Professional Documents

Culture Documents

03192005214235

Uploaded by

Daniela BuseCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03192005214235

Uploaded by

Daniela BuseCopyright:

Available Formats

Programmable Logic

Controllers:

An Emphasis on Design and Application

Kelvin T. Erickson

University of Missouri-Rolla

Dogwood

Valley

Press, LLC

Dedicated to Fran, Esther, and David

Copyright 2005 Dogwood Valley Press, LLC. All rights reserved.

No portion of this book may be reproduced, stored in a retrieval system, or transmitted in

any form or by any means, including electronic, mechanical, photocopying, scanning,

recording or otherwise, except as permitted under the 1976 United States Copyright Act,

without explicit, prior written permission of the publisher except for brief passages

excerpted for review and critical purposes.

This book was set in Times New Roman and printed on acid-free paper.

Printed in the United States of America

ISBN 0-9766259-0-3

Dogwood Valley Press, LLC

1604 Lincoln Lane

Rolla, MO 65401

1-573-426-3507

Http://www.DogwoodValleyPress.com

10 9 8 7 6 5 4 3 2 1

CONTENTS

Preface vii

Chapter 1 Introduction to PLCs 1

1.1 Introduction 1

1.2 Automatic Control in Manufacturing 1

1.3 Control System Classifications 2

1.4 History of the PLC 6

1.5 PLC Versus Other Technologies 13

1.6 Basic PLC Architecture 15

1.7 Chapter Summary 20

References 20

Chapter 2 Basic Ladder Logic Programming 23

2.1 Introduction 24

2.2 Simple Ladder Logic 24

2.3 Basic Ladder Logic Synbols 29

2.4 Ladder Logic Diagram 37

2.5 PLC Processor Scan 43

2.6 Programming with NC Contact 53

2.7 Start/Stop 54

2.8 Converting Relay Logic to Ladder Logic 60

2.9 Chapter Summary 64

References 65

Problems 67

Chapter 3 Memory Organization and Addressing 77

3.1 Introduction 78

3.2 IEC 61131-3 Memory Model 78

3.3 Modicon Quantum/Momentum Memory 80

3.4 A-B ControlLogix Memory 90

3.5 A-B PLC-5 and SLC-500 Memory 97

3.6 Siemens S7 Memory 115

3.7 GE Fanuc Memory 131

3.8 Chapter Summary 140

References 140

Problems 141

Chapter 4 Input/Output Modules and Installation 147

4.1 Introduction 148

4.2 Discrete Modules 150

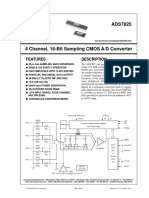

4.3 Analog Modules 164

4.4 Specialized Modules 171

4.5 Installation Wiring 176

4.6 Chapter Summary 192

References 192

Problems 195

Chapter 5 Timers and Counters 197

5.1 Introduction 199

5.2 IEC Timers and Counters 199

5.3 Modicon Timers and Counters 200

5.4 A-B ControlLogix Timers and Counters 209

5.5 A-B PLC-5/SLC-500 Timers and Counters 219

5.6 Siemens S7 Timers and Counters 225

5.7 GE Fanuc Timers and Counters 244

5.8 General Timers and Counter Situations 250

5.9 Examples 252

5.10 Chapter Summary 274

References 274

Problems 276

Chapter 6 Sequential Applications 295

6.1 Introduction 296

6.2 Function Chart 297

6.3 Implementing Function Chart in Ladder Logic 303

6.4 Complicated Reset Operation 326

6.5 Parallel Operations 347

6.6 Key Questions in the Sequential Design Process 357

6.7 Manual and Single-Step Sequential Operation 357

6.8 Transitions When PLC Has No Reset 360

6.9 Chapter Summary 360

References 365

Problems 366

Chapter 7 Comparison and Computation 429

7.1 Introduction 430

7.2 Conversion of Physical Quantity 430

7.3 IEC Comparison and Computation 434

7.4 Modicon Comparison and Computation 435

7.5 A-B ControlLogix Comparison and Computation 445

7.6 A-B PLC-5/SLC-500 Comparison and Computation 452

7.7 Siemens S7 Comparison and Computation 463

7.8 GE Fanuc Comparison and Computation 474

7.9 Application Caveats 482

7.10 Examples 482

ii Contents

7.11 Chapter Summary 512

References 513

Problems 514

Chapter 8 Other Ladder Logic Instructions 567

8.1 Introduction 567

8.2 Other IEC Function Blocks 569

8.3 Other Modicon Function Blocks 569

8.4 Other ControlLogix Function Blocks 580

8.5 Other PLC-5/SLC-500 Function Blocks 599

8.6 Other Siemens S7 Function Blocks 618

8.7 Other GE Fanuc Function Blocks 633

8.8 Examples 647

8.9 Chapter Summary 669

References 669

Problems 672

Chapter 9 Other Function Chart Implementations 677

9.1 Introduction 679

9.2 Counter-Based Sequence 679

9.3 Shift Register-Based Sequence 708

9.4 Sequencer Function Blocks 730

9.5 Unstructured Sequence 754

9.6 Chapter Summary 759

References 759

Problems 761

Chapter 10 PID Control 765

10.1 Introduction 768

10.2 Feedback Control Performance 772

10.3 PID Controller 776

10.4 PID Controller Tuning 785

10.5 PID Control Enhancements 805

10.6 Operational Aspects 817

10.7 PLC PID Function Blocks 818

10.8 Examples 839

10.9 Chapter Summary 853

References 854

Problems 856

Chapter 11 Function Block Diagram 869

11.1 Introduction 870

11.2 IEC 61131-3 Function Block Diagram 871

11.3 Modicon Function Block Diagram 874

11.4 ControlLogix Function Block Diagram 877

11.5 Siemens S7 Function Block Diagram 893

11.6 Examples 896

11.7 Chapter Summary 910

Contents iii

References 911

Problems 913

Chapter 12 Structured Text 919

12.1 Introduction 920

12.2 IEC 61131-3 Structured Text 921

12.3 Modicon Structured Text 929

12.4 ControlLogix Structured Text 930

12.5 PLC-5 Structured Text 932

12.6 Siemens S7 Structured Control Language 934

12.7 Examples 936

12.8 Chapter Summary 948

References 948

Problems 950

Chapter 13 Instruction List 953

13.1 Introduction 953

13.2 IEC 61131-3 Instruction List 953

13.3 Modicon Instruction List 958

13.4 Siemens S7 Instruction List 958

13.5 GE Fanuc Instruction List 961

13.6 Examples 962

13.7 Chapter Summary 971

References 971

Problems 972

Chapter 14 Sequential Function Chart 975

14.1 Introduction 976

14.2 IEC 61131-3 Sequential Function Chart 976

14.3 Modicon Sequential Function Chart 994

14.4 ControlLogix Sequential Function Chart 1003

14.5 PLC-5 Sequential Function Chart 1011

14.6 Siemens S7 Sequential Function Chart 1019

14.7 Examples 1028

14.8 Chapter Summary 1064

References 1064

Problems 1065

Chapter 15 Troubleshooting 1067

15.1 Introduction 1069

15.2 General Troubleshooting Procedures 1070

15.3 Troubleshooting I/O Modules 1073

15.4 Processor Status Indicators 1083

15.5 Program Problems 1086

15.6 Communication Problems 1089

15.7 Designing for Fault Diagnosis 1091

15.8 Chapter Summary 1091

References 1091

iv Contents

Chapter 16 Sensors and Actuators 1093

16.1 Introduction 1095

16.2 Discrete Sensors 1095

16.3 Analog Sensors 1109

16.4 Discrete Actuators 1148

16.5 Analog Actuators 1155

16.6 Chapter Summary 1166

References 1166

Problems 1168

Appendix - Thermocouple Conversion Polynomial Coefficients 1174

Chapter 17 Communication Networks 1181

17.1 Introduction 1183

17.2 Network Protocols 1184

17.3 Ethernet 1191

17.4 Foundation Fieldbus 1192

17.5 CIP-Related Protocols 1196

17.6 PROFIBUS (DP, PA, PROFInet) 1203

17.7 P-NET 1208

17.8 WorldFIP 1211

17.9 INTERBUS 1215

17.10 SwiftNet 1217

17.11 AS-i 1219

17.12 Seriplex 1220

17.13 Modicon Protocols 1222

17.14 Allen-Bradley Proprietary Networks 1225

17.15 GE Fanuc Proprietary Networks 1226

17.16 Ladder Logic Communication Blocks 1227

17.17 Chapter Summary 1249

References 1249

Chapter 18 Human-Machine Interface 1253

18.1 Introduction 1255

18.2 HMI Types 1255

18.3 HMI Panel Design 1259

18.4 Graphical HMI Design 1262

18.5 Graphical HMI Development 1268

18.6 Chapter Summary 1277

References 1277

Chapter 19 Control System Security 1279

19.1 Introduction 1279

19.2 Factory Automation Network Security 1280

19.3 PLC Processor Security 1284

19.4 Chapter Summary 1297

References 1297

Contents v

Chapter 20 Selecting a PLC 1299

20.1 Introduction 1299

20.2 Selection Factors 1300

20.3 PLC Families 1303

20.4 Chapter Summary 1308

References 1309

Chapter 21 Control Projects 1311

21.1 Introduction 1311

21.2 Typical Control Design Project 1312

21.3 Example Control Requirements Definition 1320

21.4 Standardization 1327

21.5 Testing 1387

21.6 Chapter Summary 1400

References 1401

Problems 1402

Chapter 22 Example Projects 1405

22.1 Introduction 1405

22.2 Coal Handling System 1405

22.3 Multi-Unit Chemical Process 1411

22.4 Chapter Summary 1416

References 1416

Appendix A Number Systems and Conversions 1417

Appendix B Electrical Diagram Symbols 1423

Appendix C Piping and Instrumentation Diagram (P&ID) Symbols 1426

Glossary 1429

Index 1445

vi Contents

PREFACE

The field of automatic control has been undergoing a transformation over the past

twenty years. Twenty years ago, the engineering undergraduate had a course in feedback

control theory and those interested in control engineering secured a position in the

aerospace or chemical industries. Due to various factors, the number of control engineering

positions in the aerospace industry has been declining, but the number of control

engineering positions in manufacturing has been dramatically increasing to the point that

the majority of control engineering positions is now in manufacturing and involves PLCs.

This book presents the subject of programming industrial controllers, called

programmable logic controllers (PLCs) with an emphasis on the design of the programs.

Many texts teach one how to program the PLC in its languages, but little, if any, attention is

paid to how does one attack the problem: Given a set of operational specifications, how

does one develop the PLC program? This book develops the design process: the tasks

involved, breaking the programinto manageable pieces, standard code for the various parts,

and handling the sequential parts of the problem. The emphasis is toward those who will be

programming PLCs.

Because of its popularity (now and in the future), ladder logic is the language that is

used for the majority of the text. The industry trend is toward using the IEC 61131-3

(formerly IEC 1131-3) standard, and so it is the primary language. However, IEC 61131-3

is only a voluntary standard and individual manufacturers have some freedom in the

implementation. Therefore, the Allen-Bradley ControlLogix, Modicon, and Siemens S7

implementations of the 61131-3 standard are covered. Because of their large installed base,

Allen-Bradley PLC-5/SLC-500 and GE Fanuc PLC languages are also covered.

Due to the limitations of ladder logic, the IEC 61131-3 standard defines four other

languages: function block diagram, structured text, instruction list, and sequential function

chart. These four languages will become more popular in the future. Therefore, this text also

covers these languages.

Since a typical manufacturing plant may contain discrete, continuous, and batch

processes, all of these applications are treated in this text, although the emphasis is on

discrete and continuous processes. The emphasis is on a methodology that can be applied to

any automation project, regardless of the size.

Throughout, the book contains example problems demonstrating good design practice.

In addition, these problems are solved with each PLC covered in the book. The text

culminates in two full-length case studies where the application of the design techniques to

a large problem is illustrated.

This book takes a practical approach to the design of PLC control systems. Some

mathematical theory is used to backup the presentation on PID controllers. However, the

theory is not detailed and can be omitted.

Except for Chapters 1 and 13, every chapter begins with a scenario that reflects the

experience of the author and his colleagues in the challenging world of factory automation.

vii

These scenarios present a small problem and the solution and are intended to illustrate

troubleshooting techniques.

Objectives

The main objectives of this text are to teach:

PLC programming languages (with emphasis on IEC 61131-3)

Approach to sequential problems

Good program design practice

Simple PID control tuning

Introduction to sensors and actuators

Factory communications

Human-machine interface (HMI) concepts

Content Overview

The book starts by introducing programmable logic controllers (PLCs) and their

distinguishing characteristics. Chapters 2 5 cover basic ladder logic programming:

contact, timer, and counter instructions. As part of the basics, the memory structure of the

five particular PLCs and installation topics are treated. Chapter 6 covers ladder logic

program design for sequential applications, probably the most significant contribution of

the text. Chapters 7 and 8 treat computation, comparison, and advanced ladder logic

instructions. Alternate sequential implementations in ladder logic are covered in Chapter 9

and PID controller tuning is covered in Chapter 10. Chapters 11 14 cover the other four

IEC programming languages: function block diagram, statement list, instruction list, and

sequential function chart. PLC troubleshooting is covered in Chapter 15. Sensors and

actuators appear in Chapter 16. Chapter 17 introduces factory communication networks.

Operator interface, often called human-machine interface (HMI), issues are treated in

Chapter 18. Control system security is addressed in Chapter 19 and PLC selection is

introduced in Chapter 20. Chapter 21 presents the perspective of an entire automation

project, bringing together the various pieces of PLCcontrol design. Chapter 22 outlines two

full-length project case studies. One case study is for a process that is primarily discrete and

the other case study is for a process that is primarily continuous in nature. Details about

number systems and drawing symbols are included as appendices, rather than interrupt the

flow of the text material.

The Audience

This book primarily serves the academic market, at the junior or senior undergraduate

electrical, mechanical, or industrial engineering or engineering technology level. This text

is also suitable for the two-year technical school market. There is nothing in the material

that requires a college degree, though the material will be more challenging than the typical

PLC textbook for this level of student.

In addition, this text serves the professional market. Economic and regulatory pressures

in the manufacturing, chemical, petrochemical, pharmaceutical, and food industries have

forced control engineers to design new systems or retrofit existing control systems. Hence,

there are many control engineers (primarily chemical and electrical) who need to rapidly

viii Preface

educate themselves in an area of technology in which they are probably only somewhat

familiar. This book is valuable to this audience.

Acknowledgements

The author wishes to acknowledge the beneficial suggestions and comments of many

colleagues. Bill Bichler, Dean Ford, and Esther Erickson reviewed drafts of this book and

provided many suggestions and corrections to improve the final product. I especially thank

Esther and Fran Erickson for correcting the entire manuscript for grammatical errors, and

Fran for doing the initial typesetting.

Portions of this material were taught in industrial short courses and university courses

and the students are acknowledged for their help in pointing out errors in the text and where

the presentation was unclear.

The following are registered trademarks of Schneider Electric: Modicon, Quantum,

Momentum, Concept, Unity, and Modbus. The following are trademarks of Schneider

Electric Modbus Plus, 984, BP85, and BM85. The following are registered trademarks of

Rockwell Automation and its various subsidiary entities: Allen-Bradley, ControlLogix,

PLC-2, PLC-3, PLC-5, Rockwell Automation, Rockwell Software, and RSLinx. The

following are trademarks of Rockwell Automation and its various subsidiary entities:

CompactLogix, Data Highway Plus, DH+, FlexLogix, GuardPLC, MicroLogix, Logix

5000, Pico, PLC-5/11, PLC-5/20, PLC-5/20E, PLC-5/26, PLC-5/30, PLC-5/40,

PLC-5/40E, PLC-5/40L, PLC-5/46, PLC-5/60, PLC-5/60L, PLC-5/80, PLC-5/80E,

PLC-5/86, PLC-5/250, RSLogix 5, RSLogix 500, RSLogix 5000, RSNetWorx, SLC,

SLC-500 and SoftLogix. SIMATIC is a registered trademark of Siemens AG. The

following are trademarks of GE Fanuc Automation North America, Inc.: CIMPLICITY,

Logicmaster, PACSystems, Series 90, Series Five, Series One, Series Six, Series Three,

VersaMax, and VersaPro. Foundation is a trademark of Fieldbus Foundation. ControlNet is

a trademark of ControlNet International, Ltd. DeviceNet is a trademark of the Open

DeviceNet Vendors Association. PROFIBUS and PROFInet are registered trademarks of

Profibus Nutzerorganisation, e.V. P-NET is a registered trademark of the International

P-NET User Organization. Seriplex is a registered trademark of the Square D Company.

Ethernet is a trademark of Digital Equipment Corporation, Intel, and Xerox Corporation.

SERCOS interface is a trademark of the Interests Group SERCOS interface e.V. (IGS).

VisSim is a registered trademark of Visual Solutions, Inc., Westford, Massachusetts.

MATLAB and SIMULINK are registered trademarks of The Mathworks, Inc., Natick,

Massachusetts. Microsoft, Windows, and Visual Basic are registered trademarks of

Microsoft Corporation.

Disclaimer

Information furnished herein is believed to be accurate and reliable; however no

responsibility is assumed for any errors. The user assumes full responsibility for the

accuracy and appropriateness of this information.

Preface ix

You might also like

- 978-0-9766259-2-6 Chap 2 ExcerptDocument36 pages978-0-9766259-2-6 Chap 2 ExcerptvitoNo ratings yet

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsFrom EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsRating: 5 out of 5 stars5/5 (1)

- Instrumentation l1 3e Courseplanning PDFDocument56 pagesInstrumentation l1 3e Courseplanning PDFMichael de LeonNo ratings yet

- Motion Control ReportFrom EverandMotion Control ReportRating: 4 out of 5 stars4/5 (1)

- Programming, Simulating and Visualizing Human Machine Interface (HMI) and Programmable Logic Controller (PLC) In Your Laptop: A No Bs, No Fluff, HMI-PLC Programming & SimulationFrom EverandProgramming, Simulating and Visualizing Human Machine Interface (HMI) and Programmable Logic Controller (PLC) In Your Laptop: A No Bs, No Fluff, HMI-PLC Programming & SimulationNo ratings yet

- Function Block ProgrammingDocument180 pagesFunction Block ProgrammingSyed SaifuddinNo ratings yet

- 1756 Um016a en P PDFDocument196 pages1756 Um016a en P PDFandrea19711971No ratings yet

- RAOTM 2017 - L07 - Micro800 PLC Programming With Connected Components Workbench Software - ManualDocument154 pagesRAOTM 2017 - L07 - Micro800 PLC Programming With Connected Components Workbench Software - ManualHuy Tran100% (2)

- The High Performance HMI Handbook: A Comprehensive Guide to Designing, Implementing and Maintaining Effective HMIs for Industrial Plant OperationsFrom EverandThe High Performance HMI Handbook: A Comprehensive Guide to Designing, Implementing and Maintaining Effective HMIs for Industrial Plant OperationsRating: 4.5 out of 5 stars4.5/5 (2)

- Analog Electronics by Godse and Bakhsi PDFDocument484 pagesAnalog Electronics by Godse and Bakhsi PDFSvh van HeerdenNo ratings yet

- Everything You Need to Know About PLCsDocument19 pagesEverything You Need to Know About PLCshemantkumarsheteNo ratings yet

- Tutorial 06 Function Block Diagram Programming With PLC TutorialDocument8 pagesTutorial 06 Function Block Diagram Programming With PLC Tutorialdony ramdhaniNo ratings yet

- Fieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005From EverandFieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005Miguel Leon ChavezNo ratings yet

- Programming Industrial Automation Laboratory Manual 2021-22Document60 pagesProgramming Industrial Automation Laboratory Manual 2021-22Insane PersonNo ratings yet

- 05 - DC Motor Control Using PLCDocument49 pages05 - DC Motor Control Using PLCKoppoju PadmaNo ratings yet

- Leverage Object-Oriented Industrial Programming - Control EngineeringDocument20 pagesLeverage Object-Oriented Industrial Programming - Control EngineeringPravivVivpraNo ratings yet

- RS Logix Sample For VFDDocument9 pagesRS Logix Sample For VFDJoe ElectricneutronNo ratings yet

- Programmable Logic Controllers An Emphasis On Design EbookDocument1 pageProgrammable Logic Controllers An Emphasis On Design EbookArnab Ghosh0% (7)

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- Topic 9Document24 pagesTopic 9bsmaldeniyaNo ratings yet

- PLC programmable logic controller A Clear and Concise ReferenceFrom EverandPLC programmable logic controller A Clear and Concise ReferenceNo ratings yet

- L04 BasicPLCProgramming PDFDocument88 pagesL04 BasicPLCProgramming PDFJose RequenaNo ratings yet

- Beginners Guide To PLC Programming Excerpt PDFDocument19 pagesBeginners Guide To PLC Programming Excerpt PDFAnonymous Nr9eWou100% (1)

- Scada System PDFDocument74 pagesScada System PDFglizNo ratings yet

- Siemens Building Technologies The Ultimate Step-By-Step GuideFrom EverandSiemens Building Technologies The Ultimate Step-By-Step GuideNo ratings yet

- Sequential Function ChartDocument6 pagesSequential Function ChartLuciano Cardoso Vasconcelos100% (1)

- BasicPLCProgramming Micro850Document88 pagesBasicPLCProgramming Micro850drkongala100% (1)

- PLC ProjectDocument69 pagesPLC Projectsovon adhikaryNo ratings yet

- Introduction to PLC Components, Logic Concepts & ApplicationsDocument108 pagesIntroduction to PLC Components, Logic Concepts & ApplicationsQais Alsafasfeh100% (2)

- Learn To Program, Simulate Plc & Hmi In Minutes with Real-World Examples from Scratch. A No Bs, No Fluff Practical Hands-On Project for Beginner to Intermediate: BoxsetFrom EverandLearn To Program, Simulate Plc & Hmi In Minutes with Real-World Examples from Scratch. A No Bs, No Fluff Practical Hands-On Project for Beginner to Intermediate: BoxsetNo ratings yet

- Certified Automation Professional A Complete Guide - 2020 EditionFrom EverandCertified Automation Professional A Complete Guide - 2020 EditionNo ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Rating: 3 out of 5 stars3/5 (2)

- Fundamentals of Control r1 0Document33 pagesFundamentals of Control r1 0Felipe Dias40% (5)

- Logix 5000 Controllers Sequential Function Charts: Programming ManualDocument81 pagesLogix 5000 Controllers Sequential Function Charts: Programming ManualFernando ArnaldoNo ratings yet

- S7 Distributed Safety Configuring and Program Min en US en-USDocument334 pagesS7 Distributed Safety Configuring and Program Min en US en-USPaulo SilvaNo ratings yet

- 2061 High Performance HMI White PaperDocument12 pages2061 High Performance HMI White Papersteam100deg8229No ratings yet

- Coherent Wireless Power Charging and Data Transfer for Electric VehiclesFrom EverandCoherent Wireless Power Charging and Data Transfer for Electric VehiclesNo ratings yet

- 2015 PID Tuning GuideDocument20 pages2015 PID Tuning GuideDaniel ScardiniNo ratings yet

- CCST Conversions DocumentDocument5 pagesCCST Conversions DocumentnatasyaghinnaNo ratings yet

- Learning RSLogix 5000 Programming1Document10 pagesLearning RSLogix 5000 Programming1alimohebbi1361No ratings yet

- Introduction To Controlnet With Controllogix: Hands-On Lab WorkbookDocument91 pagesIntroduction To Controlnet With Controllogix: Hands-On Lab WorkbookisaorsNo ratings yet

- RSLogix 500 EtherNet-IP Logic Examples PDFDocument4 pagesRSLogix 500 EtherNet-IP Logic Examples PDFchapsboiNo ratings yet

- TcPlcControl PDFDocument249 pagesTcPlcControl PDFpaull2002No ratings yet

- Programmable Logic Controller (PLC)Document4 pagesProgrammable Logic Controller (PLC)tagaya100% (3)

- Technical HandbookDocument51 pagesTechnical HandbookBryan WahyuNo ratings yet

- Curriculum Vitae Replace With First Name(s) Surname(s)Document2 pagesCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- Sample PID Symbols and LegendsDocument32 pagesSample PID Symbols and Legendstwinbrothers97% (29)

- Curriculum Vitae Replace With First Name(s) Surname(s)Document2 pagesCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- Carti in Romana (Literatura Romana Si Universala) PDF TXT Doc RTDocument31 pagesCarti in Romana (Literatura Romana Si Universala) PDF TXT Doc RTccyyppaaxxNo ratings yet

- Sample PID Symbols and LegendsDocument32 pagesSample PID Symbols and Legendstwinbrothers97% (29)

- Employee Management System: # Rule NameDocument9 pagesEmployee Management System: # Rule NameSavitha KrishnaswamyNo ratings yet

- Choose The Correct Answer From The Following: Subject: Operating SystemsDocument2 pagesChoose The Correct Answer From The Following: Subject: Operating SystemspradeeperukullaNo ratings yet

- CRMM Bupa MapDocument2 pagesCRMM Bupa MaprafdreNo ratings yet

- Poster Excel Web PDFDocument1 pagePoster Excel Web PDFKazi Akram UddinNo ratings yet

- Astronomical Controller 5.0Document20 pagesAstronomical Controller 5.0Everest100% (1)

- BI Apps 11.1.1.8.1 Configuration GuideDocument476 pagesBI Apps 11.1.1.8.1 Configuration Guidemsujankumar100% (1)

- Lab 5.2.4 Using Features of The Internetworking Operating System (IOS) Command Line Interface (CLI)Document7 pagesLab 5.2.4 Using Features of The Internetworking Operating System (IOS) Command Line Interface (CLI)2613078No ratings yet

- Architecture Guide SafeX3V11 v1B enDocument35 pagesArchitecture Guide SafeX3V11 v1B enfsussanNo ratings yet

- Notes 34Document3 pagesNotes 34singam v reddyNo ratings yet

- ICT 29 Visual NovelDocument11 pagesICT 29 Visual NovelSteve WerbenNo ratings yet

- Introduction To IBM Power Level 1 Quiz - Attempt ReviewDocument9 pagesIntroduction To IBM Power Level 1 Quiz - Attempt ReviewFarrukh SamaNo ratings yet

- Assignment On Blockchain PDFDocument3 pagesAssignment On Blockchain PDFshahinNo ratings yet

- ZXA10 C220 XPON Optical Access Convergence Configuration Manual (CLI)Document261 pagesZXA10 C220 XPON Optical Access Convergence Configuration Manual (CLI)anon_508482696100% (3)

- Civilvalley Blogspot Com 2013 09 Top Ten Software Used in CiDocument24 pagesCivilvalley Blogspot Com 2013 09 Top Ten Software Used in CiAnonymous aIkepEPXNo ratings yet

- Features Description: 1996 Burr-Brown Corporation PDS-1304B Printed in U.S.A. October, 1997Document16 pagesFeatures Description: 1996 Burr-Brown Corporation PDS-1304B Printed in U.S.A. October, 1997Hector Jose Murillo CordobaNo ratings yet

- Application No.: Candidate Name: BISHAD SHUKLA Roll No.: UP12404315 Test Date: Test Slot: Subject: Computer Science and ApplicationsDocument71 pagesApplication No.: Candidate Name: BISHAD SHUKLA Roll No.: UP12404315 Test Date: Test Slot: Subject: Computer Science and ApplicationsHarshita SinghNo ratings yet

- Quick Installation Guide: Netis 150Mbps Wireless N Portable RouterDocument1 pageQuick Installation Guide: Netis 150Mbps Wireless N Portable RouterLuciNo ratings yet

- PM Project Postmortem SurveyDocument8 pagesPM Project Postmortem SurveyEduardo Duarte100% (1)

- Social Media Marketing Sizes Cheat SheetDocument9 pagesSocial Media Marketing Sizes Cheat SheetSam HarrelsonNo ratings yet

- Implement REST API with APIkitDocument49 pagesImplement REST API with APIkitJayati Kaul38% (8)

- SM3260 Product BriefDocument1 pageSM3260 Product BriefMrr LeeNo ratings yet

- Synopsis of Pharmacy Management System SDocument29 pagesSynopsis of Pharmacy Management System SRahul singh67% (3)

- Suvt PM ReportDocument3 pagesSuvt PM ReportRohit SaxenaNo ratings yet

- Header Linked ListDocument13 pagesHeader Linked ListSai KarthikNo ratings yet

- TP MT5510S PB803Document16 pagesTP MT5510S PB803akifrustamov5No ratings yet

- Compiler Vs InterpreterDocument8 pagesCompiler Vs InterpreterAjay SinghNo ratings yet

- MCQ in Wire and Wireless Communications System Part 10 ECE BoardDocument20 pagesMCQ in Wire and Wireless Communications System Part 10 ECE BoardIan John MontalboNo ratings yet

- Usr WWW Users Melita Safe24.md Image PDF Dsc-Powerseries-ChartasDocument1 pageUsr WWW Users Melita Safe24.md Image PDF Dsc-Powerseries-ChartasTehno PRO Supraveghere video MoldovaNo ratings yet

- Ripple Connect Product SheetDocument10 pagesRipple Connect Product SheetMlungisi Lu NdlovuNo ratings yet

- Xenapp Xendesktop 7 17 PDFDocument990 pagesXenapp Xendesktop 7 17 PDFBrad AndersonNo ratings yet