Professional Documents

Culture Documents

A Computational System For Subsea Pipelaying Simulation

Uploaded by

Anwar ALkurayshiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Computational System For Subsea Pipelaying Simulation

Uploaded by

Anwar ALkurayshiCopyright:

Available Formats

INTERNATIONAL JOURNAL OF MODELING AND SIMULATION FOR THE PETROLEUM INDUSTRY, VOL. 3, NO.

1, JUNE 2009

35

A COMPUTATIONAL SYSTEM FOR SUBSEA PIPELAYING SIMULATION

Danilo Machado Lawinscky da Silva, Carl Horst Albrecht, Breno Pinheiro Jacob danilo@lamcso.coppe.ufrj.br, carl@lamcso.coppe.ufrj.br, breno@lamcso.coppe.ufrj.br LAMCSO Laboratory of Computational Methods and Offshore Systems Department of Civil Engineering, COPPE/UFRJ, Rio de Janeiro, RJ, Brazil Isaias Quaresma Masetti, Claudio Roberto Mansur Barros, Arthur Curty Saad masetti@petrobras.com.br, claudio.mansur@petrobras.com.br, arthur.saad@petrobras.com.br PETROBRAS Petrleo Brasileiro S.A.

Abstract. Traditional analysis methods for pipelaying simulation consider an uncoupled model where the motions of the barge are previously determined, without taking into account the influence of the pipeline, and are then prescribed at the top of the pipeline. Currently, the analyses of pipelaying operations have been performed by commercial softwares, such as OffPipe. However, such tools presents restrictions/limitations related to the user interface, model generation and analysis formulations. These limitations hinder its efficient use for analyses of installation procedures for the scenarios considered by Petrobras, using the BGL-1 barge or other vessels. Therefore, the objective of this work is to present a computational tool in which the modules follow the Petrobras users specifications. The main objective of such tool is to overcome the limitations for specific needs and particular scenarios in the simulation of several types of pipeline procedures. Such tool, called SITUA-PetroPipe, presents an extremely friendly interface with the user, for instance allowing the complete customization of the configuration of laybarge and stinger rollers, and includes novel analysis methods and formulations, for instance the ability of coupling the structural behaviour of the pipe with the hydrodynamic behaviour of the vessel motions under environmental conditions. Several simulations of actual operations are shown, in order to illustrate the application of this new computational tool. Keywords: Numerical Methods, Offshore Operations, Pipeline Installation Procedures 1 - INTRODUCTION Installation of pipelines and flowlines constitute some of the most challenging offshore operations. The technical challenges have spawned significant research and development efforts in a broad range of areas, not only in studies regarding different installation methods, but also in the formulation and implementation of new computational tools required to the numerical simulation. This work addresses this latter issue. The most common installation methods are the S-Lay, J-Lay,

and Reel-Lay methods, schematically shown in Fig. 1, and Towing methods, schematically shown in Fig. 2 (Guo, Bai, 2005; Kyriakides,2007).

Figure 1 S-Lay, J-Lay and Reel-Lay Methods.

In the S-Lay method, as the laying barge moves forward, the pipe is eased off the stern, curving downward through the water until it reaches the touchdown point. After touchdown, as more pipe is played out, it assumes the S shaped curve. To reduce bending stress in the pipe, a stinger is used to support the pipe as it leaves the barge. To avoid buckling of the pipe, a tensioner must be used to provide appropriate tensile load to the pipeline (Clauss,1998). This method is used for pipeline installations in a range of water depths from shallow to deep. In the J-lay method, the pipe is dropped down almost vertically until it reaches touchdown; after that it assumes the J shaped curve. J-Lay barges have a tall tower on the stern to weld and slip pre-welded pipe sections. With the simpler pipeline shape, the J-Lay method avoids some of the difficulties of S-Laying such as tensile load forward thrust, and can be used in deeper waters. In the Reel-Lay method, the pipeline is installed from a huge reel mounted on an offshore vessel. Pipelines are assembled at an onshore spool-base facility and spooled

36

INTERNATIONAL JOURNAL OF MODELING AND SIMULATION FOR THE PETROLEUM INDUSTRY, VOL. 3, NO.1, JUNE 2009

onto a reel which is mounted on the deck of a pipelay barge. Horizontal reels lay pipe with an S-Lay configuration. Vertical reels most commonly do J-Lay, but can also S-Lay. Towing methods basically consists in weld the pipeline onshore with an onshore pipeline spread. Once the pipeline is complete and hydrotested, the pipeline is dewatered and moved into the water, while being attached to a tow vessel. It is then towed to an offshore location where each end is connected to pre-installed facilities (Silva,2007b,2008). There are four variations of the towing method: surface tow, mid-depth tow, off-bottom tow, and bottom tow (Fig. 2). In the surface tow approach, buoyancy modules are added to the pipeline so that it floats at the surface. Once the pipeline is towed on site by one or two tugboats (Silva,2008), the buoyancy modules are removed or flooded, and the pipeline settles to the sea floor. The mid-depth tow requires fewer buoyancy modules, and the pipeline settles to the bottom on its own when the forward progression ceases. The off-bottom tow involves buoyancy modules and chain weights. In the bottom tow, primarily used for soft and flat sea floor in shallow water, the pipeline is towed along the sea floor Towing could be cheaper than other methods that use laybarges. However, a case-by-case analysis is required to determine the cost-benefit ratio.

Figure 3 The BGL-1 Pipeline Launching Barge

The force on the pipeline is reacted at the seabed end of the pipeline by the dead weight of the pipeline and friction between it and the seabed. Obviously the larger the force applied by the tensioners to the pipeline, the more gradual will be the bending radius in the S portion of the laying curve. Also, as the pipe weight increases it is necessary to apply a greater force to the pipe to maintain the desired bend radius and so prevent buckling, particularly in the sag bend portion of the curve (Torselletti,2006).

Figure 2: Tow-in Methods.

2 - PIPELAYING IN OFFSHORE BRAZIL Usual pipelaying operation in offshore Brazil are performed by S-Lay procedures employing the BGL-1 barge (Fig. 3) owned by Petrobras. The BGL-1 is a second-generation anchor positioned laybarge that performs installation operations by moving forward using its own mooring lines. Basically, tug boats drop anchors at some predefined positions; then the barge winches release the stern mooring cables, and collect the mooring cables located at the bow. In order to prevent the pipe from buckling in the regions of maximum bending, the bend radius is controlled by keeping the pipe under tension, so that the pipe actually follows a lazy S shape. The tension is applied to the pipe by tensioners on the barge which are usually arrays of rubber wheels or belts which surround the pipe and apply an axial force to the pipe through the friction generated between the tensioner and the pipe external coating as shown in Fig. 4.

Figure 4 BGL-1 Tensioner.

As individual pipe lengths are welded onto the growing pipeline, the barge is winched forward and the new section of pipeline passes over the stinger towards the seabed. As mentioned before, tugs are used to continuously reposition the anchors ahead of the barge so that it can keep moving forward. 3 - REQUIREMENTS FOR PIPELAYING SIMULATION Traditional analysis methods for pipeline laying consider an uncoupled model, where the motions of the barge are previously determined without taking into account the influence of the pipeline, and are then prescribed at the top of the pipeline. For floating production systems (FPS) under the action of environmental loadings in deepwater scenarios, it has been recognized that the use of coupled dynamic analysis

SILVA et al.: A COMPUTATIONAL SYSTEM FOR SUBSEA PIPELAYING

37

tools is mandatory for the accurate numerical simulation, analysis and design (Ormberg,1997; Wichers,Heurtier,2001; Senra,2002). Coupled analysis formulations consider the non-linear interaction of the hydrodynamic behavior of the FPS hull with the structural/ hydrodynamic behavior of the mooring lines and risers, represented by Finite Element models. In the implementation of such analysis tools, the 6-DOF equations of motion of the platform hull are coupled with the equations of motion of the FEM model of the lines. It can intuitively be seen that the use of coupled formulations is important not only for the design of production platforms, but also for the simulation of offshore installation operations. In the case of pipelines in S-Lay operations, even in shallow waters the motions of the laybarge can be significantly affected by the structural behavior of the pipeline. Also regarding pipelines in S-Lay installation operations, it should be considered that the contact mechanism between the pipeline and the launching structure is complex, specified only in some points of the ramp and stinger. Traditionally, Petrobras has been performing numerical simulations of pipelaying operations employing commercial software, such as OffPipe (Malahy Jr, 1996). However, such tools present limitations related not only to the user interface, but also to the model generation and analysis formulations. These limitations hinder its efficient use for analyses of installation procedures for the scenarios considered by Petrobras, using the BGL-1 barge or other vessels, considering for instance particular types of stingers depending on depth and pipeline, with different lengths and geometries adapted to certain laying conditions in S-Lay procedures. Therefore, the objective of this work is to present the development of a in-house computational tool, referred as SITUAPetroPipe, that overcomes the limitations for specific needs and particular scenarios in the simulation of several types of pipeline procedures, and addresses the requirements regarding the analysis formulations mentioned above. As will be described in the remainder of this work, such tool presents an extremely friendly interface with the user, allowing for instance the complete customization of the configuration of laybarge and stinger rollers. 4 - SITUAPROSIM The SITUA-PetroPipe tool may be seen as specialized modules of the SITUA-Prosim system (Jacob,1997), which has been developed since 1997, in cooperation by Petrobras and LAMCSO (Laboratory of Computer Methods and Offshore Systems, at the Civil Engineering Department of COPPE/UFRJ, Federal University of Rio de Janeiro) . This system constitutes a computational tool that performs coupled static and dynamic nonlinear analyses of a wide range of offshore operations. The PetroPipe modules described here are based in the SITUA graphical interface, and in the Prosim numerical solver (Jacob,2005). This numerical solver comprises a time-domain nonlinear dynamic analysis program, which has been employed by Petrobras since 1998 in several design activities related to floating production systems.

The coupled formulation of the Prosim program incorporates, in the same computational code and data structure, a hydrodynamic model to represent the hull and a finite element model to represent the structural hydrodynamic behavior of the mooring lines, risers and pipelines. This coupled formulation allows the simultaneous determination of the motions of the hull, and the structural response of the lines. Moreover, the results will be more accurate since all dynamic and nonlinear interaction effects between the hull and the lines are implicitly and automatically considered. Details of such coupled model are presented elsewhere (Senra,2002;Jacob,2005), and will not be reproduced here The original Prosim code was oriented towards the analysis and design of FPS, considering their installed and operational situations. Later, the SITUA-Prosim system was developed by incorporating a graphical interface and adapting / specializing the code for the analysis of installation and damage situations (hence its name, from the Portuguese SITUaes de instalao e Avaria). The SITUA interface (Fig. 5) is designed to work as a pre-processor and model generator for the Prosim finite-element based numerical analysis modules, and to provide facilities for statistical and graphical post-processing and visualization of results. The model generation procedures of the interface incorporate an analytical catenary solver, able to represent complex configurations such as lines with multiple segments and different materials, connected to other lines or to platforms, and with flotation elements such as buoys or segments with distributed floaters. The interface allows a very simple and intuitive definition of the model of a line. The user needs only to specify the number, length and type of segments that comprise the line. A database with several material types is incorporated in the system. Another enhanced facility for the definition of lines for actual operations of the BGL barge consists in the definition of two of the parameters that define a catenary (including anchor position, horizontal force, total top axial tension), in a variable-length procedure. The system then automatically adjusts the laid length of the top segment of the mooring line to comply with the given parameters. A series of adaptations and enhancements had already been incorporated in the SITUA-Prosim system, intended to specialize its use for simulation of the BGL-1 mooring procedures. Some highlights of these tools are described in the text that follows; more details can be found in (Masetti,2004).

Figure 5 Main screen of the SITUA-Prosim System.

38

INTERNATIONAL JOURNAL OF MODELING AND SIMULATION FOR THE PETROLEUM INDUSTRY, VOL. 3, NO.1, JUNE 2009

4.1 - Interaction with Seabed The computational tool is able to incorporate the correct definition of the seabed from bathymetric curves. It can also automatically consider the position of the subsea obstacles, and determine possible interferences between the mooring lines or the pipeline with obstacles. This is performed through a specialized interface with the SGO (Obstacles Management System) database system. This system, developed by Petrobras, contains frequently updated information about the bathymetry and position of subsea obstacles, gathered by a special vessel equipped with a ROV (Remote Operated Vehicle) (2002). The seabed is modeled by a surface mesh in which the z-coordinate represents the depth. Soil-pipe interaction effects are modeled through nonlinear scalar elements associated to each node that comprises the spatial discretization of the pipeline. Such scalars act on the seabed, representing the friction between pipe and soil, and also as contact springs on the vertical direction (Saevik,2004; Michalopoulos,1986). Friction effects on the seabed are represented by an elastoplastic formulation that allows the consideration of anisotropic friction, through the definition of distinct soilresistance coefficients for the axial and lateral directions of the pipeline (Silva,2006a). 4.2 - Barge Motion and Interference Management Modules As mentioned before, during pipelaying the barge is moved periodically one pipe length ahead, along a predefined route. The planning of such procedure consists in the definition and charting of a series of points on this route, specifying the positioning of the anchors, the lines, the buoys and the hull of the barge. In order to help the BGL-1 barge crew to develop safe mooring procedures and to define the sequence of mooring operations that leads to the barge motion, the system is able to calculate the motions of the barge due to the operations performed with its mooring lines, leading to changes in their catenary configuration (including placement of buoys, variation of the onboard/released cable lengths, and relocating anchors). During the simulation of such mooring operations by the SITUA interface, a specialized interference management module can be employed to characterize interference situations. Such situations are detected when an obstacle falls into an exclusion volume defined around segments of a line laying on the seabed, and a vertical distance below suspended segments, with risks of collision and damage to the line and/or the obstacle (a manifold, another pipeline, etc.). Figure 6 presents a 3D view where the exclusion region around one line is graphically displayed, showing a possible interference situation with a previously installed pipeline. A more detailed visualization, including the definition of the types of obstacles and distances from the line, can be observed in 2D views such as the depicted in Fig. 7. In these views the interferences are indicated by red arrows, with the corresponding distances, and a tag defining the obstacle.

Once the possible interferences are identified, the BGL-1 operator can take measures to avoid them, including the placement of buoys in given positions along the line. Figure 8 shows a configuration of a mooring line with two buoys, to keep the line suspended well over subsea obstacles.

Figure 6 3D View of Exclusion Region with Interference.

Figure 7 2D View Detailing Interference.

Figure 8 3D View of Mooring Lines with Buoys.

5 - SITUAPETROPIPE As mentioned before, the PetroPipe modules include new tools developed following the Petrobras users specifications. These tools are intended to automate the generation of numerical models for the simulation of pipeline installation procedures (for instance, allowing the complete customization of the configuration of the laybarge and stinger rollers). Moreover, the PetroPipe modules address the requirements regarding the analysis formulations mentioned in a preceding section, including the coupling of the structural behavior of the pipe with the hydrodynamic behavior of the vessel motions. Also, the contact of lines (mooring lines, risers, pipelines) with the platform can be rigorously modeled during

SILVA et al.: A COMPUTATIONAL SYSTEM FOR SUBSEA PIPELAYING

39

a nonlinear dynamic analysis, as well as the contact involving different lines or even the contact of one line with itself. 5.1 - Modeling of Contact Traditional contact models consider for instance a generalized scalar element, consisting of two nodes linked by a non-linear gap spring (Grealish,2005). Here, the contact model consists of a generalized elastic surface contact algorithm. The contact is modeled by augmentation of the global stiffness matrix, based on the orientation and contact stiffness of the contact surfaces. Details of this algorithm are presented in (Silva,2006a,2007a). The algorithm has been shown to be able of capturing the detailed characteristics of the interaction between mooring lines, risers, pipelines, hulls, in a sophisticated model such as the illustrated in Fig. 9, depicting the contact between the pipeline and the rollers of the laybarge stinger. A more detailed example will be presented in the application presented later.

Response Delay Whenever the pipe tension leaves the operational range, the tensioner is activated but only after a given time delay, when it effectively starts working. Response Velocity After the tensioner effectively starts working, it does not restore the tension level immediately, but after a certain period defined by its design response velocity. Displacement Limit This defines the limit in which the tensioner can move the pipeline back and forth in order to compensate its tension level.

Figure 9 Contact Model.

5.2 - Tensioner Model As mentioned before, the tensioner (Fig. 4) is intended to control the tension level in the pipeline during the pipelaying operation, by keeping it within a feasible operational range. In the PetroPipe modules, the tensioner is represented by a specialized generalized scalar element, automatically added to the pipeline top end, which consists of two nodes linked by a nonlinear gap spring. Force-displacement or stiffnessdisplacement functions associated to each local direction are defined, and the local coordinates systems can also be updated at each simulation step. To simulate the tensioner behavior in keeping the tension level at the defined range, the axial stiffness of this element continually varies, leading to changes in the element length as the pipeline end moves back and forth. It should be recalled that the pipeline end motions are induced by the tensioner behavior and by the barge motions applied at the tensioner. The tensioner model is schematically shown in Fig. 10. All main characteristics of the tensioner machine are incorporated in this model, including: Operational Range defines the range of desired tension values; the tensioner is not activated whenever the pipeline end tension is within this range.

Figure 10 Tensioner Model.

6 - MODELING OF PIPELINE INSTALLATION PROCEDURES In the following sections, the facilities incorporated in the PetroPipe modules are illustrated by their application to real-case pipeline installation scenarios. 6.1 - Lateral Deflection Procedure The Lateral Deflection procedure, associated to towing methods, may be used to move the pipeline into the sea. In this context, it consists basically on deflecting the pipeline to the sea (after assembled at the coastline) using a cable connected to a tug boat. The characterization of the deflection procedure involves the determination of the better velocity and direction of the tug boat when the pipeline is leaving the shore in order to minimize its efforts (especially due to the curvatures). The PetroPipe modules have been employed to model such a procedure for an actual scenario, as presented in (Silva,2007b). Some steps of the results of numerical simulations for this procedure are illustrated in Fig. 11: the pipeline is on shore (1), at the coastline, before starting towing (2), the pipeline leaves shore (3,4) and is towed to the installation site.

40

INTERNATIONAL JOURNAL OF MODELING AND SIMULATION FOR THE PETROLEUM INDUSTRY, VOL. 3, NO.1, JUNE 2009

Figure 11: Lateral Deflection Procedure

A contingency procedure was also analyzed in (Silva,2008), for a situation in which the back tugboat is disconnected and only the front tugboat is pulling the pipeline. This configuration simulates a situation in which one of the tugboats loses control and its cable is disconnected. The results of the analyses indicated that the smaller values of cable tensions were found in configurations where the back tugboat is disconnected, indicating that the best situation occurs when it does not tension the pipe, or simply when it is not connected to the pipe. Therefore, from the results of the numerical simulations, the actual pipeline transportation was performed by Petrobras using only one tugboat, employing a smaller boat only to accompany the transport operation for safety reasons, and to perform the maneuvers needed for the subsequent pipeline launching process. During the operation, all numerical predictions related to the pipeline behavior were confirmed. 6.3 - Shore Pull The shore pull operation illustrated here consists in pulling the pipe from the BGL-1 barge onto the shore by a winch. The winch needs to keep adequate pulling force to ensure that the pipe is maintained under controlled tension within the allowed stress/strain limits. The forces applied must be controlled such that no damage to the pipeline anodes or coating occurs. Buoyancy aids can be used if required to keep pulling tension within acceptable limits. During the numerical simulation by the SITUAPetroPipe system, forces in the pipeline and cable are analyzed including any overloading, friction and dynamic effects that may occur. Figure 14 shows snapshots from the animation of the numerical results, as the pipeline is pulled from the barge and arrives on the shore.

6.2 - Tow-in As mentioned before, tow-in operations are performed in many situations to transport pipelines of several lengths. Usually, Petrobras performs these operations following a lateral deflection procedure such as the previously described. In the typical configuration for surface tow, the pipe is towed using a front and a back tugboat aligned at the transportation route, as shown in Fig. 12. Numerical simulations of actual operations were performed using the SITUA-PetroPipe system, in order to assess the pipeline behavior under environmental loadings. The studies presented in (Silva, 2008) include an alternative configuration, shown in Fig. 13, where the tugboats are not aligned. Smaller values of cable tension were obtained when the pipeline is nearly aligned with the direction of the resultant of the environmental loadings.

Figure 12: Tow-in Typical Configuration.

Figure 13: Tow-in Alternative Configuration.

Figure 14 Shore Pull Operation.

SILVA et al.: A COMPUTATIONAL SYSTEM FOR SUBSEA PIPELAYING

41

7 - GENERATION OF A S-LAY MODEL The complete generation of an S-Lay model using the specialized interface of the SITUA-PetroPipe is described in the following sections. 7.1 - Laybarge Characteristics Figure 15 and Table 1 illustrate the main geometric characteristics of the BGL-1 barge. Detailed actual data, in terms of the geometrical and hydrodynamic characteristics of the BGL-1 hull, were provided by Petrobras and employed to generate the model of the barge hull, represented in Fig. 16. The geometric data are used in the definition of the contact surface of the barge hull.

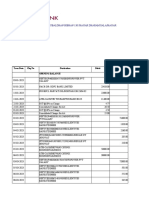

7.2 - Ramp and Stinger Data Figure 17 illustrates the configuration of the ramp and stinger considered for the application described here. The local ramp-stinger coordinate system has its origin on the stern shoe, X-axis positive direction from bow to stern and Z-axis vertical with positive direction upwards, as indicated in Fig. 18. The geometric data of ramp and stinger are summarized in Tables 2 and 3, respectively. The geometric data of the stinger structure are also used in the definition of its contact surface. During the finite element analysis the stinger is considered a rigid body connected to the barge hull and all contact forces acting on it are transferred to the barge. The hydrodynamic characteristics of the stinger are incorporated at the barge hull model by its hydrodynamic coefficients. Figure 19 shows typical configurations for roller boxes on the laybarge stinger and ramp, respectively.

Figure 15 BGL-1 Geometry

Table 1 Main geometric characteristics of BGL-1

Propriety Drought Height Beam Length Values (real scale) 5.182 m 9m 30 m 120 m Figure 17 BGL-1, Ramp and Stinger Geometry

Figure 18 Ramp/Stinger, Local Coordinate System.

Table 2 Ramp radius 150 m

Element Tensioner Roller Box 1 Roller Box 2 Roller Box 3 X (m) -56.335 -38.905 -26.574 -18.078

Figure 16 SITUA-PetroPipe BGL-1 Model

Roller Box 4 Roller Box 5

-9.292 -0.432

Z (m) 1.550 1.094 0.768 0.034 -1.241 -3.157

Length (m) 2.75 2.75 2.75 2.75 3.00

42

INTERNATIONAL JOURNAL OF MODELING AND SIMULATION FOR THE PETROLEUM INDUSTRY, VOL. 3, NO.1, JUNE 2009

Table 3 Stinger radius 150 m

Element Roller Box 1 Roller Box 2 Roller Box 3 Roller Box 4 Roller Box 5 Roller Box 6 Roller Box 7 Roller Box 8a Roller Box 8 X (m) 5.277 9.094 12.856 16.586 20.275 23.882 27.443 29.361 30.883 Z (m) -4.632 -5.825 -7.156 -8.555 -10.099 -11.770 -13.581 -15.198 -15.835 Offset (m) 0.687 0.687 0.694 0.714 0.748 0.793 0.850 0.919 0.950 Length (m) 4.00 4.00 4.00 4.00 4.00 4.00 4.00 ---

Figure 21 Stinger Configuration.

7.3 - Mooring Lines The BGL-1 has eleven fairleads, but in usual operations only nine or ten mooring lines are connected. All mooring lines are composed by two segments, with characteristics presented in Table 4. The length value for segment 2 corresponds to the total length available on the winch drum; the released length varies during the mooring operations, as presented in (Masetti,2004). The catenary solver provides the results defining the equilibrium configuration of the mooring system, and the interference management module allows the identification of several possible interferences with obstacles. All interferences are successfully avoided by placing two buoys on most of the lines. Detailed tables indicating position in the line measured from the anchor, and the length of the pendant for each buoy, can be found in (Masetti,2004).

Figure 19 Configuration of Rollers (Stinger and Ramp)

As mentioned before, this configuration of the laybarge ramp and stinger roller boxes can be easily and completely customized by the new modules of the graphical interface of the SITUA-PetroPipe system, as illustrated in Figs 20, 21 and 22. A general view of the generated model for the BGL-1 is shown in Fig. 22.

Figure 20 Ramp Configuration.

Figure 22 General View of the Generated Model

SILVA et al.: A COMPUTATIONAL SYSTEM FOR SUBSEA PIPELAYING

43

Table 4 Characteristics of Mooring Line Segments

Segment 1 (anchor) 2 Length (m) 150 1780 (max) Material R3S Stub Chain 3 EEIPS Steel Wirerope 2.5

7.4 - Pipeline All pipeline characteristics can be defined by the user. A database with common material properties and usual pipeline characteristics, such as wall thickness and coating, is incorporated in the system. The model generated here considers a typical 16-in pipeline, with physical and geometric properties presented in Table 5. Table 5 16 Pipeline data

Parameter Outside Diameter Wall Thickness Yield Stress Modulus of Elasticity of steel Axial Stiffness (EA) Flexional Stiffness (EI) Poisson Coefficient Density of steel Corrosion Coating Thickness Corr. Coating Weight Density Concrete Coating Thickness Concrete Coating Weight Density Hydrodynamic Diameter Tube Length Field Joint Length Joint Fill Weight Density Weight in Air Weight Submerged Value 0.40640 0.011125 414000 207000 2859694.14 55894.90 0.3 77 0.0032 9.32 0.0381 21.974 0.489 12 0.6 10.065 2.255935 0.368493 Unit m m kN/m2 MPa kN kN*m2 kN/m3 m kN/m3 m kN/m3 m m m kN/m3 kN/m kN/m Figure 23 SITUA-PetroPipe S-Lay Model

7.6 - Typical Results Besides typical results in terms of tension and Von Mises stresses along the pipe length, as shown in Figs 24 and 25, information about distances between the pipeline and its supports as well as the reaction at each roller box are generated during static and dynamic analyses. Specific reports are automatic generated for relevant information such as distance from the laybarge stern and the pipeline touchdown point. Reports for all relevant information about the mooring lines are also automatic generated.

7.5 - Visualization of the Complete Model The initial equilibrium configuration of the pipeline is generated using dynamic relaxation techniques as proposed in (Silva,2006b). The top tension in the pipeline is the parameter that defines the S shape. The generated S-Lay configuration is shown in the figures that follow. The actual bathymetric data and soil properties are considered for the pipeline behavior on seabed. Information about free-spans is then available during analysis.

Figure 24 Von Mises Stress (static).

44

INTERNATIONAL JOURNAL OF MODELING AND SIMULATION FOR THE PETROLEUM INDUSTRY, VOL. 3, NO.1, JUNE 2009

of the coupled model (barge + mooring lines + pipeline) on the dynamic pipeline-laybarge behavior in such different scenarios, indicating where a coupled pipelay analysis, rather than a traditional uncoupled analysis, is required.

Figure 25 Von Mises Stress (dynamic).

Acknowledgements The authors would like to acknowledge the members of the BGL-1 crew that actively contributed with the development of the SITUA-PetroPipe software, with valuable comments and suggestions. REFERENCES BAI, Y., BAI Q., 2005, Subsea Pipelines and Risers, Great Britain, Elsevier Science, 2d Ed. CLAUSS, G.F., SAROUKH, A., WEEDE, H., 1998, Prediction of Limiting Sea States for Pipelaying Operations. Procs of the 17th Int. Conf. on Offshore Mechanics and Arctic Engineering, Lisbon, Portugal. GREALISH, F., LANG, D., CONNOLLY, A., LANE, M., 2005, Advances in Contact Modelling for Simulation of Deepwater pipeline Installation, Rio Pipeline Conference & Exposition, Rio de Janeiro, Brazil. GUO, B., SONG, S., CHACKO, J., GHALAMBOR, A., 2005, Offshore Pipelines, United States, Elsevier. HEURTIER, J.M., BUHAN, P.LE, FONTAINE, E., CUNFF, C.L., BIOLLEY, F., BERHAULT, C., 2001, Coupled Dynamic Response of Moored FPSO with Risers. Procs. of the 11th Intl Offshore and Polar Engineering Conference, Stavanger, Norway. JACOB, B.P., MASETTI, I.Q., 1997, Prosim: Coupled Numerical Simulation of the Behavior of Moored Units (in Portuguese), COPPETEC-Petrobras Internal Report, Rio de Janeiro. JACOB, B.P., 2005, Prosim Program: Coupled Numerical Simulation of the Behavior of Moored Floating Units Theoretical Manual, ver. 3.0 (in Portuguese), LAMCSO/PEC/ COPPE, Rio de Janeiro. KYRIAKIDES, S., CORONA, E., 2007, Mechanics of Offshore Pipelines, Volume 1: Buckling and Collapse, Slovenia, Elsevier. MALAHY Jr, R.C., 1996, OffPipe Users Guide - Version 2.05. MASETTI, I.Q., BARROS, C.R.M., JACOB, B.P., ALBRECHT, C.H., LIMA, B.S.L.P., SPARANO, J.V., 2004, Numerical Simulation of the Mooring Procedures of the BGL-1 Pipeline Launching Barge. Procs of the 23st Int. Conf. on Offshore

8 - FINAL REMARKS The in-house computational system described in this work has already been employed by the BGL-1 crew in the simulation and planning of actual mooring procedures for pipeline laying operations in Campos Basin. The system has been shown to be able to calculate the motions of the barge due to the operations performed with its mooring lines (including placement of buoys, and variation of the onboard/released cable lengths), taking into account general seabed data and interferences with subsea obstacles. Regarding the simulation of the actual pipeline launching process, the Prosim finite-element numerical solver already included a 3D frame element that can account for all material and geometrically nonlinear effects that arise in the pipeline behavior during the laying operation. It was also able to couple the structural behavior of the pipe with the hydrodynamic behavior of the vessel motions under environmental conditions, considering all mooring lines also modeled by Finite Elements, which in itself is a step further over traditional methods for the numerical simulation of pipelaying operations. In order to comprise an accurate and user-friendly alternative for the analysis of pipeline installation procedures, some adaptations in the SITUA interface and in the Prosim numerical solver were needed. Therefore, this work described some of the recent implementations that comprise the SITUA-PetroPipe modules, including: a) Generation of initial finite-element meshes for the S-laying configuration of the pipeline by a dynamic relaxation procedure; b) Inclusion of generalized scalar elements to represent the tensioner; c) Implementation of automatic customization facilities for the definition of the ramp and stinger rollers; d) Development of a rigorous contact algorithm to represent the variable contact between the pipeline and the rollers; e) Generation of finite-element models for other types of laying operations that may eventually be considered for the BGL-1 or other laybarges, including J-lay and reeling methods. Due to limitations in space, these latter facilities (regarding J-Lay and Reeling procedures) could not be presented here, and will be demonstrated in future works. As the result of the recent implementations described in this work, the SITUA-PetroPipe system now comprises a computational tool intended to improve the applicability and accuracy of analysis of pipeline installation operations, making the simulations more realistic. Several parametric studies are currently being performed considering the described modeling facilities, for different scenarios including shallow to deep waters, and different pipeline sizes. The results of these studies will also allow the precise assessment of the influence of the application

SILVA et al.: A COMPUTATIONAL SYSTEM FOR SUBSEA PIPELAYING

45

Mechanics and Arctic Engineering, Vancouver, Canada. MICHALOPOULOS, C.D., 1986, Nonlinear Random Response of Marine Pipelines in Contact with the Seabed. Proceedings of the 5th Int. Conf. on Offshore Mechanics and Arctic Engineering, Tokyo, Japan. ORMBERG, H., FYLLING I. J., LARSEN K., SODAHL N., 1997, Coupled Analysis of Vessel Motions and Mooring and Riser System Dynamics. Procs of the 16th Int. Conf. on Offshore Mechanics and Arctic Engineering, Yokohama, Japan. SENRA, S.F., CORRA, F.N., JACOB, B.P., MOURELLE, M.M., MASETTI, I.Q., 2002, Towards the Integration of Analysis and Design of Mooring Systems and Risers: Part I Studies on a Semisubmersible Platform. Procs of the 21st Int. Conf. on Offshore Mechanics and Arctic Engineering, Oslo, Norway. SAEVIK, S., GIERTSEN, E., BERNTEN, V., 2004, Advances in Design and Installation Analysis of Pipelines in Congested Areas with Rough Seabed Topography. Procs of the 23rd Int. Conf. on Offshore Mechanics and Arctic Engineering, Vancouver, Canada. SILVA, D.M.L., CORRA, F.N., JACOB, B.P., 2006a. A Generalized Contact Model for Nonlinear Dynamic Analysis of Floating Offshore Systems. Procs of the 25st Int. Conf. on Offshore Mechanics and Arctic Engineering, Hamburg, Germany. SILVA, D.M.L., JACOB, B.P., RODRIGUES, M.V., 2006b. Implicit and Explicit Implementation of the Dynamic Relaxation Method for the Definition of Initial Equilibrium Configurations of Flexible Lines. Procs of the 25st Int. Conf. on Offshore Mechanics and Arctic Engineering, Hamburg, Germany. SILVA, D.M.L., PEREIRA, A.C.P., JACOB, B.P., 2007a. A Contact Model for the Simulation of Line Collision in Offshore Oil Exploitation. Procs of the XXVIII Latin American Congress on Computational Methods in Engineering, The Port City, Portugal. SILVA, D. M. L., BAHIENSE, R.A., JACOB, B.P., TORRES, F.G.S., MEDEIROS, A.R., COSTA, M.N.V., 2007b. Numerical Simulation of Offshore Pipeline Installation by Lateral Deflection Procedure. Procs of the 26st Int. Conf. on Offshore Mechanics and Arctic Engineering, San Diego, USA. SILVA, D. M. L., BAHIENSE, R.A., JACOB, B.P., TORRES, F.G.S., MEDEIROS, A.R., 2008. Analysis of an Alternative Pipeline Installation Procedure that Combines Onshore Deflection and Offshore Transportation. Procs of the Marine Operations Specialty Symposium, Singapore. TORSELLETTI, E., VITALI, L., BRUSCHI, R., LEVOLD, E.,

COLLBERG, L., 2006, Submarine Pipeline Installation Joint Industry Project: Global Response Analysis of Pipeline During S-Laying. Procs of the 25th Int. Conf. on Offshore Mechanics and Arctic Engineering, Hamburg, Germany. WICHERS, J.E.W., DEVLIN, P.V., 2001, Effect of Coupling of Mooring Lines and Risers on the Design Values for a Turret Moored FPSO in Deep Water of the Gulf of Mexico. Procs. of the 11th Intl. Offshore and Polar Engineering Conference, Stavanger, Norway. ___, 2002. SGO User Manual (in Portuguese) Petrobras, Rio de Janeiro.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 151Document7 pages151Anwar ALkurayshiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 4Document8 pages4Anwar ALkurayshiNo ratings yet

- Deep Water PipelineDocument9 pagesDeep Water PipelineAnna Yunita Sitompul100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Optimum Design of Structures With Stress and Displacement Constraints Using The Force MethodDocument21 pagesOptimum Design of Structures With Stress and Displacement Constraints Using The Force MethodAnwar ALkurayshiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Wave Loads On Ships Sailing in Restricted Water DepthDocument17 pagesWave Loads On Ships Sailing in Restricted Water DepthAnwar ALkurayshiNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 5Document8 pages5Anwar ALkurayshiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Seabed Interaction Effects On Stress Distribution Along The J-Lay PipelinesDocument1 pageSeabed Interaction Effects On Stress Distribution Along The J-Lay PipelinesAnwar ALkurayshiNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Analytical Approximations For Offshore Piplaying ProblemsDocument10 pagesAnalytical Approximations For Offshore Piplaying ProblemsAnwar ALkurayshiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Computational Fluid Dynamics Modelling of Pipe Soil Interaction in CurrentDocument5 pagesComputational Fluid Dynamics Modelling of Pipe Soil Interaction in CurrentGuomin JiNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Seismic Analysis of Suspended Submarine PipelinesDocument5 pagesSeismic Analysis of Suspended Submarine PipelinesAnwar ALkurayshiNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Modeling and Control of Offshore Pipelay Operations Based On A Finite Strain Pipe ModelDocument6 pagesModeling and Control of Offshore Pipelay Operations Based On A Finite Strain Pipe ModelAnwar ALkurayshiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Modeling and Control of Offshore Pipelay Operations Based On A Finite Strain Pipe ModelDocument6 pagesModeling and Control of Offshore Pipelay Operations Based On A Finite Strain Pipe ModelAnwar ALkurayshiNo ratings yet

- Wave Loads On Ships Sailing in Restricted Water DepthDocument17 pagesWave Loads On Ships Sailing in Restricted Water DepthAnwar ALkurayshiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 16Document1 page16Anwar ALkurayshiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Stress Analysis of Submarine Pipeline During InstallationDocument1 pageStress Analysis of Submarine Pipeline During InstallationAnwar ALkurayshiNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 151Document7 pages151Anwar ALkurayshiNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Wave Induced Uplift Forces Acting On Half-Buried SubmarineDocument11 pagesWave Induced Uplift Forces Acting On Half-Buried SubmarineAnwar ALkurayshiNo ratings yet

- Stress Analysis of Submarine Pipeline During InstallationDocument1 pageStress Analysis of Submarine Pipeline During InstallationAnwar ALkurayshiNo ratings yet

- Windows-1256 - Bending Stresses From External Loading On Buried PipeDocument10 pagesWindows-1256 - Bending Stresses From External Loading On Buried PipeAnwar ALkurayshiNo ratings yet

- Evaluation of Stability of Seabed AroundDocument15 pagesEvaluation of Stability of Seabed AroundAnwar ALkurayshiNo ratings yet

- Group Members: - Muhamad Sahli B Muda - Nurul Hana Balqis Baharom - Napsiah Abdul RahmanDocument18 pagesGroup Members: - Muhamad Sahli B Muda - Nurul Hana Balqis Baharom - Napsiah Abdul RahmanNurul Hana BalqisNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Calendar of Activities A.Y. 2015-2016: 12 Independence Day (Regular Holiday)Document3 pagesCalendar of Activities A.Y. 2015-2016: 12 Independence Day (Regular Holiday)Beny TawanNo ratings yet

- God Reproducing Himself in UsDocument6 pagesGod Reproducing Himself in UsLisa100% (1)

- Sustainable Strategic Management BarbosaDocument11 pagesSustainable Strategic Management BarbosapurwawardhaniNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Perception of Luxury Cars MA Thesis 25 03Document60 pagesThe Perception of Luxury Cars MA Thesis 25 03Quaxi1954No ratings yet

- VTB Datasheet PDFDocument24 pagesVTB Datasheet PDFNikola DulgiarovNo ratings yet

- UserProvisioningLabKit 200330 093526Document10 pagesUserProvisioningLabKit 200330 093526Vivian BiryomumaishoNo ratings yet

- Panera Bread Case StudyDocument28 pagesPanera Bread Case Studyapi-459978037No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresDocument39 pagesCode of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresIshor ThapaNo ratings yet

- Taylorism vs. FordismDocument2 pagesTaylorism vs. FordismLiv Maloney67% (3)

- Pizza Restaurant PowerPoint TemplatesDocument49 pagesPizza Restaurant PowerPoint TemplatesAindrila BeraNo ratings yet

- Democracy or Aristocracy?: Yasir MasoodDocument4 pagesDemocracy or Aristocracy?: Yasir MasoodAjmal KhanNo ratings yet

- Present Perfect Simp ContDocument14 pagesPresent Perfect Simp ContLauGalindo100% (1)

- C103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratoriesDocument19 pagesC103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratorieshuidhyiuodghNo ratings yet

- Sub-Wings of YuvanjaliDocument2 pagesSub-Wings of Yuvanjalin_tapovan987100% (1)

- Collins Ks3 Science Homework Book 3Document5 pagesCollins Ks3 Science Homework Book 3g3pz0n5h100% (1)

- Lesson Plan Letter SDocument4 pagesLesson Plan Letter Sapi-317303624100% (1)

- DatuinMA (Activity #5 - NSTP 10)Document2 pagesDatuinMA (Activity #5 - NSTP 10)Marc Alen Porlaje DatuinNo ratings yet

- LAB REPORT - MGCLDocument5 pagesLAB REPORT - MGCLKali stringsNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Volcanoes Sub-topic:Volcanic EruptionDocument16 pagesVolcanoes Sub-topic:Volcanic EruptionVhenz MapiliNo ratings yet

- GR 9 Eng CodebDocument6 pagesGR 9 Eng CodebSharmista WalterNo ratings yet

- Derivation Bragg's Snell Law PDFDocument4 pagesDerivation Bragg's Snell Law PDFVaswati BiswasNo ratings yet

- Arc Hydro - Identifying and Managing SinksDocument35 pagesArc Hydro - Identifying and Managing SinkskbalNo ratings yet

- WD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerDocument3 pagesWD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerZowl SaidinNo ratings yet

- XXXX96 01 01 2023to28 08 2023Document18 pagesXXXX96 01 01 2023to28 08 2023dabu choudharyNo ratings yet

- Hackerearth Online Judge: Prepared By: Mohamed AymanDocument21 pagesHackerearth Online Judge: Prepared By: Mohamed AymanPawan NaniNo ratings yet

- Monster Hunter: World - Canteen IngredientsDocument5 pagesMonster Hunter: World - Canteen IngredientsSong HoeNo ratings yet

- Setting and Plot: Old YellerDocument8 pagesSetting and Plot: Old YellerWalid AhmedNo ratings yet

- Nationalism, Feminism, and Modernity in PalestineDocument26 pagesNationalism, Feminism, and Modernity in PalestinebobandjoerockNo ratings yet

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)