Professional Documents

Culture Documents

Paperworks in Acdc - PCPI

Uploaded by

Clariza CaponesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paperworks in Acdc - PCPI

Uploaded by

Clariza CaponesCopyright:

Available Formats

REPUBLIC OF THE PHILIPPINES POLYTECHNIC UNIVERSITY OF THE PHILIPPINES TAGUIG CAMPUS General Santos Avenue, Lower Bicutan, Taguig

City

In partial fulfillment of the requirements in ECEN 2014 (AC/DC Machineries)

Submitted by: CAPONES, Clariza B. CARILO, Jonathan FRAGO, Christopher HERNANDEZ, Julius A. LABRADOR, Reymart E.

Submitted to: Engr. Reginald Raquiza

History of Ready-Mix Concrete

The term ready mix concrete refers to a type of concrete that is manufactured in a batching plant or factory according to a specific formula and is then delivered to a work site by truck-mounted transit mixers. Although the first load of ready mix concrete was delivered to a building site in Baltimore, Maryland, in 1913, the early ready mix plants appeared in the 1930s when the standard of practice was for contractors to mix concrete at the work site from bagged cement and aggregates delivered separately. The ready mix concrete industry expanded significantly in the 1960s. Modern ready mix concrete is made under computer-controlled conditions. This results in specialty mixtures designed for very specific purposes. The use of ready mix concrete allows a precise recipe to be delivered to the work site. This eliminates the need for an on-site concrete mixing plant and the need for storage space for the materials to make concrete at the site. Ultimately, the use of ready mix concrete reduces noise and labor costs and can improve air quality at the work site. The concrete is delivered freshly mixed and in a plastic state from a centrally located batching plant that can serve a wide area. This is an advantage as the plant can be located, for instance, in an industrially zoned area and make deliveries to residential districts or into congested city work sites. However, when the materials are combined at a batch plant, the mixing begins at the plant so travel time from the plant to the work site is critical. Batch plants cannot be too far away from the site. The concrete should be placed within ninety minutes of being mixed. The weight of concrete is 1,776 kg/cubic meter (3,915 lbs/cubic yard) for general purpose concrete, and means that the transit mix truck is 33 tons for a normal 7.6-cubic-meter (10-cubic-yard) load. Therefore, concrete manufacturers strive to keep transportation distances to a minimum to avoid hauling heavy loads great distances.

History of Pacific Concrete Products, Inc.

Founded in the year 1950s, Pacific Concrrete Products, Inc.s first product to manufacture was hollow blocks made from granolithic materials. Then not for long, they later introduce concrete hollow blocks. After three decades of producing quality concrete products wherein they have achieved not only acceptance but leadership in the field of cement tile, granolithic and concrete pipe manufacturing, the company embarked on the production of Ready Mix Concrete in the year 1989. At its onset, all the big subdivisions being developed near the Ready Mix Plant site in Brgy. Malhacan, Meycauayan, Bulacan were supplied by their company. There was the Metrogate Subdivision in Brgy. Malhacan, Meycauayan; the Philiville Subdivision Phase I, II, II, & IV in Brgy. Sto. Nino, Meycauayan; the Moldex Subdivision in Marilao, Bulacan. Other subdivisions being supplied by PCPI were the Palmera Development in Fairview, Quezon City, Active Realty Subdivision in Marilao, Bulacan. Among the other projects undertaken by our Ready Mix Company was the Navotas Fishpoint expansion project; the PLDT expansion project in Malolos, Bulacan being undertaken by the Electronic Telephone Systems, Inc. (ETSI); the PLDT expansion program in Binondo, Novaliches and Commonwealth Avenue also being undertaken by ETSI. Due to their consistency and track record in asphalting roads, PCPI has been given the AAA (Triple A) rating of the Philippine Contractors Association Board, the highest rating given, and is qualified by the government to undertake the biggest and largest Road Projects. The MERALCO transmission line expansion project from Valenzuela to Meycauayan to Bocaue, the Manila Hotel Veranda expansion projects, the PLDT shipyard and drydock in Navotas and several other Road Project in Malabon, Navotas, Valenzuela, Meycauayan and Malinta, Bulacan. .

Products

Asphalt Pacific Asphalt and Concrete Mix offer a wide range of cost effective, high performance asphalt products that can be used on major highway systems, driveways, parking areas, or rural country roads. Designed for consistency and reliability, our asphalt products can be tailored to cater for different weight loads, traffic volumes, and weather conditions.

Ready-mix Concrete Concrete is the second most consumed product in the world after water! As market leaders in concrete production, Pacific Asphalt and Concrete offer a wide range of products and solutions.

Aggregates Aggregates are composed of geological materials such as stone, sand, and gravel and are used in virtually all forms of construction. They can be used in their natural state or can be crushed into smaller pieces.

Concrete Pipes From our extensive range of products, our clients can avail an utmost quality assortment of Concrete Pipes. They can avail the range in various sizes and lengths to meet their application requirements. Further, for the fabrication purpose of the range, we have used the best quality raw material that is procured from most trusted vendors of the industry.

Hollow Blocks Concrete Hollow Blocks are a new innovative technology in the building infrastructure. These concrete hollow blocks are a better substitute to work faster and faster to build a structure long lasting value.

Company Profile

Vision Statement To be the Top Construction Materials and Construction Company in the eyes of our customers, shareholders, and in the communities we do conduct our business.

Mission Statement To become the best company in the country producing products and services of the highest engineering and product standards at the best value and provide the best returns on the investment of our shareholders investors as well as the best value of our stakeholders and partners.

Quality Policy The company (PCPI) its managers, supervisors, and all its employees through the Quality Managements Committee are committed to the quality of our products and services and our stated quality goals towards Customer Satisfaction.

List of officers

Engr. Eresto Vergara Construction Superintendent

Engr. Cesar Reyes Contract Manager

Eureka Ycasiano Chief Accountant

Engr. Ramir Vinzon Plant Manager (Asphalt)

Engr. Lorenzo Lim Plant Manager (Concrete)

Engr. Norberto Isleta Plant Manager (Concrete)

Location

Pacific Concrete Products, inc. (Asphalt) Malhacan, Meycauayan, Bulacan Pacific Concrete Products, inc. (Concrete) Km. 19 East service Rd. Malhacan, Meycauayan, Bulacan Pacific Concrete Products, inc. Km. 17 East Service Road South Super Highway, Paranaque

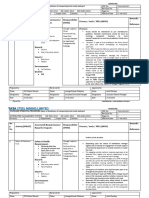

Ready Mix Concrete Process

Storage of Materials

Compartment

Aggregates The raw materials, coarse and fine aggregates are placed in the compartment. These materials are being fed manually to the ground hopper. After the materials were fed to the ground hopper, these aggregates will be weighed by the aggregate weighing bin. Air cylinders will open the bin and the aggregates will come out to the horizontal conveyor which in turn will convey the weighed coarse and fine aggregates to inclined Conveyor. The inclined conveyor bin will then convey the weighed coarse and fine aggregates to the aggregate transfer bin. The purpose of this aggregate transfer bin is for storage on top of the mixer. Cement Cement is generally stored in silos. The loading of cement is done with the help of pneumatic blower systems either installed on bulk carriers or a separate system available at the plant. If baggage cement is used then the cement is loaded using a compressed air loader and a splitter unit. Cement is weighed separately, and is transported from the silo into a mechanical or electromechanical weigher by means of a screw conveyor.

Water Water is generally stored in tanks located close to the plant. It is accurately measured by a water gauge and microprocessor controlled system. The plants have recorders that measure the moisture present in sand while the entire batch flows past. A recording unit calculates the average moisture value of the sand and passes on the information to the batching control unit to allow corrective action to be taken. Consistency of the mix is checked by a remote recording system. If concrete is very dry (stiff) the electrical resistance of the batch is measured and if the concrete is wet the motor output is measured. Accurate maintenance of the workability (consistency) of one cubic meter batch of concrete may depend on as little as one litre or less of water .It is scarcely conceivable that such a production process could be controlled without actually measuring the workability and later correcting the consistency. Mixing Arrangement The power mixer sets in motion the materials positively. The materials get thoroughly mixed by rotating arms. These mixers have shorter mixing time, give better homogeneity, consistency and strength to the concrete.

Control Systems Almost all imported production plants offer automatic systems for control functions. hese controls are operated from main desk. It also has material availability monitor and printer plus an additional batching monitor. The entire plant can be operated by just one person.Microprocessor control besides having fully automatic running facility offers number of additionalfeatures like statistical data recording and processing, a printer unit, moisture adjustmentarrangement, customer address, memory etc.All you need to do is push the required mix template into the slot and press the "start" buttonand the control system does the rest. Aggregate and cement weighment, moisture correction, overruncorrection and additive weighment are done accurately to give the concrete mix of desired strengthand workability.The built in trouble shooting programmes are most valuable and have a high reliability factor.Even upto 1500 mixes of different types can be stored along with names and addresses of theconsumer and other data which is required to be stored in the computer for operation of the plant.The mix data with quantity can be if required printed by the printer which is very useful for invoicing the consumer for the concrete supplied to them.

You might also like

- PolypropyleneDocument10 pagesPolypropylenePurushothama Nanje GowdaNo ratings yet

- Field Book for Quality Control in Earthwork Operations: Project Construction Management BookFrom EverandField Book for Quality Control in Earthwork Operations: Project Construction Management BookNo ratings yet

- Concrete Batch CONCRETE BATCH PLANTSPlantsDocument23 pagesConcrete Batch CONCRETE BATCH PLANTSPlantsemorider100% (4)

- Concrete Batching PlantDocument4 pagesConcrete Batching PlantGradia Olfactra IlokanaNo ratings yet

- Bendix Airbrake General CatalogueDocument132 pagesBendix Airbrake General CatalogueKOKNo ratings yet

- Ready Mix Concrete PPT 01Document28 pagesReady Mix Concrete PPT 01Pavan Kumar88% (16)

- Welding Personal Protection and Safety Equipment: Expert GuideDocument15 pagesWelding Personal Protection and Safety Equipment: Expert GuidedokundotNo ratings yet

- Fibo Mobile Concrete Plants-BrochureDocument4 pagesFibo Mobile Concrete Plants-BrochureHans Hans SadzNo ratings yet

- Manufacturing and Placing TechniquesDocument40 pagesManufacturing and Placing TechniquesAparna SwaminathanNo ratings yet

- ANSYS AutodynDocument4 pagesANSYS AutodynJaiveer YadavNo ratings yet

- Global Strategy of CEMEXDocument29 pagesGlobal Strategy of CEMEXAbhishek Jain100% (1)

- Ready Mix ConcreteDocument23 pagesReady Mix ConcreteDevesh Sharma100% (1)

- RMC Plant-Classification, Operation & Cost Analysis of ProductionDocument40 pagesRMC Plant-Classification, Operation & Cost Analysis of ProductionSacrosanctSayantan100% (1)

- Study On Auto Bricks Bangladesh Perspect PDFDocument26 pagesStudy On Auto Bricks Bangladesh Perspect PDFMohiminul Khan100% (1)

- Quality Control of Ready Mixed Concrete Can Be Divided Into Three Convenient Areas LikeDocument11 pagesQuality Control of Ready Mixed Concrete Can Be Divided Into Three Convenient Areas Likeee iabNo ratings yet

- A Report On Ready Mix Concrete Jayedul I PDFDocument30 pagesA Report On Ready Mix Concrete Jayedul I PDFMD MOSADDIKNo ratings yet

- Ready Mix ConcreteDocument5 pagesReady Mix ConcreteSanu GhoshNo ratings yet

- RMC NotesDocument12 pagesRMC NotesKannagi R PillaiNo ratings yet

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Technology and Management of High Rise and Special BuildingsDocument11 pagesTechnology and Management of High Rise and Special BuildingsNomanNo ratings yet

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- Ultratech RMCDocument59 pagesUltratech RMCChanchal Vishnoi100% (2)

- Types XK and XJ: Controllers and Controller StationsDocument65 pagesTypes XK and XJ: Controllers and Controller StationsOsun Deji LanaNo ratings yet

- Volumetric Concrete Mixer Proposal For Ready Mix CompaniesDocument6 pagesVolumetric Concrete Mixer Proposal For Ready Mix CompaniesHabtamu Sedie0% (1)

- The Nature of Industrial BuyingDocument40 pagesThe Nature of Industrial Buying99862123780% (1)

- RMC Batching PlantDocument20 pagesRMC Batching Plantaditishah20392No ratings yet

- MSDN 0111DGDocument94 pagesMSDN 0111DGpiyushn86No ratings yet

- BQ - PreliminariesDocument10 pagesBQ - PreliminariesMichael TanNo ratings yet

- 1.1 Brief Introduction To Concrete Construction IndustryDocument12 pages1.1 Brief Introduction To Concrete Construction IndustryGauresh GawasNo ratings yet

- Premix Concrete Supplier - Company ProfileDocument7 pagesPremix Concrete Supplier - Company ProfileSolomon BalemeziNo ratings yet

- Diamond Cement Products EnterprisesDocument15 pagesDiamond Cement Products EnterprisessamrudhrsarikarNo ratings yet

- Concrete SolutionsDocument27 pagesConcrete SolutionsRollyn Mae Garcia BasbañoNo ratings yet

- Final Na Inin Jama Sa Feasibility StudyDocument8 pagesFinal Na Inin Jama Sa Feasibility StudyEstiven GierNo ratings yet

- Dillu Technical ReportDocument12 pagesDillu Technical ReportDileep SKNo ratings yet

- AE - Training MaterialDocument18 pagesAE - Training MaterialPandianKalaimaniNo ratings yet

- Davao Del Norte: Highway and Railroad EngineeringDocument3 pagesDavao Del Norte: Highway and Railroad Engineeringpaulo rivasNo ratings yet

- Ready Mix ConcreteDocument15 pagesReady Mix ConcreteSharukh KhanNo ratings yet

- Ready Mix ConcreteDocument57 pagesReady Mix Concreteeyob yohannesNo ratings yet

- Concrete Sand Water Aggregate Rocks Gravel Fly Ash Potash CementDocument2 pagesConcrete Sand Water Aggregate Rocks Gravel Fly Ash Potash CementWillard ApengNo ratings yet

- Thesis On Ready Mix ConcreteDocument6 pagesThesis On Ready Mix Concretegbxqaf9v100% (1)

- Organisational Study at Ahlcon Ready Mix Concrete PVTDocument57 pagesOrganisational Study at Ahlcon Ready Mix Concrete PVTSuraj DeyNo ratings yet

- Eyu Internship ReportDocument12 pagesEyu Internship ReportAbel Lema100% (2)

- Ready Mixed Concrete FinalDocument35 pagesReady Mixed Concrete FinalNaveen Tibba100% (2)

- Project MBADocument29 pagesProject MBARony JamesNo ratings yet

- RMC - Ready Mix Concrete: Advanced Construction Material and TechnologyDocument14 pagesRMC - Ready Mix Concrete: Advanced Construction Material and TechnologyIqRa JaVedNo ratings yet

- 7 Industrial Concrete Mixers Key Advantages and Also ApplicationstrhbxDocument4 pages7 Industrial Concrete Mixers Key Advantages and Also Applicationstrhbxcurveactor12No ratings yet

- Model Chart of Quality Control Process For Ready Mixed Concrete PlantsDocument5 pagesModel Chart of Quality Control Process For Ready Mixed Concrete PlantsShraddha PatelNo ratings yet

- 1.1 Ready Mix Concrete: Thus R Es Abli in A. RM Soo M R L Known Ind N D Fro Mix oDocument18 pages1.1 Ready Mix Concrete: Thus R Es Abli in A. RM Soo M R L Known Ind N D Fro Mix otejas_12345No ratings yet

- Cem Unit 3Document15 pagesCem Unit 3SATVIKNo ratings yet

- Ready Mix Concrete: in Partial Fulfilment of The Requirements For The Award of The Degree ofDocument20 pagesReady Mix Concrete: in Partial Fulfilment of The Requirements For The Award of The Degree ofDileep SKNo ratings yet

- Dileep ReportDocument20 pagesDileep ReportDileep SKNo ratings yet

- Sustainability in Cement and Concrete IndustriesDocument32 pagesSustainability in Cement and Concrete IndustriesnikitaNo ratings yet

- About UltraTech ConcreteDocument7 pagesAbout UltraTech ConcreteZarkima RanteNo ratings yet

- Quality Control of Ready Mixed Concrete Can Be Divided Into Three Convenient Areas LikeDocument15 pagesQuality Control of Ready Mixed Concrete Can Be Divided Into Three Convenient Areas Likeee iabNo ratings yet

- Ready Mix Concrete: Unit 5Document49 pagesReady Mix Concrete: Unit 5YASHWANTH.M.KNo ratings yet

- A Brief Study of Ready-Mix Concrete: Features & Uses in Construction On The Context of BangladeshDocument3 pagesA Brief Study of Ready-Mix Concrete: Features & Uses in Construction On The Context of BangladeshmunzuaraNo ratings yet

- Dokumen - Tips Kolkata Metro Rail Via Duct ProjectDocument33 pagesDokumen - Tips Kolkata Metro Rail Via Duct ProjectHeleena SenguptaNo ratings yet

- Ipe Plant DesignDocument31 pagesIpe Plant DesignAngelica BrazaNo ratings yet

- Cement Concrete PlantsDocument24 pagesCement Concrete PlantsajayNo ratings yet

- Cement Testing For World Cement June 2011 PDFDocument5 pagesCement Testing For World Cement June 2011 PDFarrijaljNo ratings yet

- Adding Value To ConcreteDocument16 pagesAdding Value To ConcreteFrancois KokNo ratings yet

- Advantages. Disadvantages. Transit Mixed Concrete. Shrink Mixed ConcreteDocument14 pagesAdvantages. Disadvantages. Transit Mixed Concrete. Shrink Mixed ConcretekomalNo ratings yet

- Field Trip QuestionsDocument4 pagesField Trip QuestionsYRA sachachNo ratings yet

- Choosing A Concrete Conveyor - tcm45-343213Document3 pagesChoosing A Concrete Conveyor - tcm45-343213Anirudh JaswalNo ratings yet

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12From EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12No ratings yet

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Porsche Financial Services BrochureDocument8 pagesPorsche Financial Services BrochureAndre BarnesNo ratings yet

- Is 458 2003Document68 pagesIs 458 2003Yazer ArafathNo ratings yet

- Pany ProfileDocument31 pagesPany ProfilehungleteNo ratings yet

- Chartered IT Professional - Specialism List: CITP Specialism SFIA Skill Information Management and SecurityDocument3 pagesChartered IT Professional - Specialism List: CITP Specialism SFIA Skill Information Management and Securityudara86No ratings yet

- Sustainable Training of Office TPM Using A "Teaching Office"Document31 pagesSustainable Training of Office TPM Using A "Teaching Office"ImamRNNo ratings yet

- 2 Doing Business With CERN - Laszlo AbelDocument28 pages2 Doing Business With CERN - Laszlo AbelAnonymous oEuuohz8No ratings yet

- Company Profile JMM 2Document23 pagesCompany Profile JMM 2Stephen MulengaNo ratings yet

- Air Line Pilot January 2013Document56 pagesAir Line Pilot January 2013kfcarp29030% (1)

- ABAP MaterialDocument104 pagesABAP MaterialgvrahulNo ratings yet

- VanderLey Contributions RecordDocument4 pagesVanderLey Contributions RecordJacob EngelsNo ratings yet

- Inkoma Friction Locking BushesDocument20 pagesInkoma Friction Locking BushesRuiNo ratings yet

- TWS Troubleshooting GuideDocument203 pagesTWS Troubleshooting GuideJosé E. FélixNo ratings yet

- SOP For Breakdown of Vehicle - 17. Rev-2Document3 pagesSOP For Breakdown of Vehicle - 17. Rev-2syed aquibNo ratings yet

- New Text DocumentDocument31 pagesNew Text DocumentAhmad PooladiNo ratings yet

- POM Six SigmaDocument10 pagesPOM Six SigmaleenaNo ratings yet

- Inventory Mana - Mahindra-21Document87 pagesInventory Mana - Mahindra-21MOHAMMED KHAYYUMNo ratings yet

- ESC 230 TraverseDocument31 pagesESC 230 TraverseIon PusculitaNo ratings yet

- 01 Samss 010 PDFDocument11 pages01 Samss 010 PDFAnonymous hBBam1nNo ratings yet

- CNC Lathe Machine Technician and ProgrammerDocument16 pagesCNC Lathe Machine Technician and ProgrammermanjuNo ratings yet

- Range Brochure 2009-Sampling TechnologiesDocument92 pagesRange Brochure 2009-Sampling Technologiesas_001No ratings yet

- Mini-Risers Are A Big Improvement For Feeding Performance - Feature Content From FoundrymagDocument3 pagesMini-Risers Are A Big Improvement For Feeding Performance - Feature Content From FoundrymagIndra Pratap SengarNo ratings yet

- Mil M 81531Document12 pagesMil M 81531Lul preetNo ratings yet