Professional Documents

Culture Documents

Example I-1 PDF

Uploaded by

boone37Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Example I-1 PDF

Uploaded by

boone37Copyright:

Available Formats

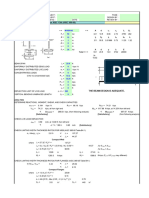

Example I-1: Composite Beam Design

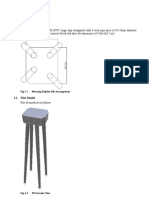

A series of 45 ft span composite beams at 10 ft o/c are carrying the loads shown below. The beams are ASTM A992 and are unshored. The concrete has f'c = 4 ksi. Design a typical floor beam with 3 in, 18 gage composite deck and 4.5 in normal weight concrete above the deck for fire protection and mass. Select an appropriate beam and required number of shear studs.

Lbeam 45 ft S 10 ft tslab 7.5 in

Material Properties: Fy 50 ksi f`c 4 ksi Loads: Dead load: kip Slab 0.075 ft 2 kip (assumed) Beam 0.008 ft 2 kip Misscellaneous 0.01 ft 2 Live load: kip Live 0.10 ft 2 (non-reduced) (ceiling, hangers, etc.) Fu 65 ksi E 29000 ksi [AISC Table 2-3, p. 2-39]

Example I-1: Composite Beam Design

Construction Load: kip Constructiondead 0.083 ft 2 kip Constructionlive 0.02 ft 2 Since each beam is spaced at 10 ft o/c: kip Dead ( (Slab + Beam + Misscellaneous) ) 10 ft = 0.93 ft kip Live Live 10 ft = 1 ft kip Constructiondead Constructiondead 10 ft = 0.83 ft kip Constructionlive Constructionlive 10 ft = 0.2 ft Calculate Factored Moment: kip wu 1.2 ( (Dead) ) + 1.6 ( (Live) ) = 2.72 ft

2 wu Lbeam Mu = 687 kip ft 8

[AISC Table 3-23, Example 1, p. 3-211]

Determine Effective Width: The effective width of the concrete slab is the sum of the effective widths for each side of the beam centerline which shall not exceed: 2 Lbeam 2 S beff min = 10 ft 2 8

[AISC

I3.1, p. 16.1-83]

Calculate the moment arm for the concrete force measured from the top of the steel shape, Y2. Assume a = 1in (Some assumption must be made to start the design process. An assumption of 1.0 in has proven to be a reasonable starting point in many design problems.)

Example I-1: Composite Beam Design

atrial 1 in atrial Y2 tslab = 7 in 2 Enter Manual Table 3-19 with required strength and Y2 = 7.0 in. Select a beam and nuetral axis location that indicates sufficient available strength. Select a W21x50 as a trial beam With PNA = BNL (See p 3-30, Figure 3.3c): bMn 770 kip ft flexural_strength if Mu bMn good else not good flexural_strength = good Check beam deflections and available strength. Check the deflection of the beam under construction considering only the weight of the concrete as contributing to the construction dead load. Limit the deflection to a maximum of 2.5 in to facilitate concrete placement (construction). 5 Constructiondead Lbeam 4 Ireq = 1056 in 4 384 E 2.5 in From Manual Table 3-20, a W21x50 has a Ix = 984, therefore this member doesn't satisfy the deflection criteria under construction. Using Manual Table 3-20 revise the trial secion to a W21x55 which has Ix = 1140 as noted in parenthesis below the shape designation. Check selected member strength as an unshored beam under construction loads assuming adequate lateral bracing through the deck attachment to the beam flange. Factored construction loads: [AISC, Table 3-19, p. 3-177]

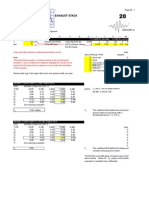

Example I-1: Composite Beam Design

kip C1 1.4 Constructiondead = 1.16 ft kip C2 1.2 Constructiondead + 1.6 Constructionlive = 1.32 ft kip C max C1 C2 = 1.32 ft C Lbeam 2 Mu.unshored = 333 kip ft 8 bMpx 473 kip ft flexural_strength if Mu.unshored bMpx| | good | | else | not good | flexural_strength = good For a W21x55 with Y2 = 7 in, the member has sufficient available strength when PNA is at location 6 and Qn = 292 kips. Manual Table 3-19, p. 3-177 and Manual Table 3-20, p. 3-200. bMn 756 kip ft [AISC, Table 3-19, p. 3-177] [AISC, Table 3-2, p. 3-17]

flexural_strength if Mu bMn | | good | | else not good | | flexural_strength = good Check "a": Qn 292 kip Qn a = 0.716 in 0.85 f`c beff

Example I-1: Composite Beam Design

| check_a if a atrial | good | | else not good | | flexural_strength = good Check live load deflection: Lbeam LL.allowable = 1.5 in 360 A lower bound moment of inertia for composite beams is tabulated in Manual Table 3-20. For a W21x55 with Y2 = 7 in and the PNA at location 6, Ilb = 2440. ILB 2440 in 4 5 Live Lbeam 4 LL = 1.3 in 384 E ILB deflection if LL LL.allowable| | good | | else | not good | deflection = good Determine if the beam has sufficient available shear strength: Lbeam Vu wu = 61 kip 2 vVnx 234 kip shear if Vu vVnx | | good | | else not good | | shear = good [AISC, Table 3-2, p. 3-17] [AISC, Table 3-20, p. 3-200]

Example I-1: Composite Beam Design

Determine the required number of shear studs: Using perpendicular deck with one 0.75 in diameter weak stud per rib in normal 4 ksi concrete, Qn = 17.2 kip/stud. dstud 0.75 in Qn 17.2 kip Qn Studs = 17 Qn [AISC, Table 3-21, p. 3-207]

(on each side of the beam)

Total number of shear connectors; use 2(17) = 34 shear connectors Check the spacing of the shear connectors: stud_spacing if 6 dstud < 12 in < 8 tslab good else not good stud_spacing = good The studs are to be 5 in long so that they will extend a minimum of 1.5 in into the slab.

You might also like

- AISC ExamI1&2&3Document11 pagesAISC ExamI1&2&3Dhurai KesavanNo ratings yet

- Mid Rise Building Having Oblique Column With and Without Damper A ReviewDocument5 pagesMid Rise Building Having Oblique Column With and Without Damper A ReviewIJRASETPublicationsNo ratings yet

- Steel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)Document22 pagesSteel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)AlphaNo ratings yet

- Beam To Column'S Flange Fixed Connection - Bcff-4: Design DataDocument6 pagesBeam To Column'S Flange Fixed Connection - Bcff-4: Design DataAchmad RifaiNo ratings yet

- HY-8 Quick Start GuideDocument30 pagesHY-8 Quick Start Guidesach1116No ratings yet

- Design Head: ABS MODU 2014, Part 3-2-3/15.3 Page No. 82Document2 pagesDesign Head: ABS MODU 2014, Part 3-2-3/15.3 Page No. 82YusufNo ratings yet

- Beam - Deflection CheckDocument8 pagesBeam - Deflection ChecksharanekkmNo ratings yet

- Rowan Middle Town: Checking of Mouse Hole Support Structure For Dropped ObjectDocument4 pagesRowan Middle Town: Checking of Mouse Hole Support Structure For Dropped ObjectNripendra MishraNo ratings yet

- Believer: Slowly and FreelyDocument3 pagesBeliever: Slowly and FreelyGeovaniPedrosoNo ratings yet

- A 400 MM B 318 MM: Wheel Loading CompensationDocument5 pagesA 400 MM B 318 MM: Wheel Loading CompensationOliver John VeniegasNo ratings yet

- HSS Chevron Brace Connection DesignDocument5 pagesHSS Chevron Brace Connection Designeduardox11No ratings yet

- Beam DesignDocument11 pagesBeam DesignImranSohailNo ratings yet

- Reinforced Concrete Beam Design DetailsDocument16 pagesReinforced Concrete Beam Design Detailsabdul kareeNo ratings yet

- 4 ExtremeWaveAnalysis COASTHYDRODYN 2014Document42 pages4 ExtremeWaveAnalysis COASTHYDRODYN 2014Kenny TournoyNo ratings yet

- Teoria WeibullDocument4 pagesTeoria WeibullFabian MorenoNo ratings yet

- Bottom Stiffener DesignDocument10 pagesBottom Stiffener Designyogs_184No ratings yet

- AISC LRFD-93 Example 001 PDFDocument7 pagesAISC LRFD-93 Example 001 PDFDompu MengajiNo ratings yet

- AISC 360 VerificationBeamDesign PDFDocument7 pagesAISC 360 VerificationBeamDesign PDFCarl Patrick Erni RagasNo ratings yet

- Enhanced Steel BeamDocument4 pagesEnhanced Steel BeamBang SutresNo ratings yet

- Dynamic Analysis of Offshore Wind Turbine TowersDocument21 pagesDynamic Analysis of Offshore Wind Turbine TowersHaithem NessNo ratings yet

- Torsional beam design with USD methodDocument2 pagesTorsional beam design with USD methodShane BondNo ratings yet

- U Grouted Members: Theory Description of Use VerificationDocument40 pagesU Grouted Members: Theory Description of Use VerificationanandakoeNo ratings yet

- Dropped Anchor Calculation 1.7 MDocument3 pagesDropped Anchor Calculation 1.7 MAfriansyah100% (1)

- Transverse Shear-Build Up SectionsDocument8 pagesTransverse Shear-Build Up SectionsKavish DayaNo ratings yet

- M1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)Document2 pagesM1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)innovativekarthiNo ratings yet

- Moment of InertiaDocument3 pagesMoment of InertiaFreed CreedNo ratings yet

- Equipment Anchorage To Wood Roof Based On NDS 05 / IBC 09 / CBC 10 Input Data & Design SummaryDocument1 pageEquipment Anchorage To Wood Roof Based On NDS 05 / IBC 09 / CBC 10 Input Data & Design SummaryMarianne Aravilla Dela CruzNo ratings yet

- Solar panel anchorage design for 100 mph windsDocument2 pagesSolar panel anchorage design for 100 mph windsAamirShabbirNo ratings yet

- Weibull Analysis To A Practical CaseDocument23 pagesWeibull Analysis To A Practical CaseGuadagustinNo ratings yet

- ANSYS Stiffness Matrix v8p1Document3 pagesANSYS Stiffness Matrix v8p1Luis Beltran CobosNo ratings yet

- Design of Beam Member No.: F F 0.48 X /D 415 N/MMDocument20 pagesDesign of Beam Member No.: F F 0.48 X /D 415 N/MMUttam Kumar Ghosh100% (1)

- Bulk Head - 180515Document90 pagesBulk Head - 180515A M Nagabhushan AjwalNo ratings yet

- CVE 372 Exercise Problems - Pipe FlowDocument10 pagesCVE 372 Exercise Problems - Pipe FlowMahmoud I. MahmoudNo ratings yet

- Roark Case 6-1Document16 pagesRoark Case 6-1KekekLagosNo ratings yet

- Analysis of Pile-Soil Interaction Under Lateral Loading Using Infinite and Finite ElementsDocument32 pagesAnalysis of Pile-Soil Interaction Under Lateral Loading Using Infinite and Finite Elementsaln123No ratings yet

- Sneha Seminar ReportDocument59 pagesSneha Seminar ReportSneha ZaveriNo ratings yet

- USD T BeamDocument10 pagesUSD T BeammanowarNo ratings yet

- Pedestal DesignDocument11 pagesPedestal DesignNikhil TawadeNo ratings yet

- Free Standing Masonry Wall Design Based On ACI 530-05 & ACI 318-05Document9 pagesFree Standing Masonry Wall Design Based On ACI 530-05 & ACI 318-05SadatcharaMoorthi NNo ratings yet

- Distribution (Weibull) FittingDocument40 pagesDistribution (Weibull) FittingscjofyWFawlroa2r06YFVabfbajNo ratings yet

- Stability CritariaDocument9 pagesStability CritariaAbu Bakar Siddke RumiNo ratings yet

- CR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFDocument3 pagesCR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFInamullah KhanNo ratings yet

- Det-8 Ub533x210x92Document4 pagesDet-8 Ub533x210x92ihpeterNo ratings yet

- Shear Failure of Bolted Joints Lab ReportDocument1 pageShear Failure of Bolted Joints Lab Reportboo huNo ratings yet

- Sum FHT MD-SLDDocument5 pagesSum FHT MD-SLDNebula RockbandNo ratings yet

- Design of Stel Compression Members BS F950Document12 pagesDesign of Stel Compression Members BS F950Rotich VincentNo ratings yet

- Retaining wall design calculationsDocument13 pagesRetaining wall design calculationsHanafiahHamzahNo ratings yet

- ABS Seminar On Baltic Ice ClassDocument69 pagesABS Seminar On Baltic Ice ClassJonathanNo ratings yet

- Exhaust Stack: Engineering With The SpreadsheetDocument16 pagesExhaust Stack: Engineering With The SpreadsheetMakanjuola Ronald OlaitanNo ratings yet

- Slab Punching Design Based On ACI 318-19: Project: Client: Design By: Job No.: Date: Review byDocument2 pagesSlab Punching Design Based On ACI 318-19: Project: Client: Design By: Job No.: Date: Review byAndy BenNo ratings yet

- Purlin and Roof Design PDFDocument4 pagesPurlin and Roof Design PDFAlthara BaldagoNo ratings yet

- Beam To Column'S Flange Fixed Connection - Bcff-3: Design DataDocument6 pagesBeam To Column'S Flange Fixed Connection - Bcff-3: Design DataAchmad RifaiNo ratings yet

- Fatigue Design Criteria for Ship StructuresDocument17 pagesFatigue Design Criteria for Ship StructuresPaul Renato MonteroNo ratings yet

- Concreto Aci 318-051Document20 pagesConcreto Aci 318-051Freddy Gallo SanchezNo ratings yet

- SWL CalculationDocument3 pagesSWL CalculationKarl NagacNo ratings yet

- COMPRESS Saddle DesignDocument2 pagesCOMPRESS Saddle Designarif99pakNo ratings yet

- Din, En, Ansi, Asme, Astm, IsoDocument31 pagesDin, En, Ansi, Asme, Astm, Isoвасилий ловцовNo ratings yet

- Aisc Asd Gusset Plate Aisc341 16Document12 pagesAisc Asd Gusset Plate Aisc341 16Zarna Modi100% (1)

- Encased Composite Column in Axial CompressionDocument6 pagesEncased Composite Column in Axial Compressionboone37No ratings yet

- ASDIP Steel - Composite Beam Verification ExampleDocument6 pagesASDIP Steel - Composite Beam Verification ExampleEdwin VizueteNo ratings yet

- Encased Composite Column in Axial CompressionDocument6 pagesEncased Composite Column in Axial Compressionboone37No ratings yet

- Example I-2 Filled Composite Column in Axial CompressionDocument4 pagesExample I-2 Filled Composite Column in Axial Compressionboone37No ratings yet

- Example H.1bDocument2 pagesExample H.1bboone37No ratings yet

- Example 2aDocument4 pagesExample 2aboone37No ratings yet

- W ShapesDocument1 pageW Shapesboone37No ratings yet

- Example 2aDocument4 pagesExample 2aboone37No ratings yet

- PTC Controls Worksheet PrintingDocument2 pagesPTC Controls Worksheet Printingboone37No ratings yet

- Buoyancy Analysis of Open Rectangular Concrete Pit or TankDocument3 pagesBuoyancy Analysis of Open Rectangular Concrete Pit or Tankboone37100% (1)

- Bolted Field SpliceDocument49 pagesBolted Field Spliceboone37No ratings yet

- Stiffener DesignDocument5 pagesStiffener Designboone37No ratings yet

- SHAPES AND BOND ANGLES OF SIMPLE MOLECULESDocument78 pagesSHAPES AND BOND ANGLES OF SIMPLE MOLECULESKareem MckenzieNo ratings yet

- Top study habits for chemistryDocument74 pagesTop study habits for chemistrysaifNo ratings yet

- Structure of Atom: NEET/JEE: 2020-21Document3 pagesStructure of Atom: NEET/JEE: 2020-21shantinath123gmailcoNo ratings yet

- Separation ProcessesDocument57 pagesSeparation ProcessesAngelo X0% (1)

- Maxon Shut Off Valve Sizing ChartDocument3 pagesMaxon Shut Off Valve Sizing ChartJohn HowardNo ratings yet

- 6.moving Charges and MagnetismexericseDocument60 pages6.moving Charges and MagnetismexericseAryanNo ratings yet

- Introduction To Spectrochemical MethodsDocument25 pagesIntroduction To Spectrochemical MethodsSİNEM GÜVENNo ratings yet

- Frequently Examined Questions For Physics PracticalDocument2 pagesFrequently Examined Questions For Physics PracticalShuchi HossainNo ratings yet

- Chinese Physics Olympiad 2019 Finals Theoretical ExamDocument11 pagesChinese Physics Olympiad 2019 Finals Theoretical ExamMinh Công100% (1)

- Theory of Vibration 5th Edition BookDocument2 pagesTheory of Vibration 5th Edition BookSaad Afzal0% (1)

- Manual de Engilab PDFDocument144 pagesManual de Engilab PDFRoberto GuzmanNo ratings yet

- Montecarlo in AerodynamicsDocument32 pagesMontecarlo in AerodynamicsVíctor QuezadaNo ratings yet

- Qs Ans NEET-2023 (Code-F2) FinalDocument41 pagesQs Ans NEET-2023 (Code-F2) FinalYash KumarNo ratings yet

- DPC 2014 6 1 61 76Document16 pagesDPC 2014 6 1 61 76Nalla Umapathi ReddyNo ratings yet

- PHOTOCHEMISTRYDocument5 pagesPHOTOCHEMISTRYyuki_akitsuNo ratings yet

- HPLC Method DevelopmentDocument66 pagesHPLC Method DevelopmentPavan Kumar PrathipatiNo ratings yet

- Al-Qalam Academy of Sciences, Muzaffarabad: RT RTDocument4 pagesAl-Qalam Academy of Sciences, Muzaffarabad: RT RTSultan KhanNo ratings yet

- Physics Iup Itb Bab 4 - 5Document15 pagesPhysics Iup Itb Bab 4 - 5Emmyr FaiqNo ratings yet

- Ejercicios de Calculos QuimicosDocument70 pagesEjercicios de Calculos QuimicosMelinda AndersonNo ratings yet

- Ant Theor p1 RECollinDocument676 pagesAnt Theor p1 RECollinpratik vadhelNo ratings yet

- Questions Physical SciencesDocument6 pagesQuestions Physical SciencesJoseph Sebastian Dee100% (1)

- MHH Gaussian Point-Reflection-New StepwiseDocument18 pagesMHH Gaussian Point-Reflection-New StepwisesaddamNo ratings yet

- ELECTROMAGNETIC THEORY AND TRANSMISSION LINES QUESTION BANKDocument3 pagesELECTROMAGNETIC THEORY AND TRANSMISSION LINES QUESTION BANKvijay bhaskar nathiNo ratings yet

- F.SC - II Physics Q-Bank CH # 19Document4 pagesF.SC - II Physics Q-Bank CH # 19Mujtaba AliNo ratings yet

- Magnetrol Level Instruments - GWRDocument44 pagesMagnetrol Level Instruments - GWRVinodKumarNo ratings yet

- Gauss's law for electric fields explainedDocument26 pagesGauss's law for electric fields explainedssrecsvceNo ratings yet

- Sandstone Petrology and Provenance of The Neoproterozoic Voltaian Group in The Southeastern Voltaian Basin, GhanaDocument16 pagesSandstone Petrology and Provenance of The Neoproterozoic Voltaian Group in The Southeastern Voltaian Basin, GhanaGrace NorteyNo ratings yet

- Design and Analysis of a Flat Heat PipeDocument102 pagesDesign and Analysis of a Flat Heat Pipeafic219473No ratings yet

- Mass, Inertia, Weight & CM Exercise-PureDocument10 pagesMass, Inertia, Weight & CM Exercise-Puremaatla monkgeNo ratings yet

- Why Does A Stream of Water Deflect in An Electric FieldDocument2 pagesWhy Does A Stream of Water Deflect in An Electric Field1_2_3_4asdfNo ratings yet