Professional Documents

Culture Documents

Chu Trinh Lam Lanh Bang Propan

Uploaded by

Dương Thị Thúy HoaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chu Trinh Lam Lanh Bang Propan

Uploaded by

Dương Thị Thúy HoaCopyright:

Available Formats

Refrigeration

Refrigeration

1998 AEA Technology plc - All Rights Reserved Nat Gas Lec 8_1.pdf

Lecture

Lecture

Refrigeration systems are commonly found in the natural gas processing industry. Refrigeration is used to cool gas to meet a hydrocarbon dewpoint specification and to produce a marketable liquid.

Learning Objectives

In this module you will learn about:

Typical refrigeration equipment Use of a P-H diagram in refrigeration systems

Terminology

Chiller

A heat exchanger in which the liquid refrigerant is vaporized by a process stream which is in turn cooled.

Condenser

A heat exchanger in which the refrigerant is condensed by rejection of heat to a cooling medium.

LPG

"Liquefied petroleum gas". Predominantly propane or butane,either separately or in mixture, maintained in its liquid state.

Lecture

Theoretical Foundations

The refrigeration process is used in gas plants to remove heat from certain process streams. One such application is to meet the hydrocarbon dewpoint as well as the water dewpoint specification for residue or sales gas. The temperature to which the gas is cooled depends firstly on meeting these dewpoint specifications. This would be the minimum cooling requirement. Cooling the gas to lower temperatures than the minimum temperature would have to be justified by the economics of LPG recovery. This requires a cost analysis of additional LPG recovery versus increased capital and operating costs.

Additional recovery of LPGs can be achieved by chilling the gas to colder temperatures, such as to - 20 to - 40 F, or by contacting the gas stream with lean oil in an absorption tower.

Refrigeration is basically pumping heat from one medium to another. Heat by itself can only flow from a higher temperature medium to a lower temperature medium. Thus refrigeration is a process that provides the cooling medium to which the gas is exposed.

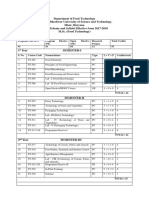

Typical refrigeration equipment is shown in Fig. 14-3.

Section 14 of the Data Book provides the technical data that explains the refrigeration process. Fig. 14-3 shows the typical refrigeration equipment for natural gas cooling. Fig. 8-1 of these notes illustrates a refrigeration unit in more detail. The heat exchanger cools the incoming gas to the refrigeration unit by exchanging heat with the cold gas, which has been chilled to the design cold temperature in the chiller.

Fig. 8.1

Lecture

Since the gas entering the refrigeration unit is normally saturated with water vapour, and since the temperature to which the gas will be cooled is substantially below the freezing point of water, some means of preventing ice or hydrate formation has to be instituted. As was discussed earlier, the formation temperature of hydrates at a given pressure can be suppressed by the addition of chemicals such as methanol or glycol. In refrigeration systems, the common chemical used for hydrate suppression is monoethylene glycol, usually referred to as ethylene glycol, EG, or simply glycol. Glycol has to be added to the natural gas being cooled at two points, namely at the inlet to the heat exchanger and at the inlet to the chiller. It is important that the glycol be evenly distributed in the gas stream, so that all gas is protected from freezing. This requires spraying the regenerated glycol evenly onto the tube sheet in these two vessels, so that some glycol travels through each tube with the gas.

Propane boils in the chiller at a very low, controlled temperature, removing heat from the gas stream, and thereby condensing a portion of this gas. The cold gas, condensate and glycol flow from the chiller to a three phase separator.

The condensate goes to a fractionation unit. The gas has been sufficiently cooled so that it meets both the hydrocarbon and water dewpoints. It exchanges heat with the incoming gas to the refrigeration process.

The rich glycol is separated from the hydrocarbon gas stream in a three-phase separator, and is routed to a regenerator. The concentration of the regenerated glycol is usually in the order of 75 % to 80 % glycol, with the balance being water. Sufficient glycol is injected at the two injection points to result in a mixture of water and glycol to depress the hydrate temperature to the required level, which for design purposes would be the refrigerant boiling temperature.

Lecture

The amount of glycol to be injected requires a determination of the hydrate temperature depression and a calculation of the rich glycol concentration by the Hammerschmidt equation. The glycol injection rate can be determined by Eq. 20-6: Eq. 20-6 XR m H 2 O m r = -----------------------XL XR

As mentioned, the refrigeration effect is brought about by the vaporization of a refrigerant, such as propane, in the chiller. Propane is suited for this application, as it boils at temperatures near and below ambient temperatures. The vaporization of propane, or boiling, requires heat to effect the phase change from liquid to vapour, namely the latent heat of vaporization. By controlling the pressure at which the boiling of the propane takes place, the desired refrigeration temperature, down to about - 40 C, can be achieved.

The amount of heat or enthalpy to vaporize 1 kg of propane at various pressures can be obtained from pressure - enthalpy (P-H) diagrams. A P-H diagram for propane is provided in Fig. 24-27 of the Data Book. The use of this information is illustrated in Fig. 14-2, and is explained on pages 14-2 and 14-3 of the Data Book, and will be reviewed during the presentation in the course.

Lecture

Problem 8-1

The gas coming off the sweetening absorber is at a temperature of 40 C and a pressure of 6700 kPa, and enters the heat exchanger ahead of the propane chiller. After coming out of the heat excahnger, the gas temperature is 0 C, and about 1 mole % of the flow has been liquefied. The gas and condensate then enter the propane chiller, where the gas is cooled to - 20 C. In the chiller, an additional 3 % of the gas is liquefied.

Determine the propane refrigerant flow required to cool the gas from 0 to - 20 C. Saturated liquid propane is available at 1400 kPa (abs), and is boiled in the chiller at - 25 C. Determine the total amount of ethylene glycol to be injected ahead of the heat exchanger and chiller to depress the hydrate temperature to - 25 C. The ethylene glycol available for injection has a concentration of 75 mass %, the balance being water.

Lecture

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- TRANE - HVAC Resource Guide For LEED PDFDocument36 pagesTRANE - HVAC Resource Guide For LEED PDFjupoc100% (1)

- Hitachi Split Systems Guide with PricesDocument41 pagesHitachi Split Systems Guide with PricesMian AlmasNo ratings yet

- MEC551 Thermal Engineering Heat ExchangerDocument95 pagesMEC551 Thermal Engineering Heat ExchangerFaris HalimNo ratings yet

- Catalogue Air Cooled Chiller Uaa St3 Uay r134Document84 pagesCatalogue Air Cooled Chiller Uaa St3 Uay r134kirboikaladNo ratings yet

- History and development of automotive air conditioning systemsDocument10 pagesHistory and development of automotive air conditioning systemsSamiYousifNo ratings yet

- Leading Heat Transfer Oil Data SheetDocument3 pagesLeading Heat Transfer Oil Data SheetHamid KharazmiNo ratings yet

- Heat Transfer Lab ReportDocument7 pagesHeat Transfer Lab Reportمحمود محمدNo ratings yet

- Shell Lubricants HandBookDocument358 pagesShell Lubricants HandBookjizu100% (1)

- Cooling tower air and water mass flow ratesDocument3 pagesCooling tower air and water mass flow ratesSundar DAACNo ratings yet

- Jacketed Vessel DesignDocument4 pagesJacketed Vessel Designhero100% (1)

- Thesis On Design of Heat ExchangerDocument7 pagesThesis On Design of Heat ExchangerSandra Valenzuela100% (2)

- Work Bench VerificationDocument220 pagesWork Bench Verificationchkarthiksai0% (1)

- Module-III: Subject Code: FOOD315 Subject Name: Food Engineering-II PsychometricsDocument10 pagesModule-III: Subject Code: FOOD315 Subject Name: Food Engineering-II PsychometricsShubham MannaNo ratings yet

- Bioseparation Dr. Kamal E. M. Elkahlout: Mass TransferDocument56 pagesBioseparation Dr. Kamal E. M. Elkahlout: Mass TransferKemal ELkahloutNo ratings yet

- Thesis Proposal Abstract SampleDocument8 pagesThesis Proposal Abstract SampleMichael Christian Silvestre JaramillaNo ratings yet

- Colegio de Santa Catalina de Alejandria Review Materials On Fire Tech. and Arson Investigation By: Sir Bimboy C. Cueno, CRMGST, MSCJDocument6 pagesColegio de Santa Catalina de Alejandria Review Materials On Fire Tech. and Arson Investigation By: Sir Bimboy C. Cueno, CRMGST, MSCJBimboy CuenoNo ratings yet

- BNBC HVAC PWD Course Materials 19 MayDocument51 pagesBNBC HVAC PWD Course Materials 19 Mayfakir mohammadNo ratings yet

- Aaon - WV Vertical WSHP IOM (April 2019)Document56 pagesAaon - WV Vertical WSHP IOM (April 2019)Trever TomesNo ratings yet

- Application Guide and Service Manual: Air Conditioners and Heat Pumps Using R-22 RefrigerantDocument52 pagesApplication Guide and Service Manual: Air Conditioners and Heat Pumps Using R-22 RefrigerantDesiderio BourdetNo ratings yet

- 2014 Marine Air PricebookDocument116 pages2014 Marine Air Pricebooknwmarineair2869No ratings yet

- Basics of Heat Transfer: 1.1 Difference Between Heat and TemperatureDocument179 pagesBasics of Heat Transfer: 1.1 Difference Between Heat and TemperatureJam Arun Kumar100% (2)

- Developing Heat Transfer in Rectangular Channels With Rib TurbulatorsDocument13 pagesDeveloping Heat Transfer in Rectangular Channels With Rib Turbulatorshamid_zoka6069No ratings yet

- Nursing Diagnosis Nursing Goals Nursing Outcome: (Goal Attainable Within The Shift) (With Rationale & Source)Document2 pagesNursing Diagnosis Nursing Goals Nursing Outcome: (Goal Attainable Within The Shift) (With Rationale & Source)merryNo ratings yet

- Programmable Touchscreen Thermostat: Ideal For Light Commercial ApplicationsDocument2 pagesProgrammable Touchscreen Thermostat: Ideal For Light Commercial ApplicationsnasierrasNo ratings yet

- Matrix Analysis of Heat Transfer Problems: e (X, T) I (X, T)Document12 pagesMatrix Analysis of Heat Transfer Problems: e (X, T) I (X, T)Anders AguilarNo ratings yet

- Botany SyllabusDocument30 pagesBotany SyllabusKuljeet KasniyaNo ratings yet

- Heater Selection GuideDocument2 pagesHeater Selection Guidemacanipharoldf6220No ratings yet

- HCHEDocument6 pagesHCHEbacbk.dvNo ratings yet

- Copeland Selection Software: Version 7.16 / 43364 (09/18) WWW - Emersonclimate.euDocument2 pagesCopeland Selection Software: Version 7.16 / 43364 (09/18) WWW - Emersonclimate.euChandrashekhar Saraf0% (1)

- How to Account for System Effects in Fan Performance CurvesDocument51 pagesHow to Account for System Effects in Fan Performance CurvesVivek P P100% (2)