuel InterlockDocument3 pagesSulzer Running Direction Fuel InterlockKarthik Reddiar100% (1)

- Comfosystems Prices 2013 Ventilation and Air DistributionDocument21 pagesComfosystems Prices 2013 Ventilation and Air DistributionWPenrithNo ratings yet

- Serie (Conducción en Estado Estable)Document6 pagesSerie (Conducción en Estado Estable)Arturo CoPaNo ratings yet

- Product Datasheet Green Up Troffer RC320Document1 pageProduct Datasheet Green Up Troffer RC320Bahrowi Adi WijayaNo ratings yet

- Fire ExtinguisherDocument21 pagesFire Extinguisheramit dhingraNo ratings yet

- Yokes Y6 Y7 Y8Document4 pagesYokes Y6 Y7 Y8KuKu FunNo ratings yet

- DDG Projects Format for DPRDocument26 pagesDDG Projects Format for DPRsivesh_rathiNo ratings yet

- The vertical axis wind turbine for built environmentsDocument16 pagesThe vertical axis wind turbine for built environmentsBOEING21No ratings yet

- Tutorial 4 Refrigeration System BDA 3043 - Thermodynamics II Winardi SaniDocument4 pagesTutorial 4 Refrigeration System BDA 3043 - Thermodynamics II Winardi Saniwanpudin0% (1)

- Eb Application SubmittedDocument3 pagesEb Application SubmittedPrasadNo ratings yet

- Mitsubishi mt160-180 Repair Manual Part 1 Optimized PDFDocument177 pagesMitsubishi mt160-180 Repair Manual Part 1 Optimized PDFKemal Lisnik Arnautovic100% (1)

- ERC Philippines power plant inspection standardsDocument4 pagesERC Philippines power plant inspection standardsAubry GarciaNo ratings yet

- Green Building Technologies and BenefitsDocument11 pagesGreen Building Technologies and BenefitsGori AkashNo ratings yet

- What Is The Cost of Waste To Energy Projects in India - Ankur Scientific PDFDocument1 pageWhat Is The Cost of Waste To Energy Projects in India - Ankur Scientific PDFPrashu RajputNo ratings yet

- High Performance Design Strategies For K-12 SchoolsDocument90 pagesHigh Performance Design Strategies For K-12 Schoolsmohammed hassainNo ratings yet

- Electrical Machines I Lab Twisted QuestionsDocument4 pagesElectrical Machines I Lab Twisted QuestionsPranav MenonNo ratings yet

- Chap 10 SolnDocument20 pagesChap 10 Solngarbage94No ratings yet

- White Collar FactoryDocument14 pagesWhite Collar FactoryAnder AndersenNo ratings yet