Professional Documents

Culture Documents

Vol-2-9-33kV Switchgear Technical Specification

Uploaded by

Tejaswi ShuklaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vol-2-9-33kV Switchgear Technical Specification

Uploaded by

Tejaswi ShuklaCopyright:

Available Formats

33KV SWITCHGEAR SPECIFICATIONS 1 Scope, Specific Technical Requirements and Quantities 1.

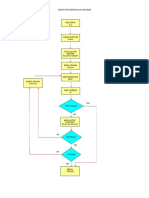

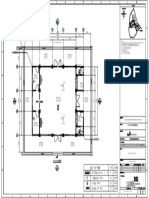

1 Scope This specification covers the requirements for design, engineering, manufacture, assembly, stage testing, inspection, testing before supply, packing and loading at works of 33kV Indoor Switchgear along with its accessories and auxiliary equipments / instruments etc. and erection, testing & commissioning as mentioned in this section and in various other sections of this specification for 33 KV switchgear. Bidder will provide transportation, unloading, storage and ETC for these items at site. The scope shall encompass and include all the activities listed above. 1.2 General Requirements 1.2.1 At Parsa 132kV Substation three numbers of 33kV incoming feeders (Including Spare) from Transformer have been considered, which will be terminated on two separate sections of a 33kV Indoor as incomers. There shall be three out going feeders (Including Spare) in distributed over both the bus section of the switchboard. 1.2.2 For the purpose of design of equipment / systems, an ambient temperature of 50oC and humidity of 100% shall be considered. The equipment shall operate in a highly polluted and highly corrosive environment. 1.2.3 All equipment shall be suitable for voltage variations of 10% of the rated value and frequency variations of 5% of the rated value. 1.2.4 The creepage distance of the insulators shall be generally not less than 25mm/kV per unit of system phase to phase voltage. 1.2.5 Degree of protection for the switchgear shall be IP4X as per IS 13947.

33KV SWITCHGEAR SPECIFICATIONS Specific Technical Requirements: Sr. No. 1 2 3 4 5 6 7 8 9 Description Required Highest System Voltage Current Rating Number of Phases System Frequency Fault Current Insulation Level Auxiliary Supply 33kV Bus Protection 33kV Transformer Protection Parameters 36kV 1600A 3 50Hz 25kA for 1 sec. 36/70/170kVp 240v 1-phase AC & 110V DC Differential feeder Transformer differential, O/C E/F &

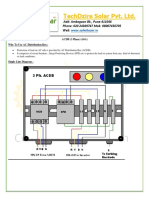

Bill of Quantities Three phase, 33kV Indoor Switchgear One no of 33kV metal clad switchgear,1600A,25kA rms for 1 sec suitable for 110V DC control supply with following feeder/equipment for each 33kV Metal clad switchgear. i) Incomer feeder ii) Outgoing feeder iii) Spare incomer feeder iv) Spare Outgoing feeder v) Bus Coupler vi) Bus VT Earthing Truck Earthing arrangement for breaker/NT trucks shall be provided either through integral earth switch separate earthing truck. In case of latter arrangement, one set of different types of earthing : 1600A, 2nos. : 1600A, 2 nos. : 1600A, 1 no. : 1600A, 1 no. : 1600A, 1 no. : 2 nos.

33KV SWITCHGEAR SPECIFICATIONS trucks per switchboard shall be supplied. Recommended Spares Supplier to propose the list of recommended spares for 3 years of trouble free operation. Type Tests, Routine Tests and Acceptance Test: Bidder shall submit valid reports of type test carried out with in ten years. These reports should have been conducted as per technical specification and relevant IS/IEC. In case of more than ten year old type test reports OR invalid type test reports are submitted, the tests shall be conducted free of charge. No separate type test charges shall be paid. All the Routine and Acceptance test shall be carried out as per relevant standards.

Equipment Specification Switchgear and Breakers IEC 60298, IEC 60056, IS 13118

2.1 Codes and Standards 2.2 List of fitments on various modules The various feeders and bus VT panel shall at least contain following fitments:

S. No. 1

Module Incoming Feeder

Brief Description of major fitments 1600A Circuit breaker (Vacuum or SF6 Type), Sets of CTs ( for metering and protection), 30kV Lightning Arrester, Cable termination kit, Truck mounted 3 nos. single phase feeder VTs complete with HT fuses, T/N/C switch, L/R switch, AC/DC On/Off switches, Digital Ammeter, Digital Voltmeter, Digital Wattmeter, Digital Energy meter , O/C & E/F protection relay, Anti-pumping relay, Tripping relay, latch type contact multiplication relay, DC supervision relay, Trip circuit supervision relay, PT fuse failure relay, Current transducer, painted mimic to represent SLD,

Outgoing Feeder

Buscoupler

33KV SWITCHGEAR SPECIFICATIONS Auxiliary relay, facia annunciator. 1600A Circuit breaker (Vacuum or SF6 Type), Set of CTs (for metering and protection), Cable termination kit, T/N/C switch, L/R switch, AC/DC On/Off switches, Ammeter with selector switch, Digital Energy meter, Wattmeter, O/C & E/F protection relay, Antipumping relay, Tripping relay, latch type contact multiplication relay, DC supervision relay, Trip circuit supervision relay, Current transducer, painted mimic to represent SLD, Auxiliary relays, facia annunciator. 1600A Circuit breaker (Vacuum or SF6 Type), Set of CTs (for metering and protection), Cable termination kit, T/N/C switch, L/R switch, AC/DC On/Off switches, Ammeter with selector switch, Digital energy meter, Wattmeter, O/C & E/F protection relay, Antipumping relay, Tripping relay, latch type contact multiplication relay, DC supervision relay, Trip circuit supervision relay, Current transducer, painted mimic to represent SLD, Auxiliary relay, facia annunciator. Additionally 33kV Bus bar differential protection relay shall be mounted in Buscoupler Panel. Truck Mounted bus connected 3 nos. single phase PTs Ratio 33kV/3/110V/3 complete with HT fuses, MCBs for AC/DC main supply, AC/DC On/Off switches, voltmeter with selector switch, U/V, O/V protection relay, PT fuse failure relay, DC sup. Relay, Voltage transducer, painted mimic to represent SLD, Auxiliary relay, facia annunciator.

Bus VT Panel

2.3

Constructional Details 2.3.1 The switchgear shall be fully compartmentalized metal clad construction, comprising of a row of free standing floor mounted panels. The switchgear assembly shall be rodent and vermin

33KV SWITCHGEAR SPECIFICATIONS proof. 2.3.2 The circuit breakers, bus voltage transformers shall be mounted on withdraw able trucks, having distinct 'Service', 'Isolated' and 'Withdrawn' positions. Testing of breaker shall be possible in isolated position by keeping control plug connected. 2.3.3 In panel design where breaker compartment does not have a door i.e. Breaker truck front serves as a door, suitable blanking covers, one for each size of panel per switchboard shall be supplied. Use of inflammable material such as Hylam as an interpole barrier shall not be accepted. 2.3.4 The height of panels shall not exceed 2600mm. Bushing or other sealing arrangement between breaker and bus-bar/cable compartments shall be provided so that there is no air communication around isolating 'contacts in the safety shutter area with truck in service position. The horizontal bus-bars, vertical droppers and connections to the fixed end of the isolating contacts shall be of high conductivity aluminum alloy or copper. Pressure relief device shall be provided in each high voltage compartment. 2.3.5 The over-voltage generated by switching of breaker under any duty condition shall not exceed 2.5 pu of nominal line to neutral voltage. Evaluation criteria shall be as per IEEE envelope. 2.3.6 Bus-bar insulators shall be of track-resistant, high strength, non-hygroscopic, noncombustible type and suitable to withstand stresses due to over-voltages and short circuit current. The temperature rise of bus-bars shall not exceed 55C for silver plated joints and 40C for other joints under any condition over an ambient of 50C. 2.3.7 The internal earth bus shall be provided to withstand short circuit currents for one second. All enclosures shall be connected to this earth bus. Earthing arrangement for breaker/NT trucks shall be provided either through integral earth switch or through separate earthing truck. In case of latter arrangement, one set of different types of earthing trucks per switchboard shall be supplied. Suitable mechanical interlock shall be provided to prevent inadvertent earthing of any live part. Earthing switch shall have short time (1 second) current withstand capability equal to the breaker. 2.3.8 All components shall be correctly rated. 2.3.9 Panels should be suitable for top/bottom cable entry. 2.3.10 Each 33kV switchgear section shall have three phase VT.

33KV SWITCHGEAR SPECIFICATIONS 2.3.11 All CTs and VTs shall be completely cast resin encapsulated type with insulation class 'E' or better and suitable for continuous operation. All VTs shall have suitable HRC current limiting fuses / MCB on both primary and secondary sides, and under voltage relays, timers, etc. for motor tripping and remote annunciation on supply failure. Voltmeter with selector switch shall be provided with each bus-section. Primary fuse replacement shall be possible with VT truck in isolated position. 2.3.12 Each breaker panel shall have breaker control switch of spring return type and a local/ remote selector switch of stay-put type. The panel shall also have 'On', 'Off', 'Spring charged' and Control supply healthy' indicating lamps. The lamps shall be filament type and low watt consumption with built-in resistors. 2.3.13 Each switchboard/panel shall have suitable arrangement to receive and distribute ac and dc supplies. Control dc supply shall be duplicated for each board. Each switchgear panel shall have thermostatically controlled space heater with switch, illumination and power plug point. 2.3.14 All panels on front and back as well as inside shall have engraved nameplate giving feeder description and component identification. 2.4 Circuit Breakers The breakers shall be of SF6 type or vacuum type. They shall be re-strike free, stored energy operated, trip free, and with electrical anti-pumping feature. For SF6 breakers, necessary pressure/density monitoring device shall be provided for lowpressure alarm. Only motor wound closing spring charging arrangement shall be accepted. Operating cycle shall be 'O3min.-CO-3min.-CO'. The breaker shall be controlled locally and /or remotely as required. The closing and tripping coils shall operate under extreme conditions of control voltage variation. Supervision relays shall be provided for trip coil monitoring. Facilities shall be provided for mechanical tripping of breaker and manual charging of closing spring. 2.5 Relays and Protection All relays and timers shall be flush mounted with connections from inside. They shall have transparent & dust tight cover, removable from front. Draw out construction for easy replacement from the front.

33KV SWITCHGEAR SPECIFICATIONS They shall have built-in test facilities, or can be provided with necessary test blocks and test switches. One testing plug shall be provided for each switchboard. The auxiliary relays and timers may be in non-draw out cases. The relays and timers shall operate under extreme conditions of control voltage variation. They shall not have any inbuilt batteries, and shall operate on available dc supply. They shall be provided with hand-reset operation indicators (flags) or LEDs with push buttons for resetting for analyzing the cause of breaker operation. All equipments shall have necessary protections. However, following minimum protections shall be provided and also relays shall be Static/numerical type. a) Over current (51) & Earth Fault (51N) protection for all feeders and Bus-coupler b) 33kV Bus differential protection (87B) (To be located in Bus Coupler feeder panel) c) Over current protection (50/51) and Differential protection (87) relays on the primary side of Outgoing feeders for Transformers. d) Aux. relays with indicating flags/LED for transformer buchholz and temperature protection. 2.6 Main Bus-bar High conductivity 1600A aluminium alloy/ copper bus-bar shall be provided as per attached SLD. Bus-bar thickness shall be such to withstand system short circuit level and it shall also in accordance with other system parameters such as rated current etc. Minimum thickness of conductor bus-bar shall be as per relevant Indian standard.

2.7 Current Transformers Each feeder of 33kV switchgear shall be provided with Current Transformers with following core details:Core Current Ratio Accuracy Application

33KV SWITCHGEAR SPECIFICATIONS 1 2 3 400-200/1A 400-200/1A 400-200/1A 1.0 5P20 PS Metering Over Current Protection Differential Protection

2.8 Voltage Transformer The main bus-bar of 33kV switchgear shall be provided with Bus VT. The bus VT shall have following core details: Core Voltage Ratio 1 2 33kV/3/110/3 33kV/3/110/3 Burden 100VA 50VA Accuracy 1.0 3P Application Metering Protection

2.9 Control and Secondary Wiring All switchboards shall be supplied, completely wired internally up to the terminal blocks. All inter-cubicle and inter-panel wiring and connections between panels of same switchboard including all bus wiring for AC and DC supplies is in bidders scope. All internal wiring shall be carried out with 1100 V grade, single core, 1.5 square mm or larger stranded copper wires having colour coded, PVC insulation. CT circuits shall be wired with at least 2.5 square mm copper wires. Voltage grade and insulation shall be same as above. Extra-flexible wires shall be used for wiring to device mounted on moving parts such as hinged doors. All wiring shall be properly supported, neatly arranged, readily accessible and securely connected to equipment terminals and terminals blocks. 2.10 Power Cables Termination Cable termination compartment and arrangement for power cables shall be suitable for stranded aluminium conductor, armoured XLPE insulated and sheathed single core/three core, 36 kV grade cables.

33KV SWITCHGEAR SPECIFICATIONS All necessary cable terminating accessories such as Gland plates, supporting clamps and brackets, power cable lugs, hardware etc. shall be provided by the contractor to suit the final cable sizes, which would be advised during detailed engineering. The gland plate shall be of removable type. Bidder shall also ensure that sufficient space is provided for all cable glands. Gland plates shall be factory-drilled according to the cable gland sizes and number which shall be informed to the Contractor later. For all single core cables, gland plates shall be of non-magnetic material

Conceptual SLD for 33kV System Trafo -1 I/C-1 Trafo-2 I/C-2 Spare I /C

V3 VT

X X X

VT

O/G-1

O/G-2

Spare O/G

33KV SWITCHGEAR SPECIFICATIONS MANDATORY SPARE LIST

1. Each Type of Limit Switch 2. Each Type of Aux. Relay 3. Each Type of LED lamp 4. Each Type of Push Button 5. Each Type of Control Fuse 6. Each Type of MCB 7. Local/Remote Selector Switch 8. Breaker control switch 9. Current Transformer

- 1 no - 1 no - 2 nos - 2 nos - 5 nos - 1 no - 2 nos - 1 no - 1 no

You might also like

- Technial Specification of Panel .Wiring, SwitchgearDocument19 pagesTechnial Specification of Panel .Wiring, SwitchgearkiroNo ratings yet

- Phase Failure RelaysDocument8 pagesPhase Failure RelaysPuneet RanaNo ratings yet

- Electrical DesignDocument50 pagesElectrical DesignNethajiNo ratings yet

- Arc Control in Circuit Breakers: Low Contact Velocity 2nd EditionFrom EverandArc Control in Circuit Breakers: Low Contact Velocity 2nd EditionNo ratings yet

- Busbar Eet414Document34 pagesBusbar Eet414yahyeNo ratings yet

- Electrical LV Panel Form ClassificationDocument2 pagesElectrical LV Panel Form Classificationjlcheefei9258No ratings yet

- Panel BoardDocument7 pagesPanel BoarduddinnadeemNo ratings yet

- Capacitor SelectionDocument72 pagesCapacitor SelectionSatyendra Kumar100% (2)

- Calculate Cable Size and Voltage Drop Electrical Notes Articles PDFDocument10 pagesCalculate Cable Size and Voltage Drop Electrical Notes Articles PDFKamugasha Kagonyera100% (1)

- Terminaiton Kit SpecificaitonDocument5 pagesTerminaiton Kit SpecificaitonVaibhav ShahNo ratings yet

- 4000A Bus DuctDocument9 pages4000A Bus DuctRan Vijaysingh100% (1)

- Grounding and Bonding For Electrical Systems-Rev01Document11 pagesGrounding and Bonding For Electrical Systems-Rev01Mohamed Hamed100% (1)

- Generator SizingDocument32 pagesGenerator SizingjaredNo ratings yet

- CPWD Part-2 External 2023Document238 pagesCPWD Part-2 External 2023Assistant Engineer Elect CED III CCU100% (1)

- Calculation To Choose Capacitor For Detuned FilterDocument3 pagesCalculation To Choose Capacitor For Detuned Filterjiguparmar1516No ratings yet

- Guide For The Design and Production of LV Power Factor Correction CubiclesDocument76 pagesGuide For The Design and Production of LV Power Factor Correction CubiclesGunadevan Chandrasekaran100% (1)

- General Specifications For Soft StarterDocument7 pagesGeneral Specifications For Soft StarterIsmael AhmedNo ratings yet

- LS Cast Resin Transformers: Technical PerformanceDocument16 pagesLS Cast Resin Transformers: Technical PerformanceSayemAbusadat100% (1)

- Busduct FormatDocument5 pagesBusduct FormatAjish Rajan TNo ratings yet

- VCB PanelsDocument17 pagesVCB PanelsSenthil Prasadh100% (1)

- Voltage DropDocument5 pagesVoltage DropZulkarnain DahalanNo ratings yet

- Soft Starter CatalogueDocument28 pagesSoft Starter CatalogueBADRI VENKATESHNo ratings yet

- 33kv Indoor VCB 3 Panel Sets and 5 Panel SetsDocument88 pages33kv Indoor VCB 3 Panel Sets and 5 Panel SetsAssistant Engineer SCM XTNo ratings yet

- Sandwhich BusductDocument5 pagesSandwhich BusductHarmandeep Ahluwalia100% (1)

- Current Carrying CapacitiesDocument46 pagesCurrent Carrying Capacitiesnagraj204No ratings yet

- 02-Annexure - Electrical System Design ParametersDocument6 pages02-Annexure - Electrical System Design ParametersPrasenjit DeyNo ratings yet

- Sewage Treatment Package Cable Sizing: Project: Ardebil Gas Turbine Power PlantDocument5 pagesSewage Treatment Package Cable Sizing: Project: Ardebil Gas Turbine Power Plantnourfarmajid0% (1)

- MINILEC Full Cat PDFDocument68 pagesMINILEC Full Cat PDFDakshinaMoorthyNo ratings yet

- Earthing Design Calculation Sheet - 1Document1 pageEarthing Design Calculation Sheet - 1Kanhaiya AbhiNo ratings yet

- Design Knowhow Low Voltage Substation Layouts Earthing Fire Protection and Tests PDFDocument24 pagesDesign Knowhow Low Voltage Substation Layouts Earthing Fire Protection and Tests PDFsalemg82No ratings yet

- Cable GlandsDocument20 pagesCable GlandsBalaji VenkatesanNo ratings yet

- 11KV VCBDocument3 pages11KV VCBeagles1109No ratings yet

- 8.I-11 KV Xlpe CablesDocument5 pages8.I-11 KV Xlpe CablesAnkur SinhaNo ratings yet

- Module 5 MV Switch TestingDocument68 pagesModule 5 MV Switch TestingSuresh K Krishnasamy100% (1)

- Earthing Calculation As Per Ieee 80Document10 pagesEarthing Calculation As Per Ieee 80Ben HurNo ratings yet

- Busway TrainingDocument72 pagesBusway TrainingThức VõNo ratings yet

- AHF Manual R5 1-27-2012 PDFDocument54 pagesAHF Manual R5 1-27-2012 PDFkaushikray06No ratings yet

- Erection Procedures For Medium Voltage Switchgear - EEP PDFDocument5 pagesErection Procedures For Medium Voltage Switchgear - EEP PDFMoucha JustdoitNo ratings yet

- Abb Switchgear PricelistDocument360 pagesAbb Switchgear PricelistH.S Engineering worksNo ratings yet

- MR - On Load Tap Changer For DTs - F0338803 - ECOTAP - VPD - EN PDFDocument24 pagesMR - On Load Tap Changer For DTs - F0338803 - ECOTAP - VPD - EN PDFalbertohiggs6100% (1)

- Test Reports: SL - No Description Results / ObservationsDocument3 pagesTest Reports: SL - No Description Results / ObservationsAROCKIA STEPHAN SESUMANINo ratings yet

- ReportDocument2 pagesReportArka EnergyNo ratings yet

- Ec Axial Fan W3g800gu2501 EngDocument5 pagesEc Axial Fan W3g800gu2501 EngmacmottaNo ratings yet

- Electrical Calculations Sheet - Main - Electrical KnowhowDocument16 pagesElectrical Calculations Sheet - Main - Electrical KnowhowUjjal ChakmaNo ratings yet

- Formula MCCBDocument104 pagesFormula MCCBthomaswangkoro100% (1)

- Main Components of Electrical Substation: Incoming LineDocument10 pagesMain Components of Electrical Substation: Incoming LineShiv Kumar Verma100% (1)

- How To Size DG Set - CumminsDocument4 pagesHow To Size DG Set - CumminsNalin KumarNo ratings yet

- VCB Panel SpecsDocument10 pagesVCB Panel SpecsanandpurushothamanNo ratings yet

- Electrical Design A Good Practice Guide Pub 123Document92 pagesElectrical Design A Good Practice Guide Pub 123JOSE LUIS FALCON CHAVEZNo ratings yet

- MV Switchgear Technical Specification PDFDocument109 pagesMV Switchgear Technical Specification PDFWhite HeartNo ratings yet

- Low Voltage Circuit Breaker Designing: Compiled By: Er. SADIQ HUSSAIN - INDIADocument16 pagesLow Voltage Circuit Breaker Designing: Compiled By: Er. SADIQ HUSSAIN - INDIAsaleh gazi100% (1)

- Earthing PitDocument4 pagesEarthing PitChaitanya ShakyaNo ratings yet

- Electrical Design-StepsDocument13 pagesElectrical Design-Stepsnadeem UddinNo ratings yet

- Vol 2-9-33kV Switchgear Technical SpecificationDocument10 pagesVol 2-9-33kV Switchgear Technical SpecificationbinodeNo ratings yet

- Uflex@sanand Elect Est R0Document28 pagesUflex@sanand Elect Est R0ranjeet.globalgreenNo ratings yet

- Enquiry - PanelDocument8 pagesEnquiry - Panelrkpatel40No ratings yet

- SpecificationsDocument7 pagesSpecificationspvenkyNo ratings yet

- 245kv GTP Sf6 BreakersDocument4 pages245kv GTP Sf6 BreakersTejaswi ShuklaNo ratings yet

- Disclosure To Promote The Right To InformationDocument34 pagesDisclosure To Promote The Right To InformationTejaswi ShuklaNo ratings yet

- Ehv Instrument TransformersDocument3 pagesEhv Instrument TransformersTejaswi ShuklaNo ratings yet

- 33kv Cables SpecsDocument20 pages33kv Cables SpecsMohamed WahidNo ratings yet

- 20 Mvar Capacitor BankDocument9 pages20 Mvar Capacitor BankTejaswi ShuklaNo ratings yet

- Grid Tied Solar Inverters Hitachi1250 KvaDocument4 pagesGrid Tied Solar Inverters Hitachi1250 KvaTejaswi ShuklaNo ratings yet

- Competence Mapping & Training Need Identification Form: Name: Tejaswi ShuklaDocument1 pageCompetence Mapping & Training Need Identification Form: Name: Tejaswi ShuklaTejaswi ShuklaNo ratings yet

- Technical Specs PLCCDocument2 pagesTechnical Specs PLCCTejaswi ShuklaNo ratings yet

- 66 KV Circuit Switcher Product OverviewDocument2 pages66 KV Circuit Switcher Product OverviewTejaswi ShuklaNo ratings yet

- Aux Cable SheduleDocument16 pagesAux Cable SheduleTejaswi ShuklaNo ratings yet

- 33 KV HT Panel - BomDocument2 pages33 KV HT Panel - BomTejaswi ShuklaNo ratings yet

- Short Circuit Current CalculationDocument2 pagesShort Circuit Current CalculationTejaswi ShuklaNo ratings yet

- Customer Benefits: MV Air-Insulated Switchgear RangeDocument8 pagesCustomer Benefits: MV Air-Insulated Switchgear RangeTejaswi ShuklaNo ratings yet

- Bom - VCB OswalDocument2 pagesBom - VCB OswalTejaswi ShuklaNo ratings yet

- Philips Price ListDocument82 pagesPhilips Price ListTejaswi ShuklaNo ratings yet

- Electric Arc Furnace (EAF)Document1 pageElectric Arc Furnace (EAF)Tejaswi ShuklaNo ratings yet

- Srex PowerDocument20 pagesSrex PowerTejaswi ShuklaNo ratings yet

- Vijay Resume For Summer TraningDocument2 pagesVijay Resume For Summer TraningTejaswi ShuklaNo ratings yet

- Navin Kumar TripathiDocument2 pagesNavin Kumar TripathiTejaswi ShuklaNo ratings yet

- Elmeasure Transducer CatalogDocument1 pageElmeasure Transducer CatalogSEO BDMNo ratings yet

- Grid Automation l3 Mvaa 2524 2010 12 enDocument4 pagesGrid Automation l3 Mvaa 2524 2010 12 enSamsung JosephNo ratings yet

- LGE001-MEC-LAY-005 HVAC Layout - MosqueDocument1 pageLGE001-MEC-LAY-005 HVAC Layout - MosqueRemmo ArdianNo ratings yet

- Fuels Solutions r0Document2 pagesFuels Solutions r0BryanJianNo ratings yet

- Dynamics StudentDocument19 pagesDynamics StudentRioNo ratings yet

- Tesla 02Document19 pagesTesla 02Pedretosko LabsNo ratings yet

- Transformer ProtectionDocument27 pagesTransformer ProtectionYogesh Mittal100% (2)

- L:3 T:1 P:0 Credit:4: MEC 216 Thermal EngineeringDocument91 pagesL:3 T:1 P:0 Credit:4: MEC 216 Thermal EngineeringAmit aroraNo ratings yet

- Motor Parameters 03Document2 pagesMotor Parameters 03Miguel eNo ratings yet

- Introduction To Parallel Computing, Second Edition-Ananth Grama, Anshul Gupta, George Karypis, Vipin KumarDocument2 pagesIntroduction To Parallel Computing, Second Edition-Ananth Grama, Anshul Gupta, George Karypis, Vipin KumarjulioNo ratings yet

- High Volt Electric Defstan PDFDocument26 pagesHigh Volt Electric Defstan PDFMuhammad Jawwad Moeen AhmedNo ratings yet

- Sunpower T0 Tracker: BenefitsDocument2 pagesSunpower T0 Tracker: BenefitsSaikumar NemalikantiNo ratings yet

- Single Phase Differential Transformer Protection Using ArduinoDocument4 pagesSingle Phase Differential Transformer Protection Using ArduinoHana AliNo ratings yet

- Vdocuments - MX - The Physics of Archery 1Document29 pagesVdocuments - MX - The Physics of Archery 1Music PranaNo ratings yet

- TGBS Open Day 2021 Aiman FMD 14 Oct 2021 ZZ Without VideoDocument22 pagesTGBS Open Day 2021 Aiman FMD 14 Oct 2021 ZZ Without VideoAr AimanNo ratings yet

- RZ Power Limited: Thakurgaon Road, Thakurgaon Engine StatusDocument35 pagesRZ Power Limited: Thakurgaon Road, Thakurgaon Engine StatussaifulNo ratings yet

- Course OutlineDocument14 pagesCourse OutlineTony SparkNo ratings yet

- EC135 Classic B1 R06EN 10 - Electrical System.22911.2020 11 03.printableDocument76 pagesEC135 Classic B1 R06EN 10 - Electrical System.22911.2020 11 03.printableTitou GoltzNo ratings yet

- Thermodynamics and Its ApplicationsDocument30 pagesThermodynamics and Its ApplicationspoletoNo ratings yet

- Quantum Mechanics - Britannica Online Encyclopedia PDFDocument29 pagesQuantum Mechanics - Britannica Online Encyclopedia PDFMahesh MaheshwariNo ratings yet

- Physics II ProblemsDocument1 pagePhysics II ProblemsBOSS BOSSNo ratings yet

- Waste - To - Energy - Concepts For Efficient Power PlantsDocument150 pagesWaste - To - Energy - Concepts For Efficient Power PlantsNuyul FaizahNo ratings yet

- Progress Report #1: CO-OP Training in YASREFDocument9 pagesProgress Report #1: CO-OP Training in YASREFMuhammed ajmalNo ratings yet

- DG Set SpecsDocument57 pagesDG Set SpecsGautam LohiaNo ratings yet

- LP Module 1 4 Eapp 1Document25 pagesLP Module 1 4 Eapp 1John kharl RustiaNo ratings yet

- EEE (16-17) Project Review Evaluation SheetsDocument12 pagesEEE (16-17) Project Review Evaluation SheetsHaritha ANo ratings yet

- Vastushastra Presentation DamauliDocument41 pagesVastushastra Presentation DamauliSHristi ShaRmaNo ratings yet

- SCIENCE GRADE 6 - ST1-4 Answer KeyDocument4 pagesSCIENCE GRADE 6 - ST1-4 Answer KeyJill Maguddayao100% (6)

- Wind Energy and Wind Turbine PDFDocument13 pagesWind Energy and Wind Turbine PDFE Cos LopezNo ratings yet

- FC12 9 1Document2 pagesFC12 9 1Jose Angel FernandezNo ratings yet

- The Importance of Being Earnest: Classic Tales EditionFrom EverandThe Importance of Being Earnest: Classic Tales EditionRating: 4.5 out of 5 stars4.5/5 (44)

- The Inimitable Jeeves [Classic Tales Edition]From EverandThe Inimitable Jeeves [Classic Tales Edition]Rating: 5 out of 5 stars5/5 (3)

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherFrom EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNo ratings yet

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedFrom EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedRating: 4.5 out of 5 stars4.5/5 (5)

- The Book of Bad:: Stuff You Should Know Unless You’re a PussyFrom EverandThe Book of Bad:: Stuff You Should Know Unless You’re a PussyRating: 3.5 out of 5 stars3.5/5 (3)

- Sex, Drugs, and Cocoa Puffs: A Low Culture ManifestoFrom EverandSex, Drugs, and Cocoa Puffs: A Low Culture ManifestoRating: 3.5 out of 5 stars3.5/5 (1428)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticFrom EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticRating: 3.5 out of 5 stars3.5/5 (10)

- The Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolFrom EverandThe Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolRating: 4 out of 5 stars4/5 (14)

- The Most Forbidden Knowledge: 151 Things NO ONE Should Know How to DoFrom EverandThe Most Forbidden Knowledge: 151 Things NO ONE Should Know How to DoRating: 4.5 out of 5 stars4.5/5 (6)

- The Comedians in Cars Getting Coffee BookFrom EverandThe Comedians in Cars Getting Coffee BookRating: 4.5 out of 5 stars4.5/5 (8)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)