Professional Documents

Culture Documents

Welding

Uploaded by

Brandon AllenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding

Uploaded by

Brandon AllenCopyright:

Available Formats

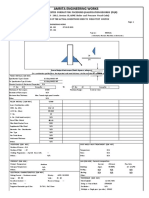

Benchmark Problem 1 A six-pass plate welding problem from literature [1] is used to illustrate the application of the Abaqus

Welding Interface (AWI) to setup welding simulations. The problem consists of two low carbon steel flat plates of size 150 X 140 X 12 mm, that form a V-groove between them, welded together in six passes. In [1], temperature histories at select locations in both the left and the right plates obtained from thermocouple measurements during welding are reported. The finite element mesh used for the AWI model of the same plate problem is shown in Fig. 1. The locations where the temperature histories will be monitored are highlighted in Fig. 2 & 3, and match the thermocouple locations from [1]. The material properties and film coefficients for convective cooling are the same as what was used in [2], where the same plate problem was analyzed.

Figure 1 Finite element mesh of the plate welding problem

Figure 2 Top view of the meshed plate showing thermocouple locations

Figure 3 Side view of the meshed plate showing thermocouple locations

Input Parameters and Options for the AWI Model of the Plate. A target torch temperature of 2800 F was assumed, and each bead was subdivided into ten (element-based) chunks (Fig. 4). In general, with the prescribed temperature approach, temperature magnitude above liquidus temperature will need to be used to ensure adequate penetration of heat. In the present example, the liquidus temperature is approximately 2700 F. A total torch time of 6.2 seconds was used for each chunk, based on the average of the torch speeds for the six passes for the particular case presented in [1]. The ramp and hold option was used, with the temperature ramped up to target temperature over 10 % of the torch time and held constant for the remainder of the torch time for each chunk. A two-minute interpass cool-down step was also inserted between all passes, consistent with the welding process described in [1]. This was easily accomplished by utilizing the user-defined step option provided by the AWI, which allows extra analysis steps to be inserted within any weld pass, in addition to the standard steps created for all passes in the AWI.

Figure 4 Division of beads into discrete chunks in the torch direction

Results. A direct comparison of the predicted temperature results from the AWI model to the thermocouple data from [1] is not attempted (primarily due to insufficient information on the total time scale of the results presented in [1]), but the AWI results shown in Fig. 5 & 6 reproduce the trends well as compared to the data reported in [1]. Since a precise control of energy input is not possible when the temperature-based heat input is used, some trial and error with respect to parameters such as the number of discrete chunks the bead is subdivided into in the torch direction, the target torch temperature used for the temperature boundary condition, time to ramp up to the torch temperature, and the time the boundary is held at torch temperature would be necessary to calibrate and benchmark different classes of welding problems. The sum of the nodal reaction fluxes (variable RFLE) in the whole model can be compared with the desired power input during these trial-and-error runs. AWI makes it easy to change any of the parameters related to welding model setup and regenerate the model, and can be used within an optimization loop with a program such as Isight (which has a data matching component) to determine the correct values of the parameters.

Figure 5 Predicted thermal histories at left plate TC locations from AWI model

Figure 6 Predicted thermal histories at right plate TC locations from AWI model

References [1] S. Murugan, P.V. Kumar, B. Raj, M.S.C. Bose, Temperature distribution during multipass welding of plates, International Journal of Pressure Vessels and Piping 75 (1998) 891905. [2] David J. Dewees, Comparison of 2d and 3d welding simulations of a simple plate, Proceedings of the ASME 2012 Pressure Vessels & Piping Division Conference, July 15-19 (2012), Toronto, Ontario, Canada

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- E BrochureDocument17 pagesE BrochureBrandon AllenNo ratings yet

- Time Table Deptl Test July 2017Document21 pagesTime Table Deptl Test July 2017Brandon AllenNo ratings yet

- The Fertilisers and Chemicals Travancore LimitedDocument31 pagesThe Fertilisers and Chemicals Travancore LimitedBrandon AllenNo ratings yet

- Ticf Hm´¿ Atxm-Dn‰N: 2016 Unkw- - -Dn¬ /S-°P∂ Πw - Nwkv Ssek≥Kv) Co-£-Bv°P≈ At) £Document8 pagesTicf Hm´¿ Atxm-Dn‰N: 2016 Unkw- - -Dn¬ /S-°P∂ Πw - Nwkv Ssek≥Kv) Co-£-Bv°P≈ At) £Brandon AllenNo ratings yet

- 001 How To Prepare IES, GATE & PSU Using My Notes IES AcademyDocument9 pages001 How To Prepare IES, GATE & PSU Using My Notes IES AcademyAtul kumar Kushwaha100% (2)

- Power PlantDocument15 pagesPower PlantBuckshu PhdNo ratings yet

- Unit 1 Introduction To Automobile Engineering: StructureDocument6 pagesUnit 1 Introduction To Automobile Engineering: StructureSeth BeckNo ratings yet

- Time Table Deptl Test July 2017Document21 pagesTime Table Deptl Test July 2017Brandon AllenNo ratings yet

- Syllabus Technicial SupervisorDocument6 pagesSyllabus Technicial SupervisorBrandon AllenNo ratings yet

- Vocational Teacher (Maintenance and Repairs of Automobiles)Document7 pagesVocational Teacher (Maintenance and Repairs of Automobiles)Brandon AllenNo ratings yet

- Reduce Leaks: Using Water Audits and Leak Detection SurveysDocument6 pagesReduce Leaks: Using Water Audits and Leak Detection SurveysBrandon AllenNo ratings yet

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- Linear AlgebraDocument1 pageLinear AlgebraBrandon AllenNo ratings yet

- Turnaround ManagementDocument7 pagesTurnaround ManagementBrandon AllenNo ratings yet

- M.E. MANUFACTURING ENGINEERING AU SyllabusDocument35 pagesM.E. MANUFACTURING ENGINEERING AU SyllabusJoswa CaxtonNo ratings yet

- Nitcalicut ME 2006Document56 pagesNitcalicut ME 2006Brandon AllenNo ratings yet

- Me 601Document4 pagesMe 601Deepak SunilNo ratings yet

- 88Document3 pages88Brandon AllenNo ratings yet

- Drdo Syllabus MechanicalDocument2 pagesDrdo Syllabus MechanicalArvind SinghNo ratings yet

- Ee010 306 (Me) Mechanical TechnologyDocument2 pagesEe010 306 (Me) Mechanical TechnologyBrandon AllenNo ratings yet

- (Engineering) - : B.Tech. Degree Examtnation, DecemberDocument2 pages(Engineering) - : B.Tech. Degree Examtnation, DecemberBrandon AllenNo ratings yet

- 88Document3 pages88Brandon AllenNo ratings yet

- Drdo Syllabus MechanicalDocument2 pagesDrdo Syllabus MechanicalArvind SinghNo ratings yet

- SCM Presen 14Document6 pagesSCM Presen 14Brandon AllenNo ratings yet

- Changing Role of Trade UnionsDocument3 pagesChanging Role of Trade UnionsBrandon AllenNo ratings yet

- Crack Growth Modelling in Industrial Welded StructuresDocument1 pageCrack Growth Modelling in Industrial Welded StructuresBrandon AllenNo ratings yet

- Introduction To GearsDocument28 pagesIntroduction To Gearssandeep_gaikwad2100% (4)

- DrillingDocument27 pagesDrillingBrandon AllenNo ratings yet

- BearingsDocument18 pagesBearingsBrandon AllenNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- V12 TIG JT200DS Mini Digital ManualDocument56 pagesV12 TIG JT200DS Mini Digital Manualoscar martinezNo ratings yet

- Method Statement For PRE-ENGINEERED BUILDING ASSEMBLYDocument39 pagesMethod Statement For PRE-ENGINEERED BUILDING ASSEMBLYStephanie EmersonNo ratings yet

- Clancy Walthers ResumeDocument1 pageClancy Walthers Resumeapi-372163418No ratings yet

- Steel Tubes For Mechanical AND Genewl Eng Eewg Purposes - SpecificationDocument20 pagesSteel Tubes For Mechanical AND Genewl Eng Eewg Purposes - SpecificationSajal DeyNo ratings yet

- Underwater Welding EssayDocument11 pagesUnderwater Welding Essayapi-248835946No ratings yet

- GE Inspection Technologies Angle Beam Transducers - InstrumartDocument5 pagesGE Inspection Technologies Angle Beam Transducers - InstrumartFethi BELOUISNo ratings yet

- General Solution Eccentric Loads Weld Groups PDFDocument10 pagesGeneral Solution Eccentric Loads Weld Groups PDFclam2014No ratings yet

- T TH HE EA AR RC CW WE EL LD Diin NG GB BO OO OK KS SH HE EL LF FDocument4 pagesT TH HE EA AR RC CW WE EL LD Diin NG GB BO OO OK KS SH HE EL LF FCoordinador - MantenimientosNo ratings yet

- PM1155 Load Cell Installation Guidelines V1.0Document16 pagesPM1155 Load Cell Installation Guidelines V1.0Akrom77khasaniNo ratings yet

- Metals Industry Journals&MagazinesDocument9 pagesMetals Industry Journals&MagazinesSarav AnanNo ratings yet

- Coursework Enm302 Salim-GDocument14 pagesCoursework Enm302 Salim-GgaddasalimNo ratings yet

- Technical Specifications BAMULDocument133 pagesTechnical Specifications BAMULjaya100% (1)

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNo ratings yet

- Data Sheet VDM Alloy 59Document16 pagesData Sheet VDM Alloy 59Iniyan Thiruselvam Navaladi KarthikeyanNo ratings yet

- Al-Cu-Si General Purpose Casting Alloy: WeldabilityDocument1 pageAl-Cu-Si General Purpose Casting Alloy: Weldabilitymanjunath k sNo ratings yet

- RDSO Vendor1Document169 pagesRDSO Vendor1adarshietk100% (1)

- JNKI-SOP-004-Welder Continuity Procedure - RevisionDocument3 pagesJNKI-SOP-004-Welder Continuity Procedure - RevisionAvishek GuptaNo ratings yet

- Obe Curriculum For The Course: RGPV (Diploma Wing) BhopalDocument6 pagesObe Curriculum For The Course: RGPV (Diploma Wing) BhopalRavi Nagar 47No ratings yet

- Inspection, Iso, NDT, Expediting, ProjectsDocument4 pagesInspection, Iso, NDT, Expediting, ProjectsdashNo ratings yet

- Method Statement For Ug Piping 6423dp420!00!00200 00 - Rev03Document20 pagesMethod Statement For Ug Piping 6423dp420!00!00200 00 - Rev03mister pogi100% (2)

- KFC Solano - Strucl - 041217 PDFDocument31 pagesKFC Solano - Strucl - 041217 PDFFroilan EspinosaNo ratings yet

- Investigation of Process Parameters For T-Joint 6061-T6 Aluminum Friction Stir Welding Using Nanocomposites MaterialDocument10 pagesInvestigation of Process Parameters For T-Joint 6061-T6 Aluminum Friction Stir Welding Using Nanocomposites MaterialJose ManuelNo ratings yet

- Usw Review PaperDocument23 pagesUsw Review PaperRahul KumarNo ratings yet

- NCH 2369 of 2003 - Seismic Design For Industrial Structures and FacilitiesDocument126 pagesNCH 2369 of 2003 - Seismic Design For Industrial Structures and Facilitiesoogaz2100% (2)

- Astm A134Document4 pagesAstm A134Francisco HernandezNo ratings yet

- Design and Fabrication Multipurpose Agricultural EquipmentDocument20 pagesDesign and Fabrication Multipurpose Agricultural EquipmentAbhay DesaiNo ratings yet

- DNV OS C104 Elev UnitsDocument26 pagesDNV OS C104 Elev UnitsSaid ElhamydyNo ratings yet

- 08 3 PDFDocument42 pages08 3 PDFmakoi100% (1)

- Container ProcessDocument87 pagesContainer ProcessNarayan RoyalmechNo ratings yet

- Esab Weld 71T - 1Document1 pageEsab Weld 71T - 1Abhishek AnandNo ratings yet