Professional Documents

Culture Documents

CS Series Float & Thermostatic Steam Traps

Uploaded by

Gustavo Garces GuerreroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CS Series Float & Thermostatic Steam Traps

Uploaded by

Gustavo Garces GuerreroCopyright:

Available Formats

CS Series Float & Thermostatic Steam Traps

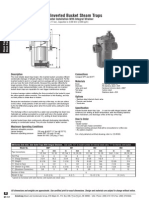

For Pressures to 465 psig (32 bar)...Capacities to 13,281 lb/hr (6,024 kg/hr)

Carbon Steel for Horizontal or Vertical Installation, With Thermostatic Air Vent

Steam Trapping and Steam Tracing Equipment

Body may be rotated 90 to place the inlet on the Top (CST), Right (CSR) or Left (CSL)

D

IN

Top Inlet Configuration (CST) Shown

A Cap

Drain Plug (B)

OUT

ARMSTRONG A216 WCB

UP

Carbon Steel Float & Thermostatic Steam Traps

The simple yet rugged construction of the CS Series Carbon Steel Float and Thermostatic Trap is designed to assure long, trouble-free service. The CS Series offers horizontal or vertical piping configurations from the same trap. Additionally, in-line repairability is very easy because the cap and mechanism detach quickly while the body stays in-line. For added versatility a full range of connection sizes are offered 1/2'' through 2'' in NPT, socketweld and flanged.

Specification

Steam traps shall be float and thermostatic type having carbon steel cap and body, stainless steel valve and seat and stainless steel float. Piping connections shall be in the trap body and shall be capable of being horizontal with the inlet on either side or vertical with the inlet on top. Cap with mechanism shall be completely removable without disturbing the piping. Integral thermostatic element shall be wafer type constructed of Hastelloy and stainless steel. Thermostatic element shall be capable of withstanding 45F (7.2C) of superheat and resistant to water hammer damage. For a fully detailed certified drawing, refer to CD #1123.

Benefits

Horizontal or vertical piping arrangements are available from the same trap Inlet and outlet connections are in the body for easy in-line repairability More connection sizes available

How to Order

Pressure

*

Materials

Body and cap: Internals: Valve(s) and seat(s): Drain plug: Thermostatic air vent:

ASTM A216 WCB All stainless steel Stainless steel Carbon steel Wafer type stainless steel withHastelloyelement

Model

CS

Inlet Flow Direction

T

Connection Size

2 2 = 1/2" 3 = 3/4" 4 = 1" 5 = 1-1/4" 6 = 1-1/2" 8 = 2"

Connection Type

NPT NPT SW Flanged (Specify type and class offlange)

CS = Carbon Steel

T = Vertical Top Inlet R = Horizontal Right Inlet L = Horizontal Left Inlet

*Refer to capacity charts for maximum operating pressures.

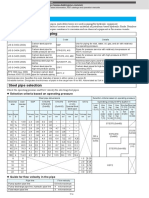

CS Series Float & Thermostatic Steam Traps Body Inlet Orientation Model No. CST Top Inlet Connection CSL Left Inlet Connection CSR Right Inlet Connection in 1/2, 3/4 6-11/16 1/4 6-3/4 8-1/2 28 (13) mm 15, 20 170 6 172 216 in 1, 1-1/4 8-1/8 3/8 8-3/8 10 mm 25, 32 206 10 212 255 in 1-1/2, 2 10-3/4 3/8 11 14-1/4 100 (45) mm 40, 50 274 10 280 362

Connections A Diameter of Flange B Drain Plug (NPT or BSPT) C Face to Face D Overall Length Weight NPT, BSPT & SW lb (kg) Maximum Allowable Pressure (Vessel Design) Maximum Operating Pressure

45 (20) 600 psi @ 650F* (41 bar @ 343C) 465 psi (32 bar)

*Caution: Superheat in excess of 650F (343C) could damage the thermostatic air vent.

134

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacific Rim

armstronginternational.com

CS Series Float & Thermostatic Steam Traps

For Pressures to 465 psig (32 bar)...Capacities to 13,281 lb/hr (6,024 kg/hr) Model CS Series Capacity 1/2'' & 3/4'' Pressure, bar

0.1

2,500 2,000 1,500 2 3 5 7

1/2 & 3/4 Steel F&T

& 1-1/4 Steel F&T Carbon Steel for Horizontal or Vertical Installation, With Thermostatic Air 1 Vent

Steam Trapping and Steam Tracing Equipment

Model CS Series Capacity 1'' & 1-1/4'' Pressure, bar

7

10

0.1

10

7 1,500

75 150 175 225 300 465

1,000

700 500

4,000 3,000 2,500 2,000 1,500

40 65 100 150 200 300 5/16

11/4

1,000

700

1,000

465

Capacity, lb/hr

Capacity, lb/hr

1/8

500 400 300 250 200 150

250 200 150

Capacity, kg/hr

700

300

1,000

700 500 400 300 250 200 150

3/16 5/32 1/8 3/32

300 250 200 150

7/64 3/32 5/64

100

1/16

70 50 5 7

100

70 50 2 3 5 7

100 1

1-1/2 & 2 Steel F&T

7

10

100

1000

Pressure, psi

100 1

10

100

1000

Pressure, psi

Model CS Series Capacity 1-1/2'' & 2''

Pressure, bar 0.1

15,000 12,000 2 3 5 7

10

180

5 6,000 5,000

50

90

10,000 Capacity, lb/hr

7,000 5,000

300 465

1/2 3/8 5/16

2,500 2,000 1,500

3,000 2,500 2,000 1,500

1/4

1,000

700 500 2 3 5 7

1,000 1

10

100

1000

Pressure, psi

When suitable, floats are chosen to maximize the operating pressure and/or the capacity. Therefore, please observe the following limits when conducting a hydrostatic test:

Model CS-2, CS-3 CS-4, CS-5 CS-6, CS-8

Orifice Size All All All

Maximum Hydrostatic Test psi bar 630 44 675 47 700 48

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

Capacity, kg/hr

5/8

3,000

Capacity, kg/hr

11/64

7/32

500

135

North America Latin America India Europe / Middle East / Africa China Pacific Rim

armstronginternational.com

Next

You might also like

- Trampas de Vapor Armstrong, Series880 PDFDocument2 pagesTrampas de Vapor Armstrong, Series880 PDFLuis Guillermo Gallardo BoscanNo ratings yet

- Armstrong - SH Series Bimetallic TrapsDocument2 pagesArmstrong - SH Series Bimetallic TrapsTaylorNo ratings yet

- DeZURIK KCG Knife Gate ValvesDocument12 pagesDeZURIK KCG Knife Gate ValvesKithkarnonNo ratings yet

- Kunkle OverviewDocument8 pagesKunkle Overviewsamix999No ratings yet

- Valves & ControlsDocument16 pagesValves & ControlseborresonNo ratings yet

- 1800 Series Inverted Bucket Steam TrapsDocument2 pages1800 Series Inverted Bucket Steam TrapsIoana PopescuNo ratings yet

- Kitz Ball Valve PDFDocument60 pagesKitz Ball Valve PDFBrant AkkanNo ratings yet

- Basco Type 500Document12 pagesBasco Type 500Sebastian OviedoNo ratings yet

- ACS11Document3 pagesACS11Ebby OnyekweNo ratings yet

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocument8 pagesTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4No ratings yet

- American Industrial Liquid Cooled Oil Heat ExchangerDocument12 pagesAmerican Industrial Liquid Cooled Oil Heat ExchangerAlejandro AguirreNo ratings yet

- Hydro SafetyReliefValves Series15002500Document12 pagesHydro SafetyReliefValves Series15002500HGuruGuruHNo ratings yet

- Cooling Tower SpecificationDocument14 pagesCooling Tower SpecificationAmzad DPNo ratings yet

- Valves - PresentationDocument119 pagesValves - Presentationkrahul100% (15)

- Apollo 89-100 SeriesDocument8 pagesApollo 89-100 SeriesMaria Emeren Mercado BabaNo ratings yet

- NeedleValve LT0389Document8 pagesNeedleValve LT0389zkmostafaNo ratings yet

- OneSteel Valve Product CatalogueDocument40 pagesOneSteel Valve Product CatalogueEr Pupone de Naza100% (1)

- BakerSPD Choke Tech Handbook 5-9-06 PDFDocument14 pagesBakerSPD Choke Tech Handbook 5-9-06 PDFCassielAlexzylalas LiambaNo ratings yet

- K Series 1/2" To 4" Stainless Steel Control Valves: DescriptionDocument2 pagesK Series 1/2" To 4" Stainless Steel Control Valves: DescriptionarafardNo ratings yet

- Hydraulic PipingDocument1 pageHydraulic Pipingpandunugraha04No ratings yet

- TBV Series 2800 Split Body Full Port Flanged Ball Valve BrochureDocument12 pagesTBV Series 2800 Split Body Full Port Flanged Ball Valve BrochuredharmeshkherNo ratings yet

- PN01CS1B02Document5 pagesPN01CS1B02ger80100% (1)

- Kunkle Safety RV Model 91Document6 pagesKunkle Safety RV Model 91gbogboiweNo ratings yet

- Ansi-Valve Body Material SelectionDocument3 pagesAnsi-Valve Body Material SelectionsatthukotienNo ratings yet

- Water SystemDocument9 pagesWater SystemArun GuptaNo ratings yet

- 3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2Document16 pages3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2zampacaanasNo ratings yet

- 56-T Series: Temperature Actuated Water Regulating ValveDocument4 pages56-T Series: Temperature Actuated Water Regulating ValveGuatemalan1979No ratings yet

- NEEDLE KF Valve BrochureDocument11 pagesNEEDLE KF Valve Brochureheldermanuel100No ratings yet

- Kunkle300 PDFDocument6 pagesKunkle300 PDFCastoriadisNo ratings yet

- CIRCOR D-Series Technical BrochureDocument12 pagesCIRCOR D-Series Technical BrochureJAYNo ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- 112.09 Heat Exchangers BrochureDocument4 pages112.09 Heat Exchangers BrochureAlexandru DinaNo ratings yet

- Pressure Releif ValveDocument24 pagesPressure Releif Valvemtalha_loveNo ratings yet

- 6400-6600 Series Catalog (394C) PDFDocument8 pages6400-6600 Series Catalog (394C) PDF20106285No ratings yet

- Navco b2 BrochureDocument16 pagesNavco b2 Brochurejorge28csNo ratings yet

- A2 1 16junDocument2 pagesA2 1 16junamitrai86No ratings yet

- Catalogo KeckleyDocument3 pagesCatalogo KeckleyYGWHNo ratings yet

- TVS 80-DC Series Automatic Differential Condensate ControllersDocument2 pagesTVS 80-DC Series Automatic Differential Condensate ControllersJozsef MagyariNo ratings yet

- 01SD0J01Document5 pages01SD0J01raobabar21No ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- N Normas Pdvsa Mid Pip Pn01cs1j01Document5 pagesN Normas Pdvsa Mid Pip Pn01cs1j01Douglas E Ana PereiraNo ratings yet

- 01CS1S02Document5 pages01CS1S02raobabar21No ratings yet

- Ca and CH Series: Product SpecificationsDocument12 pagesCa and CH Series: Product SpecificationsMark ThomasNo ratings yet

- NUTRON Models T3 and B3 Ball Valves: Forged Steel Floating Ball Valves For Heavy-Duty, Reduced Maintenance PerformanceDocument32 pagesNUTRON Models T3 and B3 Ball Valves: Forged Steel Floating Ball Valves For Heavy-Duty, Reduced Maintenance PerformanceDanny PuchaNo ratings yet

- Needle ValveDocument8 pagesNeedle ValveMuhammad Chilmi100% (1)

- Pipeline StrainersDocument6 pagesPipeline Strainerssairam2234No ratings yet

- Documents Plc150Document7 pagesDocuments Plc150Anonymous cuOIjrLINo ratings yet

- 01CB2S01Document6 pages01CB2S01raobabar21No ratings yet

- 501SHDocument2 pages501SHbhaskarbabaiNo ratings yet

- Fainger Leser Catalogue' 11Document68 pagesFainger Leser Catalogue' 11rudrakrNo ratings yet

- L & M Series Ultra-Capacity Float & Thermostatic Steam Trap: Description How To OrderDocument2 pagesL & M Series Ultra-Capacity Float & Thermostatic Steam Trap: Description How To OrderJozsef MagyariNo ratings yet

- Two-Valve Block & Bleed Manifolds: DescriptionDocument8 pagesTwo-Valve Block & Bleed Manifolds: DescriptionBalderas Rosas WilibaldoNo ratings yet

- Econ Gate ValvesDocument22 pagesEcon Gate ValvesRiyas Udheen100% (1)

- Ariel JGK and JGT CompressorsDocument5 pagesAriel JGK and JGT CompressorsPablo GutierrezNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Amprobe MANUAL Megometro Amb-5kvd PDFDocument32 pagesAmprobe MANUAL Megometro Amb-5kvd PDFSamuel ValleNo ratings yet

- Manual Lavadora FrigidaireDocument28 pagesManual Lavadora FrigidaireGustavo Garces Guerrero0% (1)

- GB ElectricalDocument54 pagesGB ElectricalGustavo Garces GuerreroNo ratings yet

- Sero7 LT Us S en ManDocument66 pagesSero7 LT Us S en ManGustavo Garces GuerreroNo ratings yet

- Basic Steam Engineering GuidelinesDocument30 pagesBasic Steam Engineering GuidelinesGustavo Garces GuerreroNo ratings yet

- Steam15 BenchmarkDocument2 pagesSteam15 BenchmarkGustavo Garces GuerreroNo ratings yet

- Manual Lavadora FrigidaireDocument28 pagesManual Lavadora FrigidaireGustavo Garces Guerrero0% (1)

- TVS 800 Series Cast Iron Trap Valve Station: Reduced CostsDocument4 pagesTVS 800 Series Cast Iron Trap Valve Station: Reduced CostsGustavo Garces GuerreroNo ratings yet

- Latihan Soal Untuk USDocument5 pagesLatihan Soal Untuk USfeira fajarNo ratings yet

- Gautam Research ReportDocument81 pagesGautam Research ReportDeep ChoudharyNo ratings yet

- Chess Pseudonyms PDFDocument31 pagesChess Pseudonyms PDFdon dadaNo ratings yet

- BMP5 Anti Piracy EquipmentDocument1 pageBMP5 Anti Piracy EquipmentGaurav SoodNo ratings yet

- Pressure Vacuum Valves PDFDocument5 pagesPressure Vacuum Valves PDFFelipe Correa MahechaNo ratings yet

- Soal Latihan Procedure TipsDocument3 pagesSoal Latihan Procedure TipsAllenNo ratings yet

- Rule 24 - Towing and PushingDocument63 pagesRule 24 - Towing and PushingMitch SpeederNo ratings yet

- 11 - Effective Pages: Beechcraft CorporationDocument36 pages11 - Effective Pages: Beechcraft Corporationaviacion gnaNo ratings yet

- Iyengar Yoga Home Practice Sequences 1 PDFDocument4 pagesIyengar Yoga Home Practice Sequences 1 PDFYogesh Sharma100% (1)

- Teste de Inglês 6º Ano 1º PeríodoDocument7 pagesTeste de Inglês 6º Ano 1º PeríodoAngela MoreiraNo ratings yet

- Comparative Anatomy LecDocument2 pagesComparative Anatomy LecKerbie JaydNo ratings yet

- Edward Winter - Capablanca Goes AlgebraicDocument7 pagesEdward Winter - Capablanca Goes AlgebraicNicolás MartínezNo ratings yet

- One Piece Monster Manual - Strong World - GM BinderDocument12 pagesOne Piece Monster Manual - Strong World - GM BinderLuis MartínezNo ratings yet

- Nocturne (Live in Los Angeles) Scott Colley and Julian LageDocument7 pagesNocturne (Live in Los Angeles) Scott Colley and Julian LageSaurabh ShivakumarNo ratings yet

- Jf016e Jf017e 1 PDFDocument4 pagesJf016e Jf017e 1 PDFValdir GomieroNo ratings yet

- Rule Book: The Supremacy of Cavalry in The Crusader Era 11th-12th CenturyDocument16 pagesRule Book: The Supremacy of Cavalry in The Crusader Era 11th-12th CenturyDWSNo ratings yet

- Kbox4 Performance GlobalDocument2 pagesKbox4 Performance Globalchrysomall_georgNo ratings yet

- Boku No Hero Academia Vol.10 Ch.380 Page 17 - MangagoDocument1 pageBoku No Hero Academia Vol.10 Ch.380 Page 17 - MangagoRian John Garcia Maneja0% (1)

- Space Shooter GameDocument18 pagesSpace Shooter GameSowmya Srinivasan100% (2)

- Top 40 song titles from documentDocument5 pagesTop 40 song titles from documentErik Rico CalvoNo ratings yet

- Nutritional Recommendations and Guidelines For Women in Gymnastics Current Aspects and Critical InterventionsDocument14 pagesNutritional Recommendations and Guidelines For Women in Gymnastics Current Aspects and Critical InterventionsInez Davega100% (1)

- 100 WODsDocument19 pages100 WODsKolaNo ratings yet

- Cruisin Knox Indiana in The 1950sDocument93 pagesCruisin Knox Indiana in The 1950sallenmo100% (1)

- 163 Automan March Issue 2015Document84 pages163 Automan March Issue 2015Automan MagazineNo ratings yet

- Self-Learning Module For Grade 11Document14 pagesSelf-Learning Module For Grade 11Joy S. Calayo100% (1)

- Non Moving TURBINEDocument44 pagesNon Moving TURBINERaja RamNo ratings yet

- Jadwal Pertandingan Porprov Xiv 2022Document10 pagesJadwal Pertandingan Porprov Xiv 2022Yankes PrimerNo ratings yet

- Sudoku Playoffs CBDocument8 pagesSudoku Playoffs CBDi CatNo ratings yet

- Ded 4 Semester Exam Aug 2015Document630 pagesDed 4 Semester Exam Aug 2015Iam JaiNo ratings yet

- Glassix Walkthrough GuideDocument5 pagesGlassix Walkthrough Guidesaga gaaraNo ratings yet