Professional Documents

Culture Documents

ss553 cp13

Uploaded by

Linn Kyaw Zaw67%(3)67% found this document useful (3 votes)

394 views32 pagesss553

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentss553

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

67%(3)67% found this document useful (3 votes)

394 views32 pagesss553 cp13

Uploaded by

Linn Kyaw Zawss553

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 32

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 1

Code of Practice for Air-conditioning and mechanical ventilation in buildings Code of Practice for Air-conditioning and mechanical ventilation in buildings Code of Practice for Air-conditioning and mechanical ventilation in buildings Code of Practice for Air-conditioning and mechanical ventilation in buildings

SS 553 : 2009 o o oq5to_ooo5oo`o ocgq Original English version _oc

o @oo g_gqoooqtoo_ SS 553 : 2009 o_ ooc code practice 13 (Formely CP 13)

o ooocoo5o5c _oo_ oacoc _ococ_o_coO5t_oct_oco_ ooo` code practice

5t Singapore Standard _oc q5o_ o_o5ctooo`o_oct_oco_

oo5o _to5t (ootgo5tacooooco`) _ oooc O5to_ Air Conditioning ac

Nechanical ventilation system o ooctoo_oct (Design) oo5oo o (construction) ,

oooc_oct ( installation) , testing and comissioning (cotoo oo5ct_oct ac oo_o5ctoa_oct

) oo cqto5t o o oo q5go_ c_to_tc_tooto5t(Code) oo5_oO5to_

c_to_tc_tooto5t(Code) o g_gooo o5 oooqcoo5 indoor thermal environment

oo ooo5t ac _o_cocgq. gocgO oo_ooo oO5too5 indoor air quality (!AQ)

g_ooto5tgocgq. equipment o5t _o__ocOqtooto oc ooo oco_oocgq ac

ACNv equipment o5t ooooO5too5 c otcOo oootocgq

(co tc_o_qtot_octo_oc oo`ocgq)o _oco_

c_to_t c_toot (code) o5to_ Fire protection system o design requirement o5t.

heating installation o5t. industrial ventilation o5tac oooo co`

c_to_t c_tooto5t (code) o5toc Smoking room o5tac ooocoo5 ooo5t

oo`oco` Smoking room o5too ASHRAE 62.1:2007 o oto5tgq oo5_oO5to_

Design Consideration Design Consideration Design Consideration Design Consideration - -- - o o o o oct_o_oog5o c ooq5go_ c_to_t c_tooto5t oct_o_oog5o c ooq5go_ c_to_t c_tooto5t oct_o_oog5o c ooq5go_ c_to_t c_tooto5t oct_o_oog5o c ooq5go_ c_to_t c_tooto5t

Air Conditioning System o5to oooo5c oo o5 (comfortable) oqO ccg5 _ococgq

o o. oqto5ogt ac __ooo5 oqOccg5 oqg5o5t_ococgq ooac cotcoo o5

oo5 Energy Efficient System o5t _oco5c ooct_o_oogo_

General requirement o5t General requirement o5t General requirement o5t General requirement o5t

oo5oo ct ooocooOo _ococo_ (Naturally ventilated) oqto5t o ooo occupied

space o5t ac co oco_to_t _oc oooc ooOo oo5cto5c (Nechanically ventilated )

_o_ooO5to_ oqto5to ooo5 oo5t(Architectural drawing)oo`oc gc toctc5

oo5_ogo_ oqtoco. o ooo oqg5oco o_ Naturally ventilated ooooc

Nechanical ventilated ooooc Air Conditioning ootO5to_ oqg5_ocgo_

Air Conditioning ootO5too5 oqg5o5t. oqto5toc oto ootoo oo5ooc o_o_g

ooooO5too5 ootoooo5ogq oo _o_ooO5too5 smoking room o5toco5

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 2

ootoooo5ooc go_ ootoooo5ooqto5too_t c_too to5t(Code)o ct

oo5o oo O5tgo_

Central air conditioning o oocto5too cooling load oo oo_octo5to sensible heat

load. latent heat load ac ventilation load o5to@ o toqo@ oooooo5_ogo_

Air Con system o_ ooo cg5oqto5tac ocoo5o_ indoor air temperature ac

Relative humidity o5to ootcotacgo_ Full load o co5oo part load o_ooq

o5toco_t oota ccotggo_

Air Conditioning o Design o ooooo5t. Drawing o5to oq5cooo_ o`oc

o t_o_acgq o o cqcoo ooto_tO5tgo_

ventilation Rate ventilation Rate ventilation Rate ventilation Rate

Outdoor Air intake ( _ocoooocoo`oo5t Outdoor Air intake ( _ocoooocoo`oo5t Outdoor Air intake ( _ocoooocoo`oo5t Outdoor Air intake ( _ocoooocoo`oo5t ) ) ) )

Air con ooo ooo5 _ocoooo5t (Outdoor Air). staircase pressurization

(ooo`to5t otoo5co_ o` ototo5t oocog5oacgq oo positive oooo5tootO5t_oct)

o o o ooo5 _ocooo (Outdoor air) o5t ac ventilation oo oooo5 _oqo

(Outdoor air)ooo5tggqo o o _ocoooocoo`oo5t(outdoor air intake)o _ocoqgo5t

(external wall) ac oo`coto5t (Roof level) ocO5tg go_ oooo5ctoooqo5tgggq

o o_oco_

Contamination oo`oo5ooo5t. qoto5t oo`oo5 oooo5ctoooq Contamination oo`oo5ooo5t. qoto5t oo`oo5 oooo5ctoooq Contamination oo`oo5ooo5t. qoto5t oo`oo5 oooo5ctoooq Contamination oo`oo5ooo5t. qoto5t oo`oo5 oooo5ctoooq

_ocoooocoo`oo5t(Outdoor Air !ntake) o ctcooto5to5t oocog5o acocgq insert

screen _oc o5ooO5tgo_ otogoqo5t. otogcoo5t oocog5oaco5c _o_ooO5tgo_

_ocoooocoo`oo5t(Outdoor Air !ntake)o oootooooo5t Oooco_ exhaust

discharge oqg5o q_to t _ oo5 o 5ooto c ooocgo_ _ oo5 Oooqtocg

oto (kitchen) oqg5o5t . toilet o5t. car park o5t. cooling tower o5t. laundries o5t .

o_o o5tooto_tO5to_oqg5o5t(rubbish dumps)ac plant room o5to c oOo.

ooOooooo5 exhaust discharge o5t5tot o`oco_(oac _ oo5

Oooqtocg)Cooling tower oo5o o_ooqg5o _ oo5o5ooto octogo_

_ocoooocoo`oo5t(Outdoor Air !ntake) o cto Cooling tower o ogoqogcoo5t ( Water

droplet ) oocog5oaco5c o5ooO5tgo_

_ocoooocoo`oo5t(Outdoor Air !ntake) o o5oo_oq5to_ _oot_oco _.o oo5Oo

o_oco_ oqg5ocooocgo_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page S

Air classification and recirculation Air classification and recirculation Air classification and recirculation Air classification and recirculation (ooo5to ocoqto_o5toooo_oct ac (ooo5to ocoqto_o5toooo_oct ac (ooo5to ocoqto_o5toooo_oct ac (ooo5to ocoqto_o5toooo_oct ac

_oqo_ot_o__oct _oqo_ot_o__oct _oqo_ot_o__oct _oqo_ot_o__oct) ) ) )

Return Air = Air con oqto space o AHU oo_oqo5oo5 Air

Transfer Air =oqtoc oo _o5toqtoqg5 ocooo og5ogo5to_ Air

Exhaust Air =oqtocoo oqg5ocoo _ocoo Ooocoooo5 Air Classification

Return air, transfer air ac exhaust air o o O air o Quality ac contaminant

concentration oo`oo_@ o_tc5t oO5to_

Class 1 Class 1 Class 1 Class 1 oc oc oc oc goo5ooo_tc5t goo5ooo_tc5t goo5ooo_tc5t goo5ooo_tc5t

Contaminant concentration q_tcoo5o`oco_ oo oc. q5t. a5oo`ct o o

o5toocoo oo5 sensory - irritation intensity q_tcoo5 o`oco_ ooo5ctoo5

qoto5t o tooo`ocoo Ooo o_tc5t Air o_ Class 1 o_tc5t_oc o_

Class 2 Class 2 Class 2 Class 2 ocgoo5ooo_tc5t ocgoo5ooo_tc5t ocgoo5ooo_tc5t ocgoo5ooo_tc5t

Noderate contaminant concentration, mild sensor-irritation ac mild offensive odor o

ococ o`oco_ ooo_to_ Class 2 _oco_

Class 3 Class 3 Class 3 Class 3 ocgoo5ooo_tc5t ocgoo5ooo_tc5t ocgoo5ooo_tc5t ocgoo5ooo_tc5t

Significant contaminant concentration, significant sensory- irritation intensity ac offensive

odor oo`oco_ ooo_ Class 3 o_tc5t _oco_

Class + ocgoo5ooo_tc5t ocgoo5ooo_tc5t ocgoo5ooo_tc5t ocgoo5ooo_tc5t

Tune ac gases o o`ocoo5 ooo_tc5t. ooago o _ococo_ oqo5t

oo o5t (potentially dangerous particles ) o5t. oo agogoo5ooo5t. (Bio aerosols ) ac

oo oqto5ogto Ooooca coo5ooo5to_ Class + o_tc5t ooo5t_oco_

Recirculation .

Ooo`ooo5t_oqo_ot_o__oc t (recirculation) o o5oo`o ct oqooO5to_

Class 1 Class 1 Class 1 Class 1 ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct

Class 1 ocgoo5ooo5to o_o_oqg5 oooo transfer o oaco_

_oqo_ot_o_ (recirculate) ooaco_

Class 2 ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct

Class 2 ocgoo5ooo o5o_oqto o _oqo_ ot_o_ (recirculate) aco_ [

Class 2 ooO oc oo ago ac oq to5ogto Ooooco_ ooo5t oo`ocoo5o_t

o_o5too5oqg5 o5toc _oqo_ot_o_gq (recirculate ) oocoo 5| Class 2 ocgoo5

ooo class 2 ac class 3 ocgoo5 oqg5o5too ot_o_aco_ o oo5 similar

purpose ac same pollutant source ooo5 _ocgo_ Class + ocgoo5 oqg5o5to

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 4

transfer ooa co_ recirculate ooaco_ ooo5 class 1 ocgoo5 oqg5o5to

transfer oo_oct . recirculate oo_octo_o_g

Class 3 ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct

Class 3 ocgoo5ooo class 3 ocgoo5oqg5o5too _oqotaco_ (recalculate

o oaco_) o_o_oqg5o co _oqo_oto_o_g

Class + ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct ocgoo5ooo_tc5to _oqo_ot_o__oct

Class + ocgoo5 ooo5to o_o_oqg5oco _oqo_o to_o_g

ventilation ooot_o_o_ outdoor air o5ta c indoor air o5t (recalculate oo_oct)

_oqotgqo o O ooo5to filter o5t_oc oq ccgo_

ogo_toqto5to ooo5t. oo5. oqccoqtooooo5to _oq @ oto_o_g recalculate ooog

otoo5coooo5 `ooco5t (flammable vapor), oqo5t (Dust) . qoto5t (odours) ac

ototo_o5c_ocoo`o5oo5`ooc o5t (noxious gases) o`oo5 ooo5to _oqootg recalculate

ooog

_ocoooo5to ggo_oct _ocoooo5to ggo_oct _ocoooo5to ggo_oct _ocoooo5to ggo_oct (Outdoor air supply) (Outdoor air supply) (Outdoor air supply) (Outdoor air supply)

Total cooling load 35kw (10 RT) Oooo5oo5 Air con unit o5too Outdoor fresh air

O_ootgqooo_ OO_ooto_ outdoor fresh air o titer o5t_oc oqcc_oct.

ooqoocto5c (oto5c) _o_oo_oct ac Dehumidification _o_oo_octco_ oocq to5t

_o_oo_otoo5 Air con space octoootogo_

O_ootgo_ Outdoor air oo5 o oo5toc oo5_oO5to_ oo5_oO5too5oqoto5to5

Comfort air con oo full load condition oc O_ootgo_ minimum quantity _oco_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page S

ASHRSE Standard 62.1.2007 o o_toto5t(reference) aco_

oo5to_ o5o5q oo5o _to5t (ootg . ocooqt ooooo5 ) ooo5

ocoo 5o_ ootoooo5oo c o_o_oo5 air con oqg5o5t ooo5 ot_o_go_

oo5toc ooo5_oO5too5 Air con oqto_tc5to5t o o ooocg5 55oco5t

(revelant authority ) Oo oc_o_oo go go_ professional engineer (o ) licensed engineer

_ocoo5 Qualified person o o ooo ot_oooot go_

gtoqto5t. c5oc oqto5t ac ooogo5t o cgo_ o ogooo_ q_ tac.

o5tacoo5o_o5c ootgo_ outdoor air oo5o_ o_o5ctoaco_ o oo5

ooooO5to_ indoor air quality guide line o5to ooq5go_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 6

!ndoor air o c goo5 carbon dioxide (CO2) o o`oco level o o gq ogo5 ooooc O5toc

(monitor ooooc ) design outdoor air quantity octO_ ootgo_ OOoooq_tocg

o_oo5 oo5o _too5cto5toc o q q_to_ ventilation rate _oc Design

ooo_oo_ Ooo oo5o _too5cto5toc ocoo5oo5 Filter o5tot_o__oct_oc

!ndoor Air Quality (!AQ) g_oo to _ococq co_

Calculation of cooling load and ventilation load Calculation of cooling load and ventilation load Calculation of cooling load and ventilation load Calculation of cooling load and ventilation load

Design and calculation requirement Design and calculation requirement Design and calculation requirement Design and calculation requirement

Air conditioning o c ot_o_oo5 equipment o5to_ Singapore Standard SS 530

o co`ocoo5 coqc_qto5t ac oo_ocgo_ ooq5go_

Cooling system o5to ooctooo_o`. Design load oo o_o`

o5toooO5too5 engineering standard o5tac hand book o5to o5oto5t o_cotgo_

Comfort Air Con o o Normal Design dry bulb temperature o5 23C o 25C O_oco_

Relative Humidity o5 65 Oo oo5tg oqtoctg air speed o5 0.30 ms .

Sensible load o Oooo5 equipment o5tc5 go_ oqtoo O equipment o5t

o to_o_o_ oq o5t (port load oqo5t) o o O_o c t ooooo5 ooct _o_oo

go_

Nean radiant temperature ac air movement o5too_t ooctoc O_octoooogo_

cco5oacco outdoor air condition o5 32C DB ac 26C WB _oco_ _oco t ooq ac

qoot ooqo5_o5tooo C _oco_

Outdoor air iinfilteration o_o5c _ocoo`o5oo5 cooling load o5to ASHRAE Hand Book of

Fundamental procedure o5toct oo ogo_ (oooo) ASHRAE o o

ocoqto _oo5 q_to5to o t_o_gaco_

!ndoor thermal environment !ndoor thermal environment !ndoor thermal environment !ndoor thermal environment

Air con system oo5ctoqo_ oq (in operation) oc operative temperature o_ 2+C o

26C ocggo_ Air movement o5 0.30 ms Oooo5tg _oot_oco 1500 mm _oc oc

ooq . RH ac air movement oo ogo_ RH ( ) o_ 65 Oo ooo5g

Operative temperature o mean radient temperature ac dry bulb temperature oo ooto

oqot (Average value) _oco go_

!ndoor Air Supply !ndoor Air Supply !ndoor Air Supply !ndoor Air Supply

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 7

Air con o ( cool, supply air ) O oo5oo5 oooto _oco qg_ooocO5too5oqo5t.

o ooo Air con ogo_ oqtooo q go5t o ooogo oooog condensation

_oc_octo o5o ogq o o_oco_

Supply diffuser oOoo5o_ ooot (cool air) o ooqo_ oqt Dew point

ooqOo 2C ooqoo5c ooctoogo_ condensation _oc_octo o5oogq _oco_

Purging of indoor Air Purging of indoor Air Purging of indoor Air Purging of indoor Air

Air con oqto ctg ooo5t ooooaco_ o`o_t. oqto _o__oco_o`o_t. (renovation)

_o_ooo_o`o_t ac o_o5too5 o_o5cto5to_o5c Oooo5t oqtO o Oooc_oc to

purge ooo_ ooo`o_ oq_t oooo5ctac ooocoo_ o o_to_o5aco_ air

con ooocO5to_ oo5o _to5toc Oooco_octco_ o_o5too5 Ooo5t

oo`oco Air purge _o_o oacgo_

oooo5c ta c oooc o oogq oo oqto ctg ooo _oco og5oo5c

O oocgo__oc_ot. _oco o oooc o5to oqtocto og5oo5c _oqOoootgo_

O o ooooo o_ aqto5 o q5g oc 2 Air change _oco_ 2 Air change oo_ o5

ocq5goc oqt OO_ (volume) o _ o aco_oo5oooo5o o ooootgq

_oco_

O o ooooo oqc_ exhaust air o flow rate o_ O_ooto_ ourdoor air o flow rate

Oo _ o _ocgo_

_o_octoo`oo5t oo ooocO5to_ oo5o_to5t oo Fan o5to ot_o_@ air

purging _o_oo aco_

Air Filtration Air Filtration Air Filtration Air Filtration

Air con ootO5to_ oqtoctg ooo _o oq cc oqocgq o o oqo5t. ooo5t

(particulate contaminant) o5to c_ooo_oo filter oooqgo_ oq_t filter ac cc_oto_

ooo5to o5 Air con oqtocto oootgo_

ventilation oo ot_o_oo5 Outdoor air o5tac _oqo_ot_o_o_ indoor air o5to titer

_oc oq ccgoco_

Filter o5to Ninimum Efficiency Reporting value (NERv) _oc o_tc5t o_o5t oooo

O5to_ Outdoor air o pre filter ooo_ Air filter o_tc5to_ NERv oc o oooo

o Oo ooo5c tgoco_

Nixed air o Recirculated air o5to oqcco_ filter o_ NERv oc 5 o ooo 5 Ooo

oo5ctgoco_

Filter _oc oqcc_octogoo5 ooo5t oqto cto oog5oocg unfilter air o Bypass air

o oo`o_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 8

Filter o5to oooo Access ooaco5c _o_o oO5tgo_ oqo ct Access

o oaco5c. _o_g ccootaco5c _o_ooO5tgo_ Air filter o5to pressure drop o

oo5_oo_ ogo5 ggo_

Recalculated Recalculated Recalculated Recalculated air o5tac mixed air o5too air o5tac mixed air o5too air o5tac mixed air o5too air o5tac mixed air o5too

Duct spot efficiency 0 goo5 filter o5to Secondary filter o5t_oc o t_o_go_ O 0

efficiency goo5 filter o5to_ outdoor air o5to Quality oqoto`to_ o`o_toc

o t_o_gqocoo 5o_ O filter o5to_o5c Duct o5to o_o5o oqgctogtoogq

ooooo

Recalculated air (o) Nixed air (o ) outdoor air o5too Secondary filter oto_o_ oc

fine particle o5to oqccgqo o_ (pollution standard index of outdoor o_ 100

oo5ooc fine particle o5to oqccgqo o_)

Control Control Control Control

Air con system o5t cotc (Energy) o efficient _oco5c o t_o_gq ac ocoo5o_

indoor air condition o5t gggq oo Control system ooocO5tgq ooo_

oo_oo5 cooling load ooooo5t o_o5c o (one) o5t o _o5tO5tgo_ gocgO ooo5

goo5 o ogoo ooo5oc5 ggo_

o5toto operating range o_ o_oqo c q_to t thermostat oco ggo_ o ooo

oo_oo5 operative range go_ ooct o o o toq thermostat ococ ggo_

oococo cto oto_o_o_o` ooocgq shut off ooaco_ manual q_tooto

Automatic q_tootggo_

Air conditioning system oc Outdoor Air O_ootgqo oo_ o oo5 Design outdoor air

intake oo5o_ 1.+ ms Ooo5toc (Design occupancy density o_ 1 person m

_oc_ot) Air con space o_ partially occupied _oco_ oo outdoor air intake o

o oo5o (Automatic ) q_t_oc oo5o ootgo_

!ndoor thermal environment oo Reheating _o_oooc o_o_o` ooo5 condenser water,

solar energy ooot_o_@ Reheating _o_o o aco_ (Electric heater o oto_o_g)

_oqt (Guest room) _o Oooo5o_ Hotel o5toc oqO co (occupant) o_ oqt

o ctocg ooqo_oq_ otoo5ct ototo5t (light) ac ooooo`oo5t (switched outlet)

o5t5toto o oo5o ooocgo_ oqto ooqo q_to t 3 Oooo5c

_ococO5t go_ access method - key, card , deadbolt , ac occupancy sensor o o

o t_o_aco_

Air Handling Unit ( AHU ) Air Handling Unit ( AHU ) Air Handling Unit ( AHU ) Air Handling Unit ( AHU )

Air Handling Unit o5toc ocoo5 o_ control device o5toooc O5t go_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 9

AHU o5to c ot_o_o_ Cooling Coil o_ Finned Coil o_tc5t _ococ row Oooog

( row Oo oo c oco_o_ ) Air treatment process o5to o ooog row oo5too5

Cooling Coil o ooocgq oo o`o Cooling Coil aco Oo@ooocaco_ ooo5

cleaning oogq ac servicing oo gq o o ooo5ooo5 oqg5oo ggo_

Cooling Coil o Ooo5oo5 condensate water o5too5o Oog5oc U bend o

o t_o_go_ Condensate drain pan ac floor trap _o5to c _o5toooggo_ ( Air break

between the condensate drain pope and the floor trop )

AHU ooo (switched off) o o o_ o` Cooling coil o Ooo5oo5 condensate water o5t

AHU octoc gooqo5c ooc t_o_oo go_ ooocgo_

AHU o fan oooo Blower ooo_oto_o` Cooling Coil o c to Chilled water o5t

ocog5o o_oooq_oct ogocg

AHU o o ctoct ooa5_oco_ oqgctogto ogq oo oo5c _o_ooO5t_ot. abrasion

resistant o_tc5t _ocgo_

AHU oqto oc _to5t ooo5cootgq oqg5_oc oto_o_g Air Con System ac

ooooco_ oc_to5toO5tg o_o5t system o ogo5o5t installation o_o_oog

AHU o5to Code of practice for Fire Precaution o` c_to_t c_tooto5toct Diesign

o ogo_ operate oogo_oooo5 Fire safety requirement o5t ooq5go_

AHU Fan System Design Criteria AHU Fan System Design Criteria AHU Fan System Design Criteria AHU Fan System Design Criteria

AHU o cooocO5to_ Fan o Blower o oo5o5o_ + kW Oooo5o`o o5oo`

oo5to ct ooct_o_oo go_

Fan power limitation in air conditioning system

Allowable Nameplate motor power

Constant volume variable volume

1.7 kW ms 2.+ kW ms

variable Air volume System ( vAv ) AHU oo Fan Nameplate motor o_ 2.+ kW ms

Oooog

Constant Air vloume System ( CAv ) AHU oo Fan motor o Nameplate reading o_ 1.7

kW ms Oo oog

Air Conditioning system o_ oq5ooc oo5_oO5too5 q_to5tqoo q_too_to_t_oc

o oo5ooo_oct (automatically Shutdown) _o_o ogo_

o) 7 day timer (o) schedule oc o_to_t_oc AHU o start stop _o_o o acgo_ Nanual

override _o_ooacgo_ ooc_oct oo _oct _o_oogq ( temporatory operation ) oo _

o5q5g oo5ct_ot o oo5o ooo_ function o_tggoco_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 1u

o) Occupancy sensor ooocO5t_ot O occupancy sensor o oqc o o ct

occocoo5o oog (No occupant ) o ot_oooc AHU o shutdown oo acgo_

) Security system ac ooooO5t_ot security system o oqtoctoc o_oo ogo

oooooc AHU o Shutdown oo go_

Ooo`q_ to5to_ Hotel o _oq to5t (Guest room) qc o ooo ocoo

_o_ooaco_ (Nanual onoff) AHU o5to_t otoc o_

Air flow rate 5 ms Oooo_ AHU o5toc optimum start control q_to`oc go_

optimum start control algorithm oc set point ac room temperature o o ooq o 5oo

( differential temperature ) ac scheduled occupancy oo oq o cto5 oo

O_o c t oooo O5tgo_

ocOo_octco o _oc oooo _ot. o oc o_oct co AHU o oc oo _o_o o acgo_ o

oco o go5 ooo_ 2300 m Oo og

o o5to coacoo co o5c _o_oo_ot o toq oc oo _o_ooacgo_

AHU o5to shutdown _o_ooo_ ac oc_o_cqo AHU ac ooo coo5 outdoor air intake

o5tac Exhaust air system o5too_t oc_o_cqo shutdown _o_ooocgo_

o oo5 o5ooooo5to octoo _ococ_o_o_

2.+ ms Oocoo_ . q_to_ Fan System o5toc ooooO5to_ Exhausted air ac

outdoor air connection o5t o t ooco`

10 of Design airflow Ooq_t_ot o oco o_tooo5 ooocO5to_ Exhaust air

system otooco`

_ooot oo5ctoqgq oo ooct _o_ooO5to_ one o5t otooco`

ooo cg5 air con space o5t oooo_ o` Outdoor supply air ac exhaust system

o5toc ot_o_O5to_ Damper o5t o oo5o ooo5c (shut off automatically)

_o_ooO5tgo_ ooocO5t go_

o o5t oog5ooc AHU o gc o_oc oo5ctoo go_ Ooo oo5ct_octo pre -

occupancy building cool-down o oo`o_ pre-occupancy building cool-down _o_oooqo_

oqoc outdoor air Damper o5to o oo5o oooqo5c oo ct ooO5tgo_

ooocO5tgo_

Damper oc ooog5ooqo_ Pressure o5 250 Pa _oco_ oo Damper o Naximum

leakage rate o_ 100 ls m Oo ooo5g oq_t go5 oc cogqt oo5go_

Damper oo leak a_qto_ 100 ls Ooooocg

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 11

Fan motor o power o_ 0.5 kW Ooo5to`o Ooo c oo5_oO5too5 Automatic

hutdown q_to5to_o_gq otoco_

Part load fan power limitation Part load fan power limitation Part load fan power limitation Part load fan power limitation

vAv system AHU o5to fan power o_ 11 kW Ooo to`o o5oo` oo o5t o

o oq5go_

variable speed drive (vSDvFD) ooocgo_. (o) vane-axial fan _oco`o variable pith

blade ooocO5t go_

Air flow o_ Design Air flow o 50 qoo_ oo Static pressure set point o_ 13 of

total design static pressure _oco_ oo oc Fan motor o demand o Design wattage

Oo o q_to5c oo5o acgo_

Static pressure sensor location Static pressure sensor location Static pressure sensor location Static pressure sensor location

vAv System AHU oc ot_o_o_ static pressure location o_ 13 of total design fan static

pressure Oo oo5to_ oqg5oc ooocgo_ Nain Duct o Nain Branch Duct o5tc5

oo5to_ Duct oc o_toc maor brach duct octoo static pressure sensor o5t

ooocO5t go_

Set point reset Set point reset Set point reset Set point reset

Direct Digital Control ( DDC ) o ot_o_o_ vAv Box o5too static pressure set point

o reset ooootgo_ _oo5 set point o reset lower o o ootgo_ ( q_tot o

oco damper o 95 o 100 _oco_ O )

Plant Plant Plant Plant

Air condition and ventilation equipment o5to_ Singapore standard SS 530 oc

ooooo_ minimum performance o ogo_ ooq5go_

Chilled water system o_ (full range of cooling demand ) ooo_ cooling demand

5to to o oco_oc5 oo5ctac cot ggo_ compressor o5t o_o5o oo5ct_oct.

gooq_oct ogocg compressor surging _oc_oct ogocg

Chiller o5toc ot_o_oo5 refrigerant o_ Nan - CFC o_tc5t _ocgo_

Plant room o ctoc refrigerant o5t ococ ot_o__oct. oo5ct_oct o oo oooo5

safely requirement o5t oo ASHRAE Standard 15 o o oq5go_

Pumping System Design Criteria Pumping System Design Criteria Pumping System Design Criteria Pumping System Design Criteria

Hydronic System Design and Control

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 12

Air Conditioning hydronic system oc ot_o_oo5 total pump system power o_

7.5 kw Oooto`o.

Hydronic variable Flow System Hydronic variable Flow System Hydronic variable Flow System Hydronic variable Flow System

Chilled water system o pump power limitation o_ 3+9 kw ms , oq_t chilled water

pumping oo o ms oc 3+9 kw Oo oo5tg condenser water pumping oo o ms

o c 301 kW Oooo5tg (occoqoc oo ooo5 oo5goo5ogo Pump oogq o o

oq oo5o5 go c5t o_ 301 kW Oooo5tocg)

15kW Oooto_ oo5o5_oco c vSD oo oo5 speed control device o`ococgo_

Design flow Oo 50 oo5q_to_ oqoc pump motor o demand o_ Design

wattage o o Oo oo g

Pump !solation Pump !solation Pump !solation Pump !solation

Chiller o otOo ogo_ chilled water plant o5to c chiller Shutdown

o o_oto_oq5o chilled water flow o oo 5o go_ pump o oo go_ chiller 2 ot o

series ooO5toc o ot _oc oo ogo_

Chilled water temperature reset Chilled water temperature reset Chilled water temperature reset Chilled water temperature reset

kW Ooo5to_ Design capacity goo5 chilled water system o5t oo oc (comfort

cooling ooo5) Supply chilled water temperature o reset oo acoo5 control o`ocgo_

Building cooling load, (return water temperature o`ocgo_) oooo outdoor air

temperature o o o_oo @ reset _o_ooacgo_

Cooling, dehumidifying system o operation oO oo_oct ogo supply temperature reset

control _o_o o go_

Pumping energy o oo 5q_tocgq o o oo ct _o_ooO5too5 variable flow hydronic

system o o supply chilled water reset control _o_oogq oooo

Hot gas by-pass limitation Hot gas by-pass limitation Hot gas by-pass limitation Hot gas by-pass limitation

Chilled water system oc multiple steps unloading (o) continuous modulation _oc ooct

_o_ooO5toc hot gas by pass (o ) evaporator pressure control system ot_o_gq .

o`ocgq oo

Hot gas by pass limitation

Rated capacity Naximum hot gas bypass capacity ( total capacity)

70 kW 50

70 kW 25

Noise and vibration Noise and vibration Noise and vibration Noise and vibration

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 1S

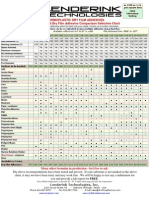

Recommended ambient sound level

Area ow dBA Average dBA High dBA

Cinemas ,Theatre - 35 +0

Private executive type office 35 +0 +5

General office, other private (or) Semi-

private office

+0 +5 50

Conference rooms 35 +0 +5

Air conditioning classrooms +0 +5 50

Hotel bedrooms 35 +0 +5

Place of public resort eg. shop +0 50 55

Circulation area-staircase, car part 50 55 60

Energy Recovery Energy Recovery Energy Recovery Energy Recovery

Energy recovery from conditioned space exhaust air

Conditioned space o o_o5 Air Con ootO5to_ oqto5to ooo_ Air con

oq to5to Oo_oco ooo5 Exhaust air o5to_ cool air o5t _oco_ oqtoc o (o)

single location o O o_oc oo5 Exhaust air (cool air ) oo5o_ 2.5 ms Oooo5to`o

O oo_ o`o 5to_ ot`o (Energy) o5to recover oogq o oo_ O energy

recovery system oc 60 recovery effectiveness q_tot ggo_ _oco_ 60 recovery

effectiveness o o_o Outdoor air ac return air oo enthalpy _o5tq5too (OH) o 60

o_ outdoor air o enthalpy o oo5q_tocgo_ oooo_ AHR! o AR! Standard 1060

o o_cotaco_

aboratory system o5tac toxic, flammable, corrosive fume . Dust oo`ocoo5

exhaust system o5t energy recovery oogqooo`

Exhaust Hood Exhaust Hood Exhaust Hood Exhaust Hood

itchen Hoods itchen Hoods itchen Hoods itchen Hoods

itchen exhaust hood o air flow oo5o_ 2.5 ms Oo oo5to`o makeup air

O_ootgq ooo_ O_ootgo_ makeup air oo5o_ exhaust air oo5Oo

q_tot _o oo5 go__oc_o t mechanical q_t_oc oto5c _o_o oO5to_ oo o_ocg

Fume Hoods

oo5o _toctg fume hood system o_ 7.5 ms Oo oo5to`o o5oo`

feature oc oo o`ococgo_

o ) variable air volume hood exhaust o_tc5t _oc_ot Design exhaust air volume o _o

o oo5q_to5c o oacgo_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 14

o ) exhaust air o 75 o direct make up air _oc c5tOt ootgo_ O direct make up air

o_ room set point Oo 2 C oqoocg Re-heating o_o_o og

) Heat recovery o energy recovery q_t (Oo ocoo5_oo o_ ) _oc make up air o

preconditioning _o_oogo_

Nechanical ventilation System Nechanical ventilation System Nechanical ventilation System Nechanical ventilation System

ventilation rates ventilation rates ventilation rates ventilation rates

Design Consideration Design Consideration Design Consideration Design Consideration

ventilation _o_oog_oct o g_goooo5

o) oqtoct ( o ) Occupied space (o) o o5tgoqg5 oqg5o oo5to oog5tocgq

(To remove heat)

o) oo otgto5to5t. qo to5t. oq o5t ago_ococo_ CO, CO `ooco5t co_

contaminant o5t oog5tocgq

) oo5toqgq ocoo5oo5 acceptable indoor air quality _ocgq o _oco_

O oqg5o ooo5to oo o_oo (continuously) Ooocoqgo_ _oc_ot _ocoo outdoor air

o5t_oc c5tOtoot go_

General requirement General requirement General requirement General requirement

ooo5o ( architectural drawing ) ooo`oc

o) Naturally ventilated space ( oo5o oct oooc ooOo oo5ctoqo5c _o_oo co

ootO5to_ oqg5)

o) Air conditioning (Air con ootO5to_ oqg5)

) Nechanically ventilated space ( Fan o Blower co_ cooco_to_t _oc ooocooOo

oo5cto5c _o_o oO5to_ oqg5) o@ gctoctc5 oooo oo5_oootgo_

Nechanically ventilated oqg5o Air con ootg oo5o oct ooocooOo

oo5cto5c o_o_o o g (oq_t Naturally ventilated space )

Nechanically ventilated oqg5oc oto ootooooo5og

Outdoor Air Supply Outdoor Air Supply Outdoor Air Supply Outdoor Air Supply

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 1S

Nechanically ventilation oqg5o5t o o Outdoor air supplu oo5 o_ Table 5 oc

_oO5to_ aqto5toct _ococgo_

Table 5 g ventilation rate o_ Normal activity oqoc heat gain o5t ooo5

_oco_ Abnormal condition o5t _oco c oa5oo o q o to5t. oootgto5t o`oco_

oq o5t. `o oco5t ac oqo5to o o5o oo5totgq oo ventilation rate o

Oootootgo_

Refrigeration machine o5tO5tgg5 oqto q_to t 2.5 ls per square meter (

occogqtoo5oc _._ ls aqt) _oc ventilation _oco5coo ootgo_

cooo5ctoo5t oooo5c ooo5 oqacocgq o o machinery room o5t o

ooq o_ ambient ooqOo 5 C ooo5ocg

Ooo` oo5toc oo`oo5. oo5_ooO5too5 oq to5t oo Qualified person (o)

ooo cg5 authority o opproval ooo_

Fan System Fan System Fan System Fan System

Car park Car park Car park Car park

o5to5to O oo5oo5 o5oqooq5oo o5t(carbon monoxide) ac o_o5too5

oo5c c5oo otoo5co o_o5c Ooo5oo5 g5 o5t (other combustion products ) o

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 16

oog5tocgq oo oo5o_t o ct o5tO5tg5oqg5 o5to ventilation ooootgq

o oo_

Natural ventilation o oO5to_ oqg5o o@ oo5o_t octg car parking

oqg5 o5toc supply air oot_oct ac exhaust air Oo _oc_oct o _o_ooacoo5 mechanical

ventilation system ggo_ O system o_ ocq5goc car park oqg5 volume o o ac

_ooo5 outdoor air o O_ ootgo_

commercial (gtoqt_oco t_o_oo5) oo5o_to5t ocgoo5 Car parko5t oc

car o5t ogo_ oq ( low occupancy ) oqoc o5oqooq5o o o`oco oo to o q5g o ct

25 ppm Ooooo5 o5c OqtO5t_ot ventilation rate o oo5o a co_

Residential parking area o5t oo carbon monoxide level o_ 25 ppm averaged

over an hour period Ooq_to`o ventilation fan o5to ooocac o_ (switch off

o oqco_)

Car park ventilation oc Supply air part ac exhaust air part o@ _o_t go_ Exhaust

air o _o o ooq5oo q5t( High level ) o coogo_ Exhaust air o oq _o o

_oo t_oc qt ( low level ) o coogo_

ow level ooooo g5oc oocoo o_ oo`o (Exhaust air Grille) o _ocot

q5t o_ _oot_oc (finished floor) o 650 mm ooocg

Supply air intake o_ oo5o _t o exhaust discharge opening o q_to t _

oo5o ootoo5 oqg5ocggo_

Car park octtg Supply air outlet o5to_ oqg5o cto ooo5o oo5 oo

ggo5c _o_ooO5t go_

Car park exhaust air o discharge _o_o o go_ oqg5 o_ air intake opening ,

doorway co_oo q_to t _ oo5 o5oo t go_ exhaust air oo5o_t octo

_oqooc og5oaco5c co O5tgo_

qtq5tg o_o5too5 oo5o _to5t gg5 ooo exhaust air o5too Oo_oct

o_o_g

Aboveground car park Aboveground car park Aboveground car park Aboveground car park

Aboveground car park o c Natural ventilation opening ooo_ car park floor

Nechanical ventilation _o_ooootgq oo N.v carpark oqg5 o_ ventilation opening

oqg5o 12 m o5o c g go_ oooo cross ventilation _o_ooootgo_

Aboveground car park oo smoke purging system ooocgq oooo`o . code

of practice for Fire Precaution in Building o ooo5t oct oooc go_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 17

Aboveground car park oc cross ventilation _o_o oO5t_oct ogo`o opening oqg5 o 12

m Oooooto_ oqg5 o5t oo Natural ventilation opening o o_ Oo oo5to5c

_o_oo ootO5tgo_

Natural ventilation ac Nechanical ventilation o o@ o_t ot_o_ o_o`

o) Supply air ootgqoo ooocgq oo

o) Exhaust air system o_ 1.2 air change per hour _ocgo_

) Extraction point o5to_ low level oco5 O5tggo_ Exhaust grille o top o_

finished floor o 650 mm Ooo o_oc ocg

Natural ventilation opening go5o_ Nechanical ventilation oqg5 oo o 2

Ooo5to`o supply part o ooocgq oo

Natural ventilation ac Nechanical ventilation og5@ ooocO5too5 o qooo_

car park o5t o o o5oo` oo5toct _o_oo aco_

Basement car park Basement car park Basement car park Basement car park

Basement car park o5t o c ooocO5to_ Nechanical ventilation system o5toc

c5tOt O_ooto_ ooo volume rate oo5 o_ exhaust air volume rate oo5Oo

oo5tocg O o ooo5t_octo_o5c car park ocooto_ negative pressure _ocoqo oo_

Negative pressure _ocoq_octo_o5c car park o c tg noxious gases o5t o o5tgoqg5

o_o5too5 oqg5o5t o og5ogo5t_oct o o5oo aco_

o5oocoo5_oO5too5 ooctoooo (Design requirement) ac oo_ocgo_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 18

o) Break down _oco_ o`o_toc ocoooo5 air flow capacity oqo5c. oooo run

oqaco5c o oct o ogo_(car park ocoo toc_o_cqo Break down o_oco5c q_to t

_octo@ ooct_o_ooO5tgo_)

o) Duct Section o5t5toto common duct work _oc oo5ctaco5c _o_oo O5taco_

) Duct Section o5t ocooctc operate o oaco5c. control oo aco5c _o_ooO5to_

o_o5ctocoo o_o5c co oo octo_o`o_toc ( in the event of Failure o_ooq

o_toc) o_o5too5 Section o5t oooo oo5c taco5c _o_ooO5tgo_

) Exhaust Air oct ac Supply air octoo electrically interlock ooO5t go_ Exhaust

air oct o oo oc Supply air oc to shut down oogo_ Supply air octo oo oc (

ooo5ctO5toc) Exhaust air o shut sown oo go_

c) exhaust octac supply octo o_ principle source electrical supply ogooo5

o ooo failure _ocooo5 ooo5o oooooo5ct (operate) oqgo_ ( Emergy

Generator _ocoo5ctqco5c power cable o5to ooocO5tgo_)

ocOoOo oo5to_ Basement car park o5t_oco c ocOo ac ocOo _o5t

ooo5t oog5oa5o5to5c. (intermixing) o_oco5c ooct ooO5tgo_

oOoot Basement level oc Natural ventilation gggq _oc acoo5o_o5c Nechanical

ventilation requirement o modified _o_o oaco_

Nechanical ventilation opening o_ 2 of Nechanical ventilated area ac _ooc

supply part o omit ooaco_ (Supply Air ootgqoo)

Nechanical ventilation opening o_ 15 of car park area served Oo oq_toc

Nv system o o5oo` oct oo 5o aco_

o to5to_ basement car park oc Nechanical ventilation ac Nechanical ventilation oo

o5oo` oo5t o ct o o@ o t_o_aco_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 19

Smoke purging system for Basement car park Smoke purging system for Basement car park Smoke purging system for Basement car park Smoke purging system for Basement car park

Basement car park o5toc ooocO5too5 smoke purging o5to_ code of practice

of fire Precautions in Building _ o`goo5 ooo5t o ooq5go_

Fan system fan power limitation Fan system fan power limitation Fan system fan power limitation Fan system fan power limitation

N.v system oc ot_o_oo5 fan o5to_ + kW Ooo oo5 power o o t_o_o`o

o5oo` oo oo o oq5go_

Fan Power imitation in Nechanical ventilation System

Allowable nameplate motor power

Constant volume variable volume

1.7 kw ms 2.+ kw ms

variable air volume (vAv) fan control variable air volume (vAv) fan control variable air volume (vAv) fan control variable air volume (vAv) fan control

Part load fan power limitation

vAv oc o t_o_oo5 fan o5to oo5o5 power o_ 11kW Ooo to`o o5o o`

oo o5t o ooq5go_

o) Fan o_ variable speed drive o ot_o_@ electrical q_t _oc control oogo_ vane

axial fan _oco`o variable pith blade o o t_o_@ mechanical q_t_oc control o ogo_

o) Air flow o_ Design Air flow o 50 qoo_ oo Static pressure set point o_ 13 of

total design static pressure _oco_ oo oc Fan motor o demand o Design wattage

Oo o q_to5c oo5o acgo_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 2u

itchens itchens itchens itchens

Nechanical q_t_oc ventilate ooo_ kitchen o5to_ ocq5go c kitchen o

volume Oo o _o oo5g oo5 oo oo5 o O_ ootgo_ O oootgo_ ( ie 20 air

change ) kitchen hoods o5t ot_o_oqo_ o`. oo5ctoqo_ o` (in operation) oc

kitchen hoods o coO ooo oo5 exhaust air oo5 o O_oo aco_

itchen Exhaust itchen Exhaust itchen Exhaust itchen Exhaust

itchen exhaust hood o5to_ o_o5oo 5 oo_o_o_oct (o) cooking process

oOoo5oo5 ototo5t. o_5qo5t. ooto5t ( Grease-laden vapour ) o5to ooto

oog5ta co5c ooct_o_o oO5t go_ grease-removal deveces o5tooocO5tgo_ Fire-

suppression equipment o5to oo`coto5t (roof) ac Building surface o5to ootg5 ooo

_to_ O5tgo_ Exhaust air o5t discharge ooo_ oqg5o o_o5too5 g5o5t_oc ooo

oto o. o5o tO5t_oct ogg

Hotel o5t . c5too5ooco5t. oo5oo co5t oc goo5 cooking area o kitchen

o5to mechanical exhaust system o5to oo5o_t octg o_o5too5 exhaust system

o5tac ot_o5t _oc o5c _o_oo O5tgo_(Fan o5t. Duct o5t o o_o5too5 system

o5t_oco ooog5oa5o t_o_oc og)

coOo oooo5 exhaust air o c5tOtgq oo ooo5ooo5 make up air o

c5tOtO_ ootgo_ kitchen hood o_ in operation _ocoqoqoc kitchen area o

negative pressure _oco5c O qtO5t go_ Table 5 oc go_ ventilation rate o5t o ct

_o_ooO5tgo_ (itchen hood oo5cto__ococ. oooo5cto__ococ)

itchen exhaust hood o exhaust flow rate Q [ms| o o5o o` formula oct

o ooaco_ (kitchen hood o_ island type hood _ocoo5 o5o o` oo5_oo5o

o t_o_aco_

Q = 1.+ v 2 ( W ) H F

v = Capture velocity which shall not be less than 0.30 ms for commercial type kitchens

= ength of cooking surface, m

W = Width of cooking surface, m

H = Distance of hood to emitting surface, m

F = 1.0 For heavy duty high temperature, grease burning , deep-fat cooking with equipment

such as works, boiler, char-boilers normally associated with solid or gas fuel burning

equipment

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 21

F = 0.7 for light duty, medium and low temperature cooking with equipment such as ovens,

steamer, ranges, griddles and fryers.

(Wall mounted hoods) qgoc oo@ ooocO5too5 hoods o island type hood

_oc oo o aco_ O o_o5c Ooo` oo5_oo5o ot_o_ aco_

Design Consideration Design Consideration Design Consideration Design Consideration

itchen hood ac kitchen exhaust duct o_ o5o o ogoo5 . otoo5cacoo5

g5oo_o5t (unprotected combustible materials) o q_tot 500 mm o 5ootoc

O5tggo_

Exhaust air o5to _oco oogo Ooocgo_ oo5o_to habitable areas

oqg5o5to ooto_ oqg5oc discharge oogo_ (cqO ogo_ ) o_o5t air intake

oqg5o5to _ oo5 o5o c Discharge oogo_

itchen exhaust duct o_ o_o5too5 oqto5to _oooo5o 5tgq o ooc

kitcheb duct o structure _oc enclosed _oco5c _o_ooO5t go_ Oo o_o_ooaco`o

kitchen o fire rating ac _ooo5to_ oq to fire rating o aco qo o_oc o_ fire

rating oct fire rated duct o _o_oogo_ Duct o octo ct (internal) ac _ococt

(external) o` fire reted _oco5c _o_o ogo_ Duct rise o_ masonry shaft _oc enclosed

o ogq ooo`o kitchen duct o o_o5too5 duct o5t . o_o5too5 service o5to installation

o5to o toq_oco5c compartmentalized _oco5c _o_oogo_

itchen duct o5toc Fire Damper o5t ooocO5t_oct o_o_g

Duct Duct Duct Duct

itchen exhaust duct ac shaft o5to effluent o5to oog5tgq oo oooo5 air

flow rate oo`oc o_oo@ size (go c5t og too go_) o o go_ oo ocgo_

itchen duct o5to o5oo` oct _o_oogo_

o) o._ oooo5 Ogo_ Nild steel oo __o5t_oc _o_oogqc o_ (Nild steel of thickness

not less than 1.2 mm ) o ooo

o) o._ oooo5 O go_ Stainless steel oo __o5t_oc _o_o ogqco_ Stainless steel of

thickness not less than 0.9 mm - o ooo

) o_o5too5oc_o_O5to_ o_tc5to5t (Other approved material) o _oc _o_oogo_

itchen duct o oqg5o5to oqg ctogt _o_o o aco5c coO5tgo_

Opening o5to_ oqgc togt _o_oogq o oo5oo_ oo ggo_

itchen duct o5to g_oct ( run of Ducting ) o qoot oqg5oc Drain oo`o

O5tggo_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 22

Exhaust hoods Exhaust hoods Exhaust hoods Exhaust hoods

oo_o_og5o ototo5t .o oto5t (cooking vapor emission) o ooto cooo_ kitchen

hood oc exhaust air flow o_ 0.15 ms velocity Oo oog

itchen exhaust o5to o5o_o5o_ oo a5_oc (hard-faced) goo5 otooo5c acoo5

mild steel, stainless steel ac aluminum co_ oo_ o_tc5t o5t_oc _o_oo go_

Seam o5to_ liquid-tight seams o5t _ocgo_ oint o5to fusion welding, lopping,

riveting, soldering o o_o5too5 approved o oO5to_ q_to5t_oc _o_oogo_

Hood o5toc) oo5oo ooto_o5acoo5 (washable grease filter)o5t ooocO5t

go_ filter o5to oooo _o_ooac o5c. _oqo_ oooc a co5c _o_o oO5tgo_

filter o qtoc oqoct oooco_oct (air leakage ) o_oco5c _o_ooO5tgo_

Hood o oct qg (internal surface) o_ oo`coo (vertical) o oo`co oo_t o

o Ooo ooc5ctoo5 o_ toc5cto5t _oc go_ filter o oo a5_oc (face of filter) o_

oo`coo o_t ( vertical ) o oo`co oo_to o og Oo oooc5ctocg

Grease filter o pressure drop o gacgq oo oqg5. oo`o. ooo o assess

ggo_

Canopy type hoods Canopy type hoods Canopy type hoods Canopy type hoods

Canopy type hoods o qoo t oqg5 (lower edge) o_ (cooking surface)

oo _o_oo_ oqg5o ooa5_oco o._ oo5 Oooog oooo _oot_oco _.o oo5

Ooooqog hood oo ocO5to_ oqg5o 150 mm _ocooo o_o5oo 5 oo_o_o_

to5t appliance o5t oog5oocg

ogo_toqto5t ( Bathroom ) , oo5o5tac oqccoqto5t ( toilet ) , locker room o5tac

O oo o t_o_o_ oqto5t ( Similar facility ) o5to o Natural ventilation

_o_ooO5t_oct og o`o mechanical ventilation _o_o ooot go_

O oqto5t oo Supply air o_ outdoor air o ventilation duct oooc

ootoaco_

Air condition unit oooc ootO5taco_

_o_octoo`oo5t oooc Naturally ventilated o oootaco_

o o`to5toc ooocoo`o louver o5t_o_o oO5t_oct_oc ooocooOo

oo5ctocaco_

Exhaust air o5too c5tOtO_ooto_ replacement air oo5o_ exhaust air

oo5Oo oo5tocg

Exit facilities Exit facilities Exit facilities Exit facilities

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 2S

Exit facilities o5to Nechanical ventilation system o5t ooctoo_octac operation

o o_octo oo Code of Practice for Fire Precautions in Buildings o`gc_to_t c_too to

o oq5go_

Exit staircase and internal exit passageway Exit staircase and internal exit passageway Exit staircase and internal exit passageway Exit staircase and internal exit passageway

Exit staircase o5tac internal exit passageway o5to ventilation system o5to_

o5ooo5_oo` ooo5to o oq5go_

o) exit staircase ac internal exit passageway o5to Nechanical ventilation system o5to_

four air change per hour _ocgo_ (ocq5go c O stair case o passageway oqtO O_

o o goo5 ooo ooo ootgo_ )

o) Supply air o _ocoo o ogoogo_ O intake point o _ oo5 ooo_oc o_o_

exhaust discharge point o ogocg

Smoke stop and fire fighting lobbies Smoke stop and fire fighting lobbies Smoke stop and fire fighting lobbies Smoke stop and fire fighting lobbies

Smoke stop ac fire fighting lobby o5to ventilation system o_ o5o oo5_oo`

oo o5to ooq5go_

o) smoke stop ac fire fighting lobby o5to ventilation system o_ supply mode only

_ocgo_ ventilation rate o5 four air change per hour _ocgo_

o) Supply air o _ocoo oogoogo_ O intake point o _ oo5 ooo_oc o_o_

exhaust discharge point o ogocg

ventilation system for fire command centers, engine driver pump rooms, generator

room. And space involving use of flammable and explosive substance.

Ooo` oqto5t.oqg5o5t o ooct ac operation o o_ Code of Practice for Fire

Precautions in Buildings o co`goo5 c_to_tc_toot o5to ooq5go_

Pressurization System Pressurization System Pressurization System Pressurization System

Exit facilities o5to pressurization system o5t ooct _o_oo_oct ac operation

o o_octo5t o o Code of Practice for Fire Precautions in Buildings oc o`goo5

c_to_tc_toot o5to ooq5go_

Nechanical smoke control system for basement occupancies (other than car parking area) Nechanical smoke control system for basement occupancies (other than car parking area) Nechanical smoke control system for basement occupancies (other than car parking area) Nechanical smoke control system for basement occupancies (other than car parking area)

Basement o c ooo o ocoq_oo_ oo5t. goqoo5t (occupancies) o5too (

Basement car park oqg5o o@ ) mechanical smoke control system o Design _o_ooo ac

operation oo_octo5t o o Code of Practice for Fire Precautions in Buildings o c o`goo5

c_to_tc_toot o5to ooq5go_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 24

Section Four - Auxiliary equipment Section Four - Auxiliary equipment Section Four - Auxiliary equipment Section Four - Auxiliary equipment

section o_ Nechanical ventilation (or) air conditioning system o5to

co oct _ocoo5 air duct system o5to ooct o o_oct. (construction) o_oo5o_oct.

oooc_oct ( installation ) o5to oo5_oO5to_

oo5o _to5t o too5co_ o` o to5t ootcogq ac ototo5t oaocgq oo

(Design requirement) ooct o ooo o5to _o_oo5c _o_ooO5tgo_ code of practice for

fire precautions in building oc o`goo5 c_ to_tc_toot o5to ooq5go_

Design Considerations. Design Considerations. Design Considerations. Design Considerations.

Air distribution system o Duct work o5to design _o_o oo_ o` Duct octoc

goo5 air velocity, material ogtoo_oct a c duct o5t_o_oo_oct o o O_oct c_tc5tgo_

ventilation duct o5to_ smoke stop ( o ) fire fighting lobby o5t octo c

_oo oqtoc o_o_ oooog5co5 _oooqto5tgoc Code of Practice for Fire Precautions in

Buildings o c o`goo5 c_to_tc_too t o5to o oq5go_

Celing ac Floor _o5toqg5 o concealed _oc .

Celing ac Roof _o5toqg5 o concealed _oc .

Raised floor ac structural floor _o5toqg5 o concealed _oc ooo oa co_

O concealed space o5to o5o o` o_ooq o5t_oc _o_coc plenum ( ooo5t ooo5c

O5tg5oqg5 ) _oc o t_o_ aco_ Concealed space o5to_ ooo5t o oooc5

ctocto5tgq ( free flow of air ) o o o5to to5t . oo ooo5t ( obstruction ) ogocg

Concealed space o5t octoc code of practice for fire precautions in building oc

o`goo5 c_to_tc_ toot o5to oo q5go_ oo_o_ material o5tac service o5to5

ggo_

Celling membrane o5to oO5o ootO5too5 support o5to_ Non - combustible

material o5t _ocgo_

Air duct o5to ooa coo oooo5c (o) oooco_oct og o5c _o_ooO5tgo_

( maintenance ) _o__ocOqto otgq oo ac operation _o_oogq oo o ooo5 opening

o5t oo@ o_o_ oo ooo5 opening o o oco_o_ Duct oct ooogo o5t (debris ) ,

coo5t a c otoo5cooo_ g5o5t ( combustible material ) gac o_ oqg5 . cootoqo_

oqg5 o5toc Og5o5to oog5t _oc gqoo Accessing opening o5t O5tgoot go_

oo@ goo5. ocacoo5 ( removable grilles ) o5to access opening _oc ot_o_aco_ (

screw o5to _o_o _oct5t_oc )

ocations of intake and return air opening ocations of intake and return air opening ocations of intake and return air opening ocations of intake and return air opening

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 2S

air-handling systems o outdoor air intakes o5to o_o5too5 ventilation o exhaust o5to

intake openings o5t_ocooooooqco_

air-conditioning ac mechanical ventilation systems o5toooooo5 outdoor air intakes

(the ventilation ac pressurisation of stairshafts o5too o`) o5to_ _ocooot qgo5t

(external walls) ac oo`cot(roof level) o5toc o_ggo_ ooo5 oq.o_q (contamination)

o5toctoo5. qo to5t(odours)oo5 oooo5ctoooqo ggqco__oco_

Air handling systems o5t. Air handling systems o5t. Air handling systems o5t. Air handling systems o5t. mechanical ventilation mechanical ventilation mechanical ventilation mechanical ventilation

Systems o5t. pressurisation systems of exit staircases and internal corridors o5t ac smoke

control systems o5too outdoor air intake Opening o5to _oo5 o 5o c o_o_

ooooo5tc qOog5oo`oo5t (exhaust discharge opening) ogocg

Outdoor air intakes o_ o_o5too5 oo5o_to5to (kitchens, toilets, car parks, cooling

towers, laundries, rubbish dumps or plant rooms co_o o cqOooo5) exhaust discharge

o5to _oo5 Oooooto_oqg5ocgocgo_

Outdoor air intakes o5toc oootoooqco_ insect screen o5t_oc o5gO5tgo_

otogcoo5toocqco5c_o_oo o5o oO5tgo_

Screening o5t o wire mesh o5to_ oootooo q co_ o_tc5to5t_ococgo_

oo5oogoc5to_ 10 mm mesh Oooo_o tocg

Cooling towers o5to occco5o_ ogcoogoo`oo5t (water droplets) outdoor air intakes

o5t octo oocog5oqco5co5oo o5totO5tgo_

return air opening 5to t ac outdoor air intake o opening o5t 5to to cto

otoo5c_octcoc_ococqco_ ot_ocoo5t(lighted matches). ootooo o5t(cigarette butts)

co_o oocog5oqco5c_o_ooO5tgo_ o5o oo5to tO5tgo_ oocc (filter media)

o5t qtoc c_o_ooqo5c (shall not be deposited) _o_o oO5tgo_

air-conditioned space o5to o outdoor air intakes o o5oo_oo_

_ocoogo5oo_ooqg5(outside floor level) o 2.1 m Oo_oco_oqg5ocggo_

O to_oc o5tO5tg5oqg5o5t. o ocO oo5too5oqg5o5tac

o5_o 5to5qco_oqg5o5to o_oco_

oo5o5t. oqccoqto5t (toilets) ac oo5to oo _o_og5oqg5o5t. oooo5c (domestic

kitchens) o5t o Exhaust duct o5to_ _o5too5 duct system o5tacooO5t_oct (connect)

ogocg ( inlet of the exhaust fan oqg5oo @)

oo@Oo oo@ooocO5t(connect)o`o fan o5to_oo_octogo_o` o c

o oqO c g5 oqto5t ooo5t a cog5oa5o 5t_octogo5c _o_ooO5tgo_ o ooo5 device

o5too ocO5tootgo_ o oo5 cogoo go5t (industrial) o

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 26

cto5t_ocoo_o_oo_otooo5co5t (commercial kitchens) o Exhaust duct o5to o_o_

duct o5taco og5oa5_oc togoco otoq (separate system) cqco_t_oco5c_o_ooO5tgo_

Exhaust duct o5to_ _oco(outdoors)o oo go og5oo5c cqOogo_ discharge

o ogo_ exhaust air cq Oog5oqg5o_ o o5toot(pedestrians)qtoco_goqo`o

o5oo_ooqg5(outside floor level) o 2.1 oo5 Oo_oco_oqg5ocggo_

Where

A: All transverse oints, longitudinal seams and penetrations in duct wall. Pressure sensitive

tape shall not be used as primary sealant.

B: All transverse oints and longitudinal seams. Pressure sensitive tape shall not be used as

primary sealant.

C: Transverse oints only.

ongitudinal seams o5to_ ooo5tg5oo (the direction of the airflow) oct _ocoo5

oint ooo5t _ocgo_

Transverse oints o5to_ duct oct (section) acoo oo oog5oqg5_oc_ot

ooo5tg5oo (the direction of the airflow) ac _o og oO5coq _ocgo_ duct o qgo5t

(walls) o oo5oO oo5too5 (Penetrations) o5t o screwo5t. pipeo5t. rodo5t. wireo5t

co_oc_toco_to_t_oc_o_ooO5tgo_

Fire dampers Fire dampers Fire dampers Fire dampers

Fire damper o5to otoo qc_octoc (fire resisting rating)o_ ventilation duct

_oo o5to_oqto qgo5t(wall)ac _ootocto5t (compartment floor) o otooq c_octoc

(fire resisting rating)Oo oqoocg Code of Practice for Fire Precautions in Buildings oc

o`goo5 c_to_to5tac oo_go_

Ducts o5to Ooo oo ctqco_oqg5o5t oc oooocO5tg ooocO5tooo5 oooo5

o5ooo5t. go5to5t_o_ooootO5tgo_

oo5o5t (toilets) qc ooo5cto_ qoto5t oooo5co_ Return air duct o5to

supply air stream gg5oqg5o5to ooqc ooooto_oqg5ocooocO5tgo_

Construction Construction Construction Construction

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 27

supply and return air duct o5to octooa5_oco5to_ oq. o_qac o_oo5t cootoq_oct

o octootocgq ooqc oooo5ooocgo_ abrasion _oc_octoo oo aco_

o_tc5t_ococgo_

ooa5ooo5toctgoqg5o5t(ceiling space)o return o5t o5to5qcg5 air plenum

_ocot_o_o` ooa5ooqgo5tacootooqgo5t(ceiling and the side-walls)o

oo5c5_oc oo5_oct(plastering) ac ootoo_oct(painting) o _o_oogo_ Nasonry duct

o5too_tOo o_oco5cooqcoo_o_oogo_

oco_ocgqo oo5 Rigid duct o5to steel, aluminium, glass-fibre batt, mineral wool ac

_o5toc_o_O5too5 oc_to_tc5to5t_oc (approved materials)o5_o_oogo_

O ooogo_

Ducts o duct linings o ootO5tooo5 glass fibre batt o mineral wool o5to_ air

stream o5tacoo goOoo oqo`o erosion of fibres o_oco5c

ocoo 5oo5o5ooo_o5t_o_ooootO5tgo_

Ducts o5to sturdily supported _oco5c_o_oogo_

Duct oO5ootootO5too5 Hangers ac brackets o5to_ oo_o_tc5t (metal)

o5to5_ococgo_

Duct covering, duct lining and flexible connection materials o5to_ otooo5cqco_

oc_to5t (non-combustible) _ococgo_

o oo5 oooo g. ooog5co5oo5o_ooqg otoo5cqco_ oc_to5t

(combustible material) oo t_o_o oo5 o5o o`ooo5t_oc_o_cocgo_

o) Code of Practice for Fire Precautions in Buildings o`goo5 q_to5toct(methods)

cotooO5toc surface flame spread rating o_ oOooc (Class 1) Oooqoocg

oo5o _to ooq5oo flame spread rating o_ Class 0 _ocooc Duct lining materials

o5to_ Class 0 rating _ocgo_

o) otoo5co_ o` O Duct oc ot_o_O5to_ oc_ to5to_ otot ac o oococo_

`ooc Ooo_q_t qcooq_t oco_ oc_to5t_ocgo_

ventilation ductwork ac terminal units o5t_oc_ooo5 ventilation grilles. Air Diffuser o

ooo oo_ Flexible connection o5t o g_o5 2 m Ooooocg

ooqq_t_octo5t_oc to_o5c _ocoo5 ogg5to_o5t (thermal movements)o

o5oogqooocO5to_ Flexible oints o5to_ 250 mm g_ Oo ooocg

Flexible oints o5to oooootooo5oqc o otcocooo5cqco_ (not easily

ignitable) oc_to5t_oc_o_o oO5tgo_ Ooc_to5to_ British Standard BS +76: Part 5 g

cotooO5to_oc_to5t_ocgo_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 28

Duct 5totoc o oqg ctog_o_oooo ocoo5o_oqg5o5to c opening

o5tO5tggo_

air ductso5t. air ducts supporto5t. fittingo5t. and plenums o5t.( oints o5t. seams o5t.

stiffening o5t. reinforcing and access opening o5t o`oc)o ASHRAE Handbook, 1HvE

guide books or SNACNA Nanuals o _o5qtoo oo O5too5 duct o5t_o_oo_oct oooc_oct

coqc_qto5t (construction standards) o ct_o_o ogo_

Ducts and plenum sealing Ducts and plenum sealing Ducts and plenum sealing Ducts and plenum sealing

Ductwork and plenums o Ooo`q_to5t oct seale o ogo_

Pipework Pipework Pipework Pipework

air-conditioning system o5toc o`ocoo5 piping system o5to ooct_o_oo_oct (design) ac

oooco_o5t(installation) o5t oo o5ooo5_oo` ooo5t5toto_toco_

Design considerations Design considerations Design considerations Design considerations

o t_o_o_oc_to5togtoo_oct (choice of material), oooctctocta_qt(rate of flow),

ccootgq._o__ocgqoo ooog5oqco_(accessibility), O oooocto_o5to

o5ooootq co_(protection against damage), o ootooo_(corrosion),

oooo__oq5o5to og5coqco_(avoidance of airlocks), water hammers

_oq5o5too5oo qco_, o_oo5t_ocoo`_oct (noise transmission), ogo_oqo5t_oct ac

o qo`o_o5tac (vibration and expansion of fluid), stress and strains, co_ooo5to pipe

work acoooc o oo5to o design oo_oct and plan o o_oct ooo

O_o c toooogo_

qgo5t _oo tocto5t o5tocoacocoo ct _oco 5to_ pipes o5to oqg5o5t passage o5t

o o protected shafts o5to ot_o_qco_

compartment walls and compartment floors o5toc ooo5t _ooo5tgqoo

oo`oo5t(passage of pipes)o oc_o_o_ O passage of pipes o

o5oo(protection)o oootgqooo_ ooo5 Code of Practice for Fire Precautions

in Buildings oc o`g oo5 c_to_to5tac oo_go_

o t_o_o_ooo5t5to tocoooo5 o coqo_ (adequate strength)ac (durability) ggo_

Pipes o5to oO5o O5t. otO5too5 support o5to_ ooo5ooo5 ocoqo_ ggo_

Pipe support o5t _ocoo5 Hangers o5ta c brackets o5to_ oo_(metal) o5t_ocgo_

Pipe o5to Oooooctqco_oqg5o5t oc oooocO5tg ooocO5tooo5 oooo5

o5ooo5t. go5to5t_o_ooootO5tgo_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page 29

!nstallation !nstallation !nstallation !nstallation

Pipe o5to o_tc5to5t ac ot_o_O5to_ fittings o5to_ g_goO5to_(intended

service)o5toc t oooo5cootqcgo_

Equipment _o_ogq. _oqoogq ac c5tOto oogqo oo ooo5tocoo5ooc

gocgOoo_ oooo5 unions o5t oooo flanged fittings o5t oooo valves o5to

ooocO5tgo_

Standard fittings o5t_oco5 tees, elbows co_o o ot_o_go_ ooo5o5 _o_o oO5too5

(fabricated fitting)o5t Non Standard fittings o5to oto_o_g

Pipe o5t. pipe supporto5t. fitting o5t. and valve o5t. o ASHRAE Handbook, !HvE guide

books o ooo SNACNA manual o ooo o5t ooo_o_O5to_ c5oo5t Piping

Handbooks o _o5qtooooO5too5 coqc_qto5t (construction standards)

o ct_o_oogo_

o5t_oco_ g_o5t(pressurised fluid) o o o t_o_o_ooo5to oto_o_oc

o5toqco_ pressure tested oogqo oo_

air-conditioning and mechanical ventilation systemo5tg pipework octot_o_o_ Thermal

insulation o5to_ associated o5oo`oo o5t ac_o_cgo_

a) pipe o5toc vapour barrier lining _ocac adhesives shall _oc ot_o_o_ Thermal

insulation oc_to5to_ Code of Practice for Fire Precautions in Buildings o`goo5

q_to5toct(methods) cotooO5to c surface flame spread rating o_ oOooc

(Class 1) Oooqoocg

oo5o _to flame spread rating o_ Class 0 _ocooc O Thermal insulation

oc_to5to_ Class 0 rating _ocgo_

the use of plastic and foam rubber insulation materials o5to o ot_o_qco_

o oo5O oc_to5to_ o5oo`oooacoo _go_

o) Ooc_to5to_ (material) o_ otooo5cqcoo5.oo5coqo_oto _cotocoo5

o_tc5t (self-extinguishing type) o_t_ocgo_ relevant authority oc_o_oo ooo_

o) otooo5cqco_ o_tc5t (non-combustible cladding materials) oc_to_t o hybrid

plaster o_tc5t o metal sheathoo insulation material _ocot_o_q co_ relevant

authority oc_o_oo oo o_

oo5o _to structure acooo co_ element o5to _oo oqto5to_ pipework

oqg5o5t o o_o_ opening o oo fire-stopped oc_to5t_ocooogo_

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page Su

Pipe o5t_ooo5to_oo`oo5to oqto fire rating ac oco_ oo5

otooqco_oc_to5t(fire resistant materials)_ocoooO5tgo_ O oo oo5 Thermal

insulation oot_o_qco_ cotooO5t_octogo_ proprietary pipework system o5too

ooo cg5cotoooqto5to otooqco_oc_to5t(fire resistant materials)

_oco_o5ctcotooo__o_oco5 relevant authorityo oc_o_oogogo_

ooo5to o_o5too5oco_ !dentification o5t oo5_oO5tgo_ !dentification o5t o Annex C

o coo5_oO5too5 og5c o5to c t (colour codes) _o_oogo_

Thermal insulation Thermal insulation Thermal insulation Thermal insulation

General requirements General requirements General requirements General requirements

Thermal insulation o5to coo_oocqto5tco oooO5to_ c (with industry accepted

standards) o5toct_o_oogo_

Thermal insulation o sunlight, moisture, equipment maintenance and wind

co_oo5oootoo5too5o ogq O ooooct_octogocgq_o_ooO5tgo_

o) _ocoocgoqo_ !nsulation o5to_ oo5oootoo5to_o5coo ctocqcoo5o_o5c

aluminium sheet metal _ocooO5tgo_ o5gO5tgo_

Code of Practice for Fire Precautions in Buildings gooo5tg oc_o_oc Cellular foam

o o_o_qco_ ooctooct_octogocgq ac oqoacotooqcgq ootoo_oct

o5g_oct (shielding)o _o_ooO5tgo_

o) !nsulation covering chilled water piping, refrigerant suction piping or cooling ducts

located outside the conditioned space o _ocoo oc ooocO5to_ chilled water

piping, refrigerant suction piping or cooling ducts o5too !nsulation o5t octo

vapour o5tocog5o _octogo5c seale o oO5tgo_ (vapour retardant _oco coo )

penetration 5totac oint o5t5to too seale o oO5tgo_

Duct and plenum insulation Duct and plenum insulation Duct and plenum insulation Duct and plenum insulation

All supply and return ducts and plenums, installed as part of a conditioned air distribution

system shall be thermally insulated in accordance with Table 10.

Table 10 - Ninimum duct insulation R-values for cooling only supply ducts and return ducts

Duct ocation Duct location R-value (m2W)*

Exterior 1.06

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page S1

ventilated attic 1.+1

Unvented attic above insulated ceiling 1.77

Unvented attic with roof insulation 1.06

Unconditioned space 1.06

Buried 1.06

!ndirectly conditioned space None

* NOTE:

!nsulation R-values (m2 W) are for insulation installed and do not include film resistance.

The required minimum thickness does not consider water vapour transmission and possible

surface condensation

The following are exempted from requirements given in 17.2

a) Factory installed plenums, casings, or ductwork furnished as part of air-conditioning

equipment tested and rated in accordance with the relevant standards;

b) Ducts or plenums located in conditioned space;

c) Connections less than 3 m in length to air terminals or air outlets, for which the rated

insulation thickness need not exceed 0.6 eNv; and

d) Backs of air outlets and outlet plenums exposed to unconditioned or indirectly conditioned

spaces with face areas exceeding 0.5 m 2, for which the insulation need not exceed 0.+ m

2W, and those 0.5 m2 or less need not be insulated.

Electrical works Electrical works Electrical works Electrical works

General requirements General requirements General requirements General requirements

o o ccacoooco_ ooo5to_ Singapore Standard SS CP 5 gc_to_to5t

c_tooto5toooq5go_

General power distribution General power distribution General power distribution General power distribution

otoo5co_o` (in the event of fire) air handling system o5to ooo co_ fan o5t

goo5to5c (partially or completely shut down) electrical distribution system qc control

o5to coO5tgo_

central monitoring and control system o5tgoc o ot_o_O5toc O oo shut

down_o_o oqccotggo_

!nstallations !nstallations !nstallations !nstallations

supply air, return air and outdoor air o5t ooogqoo_o_ooO5too5 ducts, plenum

chambers and concealed spaces octoc O_o ct ooocO5to_ Wiring installation

SS 553:2009 (Formerly CP 13) - Code of Practice for ACNv - updated 16-12-2011

oo5ctOo_q (www.acmv.org) Page S2

o_ otoo5c_oct(combustion) oo5oogqo ototo5toa_oct(flame spread)

q_tqcooq_tocgq o o5oo_co o oo _ o`oc (metallic)o_tc5t_ocgo_ metallic

o5t_ocoo5o_o5c otoo5co_ o`oc oo5cc5 (fuel) o_oc otoo5c_octo5toootqc

fire compartmented o5to qgo5t (walls). _oot_octo5t(floor)ac ooa5ooo5t(ceiling) o

oo5o _ooo5to_ wiring installation o5to_ o tooo5cqco_ (fire-stop material)

o_tc5t_oc seale oogo_ otooo5cqco_ (fire-stop material) o fire rating o_ fire

compartmented o fire rating aco_ go_

oq ac o_q o5t ac o_o5too5 oc_to5t gqco_ duct o oqa c o_qo5t

coogq_o_o oO5to_ duct o5t. flammable vapours o5too_o_ooO5to_ Dcut o5t.

cooking equipment o5too_o_ooO5too5 Duct o5t octoc o_o_ o`o5_o_t (wiring

system) o_too ooocO5toco_o_ O oo o_tc5t shaft o5t octoc o_t o_o_

o`o5_o _t (wiring system) o_too ooocO5toco_o_

Wiring in ducts or plenum chambers Wiring in ducts or plenum chambers Wiring in ducts or plenum chambers Wiring in ducts or plenum chambers

ducts o5t o ct o plenum chambers o5t octg o`o5_o_to5t(Wiring) o_ o5oo`

oo o5tac oo_go_

oogq oogq oogq oogq

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Ventilation Rule of ThumbDocument22 pagesVentilation Rule of ThumbZawzaw LinNo ratings yet

- Cooling Load Rule of ThumbDocument18 pagesCooling Load Rule of ThumbQaz Zaq100% (1)

- Bat File ProgrammingDocument12 pagesBat File ProgrammingPyae SoneNo ratings yet

- 7 July - 6-5-2012Document51 pages7 July - 6-5-2012Aung HtetNo ratings yet

- Hadith and Science RealityDocument7 pagesHadith and Science RealityownerofsweetsmileNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- Who Are The Union of Myanmar Economic Holding Limited (UMEHL) Commonly Known As U PaingDocument14 pagesWho Are The Union of Myanmar Economic Holding Limited (UMEHL) Commonly Known As U PaingPugh JuttaNo ratings yet

- The MGMGDocument429 pagesThe MGMGAyar HeinNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- How To Become A MillionaireDocument10 pagesHow To Become A MillionairesolucortefNo ratings yet

- Assume As You LikeDocument121 pagesAssume As You Likesaroakesin86% (21)

- THAI-AHU and Cooling CoilDocument38 pagesTHAI-AHU and Cooling Coilwnew2me428No ratings yet

- Burma Political Commentary (2-2011)Document5 pagesBurma Political Commentary (2-2011)Mya TheinNo ratings yet

- Ashin Wirathu - The Guilty One of HistoryDocument25 pagesAshin Wirathu - The Guilty One of HistoryMoe Ma KaNo ratings yet

- MOETHEE ZUN-real Name Myo Than Htut ABSDF NORTH CASE KILLING COMRADES - HTAY NAING MOTHER OPEN CASEDocument24 pagesMOETHEE ZUN-real Name Myo Than Htut ABSDF NORTH CASE KILLING COMRADES - HTAY NAING MOTHER OPEN CASEPugh JuttaNo ratings yet

- Ij 15-27Document80 pagesIj 15-27TheMyawadyDailyNo ratings yet

- Ij 15-28Document84 pagesIj 15-28TheMyawadyDaily100% (1)

- Compressed Air SystemDocument48 pagesCompressed Air SystemKong Lay KingNo ratings yet

- Blogger #### ZawGyi ####Document6 pagesBlogger #### ZawGyi ####naisopakaNo ratings yet

- TRUFLO FullLineDocument24 pagesTRUFLO FullLine2009tamerNo ratings yet

- Job Description Kotak.Document3 pagesJob Description Kotak.vish_talkNo ratings yet

- Aeroquip Fluid Compatibility InfoDocument5 pagesAeroquip Fluid Compatibility Infos2000ratNo ratings yet

- Drying Oil ProductionDocument21 pagesDrying Oil ProductionAhmed Ali100% (6)

- Jockey Pump Preventive Maintenance ChecklistDocument1 pageJockey Pump Preventive Maintenance ChecklistVench VoizNo ratings yet

- Appendix IDocument375 pagesAppendix IPavle MočilacNo ratings yet

- Ball Mill Checking (Compatibility Mode)Document33 pagesBall Mill Checking (Compatibility Mode)Nael100% (9)

- Planta de Producción de Aceite SecanteDocument5 pagesPlanta de Producción de Aceite SecanteJorgeAndresNo ratings yet

- WEG Brake Motor Installation Operation and Maintenance Manual 50021973 Manual EnglishDocument2 pagesWEG Brake Motor Installation Operation and Maintenance Manual 50021973 Manual EnglishRkantvyas100% (1)

- TEFULONG QualificationDocument24 pagesTEFULONG QualificationHamed GeramiNo ratings yet

- Vazadores (Punções) : E1. Cortecentral, Altura23,8 MM U N I D: 2 5 P Eç AsDocument4 pagesVazadores (Punções) : E1. Cortecentral, Altura23,8 MM U N I D: 2 5 P Eç AsLeonardoNo ratings yet

- Suu66 Moemaka 2011 LDocument132 pagesSuu66 Moemaka 2011 Loothandar2010No ratings yet

- Auiuiui !!" E2I: Search English VersionDocument3 pagesAuiuiui !!" E2I: Search English Versionnwktct3882No ratings yet

- Material Balances Design Project Production of A Drying Oil: Chemical ReactionDocument5 pagesMaterial Balances Design Project Production of A Drying Oil: Chemical ReactionJimmy Martinez CabarcasNo ratings yet

- Combined 2015Document17 pagesCombined 2015aabp pereraNo ratings yet

- Generadores de Vacío: Serie MICRO-SchmalzDocument5 pagesGeneradores de Vacío: Serie MICRO-SchmalzHoracio CalderonNo ratings yet

- Thermoplastic Dry Film Adhesives Heat Activated Dry Film Adhesive Comparison Selection ChartDocument1 pageThermoplastic Dry Film Adhesives Heat Activated Dry Film Adhesive Comparison Selection ChartSyed Arsalan AfsarNo ratings yet

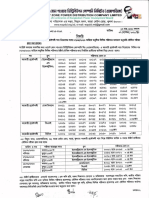

- WZPDCL Viva NoticeDocument2 pagesWZPDCL Viva Noticetoukirbueteee14No ratings yet

- Cyclo CatalogDocument28 pagesCyclo Catalograjkg421No ratings yet

- Sudu ChootiDocument2 pagesSudu ChootiAsa mathew50% (2)

- Air Filter EDocument35 pagesAir Filter EGonzalo Aranda UribeNo ratings yet

- Comprehensive Guide To ActionDocument108 pagesComprehensive Guide To ActionMoodi SejiniNo ratings yet

- Rexnord Elastomer CouplingDocument20 pagesRexnord Elastomer Couplingidontlikeebooks100% (1)

- 4jhiuhmbttft: GpsnvjejoejdbujpoboejotqfdujpoDocument4 pages4jhiuhmbttft: GpsnvjejoejdbujpoboejotqfdujpoNagLakshmananNo ratings yet

- 6 September 1966: LubricationDocument5 pages6 September 1966: LubricationSteveNo ratings yet

- Arcelormittol Goloti S.A. - RomonioDocument1 pageArcelormittol Goloti S.A. - RomonioSpeedy Gonzales Riba RibaNo ratings yet

- SMA Sunny IslandDocument6 pagesSMA Sunny IslandSINES FranceNo ratings yet

- Chalermchai - Kuliah Tamu 2012Document64 pagesChalermchai - Kuliah Tamu 2012intanrosalinaNo ratings yet

- Expmt #6 (Moisture Density Relation)Document3 pagesExpmt #6 (Moisture Density Relation)Joe A. CagasNo ratings yet

- Cat 2Document252 pagesCat 2tuan1289No ratings yet

- Ol Ict Past Paper 2020 SinhalaDocument16 pagesOl Ict Past Paper 2020 SinhalaChandradasa KNSNo ratings yet

- Start-Up Sheet For CompressorsDocument1 pageStart-Up Sheet For CompressorsGreg LundyNo ratings yet

- USDCM Volume 2 2016 PDFDocument350 pagesUSDCM Volume 2 2016 PDFLinn Kyaw ZawNo ratings yet

- Zone SummaryDocument73 pagesZone SummaryLinn Kyaw ZawNo ratings yet

- SS553 CP13 20111216Document32 pagesSS553 CP13 20111216Linn Kyaw ZawNo ratings yet

- SS 575 Overview - CP For Fire Hydrant, Rising Main & Hose Reel SystemDocument48 pagesSS 575 Overview - CP For Fire Hydrant, Rising Main & Hose Reel SystemErwinNo ratings yet

- Figure 11, WSC 079/087, 300 To 550 Tons: 36 Product Manual PM WSC/WDC-2Document1 pageFigure 11, WSC 079/087, 300 To 550 Tons: 36 Product Manual PM WSC/WDC-2Linn Kyaw ZawNo ratings yet

- Bs 6700 2006 Water Supply Services FormulatedDocument2 pagesBs 6700 2006 Water Supply Services FormulatedLinn Kyaw Zaw100% (1)

- WSC - WDC Product ManualDocument1 pageWSC - WDC Product ManualLinn Kyaw ZawNo ratings yet