Professional Documents

Culture Documents

Din 1480 2005

Uploaded by

PacoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Din 1480 2005

Uploaded by

PacoCopyright:

Available Formats

DEUTSCHE NORM

September 2005

DIN 1480

ICS 21.060.70

{

Together with DIN 34828:2005-09, supersedes DIN 1480:1975-09

Forged turnbuckles (open type)

Spannschlossmuttern, geschmiedet (offene Form)

Normen-Download-Beuth-GAMESA INNOVATION & TECHNOLOGY.-2006-11-13

Document comprises 6 pages

Translation by DIN-Sprachendienst.

In case of doubt, the German-language original should be consulted as the authoritative text.

No part of this translation may be reproduced without prior permission of DIN Deutsches Institut fr Normung e. V., Berlin. Beuth Verlag GmbH, 10772 Berlin, Germany, has the exclusive right of sale for German Standards (DIN-Normen).

English price group 6 www.din.de www.beuth.de

!,ohm"

09.06 9766974

DIN 1480:2005-09

Foreword

This standard has been prepared by Technical Committee FMV-AA 3.12.2 Spannschlsser of the Normenausschuss Mechanische Verbindungselemente (Fasteners Standards Committee). The DIN 4000-2-8.4 tabular layout of article characteristics shall apply to turnbuckles covered in this standard.

NOTE Parts of DIN 4000-2 are intended to be superseded by DIN 4000-161, in which case the DIN 4000-161-6 tabular layout of article characteristics will apply to turnbuckles complying with this standard.

Amendments This standard differs from DIN 1480:1975-09 as follows: a) b) c) d) e) f) g) h) i)

Normen-Download-Beuth-GAMESA INNOVATION & TECHNOLOGY.-2006-11-13

The title of the standard has been changed. The scope of the standard has been amended. Dimensional tolerances have been specified. Measurement of coaxiality by gauging has been introduced (see clause 6). Grade S235JR steel has been introduced. Forging grade F in accordance with DIN EN 10243-1 has been specified. For threads, tolerance 6H has been specified. Clause 8 Surface finish has been included. The designation has been amended. Specifications relating to loadability have been included. Specifications for welding studs are no longer included (but see DIN 34828). The designation of a complete turnbuckle (including turnbuckle nut and two welding studs) has been dropped.

j) k) l)

Previous editions DIN KrK 802: 1928-07 DIN 1480: 1928-07, 1935-03, 1975-09 DIN 1480-1: 1942x-04

Scope

This standard specifies requirements for M6 to M56 forged turnbuckles (open type) made of steel.

DIN 1480:2005-09

Normative references

The following reference documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. DIN 4000-2:1999-12, Tabular layouts of article characteristics for bolts, screws and fit bolts DIN 34828, Welding studs for turnbuckles DIN EN 10025, Hot rolled products of structural steels Technical delivery conditions DIN EN 10243-1, Steel die forgings Tolerances on dimensions Part 1: Drop and vertical press forgings DIN EN ISO 4042, Fasteners Electroplated coatings DIN EN ISO 10683, Fasteners Non-electrolytically applied zinc flake coatings DIN EN ISO 10684, Fasteners Hot dip galvanized coatings DIN ISO 965-2, ISO general purpose metric screw threads Tolerances Part 2: Limits of sizes for general purpose external and internal screw threads Medium quality

Dimensions

Turnbuckle dimensions shall be as given in figure 1 and table 1.

Normen-Download-Beuth-GAMESA INNOVATION & TECHNOLOGY.-2006-11-13

a b

Turnbuckle nut with left-hand thread, marked by L Turnbuckle nut with right-hand thread (without marking)

Figure 1 Turnbuckle dimensions (notation)

DIN 1480:2005-09

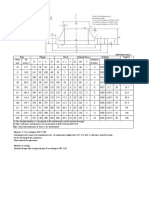

Table 1 Turnbuckle dimensions Dimensions in millimetres

Thread size (d1) Nominal dimension max. min. Nominal dimension max. min. Nominal dimension max. min. min. Nominal dimension max. min. min. max. M6 12 12,9 11,5 19 19,9 18,5 9 9,5 8,1 6 110 111,1 109,5 12 6 80 M8 15 15,9 14,5 23 23,9 22,5 11 11,5 10,1 8 110 111,1 109,5 15 8 75 M10 18 18,9 17,5 30 30,9 29,5 14 14,5 13,1 9 125 126,2 124,4 18 9 85 M12 21 21,9 20,5 34 35,1 33,5 16 16,5 15,1 11 125 126,2 124,4 21 11 80 M16 27 27,9 26,5 42 43,1 41,5 20 20,5 19,1 14 170 171,3 169,3 27 14 110 M20 34 35,1 33,5 52 53,1 51,5 24 24,5 23,1 17 200 201,3 199,3 34 17 130 M24 39 40,1 38,5 60 61,1 59,5 28 28,5 27,1 20 255 256,3 254,3 39 20 170 M30 45 46,2 44,4 74 75,2 73,4 34 34,6 32,8 23 255 256,3 254,3 45 23 160 M36 55 56,2 54,4 86 87,2 85,4 40 40,6 38,8 28 295 296,7 294,2 55 28 180 M42 63 64,3 62,3 104 105,3 103,3 50 50,7 48,7 32 330 332,1 328,9 63 32 200 M48 80 81,5 79,3 135 136,7 134,3 65 65,7 63,5 40 355 357,1 353,9 78 39 195 M56 80 81,5 79,3 135 136,7 134,3 65 65,7 63,5 40 355 357,1 353,9 78 39 195

d2

f h l1 m1 m2

Length of engagement

4

Normen-Download-Beuth-GAMESA INNOVATION & TECHNOLOGY.-2006-11-13

Material

Turnbuckles shall be made of grade S235JR steel as specified in DIN EN 10025.

Design

Turnbuckles shall be drop forged to forging grade F as specified in DIN EN 10243-1.

Coaxiality of bores

The coaxiality of bores shall be measured by means of a plug gauge as in figure 2 and table 2. The gauge shall pass through the bore in a vertical position under its own weight and without excessive force (see figure 2).

DIN 1480:2005-09

Table 2 Plug gauge dimensions Dimensions in millimetres Thread size (d1) M6 M8 M10 M12 M16 M20 M24 M30 M36 M42 M48 M56 l2 120 120 150 150 200 220 260 260 300 350 380 380 Nominal dimension 4,83 6,54 8,23 9,94 13,64 17,09 20,54 25,93 31,33 36,75 42,10 49,52 d3 Limit deviations

0,000 0,012

0,000 0,015 0,000 0,015 0,000 0,018 0,000 0,018 0,000 0,021 0,000 0,021 0,000 0,021 0,000 0,025 0,000 0,025 0,000 0,025 0,000 0,025

Normen-Download-Beuth-GAMESA INNOVATION & TECHNOLOGY.-2006-11-13

Key 1 Plug gauge 2 Turnbuckle Figure 2 Gauging of coaxiality

DIN 1480:2005-09

Screw threads

The threads of turnbuckles shall be metric coarse pitch threads as in DIN ISO 965-2, produced to tolerance 6H.

Surface finish

DIN EN ISO 4042 shall apply with regard to electroplating. DIN EN ISO 10684 shall apply with regard to hot dip galvanizing. DIN EN ISO 10683 shall apply with regard to non-electrolytically applied zinc flake coatings.

Designation

Designation of an M12 forged turnbuckle (SP) with right-hand and left-hand thread:

Turnbuckle DIN 1480 SP M12

10 Connecting components

Welding studs for turnbuckles complying with this standard are covered in DIN 34828.

NOTE Connecting components which are not standardized at present may be used, this being subject to agreement. It should, however, be noted, that the loadability of such components does not necessarily comply with that of the turnbuckle.

Normen-Download-Beuth-GAMESA INNOVATION & TECHNOLOGY.-2006-11-13

11 Assembly and loadability

Turnbuckles complying with this standard shall be assembled with welding studs as specified in DIN 34828 which are made of the same steel (S235JR). The loadability of such assemblies is higher than that of the welding studs. When using turnbuckles with connecting components made of other materials, in particular materials of higher strength, the loadability of the assembly shall be determined separately.

You might also like

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- Din 18808Document20 pagesDin 18808Silmar BiazioliNo ratings yet

- Galv Eye&EyeDocument1 pageGalv Eye&EyeTulang RorobotNo ratings yet

- Euroclad Guide To Design and Installation of Trapezoidal SystemsDocument0 pagesEuroclad Guide To Design and Installation of Trapezoidal Systemsssss2345No ratings yet

- HeaDocument1 pageHeaRianto HalimNo ratings yet

- Welding Instruction Manual PDFDocument96 pagesWelding Instruction Manual PDFyud100% (1)

- Universal BeamDocument17 pagesUniversal BeamHazwan AzamanNo ratings yet

- Tekla Structures: Modeling ManualDocument173 pagesTekla Structures: Modeling ManualKa KaNo ratings yet

- Pipe ThreadsDocument2 pagesPipe Threadsehab2003yeNo ratings yet

- Chanels Tapered Flange Metric and Universal Beams and Columns Imperial Units and UPNDocument3 pagesChanels Tapered Flange Metric and Universal Beams and Columns Imperial Units and UPNPratama YogaNo ratings yet

- Doors & WindowsDocument21 pagesDoors & Windows200211555No ratings yet

- NPT, Nps & - ThreadsDocument3 pagesNPT, Nps & - ThreadsklashincoviskyNo ratings yet

- DIN13 ISO Metric Threads enDocument1 pageDIN13 ISO Metric Threads enwagner jrNo ratings yet

- Hollow Steel Catalog PDFDocument44 pagesHollow Steel Catalog PDFaiyubi2No ratings yet

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDFrancisco RojasNo ratings yet

- 1 50ug Pipe and TubesDocument92 pages1 50ug Pipe and TubesTC İsmail TalayNo ratings yet

- Fittings Din11852 Din11850Document14 pagesFittings Din11852 Din11850dingobk1No ratings yet

- Equal Leg Angles To en 10056-1 1998 Dim - PropDocument2 pagesEqual Leg Angles To en 10056-1 1998 Dim - PropJagdish Chhugani100% (1)

- Self Drilling Screws Fasteners Product Data 1673386Document8 pagesSelf Drilling Screws Fasteners Product Data 1673386Fabio Saraiva BoxNo ratings yet

- EN - 583-2 - (2001) - Non-Destructive Testing. Ultrasonic Examination. Sensitivity and Range SettingDocument47 pagesEN - 583-2 - (2001) - Non-Destructive Testing. Ultrasonic Examination. Sensitivity and Range SettingMarcelo RodriNo ratings yet

- Universal Beams... BS 4 Part 1 2005 Dim - PropDocument2 pagesUniversal Beams... BS 4 Part 1 2005 Dim - PropJagdish ChhuganiNo ratings yet

- Fusion Welidng Acceptance CriteriaDocument25 pagesFusion Welidng Acceptance CriteriakarthickenigooNo ratings yet

- DIN 934 NutsDocument1 pageDIN 934 NutsleroniusNo ratings yet

- Round Washers SN 808: July 2000Document1 pageRound Washers SN 808: July 2000Maurício Duarte de AndradeNo ratings yet

- Aquasafe Septic SystemDocument22 pagesAquasafe Septic Systemsygmadude100% (1)

- Thread Chart PDFDocument9 pagesThread Chart PDFhisaj4uNo ratings yet

- H Section JIS G 3192Document9 pagesH Section JIS G 3192Sudath KularathnaNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsAdnan NajemNo ratings yet

- Conical Seat Spherical Washer Is 4297Document6 pagesConical Seat Spherical Washer Is 4297Rajasekaran Murugan0% (1)

- DIN ArruelasDocument35 pagesDIN ArruelasSigurbjörnBárðarsonNo ratings yet

- Iso 16028 1999Document9 pagesIso 16028 1999MussardNo ratings yet

- BS en 15614 Welder Tests Template1Document14 pagesBS en 15614 Welder Tests Template1delta lab sangliNo ratings yet

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDocument2 pagesAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987No ratings yet

- Chinese To DinDocument7 pagesChinese To DinDamla KaymakçıNo ratings yet

- Steel-Product Catalog enDocument75 pagesSteel-Product Catalog enmohammad_reza_49No ratings yet

- 2010 Catalogue AndertonDocument47 pages2010 Catalogue Andertonaiyubi2100% (1)

- WEG Roller Table 50040456 Brochure EnglishDocument12 pagesWEG Roller Table 50040456 Brochure EnglishjmartinezmoNo ratings yet

- AVK Gate Valve HandwheelDocument2 pagesAVK Gate Valve HandwheelQubit SizedNo ratings yet

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- Parallel Key Calculation According To DIN 6892Document21 pagesParallel Key Calculation According To DIN 6892zahirshah1436923No ratings yet

- Procesna ReduktoriDocument150 pagesProcesna ReduktoriMilenkoBogdanovic50% (2)

- Drafting ThreadsDocument15 pagesDrafting Threadsm_stasys9939No ratings yet

- Din 1025-3-1994 Eng PDFDocument4 pagesDin 1025-3-1994 Eng PDFAnonymous gUxMsgENo ratings yet

- DIN ISO 12944-1 (Sistemas de Proteccion de Corrosion y Pintura en Estructuras Metalicas)Document11 pagesDIN ISO 12944-1 (Sistemas de Proteccion de Corrosion y Pintura en Estructuras Metalicas)san_sanoNo ratings yet

- Strength of SteelsDocument12 pagesStrength of Steelssureshs83No ratings yet

- DIN 2076 vs. ASTM A 877Document1 pageDIN 2076 vs. ASTM A 877tobypadfieldNo ratings yet

- Iso Metric 32Document2 pagesIso Metric 32rahul caddNo ratings yet

- NavojiDocument193 pagesNavojianon_419810527No ratings yet

- BS 21 - Pressure Tight Pipe Thread JointsDocument8 pagesBS 21 - Pressure Tight Pipe Thread JointsHARSHANo ratings yet

- Kat A 1331 Lug Cerex300 L Wasser en 03 12Document6 pagesKat A 1331 Lug Cerex300 L Wasser en 03 12Sathishkumar DhamodaranNo ratings yet

- 1 2312 PDFDocument4 pages1 2312 PDFFrancisco CarrascoNo ratings yet

- Mild Steel: Mushroom Head Square Neck Bolts (Cup Square) DIN 603Document2 pagesMild Steel: Mushroom Head Square Neck Bolts (Cup Square) DIN 603MantasNo ratings yet

- DS - en 1993-1-7 DK Na - 2007 eDocument4 pagesDS - en 1993-1-7 DK Na - 2007 ep_meulendijks108No ratings yet

- Din 8140-1Document5 pagesDin 8140-1main46prairieNo ratings yet

- DIN 508-2002 - Nuts For T-SlotsDocument4 pagesDIN 508-2002 - Nuts For T-Slotslima_p4No ratings yet

- Din 6915 PDFDocument3 pagesDin 6915 PDFa.tabkhi1980100% (3)

- Din 939Document5 pagesDin 939rafael_engineer100% (3)

- DIN 2093 2006-03 eDocument18 pagesDIN 2093 2006-03 eLuis Testa100% (1)

- Ladder and Self Closing Gate For Storage TankDocument15 pagesLadder and Self Closing Gate For Storage TankAkshat JainNo ratings yet

- (DIN 28082-2 - 1996-06) - Standzargen Fã R Apparate - Teil 2 - Fuà - Ring Mit Pratzen Oder Doppelring Mit Stegen - Maà - e - 0001.de - enDocument6 pages(DIN 28082-2 - 1996-06) - Standzargen Fã R Apparate - Teil 2 - Fuà - Ring Mit Pratzen Oder Doppelring Mit Stegen - Maà - e - 0001.de - enNaveen Suresh KumarNo ratings yet

- Asme BPVC Ix Intro I-xxvi-2001-A02Document26 pagesAsme BPVC Ix Intro I-xxvi-2001-A02PacoNo ratings yet

- BS EN - 15048 2 2007 Non Preloaded Structural Bolting Assemblies Part 2 Suitability Test PDFDocument14 pagesBS EN - 15048 2 2007 Non Preloaded Structural Bolting Assemblies Part 2 Suitability Test PDFPaco100% (1)

- BS en - 1011 1 2009Document12 pagesBS en - 1011 1 2009Paco0% (1)

- En 10210-2LLDocument34 pagesEn 10210-2LLnicholas_j_vaughanNo ratings yet

- BS en - 14532 2 2004 PDFDocument26 pagesBS en - 14532 2 2004 PDFPacoNo ratings yet

- Din-En Iso 3506-1 1998 PDFDocument24 pagesDin-En Iso 3506-1 1998 PDFPaco100% (2)

- Bs-En 10079 1993 PDFDocument36 pagesBs-En 10079 1993 PDFPacoNo ratings yet

- Excel Multi Level BOM Template With HeaderDocument20 pagesExcel Multi Level BOM Template With HeaderPacoNo ratings yet

- BS en 288-2-92Document12 pagesBS en 288-2-92vuthuy94No ratings yet

- BS en - 1011 1 2009Document12 pagesBS en - 1011 1 2009Paco0% (1)

- Excel Multi Level BOM Template and ExampleDocument20 pagesExcel Multi Level BOM Template and ExamplePacoNo ratings yet

- Excel Example BomsDocument19 pagesExcel Example BomsPacoNo ratings yet

- Chapter 7Document61 pagesChapter 7PacoNo ratings yet

- Asme Boiler and Pressure Vessel Code - Quick Reference GuideDocument1 pageAsme Boiler and Pressure Vessel Code - Quick Reference GuidePacoNo ratings yet

- 03we Bond Worked Example T Shaped Gravity WallDocument0 pages03we Bond Worked Example T Shaped Gravity WallPacoNo ratings yet

- (Es, Esl, Esv) : Spare Parts CatalogueDocument24 pages(Es, Esl, Esv) : Spare Parts Cataloguegracy2288No ratings yet

- Astm A325m InnerDocument7 pagesAstm A325m InnerNgiuyen Viet TienNo ratings yet

- Ludhiana Industries-658Document100 pagesLudhiana Industries-658maxisinc.inNo ratings yet

- Pamphlet On Bio-Toilet For Maintenance in Coaching Depots - EnglishDocument4 pagesPamphlet On Bio-Toilet For Maintenance in Coaching Depots - EnglishSANNINo ratings yet

- Chainsaw Milling Summary ReportDocument72 pagesChainsaw Milling Summary ReportJohn JohnsNo ratings yet

- 1st Quater Exam TLEDocument4 pages1st Quater Exam TLERai MarkNo ratings yet

- Tech Data SheetDocument6 pagesTech Data Sheetali omarNo ratings yet

- Gantrex b17Document2 pagesGantrex b17martin100% (1)

- Anexa 3 BI261Document69 pagesAnexa 3 BI261ahmadove1No ratings yet

- KMD150Install PDFDocument72 pagesKMD150Install PDFJohn AmorteguiNo ratings yet

- GRC Process Costing ModuleDocument17 pagesGRC Process Costing ModuleKirk EscanillaNo ratings yet

- Aa 036301 001Document1 pageAa 036301 001FahadNo ratings yet

- Haldex Disc Brake DB22 Service Manual: Innovative Vehicle TechnologyDocument93 pagesHaldex Disc Brake DB22 Service Manual: Innovative Vehicle TechnologyВЛАДИМИРNo ratings yet

- Fuel System 4Document5 pagesFuel System 4Falgon IslamNo ratings yet

- Logo XxtreamDocument25 pagesLogo Xxtreamgino barnabaNo ratings yet

- HD6 Series Housings: Installation ManualDocument56 pagesHD6 Series Housings: Installation ManualpunkpantherNo ratings yet

- Sunbeam Caffe Bellissimo Em9300 Service ManualDocument21 pagesSunbeam Caffe Bellissimo Em9300 Service ManualinfomediamarketsourceNo ratings yet

- Dry Lintel ArchDocument80 pagesDry Lintel ArchGunjan UttamchandaniNo ratings yet

- Technical Specification:: A3-SIZE 121023Document4 pagesTechnical Specification:: A3-SIZE 121023MIHAINo ratings yet

- HVU Adhesive With HAS RodDocument47 pagesHVU Adhesive With HAS RodTri huỳnhNo ratings yet

- Fastener ListDocument9 pagesFastener ListMani Rathinam RajamaniNo ratings yet

- European Technical Assessment ET A - 0 3 / 0 0 0 8 o F 0 1 / 0 8 / 2 0 1 8Document10 pagesEuropean Technical Assessment ET A - 0 3 / 0 0 0 8 o F 0 1 / 0 8 / 2 0 1 8karthik1amarNo ratings yet

- Catalogo Dr200sel5 (2014-5 E24)Document72 pagesCatalogo Dr200sel5 (2014-5 E24)Javier Llumpo100% (1)

- Free LocationDocument227 pagesFree Locationadiputra0% (1)

- For Construction: MAX. DIST. 0.5EDocument1 pageFor Construction: MAX. DIST. 0.5EHimal Nilanka RathnayakaNo ratings yet

- Treadle Chicken FeederDocument10 pagesTreadle Chicken FeederEvansNo ratings yet

- ATN 910&910I&910B&950&950B Series Quick Installation Guide (19inch&ETSI Cabinet) 02Document26 pagesATN 910&910I&910B&950&950B Series Quick Installation Guide (19inch&ETSI Cabinet) 02Miky CCisNo ratings yet

- Actuador XRPDocument16 pagesActuador XRPNicolas AndradeNo ratings yet

- Lindab Ventilation DuctingDocument135 pagesLindab Ventilation DuctingOvidiu CaramangiuNo ratings yet