Professional Documents

Culture Documents

Material Mill & Test Certificate

Uploaded by

Elton SitumeangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Mill & Test Certificate

Uploaded by

Elton SitumeangCopyright:

Available Formats

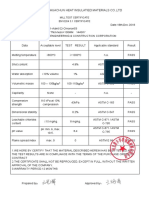

MATERIAL MILL AND TEST CERTIFICATE

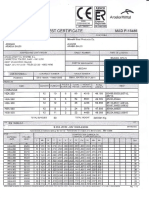

TEST CERTIFICATE ACCORDING TO ISO 10474-3.1B / BS EN 10204-3.1B CUSTOMER PO No. MILL PAGE No. MATERIAL STANDARD QA REF. No. QUANTITY DATE PAGE NO. 1 OF 1

PCS

CHEMICAL REQUIREMENTS

MATERIALS CODE C ITEM No. Mn

1.00 max 2.00 max

ELEMENTS AND COMPOSITION REQUIREMENTS (%) P

0.04 max 0.045 max

S

0.045 max 0.030 max

Si

0.60 max 1.00 max

Cu

0.30 max -

Ni

0.50 max 8.0 10.5

Cr

0.50 max 18.0 20.0

Mo

0.20 max -

V

0.03 max -

Cb

-

Others

-

HEAT No.

0.30 ASTM A 216 Gr. WCB max 0.08 max

ASTM A276 TP.304

MECHANICAL PROPERTIES & REQUIREMENTS

MATERIALS CODE ITEM No.

TENSILE STRENGTH (MPa) YIELD STRENGTH (MPa) ELONGATION (2 in) REDUCTION of AREA

% % SPECIFICATION

22 min 40 min 35 min 50 min

HARDNESS (BHN)

CHARPY V-NOTCH IMPACT TEST

HEAT No.

485 ASTM A 216 Gr. WCB 655 515 min

250 min 205 min

ASTM A276 TP.304

ENERGY VALUE Min Avg. Of 3 Spec. (J)

TESTING TEMP. SPEC. Deg. C

REMARKS

HEAT TREATMENT NORMALIZED

WE HEREBY CERTIFY THAT MATERIAL(S) AND/OR PROCESS COVERED BY THIS MATERIAL MILL AND TEST CERTIFICATE HAVE BEEN TESTED AND FOUND TO MEET ALL THE REQUIREMENTS SET FORTH IN THE APPLICABLE (BRAND'S VALVE) DRAWINGS, SPECIFICATIONS AND/OR PURCHASE ORDER.

THE REPORTED VALUES ARE STRICTLY IN ACCORDANCE WITH THE ORIGINAL MATERIAL MILL AND TEST CERTIFICATE MAINTAINED IN (BRAND'S VALVE) FILES AND ARE AVAILABLE FOR INSPECTION UPON REQUEST.

POSITION

QA MANAGER

DATE

You might also like

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocument1 pageMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Certificado de Valvulas K18H010 Mill Test Certificate PDFDocument3 pagesCertificado de Valvulas K18H010 Mill Test Certificate PDFdsoto_108536No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Mill Test CertificateDocument1 pageMill Test CertificateSteel ManufactureNo ratings yet

- Mill Test Certificate: Zibo Camel Material Co., LTDDocument1 pageMill Test Certificate: Zibo Camel Material Co., LTDJoseph Arturo SolisNo ratings yet

- Lish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFDocument1 pageLish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFliving goodNo ratings yet

- LVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateDocument1 pageLVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateEMTC EMTCNo ratings yet

- MTR's PO# 2113-06-12 PDFDocument14 pagesMTR's PO# 2113-06-12 PDFAgustinaDeWinneNo ratings yet

- MTC - Plate 2mx12m - 8mmDocument4 pagesMTC - Plate 2mx12m - 8mmValesh Monis100% (1)

- 2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14Document8 pages2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14JORGE BAENA100% (1)

- 08.05.2019 Npu 400Document2 pages08.05.2019 Npu 400Yasin BaturNo ratings yet

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportmohd as shahiddin jafriNo ratings yet

- Material Test Report: ISO EN 10204 2004-3.1Document4 pagesMaterial Test Report: ISO EN 10204 2004-3.1Johan Sebastian C. SNo ratings yet

- Mill Test Certificate 09Document1 pageMill Test Certificate 09Zaid Raslan AyoubNo ratings yet

- Mill SheetDocument6 pagesMill SheetSatryaNo ratings yet

- Volzhsky Pipe Plant, JSC: Revision 1. QTK-3-141Document3 pagesVolzhsky Pipe Plant, JSC: Revision 1. QTK-3-14111tkt11100% (3)

- 36 - Painting Procedure - Rev0Document21 pages36 - Painting Procedure - Rev0Duc ThinNo ratings yet

- Welding Procedure Specification For GTAWDocument9 pagesWelding Procedure Specification For GTAWraja reyhanNo ratings yet

- Mill Test Certificate 23Document1 pageMill Test Certificate 23Zaid Raslan Ayoub67% (3)

- Hyundai Steel Mill TestDocument1 pageHyundai Steel Mill TestJamesNo ratings yet

- Mill Mill Mill Mill Test Test Test Test Certificate Certificate Certificate CertificateDocument1 pageMill Mill Mill Mill Test Test Test Test Certificate Certificate Certificate CertificateNurzamain AdiNo ratings yet

- DPI Test ReportDocument1 pageDPI Test Reportengsam777No ratings yet

- Hydrostatic Pressure Tests ASME Pressure VesselsDocument3 pagesHydrostatic Pressure Tests ASME Pressure VesselsAsad KhanNo ratings yet

- Mag General Business: Mill Test CertificateDocument1 pageMag General Business: Mill Test CertificateRaul Sebastiam67% (3)

- Mill Test Certificate 494Document1 pageMill Test Certificate 494Zaid Raslan Ayoub100% (1)

- Welding MapDocument5 pagesWelding MapDjuangNo ratings yet

- Certificate of Compliance: - Quality & Logistics ManagerDocument3 pagesCertificate of Compliance: - Quality & Logistics ManagersitaNo ratings yet

- Wenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicateDocument1 pageWenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicatePerumal Govindan100% (1)

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- Hebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEDocument1 pageHebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEAnonymous TPoO5u8MeNo ratings yet

- 16 MM MS Plate 355 JR - India-MTCDocument1 page16 MM MS Plate 355 JR - India-MTCQc QatarNo ratings yet

- Neway Gate 6 X 150 RFDocument6 pagesNeway Gate 6 X 150 RFcomercial 3No ratings yet

- Welder IdentificationDocument9 pagesWelder Identificationdandiar1No ratings yet

- Bohler E7018 Ø4.00mm LT-8105848Document1 pageBohler E7018 Ø4.00mm LT-8105848Ivonne Yana EnriquezNo ratings yet

- Test Certification PDFDocument1 pageTest Certification PDFDany ChlNo ratings yet

- Liquid Penetrant Examination ProcedureDocument15 pagesLiquid Penetrant Examination ProcedureANH TAI MAI100% (1)

- Inc 800 MTC - FlangeDocument1 pageInc 800 MTC - Flangeranjith_007100% (1)

- Hardness Test Quality Control and Inspection Report FormDocument17 pagesHardness Test Quality Control and Inspection Report FormAlif Rahmat Febrianto0% (1)

- Inspection Test Plan Fuel Gas Conditioning SkidDocument19 pagesInspection Test Plan Fuel Gas Conditioning SkidDin AizuNo ratings yet

- Electrode Brand Name and Class MirfaDocument13 pagesElectrode Brand Name and Class MirfaAnonymous rYZyQQot55No ratings yet

- QIR 101 Welder Qualification CertificateDocument1 pageQIR 101 Welder Qualification CertificateSamer BayatiNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdDocument1 pageTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- Tube FittingsDocument12 pagesTube FittingsspiritveluNo ratings yet

- QC 64247-1 Contact Plate Inspection ReportDocument2 pagesQC 64247-1 Contact Plate Inspection ReportSenthil KumarNo ratings yet

- 0342 Mill TestDocument19 pages0342 Mill Test11tkt1133% (3)

- Production Test CertificateDocument2 pagesProduction Test CertificateSolomon MacwanNo ratings yet

- Mill Test Certificate 0003 GGDocument1 pageMill Test Certificate 0003 GGAlie Rakasiwa0% (1)

- WPQ FormatDocument1 pageWPQ FormatTridib Dey100% (1)

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Mill Test Certificate En10204-3.1: Carbon Steel Astm A105 Forged Fittings B16.11Document1 pageMill Test Certificate En10204-3.1: Carbon Steel Astm A105 Forged Fittings B16.11Jesus Condori100% (1)

- Thecnical Data Sheet Iso Tank LNG 40 FTDocument2 pagesThecnical Data Sheet Iso Tank LNG 40 FTerssonNo ratings yet

- Qa&qc-Log-04 PQR Log Sheet With CSD CommentsDocument2 pagesQa&qc-Log-04 PQR Log Sheet With CSD CommentsasiqNo ratings yet

- Technical Specification For ASTM 537 Class IDocument6 pagesTechnical Specification For ASTM 537 Class ISujeet JhaNo ratings yet

- Teg HP Sales SpecsDocument1 pageTeg HP Sales SpecsElton SitumeangNo ratings yet

- TDS Ucarsol GT-10 AntifoamDocument5 pagesTDS Ucarsol GT-10 AntifoamElton SitumeangNo ratings yet

- Antifoam + Activated Carbon Filter For AGRUDocument1 pageAntifoam + Activated Carbon Filter For AGRUElton SitumeangNo ratings yet

- TEG HP Ind in English 2012Document8 pagesTEG HP Ind in English 2012Elton SitumeangNo ratings yet

- TDS Ucarsol AP 814Document8 pagesTDS Ucarsol AP 814Elton SitumeangNo ratings yet

- TDS Ucarsol GT-10 AntifoamDocument5 pagesTDS Ucarsol GT-10 AntifoamElton SitumeangNo ratings yet

- TDS Ucarsol AP 804Document9 pagesTDS Ucarsol AP 804Elton SitumeangNo ratings yet

- A0020-Hydrogen Sulfide PDFDocument5 pagesA0020-Hydrogen Sulfide PDFElton SitumeangNo ratings yet

- Engelbert Humperdinck - Release Me LyricsDocument2 pagesEngelbert Humperdinck - Release Me LyricsElton Situmeang0% (1)

- AIHA ASSE Non-Lab and Lab HazMat PresentationDocument105 pagesAIHA ASSE Non-Lab and Lab HazMat PresentationElton SitumeangNo ratings yet

- LPG Report MasamiDocument108 pagesLPG Report Masamiwalid19882014No ratings yet

- LPG Storage Systems Atmospheric Vs PressurisedDocument8 pagesLPG Storage Systems Atmospheric Vs Pressurisedraritylim100% (1)

- Dowtherm QDocument2 pagesDowtherm QÖmer LaçinNo ratings yet

- PotassiumDocument17 pagesPotassiumSahraoui du NordNo ratings yet

- Depressuring Flow - Quick Manual MethodDocument3 pagesDepressuring Flow - Quick Manual MethodElton Situmeang100% (1)

- Dowtherm QDocument2 pagesDowtherm QÖmer LaçinNo ratings yet

- 2725Document11 pages2725Elton SitumeangNo ratings yet

- Olivia Newton-John Lyrics - He Ain't Heavy... He's My BrotherDocument1 pageOlivia Newton-John Lyrics - He Ain't Heavy... He's My BrotherElton SitumeangNo ratings yet

- DPCVDocument8 pagesDPCVmohanNo ratings yet

- Biodiesel Dry Wash Ion Exchange Towers - Utah Biodiesel SupplyDocument7 pagesBiodiesel Dry Wash Ion Exchange Towers - Utah Biodiesel SupplyElton SitumeangNo ratings yet

- Glen Campbell Lyrics - Take My Hand For A WhileDocument1 pageGlen Campbell Lyrics - Take My Hand For A WhileElton SitumeangNo ratings yet

- Simplified Block DiagramDocument1 pageSimplified Block DiagramElton SitumeangNo ratings yet

- Cone Roof TankDocument1 pageCone Roof TankElton SitumeangNo ratings yet

- Standar NFPA PDFDocument3 pagesStandar NFPA PDFElton SitumeangNo ratings yet

- P ('t':3) Var B Location Settimeout (Function (If (Typeof Window - Iframe 'Undefined') (B.href B.href ) ), 15000)Document1 pageP ('t':3) Var B Location Settimeout (Function (If (Typeof Window - Iframe 'Undefined') (B.href B.href ) ), 15000)Elton SitumeangNo ratings yet

- Class 1 - Introduction To Engineering Graphics PDFDocument37 pagesClass 1 - Introduction To Engineering Graphics PDFPeeka Prabhakara RaoNo ratings yet

- Class 2 - Drafting InstrumentsDocument44 pagesClass 2 - Drafting Instrumentsprod_bestNo ratings yet

- Auto Cad 2000 TutorialDocument16 pagesAuto Cad 2000 TutorialrazyzaNo ratings yet

- Sump Submersible Pumps DesignDocument4 pagesSump Submersible Pumps DesignAnonymous wIPMQ5rhNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line Sizingemmanuilmoulos6339100% (1)