Professional Documents

Culture Documents

Trim/Servo Assembly: Van'S Aircraft, Inc

Uploaded by

Mark Evan SalutinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trim/Servo Assembly: Van'S Aircraft, Inc

Uploaded by

Mark Evan SalutinCopyright:

Available Formats

VAN'S AIRCRAFT, INC.

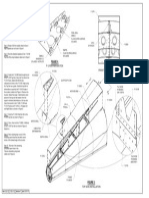

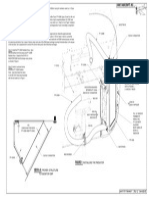

CAUTION: Install castle nuts in this section finger tight, to eliminate lateral play but allow freedom of movement, then install the cotter pin. Step 1: Attach the F-1287D-L & -R Clevis Plates together using the parts and hardware called out in Figure 1. Pay attention to the orientation of the clevis plates in relation to the F-1287C Link. Cleco the clevis plates to the F-1287E Pushrod. Pay attention to the orientation of the pushrod in relation to the clevis plates. Step 2: Match-Drill the holes in each of the F-1287D-L & -R Clevis Plates into the F-1287E Pushrod as called out in Figure 1. Remove the clevis plates with the hardware still attached. Clear away chips. Step 3: Clamp the F-1287F Threaded Insert into the curved end of the F-1287E Pushrod as shown in Figure 1. Use a rivet or similar to align the holes in the threaded insert with the holes in the pushrod. Step 4: Match-Drill the holes from the F-1287E Pushrod and the F-1287F Threaded Insert into the pushrod as called out in Figure 1. Step 5: Rivet the F-1287D-L & -R Clevis Plates to the F-1287E Pushrod using hardware called out in Figure 1. Apply pressure toward the clevis plate while setting each rivet. Rivet the F-1287F Threaded Insert to the pushrod using rivets called out in Figure 1. Hereafter refer to the pushrod, clevis plates and threaded insert as the Pushrod Assembly. F-1287F ES MSTS-T3-7A-2 SHAFT ES MSTS-T3-7A-2 16 11/16 Step 6: Install the called out rod end bearing and jam nut into the F-1287F Threaded Insert per dimensions in Figure 2. Achieve the dimension given then rotate the bearing body to align with the centerline of the Pushrod Assembly as shown in Figure 2. Step 7: Thread the jam nut onto the ES MSTS-T3-7A-2 Pitch Trim Servo shaft until it contacts the pitch trim servo housing. Thread the clevis rod end of the Pushrod Assembly onto the pitch trim servo shaft until it contacts the jam nut. Back the clevis rod end off one full turn. Tighten the jam nut against the clevis rod end. PUSHROD ASSEMBLY

BEARING MM-3 AN315-3R

AN315-3R AN665-21R

AN470AD3-9, 2 PLACES MANUFACTURED HEAD THIS SIDE.

MS24665-151 AN310-3 PUSHROD ASSEMBLY F-1287D-R AD42H, 12 PLACES MATCH DRILL #40, 2 PLACES F-1287E F-1287D-L AN665-21R AN960-10, 4 PLACES MATCH-DRILL #30, 8 PLACES AN960-10, 6 PLACES AN23-15 F-1287D-R F-1287C F-1287C F-1287E F-1287D-L AN310-3 AN960-10L, 2 PLACES MS24665-151

FIGURE 2: TRIM/SERVO ASSEMBLY

NOTE: For clarity, the Rudder, V-Stab, and Stabilator Assemblies are not shown in Figure 4. Step 8: From below the Stabilator Assembly, guide the rod end bearing of the Trim/Servo Assembly up between the stabilator main skins to the AST Assembly control horns as shown in Figure 3. Step 9: Install the F-1287A Servo Tray to the F-1211D Attach Brackets using the hardware called out in Figure 3. Prior to Section 25 Tailcone Attachment, separate the legs of the cotter pin only enough to hold it in the hole until final installation. Fully install this cotter pin after the tailcone is attached to the fuselage. Step 10: Install the rod end bearing to the AST Assemblies using the hardware called out in Figure 3. F-1287G F-1287H AN3-35 AN365-1032 F-1287A AN960-10, 3 PLACES AN3-10A TRIM/SERVO ASSEMBLY

AN23-15

F-1211D AN310-3 MS24665-151

AN960-10

FIGURE 1: PUSHROD ASSEMBLY FIGURE 3: TRIM/SERVO ASSEMBLY INSTALLATION

DATE:

AST ASSEMBLY

07/17/09

REVISION:

RV-12

PAGE

11-07

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Assembly ProcedureDocument115 pagesAssembly ProcedureAlex Castillo100% (1)

- Magic BowDocument13 pagesMagic BowSteve Dowell80% (5)

- Caja Reductora de EngranajeDocument32 pagesCaja Reductora de EngranajeJesùs AmèsquitaNo ratings yet

- Materials Inspection ManualDocument280 pagesMaterials Inspection ManualSreedhar Patnaik.MNo ratings yet

- Design Analysis Article in The October, 1944 Issue of Aviation Magazine FW190 DraftDocument36 pagesDesign Analysis Article in The October, 1944 Issue of Aviation Magazine FW190 DraftAaron ParkerNo ratings yet

- Aluminum in AircraftDocument117 pagesAluminum in AircraftMark Evan Salutin91% (11)

- SR TechniquesDocument673 pagesSR TechniquesReBeL Tv LxNo ratings yet

- Ignition Cables and Igniter Installation PDFDocument6 pagesIgnition Cables and Igniter Installation PDFMark Evan SalutinNo ratings yet

- Ignition Cables and Igniter Installation PDFDocument6 pagesIgnition Cables and Igniter Installation PDFMark Evan SalutinNo ratings yet

- Ignition Cables and Igniter Installation PDFDocument6 pagesIgnition Cables and Igniter Installation PDFMark Evan SalutinNo ratings yet

- Preparing Holes For FasteningDocument9 pagesPreparing Holes For Fasteningolegprikhodko2809100% (1)

- Wing in Ground Effect Craft Review ADA361836Document88 pagesWing in Ground Effect Craft Review ADA361836Mark Evan SalutinNo ratings yet

- WheelHorse Three Point Hitch 8-5421 Owners ManualDocument4 pagesWheelHorse Three Point Hitch 8-5421 Owners ManualKevins Small Engine and Tractor Service100% (1)

- Installation and Rigging ProceduresDocument15 pagesInstallation and Rigging ProceduresRene QueirozNo ratings yet

- Guide Line For Inspection of Overhead Crane StructureDocument43 pagesGuide Line For Inspection of Overhead Crane StructurePranoy Barua100% (1)

- Aalborg OC Boiler - PART 2 PDFDocument328 pagesAalborg OC Boiler - PART 2 PDFPhạm Quốc ToànNo ratings yet

- Airless Owners ManualDocument12 pagesAirless Owners ManualJorge GomezNo ratings yet

- Examen de Inglés para Obtener o RenovarDocument14 pagesExamen de Inglés para Obtener o RenovarRicardo Chepo Vidal100% (2)

- Van'S Aircraft, Inc.: Figure 4: Adding The Terminal BlockDocument1 pageVan'S Aircraft, Inc.: Figure 4: Adding The Terminal BlockMark Evan SalutinNo ratings yet

- Figure 1: Adding Fittings To The Inboard Main Gear Attach BracketsDocument1 pageFigure 1: Adding Fittings To The Inboard Main Gear Attach BracketsMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: FuselageDocument1 pageVan'S Aircraft, Inc.: Figure 1: FuselageMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: F-1211D PreparationDocument1 pageVan'S Aircraft, Inc.: F-1211D PreparationMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: InstallingDocument1 pageVan'S Aircraft, Inc.: Figure 1: InstallingMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: Installing The Side SkinsDocument1 pageVan'S Aircraft, Inc.: Figure 1: Installing The Side SkinsMark Evan SalutinNo ratings yet

- 3.8m C Band Circ. Pol RXTXDocument6 pages3.8m C Band Circ. Pol RXTXJoseph EdwardsNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: OptionalDocument1 pageVan'S Aircraft, Inc.: Figure 1: OptionalMark Evan SalutinNo ratings yet

- G MECHA (Panasonic)Document14 pagesG MECHA (Panasonic)phil_meeNo ratings yet

- Presser Foot Stopper Roller-C SeriesDocument8 pagesPresser Foot Stopper Roller-C SeriesjoecentroneNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: Attaching The Nose RibsDocument1 pageVan'S Aircraft, Inc.: Figure 1: Attaching The Nose RibsMark Evan SalutinNo ratings yet

- 300-5617 Cooler AssemblyDocument13 pages300-5617 Cooler Assemblyharikrishnanpd3327No ratings yet

- Figure 3: Separating The Inst Stack Angle: Attaching The F-1201A Assembly (Some Parts Not Shown For Clarity)Document1 pageFigure 3: Separating The Inst Stack Angle: Attaching The F-1201A Assembly (Some Parts Not Shown For Clarity)Mark Evan SalutinNo ratings yet

- Siemens PS2 Bracket InstallationDocument12 pagesSiemens PS2 Bracket InstallationKiaraNo ratings yet

- Van'S Aircraft, Inc.: Figure 4: SwitchDocument1 pageVan'S Aircraft, Inc.: Figure 4: SwitchMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: Routing Line Through Ribs Figure 3: Terminal Bracket InstallationDocument1 pageVan'S Aircraft, Inc.: Figure 1: Routing Line Through Ribs Figure 3: Terminal Bracket InstallationMark Evan SalutinNo ratings yet

- Figure 3: Rolling The Upper Forward Fuselage Skin: Van'S Aircraft, IncDocument1 pageFigure 3: Rolling The Upper Forward Fuselage Skin: Van'S Aircraft, IncMark Evan SalutinNo ratings yet

- Figure 1: Snap Bushing Bracket Separation: Van'S Aircraft, IncDocument1 pageFigure 1: Snap Bushing Bracket Separation: Van'S Aircraft, IncMark Evan SalutinNo ratings yet

- Vizion Autopilot Installation for Cessna 172Document50 pagesVizion Autopilot Installation for Cessna 172sandyNo ratings yet

- Van'S Aircraft, Inc.: 11-08 RV-12 Ast Assembly TravelDocument1 pageVan'S Aircraft, Inc.: 11-08 RV-12 Ast Assembly TravelMark Evan SalutinNo ratings yet

- VAN'S AIRCRAFT RUDDER PEDAL INSTALLATION GUIDEDocument1 pageVAN'S AIRCRAFT RUDDER PEDAL INSTALLATION GUIDEMark Evan SalutinNo ratings yet

- Vizion PMA Installation Guide PA-28 Appendix D 243 Rev CDocument38 pagesVizion PMA Installation Guide PA-28 Appendix D 243 Rev CAlex ProkonovNo ratings yet

- Metal Matic P 200 ManualDocument13 pagesMetal Matic P 200 ManualRon BoeserNo ratings yet

- D6 - Recoil DisassemblyDocument7 pagesD6 - Recoil DisassemblyrodriguezalejandrotucNo ratings yet

- US801453-TX9200-9500 Install and Service Manaul SW - 9 2Document63 pagesUS801453-TX9200-9500 Install and Service Manaul SW - 9 2Rickz2k8No ratings yet

- ACH13 Instruction Sheet R01Document7 pagesACH13 Instruction Sheet R01shotowjNo ratings yet

- Van'S Aircraft, Inc.: Detail A-ADocument1 pageVan'S Aircraft, Inc.: Detail A-AMark Evan SalutinNo ratings yet

- Pistons and Connecting Rods - AssembleDocument5 pagesPistons and Connecting Rods - Assembleeshopmanual limaNo ratings yet

- Attach Angle Positions: BO AR DDocument1 pageAttach Angle Positions: BO AR DMark Evan SalutinNo ratings yet

- VDO Gauge InstallationDocument4 pagesVDO Gauge Installationurule2kNo ratings yet

- Technical Bulletin: CopierDocument22 pagesTechnical Bulletin: CopiernickypanzeNo ratings yet

- Patg Pamg Turbo PartsDocument12 pagesPatg Pamg Turbo Parts1luckywolf0% (1)

- Van'S Aircraft, Inc.: Revision: DateDocument1 pageVan'S Aircraft, Inc.: Revision: DateMark Evan SalutinNo ratings yet

- Cylinder Head - Install: Disassembly and AssemblyDocument8 pagesCylinder Head - Install: Disassembly and AssemblySaeed KazemiNo ratings yet

- Van's Aircraft Flaperon Assembly InstructionsDocument1 pageVan's Aircraft Flaperon Assembly InstructionsMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Revision: DateDocument1 pageVan'S Aircraft, Inc.: Revision: DateMark Evan SalutinNo ratings yet

- A Be212 4040 DSDocument18 pagesA Be212 4040 DSLuis Antonio HermozaNo ratings yet

- Operating Instructions Dixie Cerradora de LatasDocument22 pagesOperating Instructions Dixie Cerradora de LatasMario Amieva BalsecaNo ratings yet

- 4096 406Document5 pages4096 406Pranalanka WarunawansaNo ratings yet

- Installation Instructions - Model 10 SignalDocument63 pagesInstallation Instructions - Model 10 SignalChristian CristãoNo ratings yet

- Isc 300Document37 pagesIsc 300AwanNo ratings yet

- RISO KS800 Parts List GuideDocument57 pagesRISO KS800 Parts List GuidePablo Andres Parraguez AguileraNo ratings yet

- Parts: RoebuckDocument6 pagesParts: RoebuckCary BriefNo ratings yet

- Figure 1: Oil Door Assembly Installation: Van'S Aircraft, IncDocument1 pageFigure 1: Oil Door Assembly Installation: Van'S Aircraft, IncMark Evan SalutinNo ratings yet

- Shimano Nexus Inter-7 - Coaster - BrakeDocument12 pagesShimano Nexus Inter-7 - Coaster - BrakeGeorge OrfanidisNo ratings yet

- OM5510 05 (Positioner)Document16 pagesOM5510 05 (Positioner)JayeshJayarajanNo ratings yet

- Channel Master 2-4m ManualDocument9 pagesChannel Master 2-4m ManualWilfredo AriasNo ratings yet

- Installation Instructions For:: Crank Angle Sensor Replacement For EMS P/N 30-6600Document24 pagesInstallation Instructions For:: Crank Angle Sensor Replacement For EMS P/N 30-6600Ryan FrederickNo ratings yet

- Application: Focus 3 "M" Contactor F3M112 & F3M224 Instruction SheetDocument7 pagesApplication: Focus 3 "M" Contactor F3M112 & F3M224 Instruction SheetLuis MorenoNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: Installing The Radiator View A-A: Proper StructureDocument1 pageVan'S Aircraft, Inc.: Figure 1: Installing The Radiator View A-A: Proper StructureMark Evan SalutinNo ratings yet

- Acoplamiento Sure-Flex Couplings PDFDocument4 pagesAcoplamiento Sure-Flex Couplings PDFFederico Pérez de LeónNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Ignition System - Inspection Check PDFDocument4 pagesIgnition System - Inspection Check PDFMark Evan SalutinNo ratings yet

- Ignition System - Inspection Check PDFDocument4 pagesIgnition System - Inspection Check PDFMark Evan SalutinNo ratings yet

- High Low Tension Ignition Comparison PDFDocument4 pagesHigh Low Tension Ignition Comparison PDFMark Evan SalutinNo ratings yet

- High Low Tension Ignition Comparison PDFDocument4 pagesHigh Low Tension Ignition Comparison PDFMark Evan SalutinNo ratings yet

- Permatex Form A GasketDocument3 pagesPermatex Form A GasketMark Evan SalutinNo ratings yet

- High Low Tension Ignition Comparison PDFDocument4 pagesHigh Low Tension Ignition Comparison PDFMark Evan SalutinNo ratings yet

- Material Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationShemi KannurNo ratings yet

- Petroleum JellyDocument6 pagesPetroleum JellyMark Evan SalutinNo ratings yet

- Agard 406351 Ground Effect MachinesDocument169 pagesAgard 406351 Ground Effect MachinesMark Evan SalutinNo ratings yet

- Poly FIber BR-8600 Blush RetarderDocument2 pagesPoly FIber BR-8600 Blush RetarderMark Evan SalutinNo ratings yet

- Poly Fiber Poly-TakDocument2 pagesPoly Fiber Poly-TakMark Evan SalutinNo ratings yet

- Poly Fiber Reducer R65-75Document2 pagesPoly Fiber Reducer R65-75Mark Evan SalutinNo ratings yet

- PolyFLex Evercoat.Document7 pagesPolyFLex Evercoat.Mark Evan SalutinNo ratings yet

- Simple GreenDocument4 pagesSimple GreenMark Evan SalutinNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingDocument10 pagesSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingMark Evan SalutinNo ratings yet

- Poly-Spray MSDS Paint CoatingsDocument2 pagesPoly-Spray MSDS Paint CoatingsMark Evan SalutinNo ratings yet

- Superior Graphite Tube o LubeDocument3 pagesSuperior Graphite Tube o LubeMark Evan SalutinNo ratings yet

- Rundolph Spray VarnishDocument7 pagesRundolph Spray VarnishMark Evan SalutinNo ratings yet

- Poly-Spray MSDS Paint CoatingsDocument2 pagesPoly-Spray MSDS Paint CoatingsMark Evan SalutinNo ratings yet

- Power CleanDocument2 pagesPower CleanMark Evan SalutinNo ratings yet

- Sting-X II, Aerosol Certified LabsDocument4 pagesSting-X II, Aerosol Certified LabsMark Evan SalutinNo ratings yet

- Sonnen Honing OilDocument5 pagesSonnen Honing OilMark Evan SalutinNo ratings yet

- Spotcheck Reg Cleaner Remover SKC-HFDocument3 pagesSpotcheck Reg Cleaner Remover SKC-HFMark Evan SalutinNo ratings yet

- Sulfuric Acid Electrolyte 5-05Document5 pagesSulfuric Acid Electrolyte 5-05Mark Evan SalutinNo ratings yet

- Soldering Flux PasteDocument9 pagesSoldering Flux PasteMark Evan SalutinNo ratings yet

- Modern Sewer Design: CSP Sewers Are Designed For The Deepest InstallationsDocument28 pagesModern Sewer Design: CSP Sewers Are Designed For The Deepest InstallationsJuan GrajalesNo ratings yet

- Huck Hucklok enDocument4 pagesHuck Hucklok enEldori1988No ratings yet

- Factors Affecting The Cost of Airplanes: Presented at The Aircraft Operations Session, Fourth Annual Meeting, 1. Ae. SDocument7 pagesFactors Affecting The Cost of Airplanes: Presented at The Aircraft Operations Session, Fourth Annual Meeting, 1. Ae. SnaveenreddyNo ratings yet

- System MQ: Air-Conditioning and VentilationDocument24 pagesSystem MQ: Air-Conditioning and VentilationEssam Nabih YacoubNo ratings yet

- Masonry and tile dutiesDocument3 pagesMasonry and tile dutieskamoteNo ratings yet

- The Truss Shown Carries A Weight W 500N. Find The Tensile Stress (Mpa) in Member Ac If It Has A Diameter of 8MmDocument23 pagesThe Truss Shown Carries A Weight W 500N. Find The Tensile Stress (Mpa) in Member Ac If It Has A Diameter of 8MmpamelaNo ratings yet

- Chapter 3 - Tension MembersDocument8 pagesChapter 3 - Tension MembersHipow87No ratings yet

- DME Chapter 2Document5 pagesDME Chapter 2dhananjayvermaNo ratings yet

- Punch Price BookDocument28 pagesPunch Price Book4U6ogj8b9snylkslkn3nNo ratings yet

- Specs PeDocument8 pagesSpecs PeKhairilMunawarNo ratings yet

- FD Installation StandardsDocument4 pagesFD Installation Standardsanwer_quadriNo ratings yet

- Leather Clamshell Gauntlets PlansDocument5 pagesLeather Clamshell Gauntlets PlansScott Giefer67% (3)

- AC 43.13-1B-Hardware Identification Table-3d-Ch7 - 11Document26 pagesAC 43.13-1B-Hardware Identification Table-3d-Ch7 - 11MASOUDNo ratings yet

- Mechanical Joints Types and FailuresDocument16 pagesMechanical Joints Types and FailuresArjhay GironellaNo ratings yet

- Hooked On BoltsDocument21 pagesHooked On Boltsflavian_gafitaNo ratings yet

- Chapter-5 Design of Welded JointsDocument15 pagesChapter-5 Design of Welded JointsVarshaNo ratings yet

- CS UT 252 Conduit PipelineDocument8 pagesCS UT 252 Conduit PipelineGilson VieiraNo ratings yet

- Making Tongs For Blacksmithing: Register For Our ClassDocument14 pagesMaking Tongs For Blacksmithing: Register For Our ClassTemesgen HenokNo ratings yet

- Snap Head High Nickel-Copper Alloy Rivets : Specification ForDocument10 pagesSnap Head High Nickel-Copper Alloy Rivets : Specification ForcoolkaisyNo ratings yet

- Cherry MS RivetsDocument17 pagesCherry MS RivetsKamal Jit Dhiman100% (1)

- Stress StrainDocument5 pagesStress StrainVignesh SelvarajNo ratings yet

- Temporary Allowance For Continued Operation Missing Fasteners and Grommets in L/H And/or R/H CowlingsDocument4 pagesTemporary Allowance For Continued Operation Missing Fasteners and Grommets in L/H And/or R/H Cowlingsom prakash patelNo ratings yet

- Werner LadderDocument80 pagesWerner LadderAbdullah HaroonNo ratings yet