Professional Documents

Culture Documents

42crmo4 Raw Material Specification Document: Doc Ref CSMEP/RMSPC/0001 Date 24.08.2013 Issue Rev 1.0 Page No 1 of 4

Uploaded by

mass3444Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

42crmo4 Raw Material Specification Document: Doc Ref CSMEP/RMSPC/0001 Date 24.08.2013 Issue Rev 1.0 Page No 1 of 4

Uploaded by

mass3444Copyright:

Available Formats

42CrMo4 RAW MATERIAL SPECIFICATION DOCUMENT

Doc Ref Date Issue Rev Page No

CSMEP/RMSPC/0001 24.08.2013 1.0 1 of 4

Material Material Designation 42CrMo4

Number 1.7225

Equivalent Standards SAE BS EN 4140 708M40 19A

DIN 42CrMo4

JIS SCM440-H

AISI 4140

1. Scope This document has been prepared for the purpose defining the raw material compliances for the manufacture of components using this raw material. This document shall form part of the Purchase order. 2. Standards Referred Standard EN 10083-3 EN 10083-3 EN 10083-3 EN 10083-1 EN 10083-3 ISO 643 EN 10083-1 DIN 50602 Purpose Supply condition Chemical composition Mechanical Properties Test piece preparation Grain Size Grains size determination Non metallic Inclusions Microscopic examination for non metallic inclusions Sections referred Page 23 table 1 Page 25 table 3 Page 33 table 8 Page 15 Figure 1 Page 67 Annex-A The whole Standard shall be referred along with EN10083-3 Annex A Page 43 Annex-E The whole Standard shall be referred along with EN10083-1 Annex E

3. Delivery Condition The material shall be delivered in quenched and tempered condition. (QT) 4. Chemical composition The chemical composition for 42CrMo4 shall strictly comply as shown in the table Name Number C% .38 - .45 V% Nil Si % max .4 B% Nil Mn % .60 - .90 Cu % Nil P% max .025 Al % Nil S% max .035 W% Nil Cr % .90-1.20 Ti % Nil Mo % .15-.30 Co % Nil Ni % Nil Ti % Nil

42CrMo4

1.7225

Elements not quoted in this table shall not be intentionally added to the steel. All precaution shall be taken to prevent the addition of such elements from scrap or other material used in the manufacture which affect the harden ability , mechanical properties and applicability.

Prepared By : Quality Department

Verified by : Technical Director

Issued to : Purchase department

42CrMo4 RAW MATERIAL SPECIFICATION DOCUMENT

Doc Ref Date Issue Rev Page No

CSMEP/RMSPC/0001 24.08.2013 1.0 2 of 4

5. Mechanical Properties Name 42CrMo4 Re Min in Mpa 550 Rm Mpa 800 - 950 A min % 13 Z min % 50 KV min in J 35

Re Upper yield strength or , if no yield phenomenon occurs, 0.2% proof strength Rp0.2 Rm Tensile strength A Percentage Elongation after fracture (Initial Gauge length L0=5.65S0 Z Percentage reduction in cross section on fracture KV Impact strength of longitudinal Charpy-V-notch test pieces (average of 3 individual values shall meet the minimum specified in the in the table; no individual value shall be lower than 70% of the minimum shown in the table)

Prepared By : Quality Department

Verified by : Technical Director

Issued to : Purchase department

42CrMo4 RAW MATERIAL SPECIFICATION DOCUMENT

Doc Ref Date Issue Rev Page No

CSMEP/RMSPC/0001 24.08.2013 1.0 3 of 4

5.1 Test Piece Preparation Test Pieces shall be made in compliance to EN10083-1

Nomenclature 1. Tensile test piece 2. Notched bar impact test piece 3. Rounded and similar shaped sections

Prepared By : Quality Department

Verified by : Technical Director

Issued to : Purchase department

42CrMo4 RAW MATERIAL SPECIFICATION DOCUMENT

Doc Ref Date Issue Rev Page No

CSMEP/RMSPC/0001 24.08.2013 1.0 4 of 4

6. Grain size The material taken for forging shall have an Austenite grain size of 5 or finer the grain flow in forgins shall be as follows. For discs and rings where thickness t is less than the Dia d the grain flow direction shall be parallel to d For cylinders where l is greater than d the grain flow direction shall be parallel to l For a symmetric components the grain flow direction shall parallel to the direction of the main axis 7. Non Metallic Inclusion Requirements of microscopic degree of purity when tested: In accordance with DIN 50602 (method K) which is applicable to sulfides & oxidic non metallic inclusions shall have a value of total K4 (K-sulphides +K-oxides) 50. The compliance requirements for inclusions shall be mandatory in the product supplied. 8. Documentation Requirements The supplier / manufacturer shall furnish two sets of certificates that carry the heat numbers and the results of all the above tests showing compliance to the stated requirements. 9. Acceptance criteria Agreement for purchase shall be issued once the supplier has furnished evidence for compliance of the stated requirements. All test certificates should be produced form an NABL accredited laboratory. 10. Rejection of material and recovery of payment. After purchase and on cross verification for the above requirements with an equally competent NABL accredited laboratory, should the material prove non compliant to even one of the requirements, the material will be summarily rejected and the cost along with the testing charges would be recovered. However the company reserves the right to grant concessional approval after the same has been taken up with the end customer. Until such time, the material shall be treated as rejected.

This document shall be changed without prior notice and will depend on the process and design change and will be at the discretion of Ceeyes Metal Engineering (P) Ltd. For clarifications in the contents mentioned in the above document please send a mail to the following e-mail ID : Deepak.Design@ceeyesme.com

Prepared By : Quality Department

Verified by : Technical Director

Issued to : Purchase department

You might also like

- Escort 9500ix Passport Owners ManualDocument18 pagesEscort 9500ix Passport Owners ManualQueremosabarrabás A BarrabásNo ratings yet

- 07.1 SGS-NDT-009 Procedure ASME V PTDocument14 pages07.1 SGS-NDT-009 Procedure ASME V PTErick Jair HG100% (1)

- Customer Protection Officer Test - ES MJGBDocument5 pagesCustomer Protection Officer Test - ES MJGBGB Manuel JavierNo ratings yet

- D.J. Paul: Redefining The Definition of Accredited Investor'Document3 pagesD.J. Paul: Redefining The Definition of Accredited Investor'EvelynCashen100% (1)

- Third Party Authorization Letter - BDSwiss BDS Markets MAUDocument2 pagesThird Party Authorization Letter - BDSwiss BDS Markets MAUMahieddine 270No ratings yet

- TKHMTC New Application FormDocument5 pagesTKHMTC New Application FormMbogi Toka100% (1)

- PSL 30 Log of Pre Cert ExperienceDocument5 pagesPSL 30 Log of Pre Cert Experiencenarutothunderjet216No ratings yet

- AA - SPEC - 254001 Stacker Reclaimer SpecDocument28 pagesAA - SPEC - 254001 Stacker Reclaimer SpecJD75% (4)

- Astm A312Document10 pagesAstm A312ulkerdincerNo ratings yet

- Pipe Threads-What Is The Limit PDFDocument15 pagesPipe Threads-What Is The Limit PDFMohamed RafeekNo ratings yet

- Srs Template IeeeDocument13 pagesSrs Template IeeeRohan ShahNo ratings yet

- CompuStat Technical Guide (Tape, 2000)Document180 pagesCompuStat Technical Guide (Tape, 2000)carmo-netoNo ratings yet

- Oracle Complaint Against CryptoOracleDocument31 pagesOracle Complaint Against CryptoOracleLou KernerNo ratings yet

- Vertical Treaters Separator: Crude Oil Treating SystemDocument6 pagesVertical Treaters Separator: Crude Oil Treating SystemDayo IdowuNo ratings yet

- CEX Application Form 1.0Document6 pagesCEX Application Form 1.0Dimitrije BorisicNo ratings yet

- Asme Certification ProgDocument12 pagesAsme Certification ProgLai Mei EeNo ratings yet

- Tulawan Christine Components of TourismDocument10 pagesTulawan Christine Components of TourismChristine Pura Tulawan100% (1)

- Thickness Monitoring (TM) EquipmentDocument236 pagesThickness Monitoring (TM) EquipmentTommyNo ratings yet

- List of Accepted Documents For Video Verification With WebidDocument4 pagesList of Accepted Documents For Video Verification With WebidYassine BenzirNo ratings yet

- National ID Card System Case StudyDocument50 pagesNational ID Card System Case StudyDinomarshal PezumNo ratings yet

- Fit - Up and Visual Examination Report: Attachment Drawing Joint DetailDocument1 pageFit - Up and Visual Examination Report: Attachment Drawing Joint DetailMuhammad Fitransyah Syamsuar Putra100% (1)

- D:/dont Delete User/Downloads/ (Flange Analysis NC-3658-3)Document1 pageD:/dont Delete User/Downloads/ (Flange Analysis NC-3658-3)deepakNo ratings yet

- Itinerary Receipt for HYD-DEL Flight on May 19Document3 pagesItinerary Receipt for HYD-DEL Flight on May 19www_hari786No ratings yet

- Carbon Number Vs Hydrocarbon Stream NamesDocument1 pageCarbon Number Vs Hydrocarbon Stream NamesJames RodriguezNo ratings yet

- Flow Chart To BUET Certificate 2017 PDFDocument2 pagesFlow Chart To BUET Certificate 2017 PDFShakilKhanNo ratings yet

- TenderDocument37 pagesTenderErKarmjeetSinghGillNo ratings yet

- ATT MT-2.0 Rev. 1 ProcedureDocument13 pagesATT MT-2.0 Rev. 1 ProcedurewalitedisonNo ratings yet

- 2019 Updated Kyc RequirementsDocument11 pages2019 Updated Kyc RequirementsRoy K NjokaNo ratings yet

- Analysis of Variance: - One-Way ANOVA - Two-Way ANOVADocument36 pagesAnalysis of Variance: - One-Way ANOVA - Two-Way ANOVAc3353359No ratings yet

- Report Horz PV-510Document36 pagesReport Horz PV-510ahmaddanielmatshahNo ratings yet

- Nuflo Mc-III Exp DatasheetDocument4 pagesNuflo Mc-III Exp DatasheetJerrydawangNo ratings yet

- Thickness Monitoring (TM) Functional LocationDocument237 pagesThickness Monitoring (TM) Functional LocationTommyNo ratings yet

- Enhanced Security For Online Exam Using Group CryptographyDocument83 pagesEnhanced Security For Online Exam Using Group CryptographyVamsi Krishna Kaza100% (1)

- Henley Passport Index Factsheet 2023 q1 230105 1Document6 pagesHenley Passport Index Factsheet 2023 q1 230105 1PetruNo ratings yet

- NCR APTRA Passport BrochureDocument6 pagesNCR APTRA Passport BrochurepnkemgneNo ratings yet

- Repair Works of Jagir Separator V-5100 Inspection ReportDocument7 pagesRepair Works of Jagir Separator V-5100 Inspection ReportalidadNo ratings yet

- Software Requirements SpecificationDocument7 pagesSoftware Requirements SpecificationrdkutaaNo ratings yet

- Sub Fee Protection Agreement (SFPA) : XXXXXXXDocument13 pagesSub Fee Protection Agreement (SFPA) : XXXXXXXFrida Sofia EscobarNo ratings yet

- ASME CertificationDocument3 pagesASME Certificationtamim2014No ratings yet

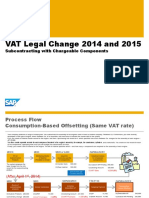

- VAT Legal Change 2014 and 2015: Subcontracting With Chargeable ComponentsDocument8 pagesVAT Legal Change 2014 and 2015: Subcontracting With Chargeable ComponentsTaro YamadaNo ratings yet

- Credit RatingDocument81 pagesCredit RatingJayesh RajwaniNo ratings yet

- KYC Doc Authorization FedExDocument1 pageKYC Doc Authorization FedExHarsh Gupta0% (1)

- Quality Control Manual: Rev. DateDocument1 pageQuality Control Manual: Rev. DatealokbdasNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Hardness Procedure OF Heat Exchanger and Pressure VesselDocument3 pagesHardness Procedure OF Heat Exchanger and Pressure VesselAozoraLazoraNo ratings yet

- Composite Construction Works For CNG Station at Kovvur, West Godavari District, A.PDocument209 pagesComposite Construction Works For CNG Station at Kovvur, West Godavari District, A.Pvinay1999No ratings yet

- Certificate of Calibration: Prover InformationDocument12 pagesCertificate of Calibration: Prover InformationFarizal AmriNo ratings yet

- 11RCFA-CPF2-HP Gas CompBDocument5 pages11RCFA-CPF2-HP Gas CompBJinlong SuNo ratings yet

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- Supply of Flanges Full TenderDocument294 pagesSupply of Flanges Full TenderApna time aayegaNo ratings yet

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- Test Doc 2Document3 pagesTest Doc 2Kor KortNo ratings yet

- Piping Punch List and Mechanical Clearance ChecklistDocument39 pagesPiping Punch List and Mechanical Clearance ChecklistrajuNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityYASH PAREKH100% (1)

- PS 3103Document9 pagesPS 3103JayeshNo ratings yet

- PMI Procedure Rev.00Document13 pagesPMI Procedure Rev.00Abdul Khaliq40% (5)

- AMEC Specification For Titanium 01Document9 pagesAMEC Specification For Titanium 01cenkturkerNo ratings yet

- Astm f136 Rev ADocument4 pagesAstm f136 Rev AAhmad BrianNo ratings yet

- Material Specification: Safety And/Or Government Regulated PartDocument21 pagesMaterial Specification: Safety And/Or Government Regulated PartAbhishek ChauhanNo ratings yet

- Kuwait Oil Company Pipeline Welding SpecificationDocument17 pagesKuwait Oil Company Pipeline Welding SpecificationnpwalNo ratings yet

- AMS2411Document9 pagesAMS2411Pankaj Shah100% (1)

- Petronas Technical Standards: Shop and Field Fabrication of Steel PipingDocument30 pagesPetronas Technical Standards: Shop and Field Fabrication of Steel PipingAli YarahmadiNo ratings yet

- Impact Toughness of Medium Carbon SteelsDocument14 pagesImpact Toughness of Medium Carbon Steelsmass3444No ratings yet

- Ensayo de Ultrasonido Industrial Astm1444 PDFDocument12 pagesEnsayo de Ultrasonido Industrial Astm1444 PDFBetzabethZuñigaNo ratings yet

- Rigs Installed BaseDocument184 pagesRigs Installed BaseGopu PerumalNo ratings yet

- Standard Pipe Sizes ME303-4.1.1Document5 pagesStandard Pipe Sizes ME303-4.1.1manashbdNo ratings yet

- Cam BasicsDocument50 pagesCam Basicsmass3444No ratings yet

- Pipe Thread Types and DesignationsDocument6 pagesPipe Thread Types and Designationsvijayn33No ratings yet

- 12 - Fatigue of MetalsDocument55 pages12 - Fatigue of Metalsvoldemorts100% (1)

- A576 Tvwe2918Document6 pagesA576 Tvwe2918mass3444No ratings yet

- Weight Chart For Hexagon Bolts & NutsDocument1 pageWeight Chart For Hexagon Bolts & Nutsmtanoglu111No ratings yet

- Fundamentals of Centrifugal PumpsDocument120 pagesFundamentals of Centrifugal Pumpswholenumber100% (1)

- Engg Metallurgy Lecture 5Document54 pagesEngg Metallurgy Lecture 5Patil Sudheer GowdNo ratings yet

- Little Pump Big Head - The Regenerative Turbine PumpDocument4 pagesLittle Pump Big Head - The Regenerative Turbine Pumpmass3444No ratings yet

- Fluid 12Document156 pagesFluid 12fadapow4uNo ratings yet

- Metallurgical Test Certificate: MCIE Die NoDocument1 pageMetallurgical Test Certificate: MCIE Die Nomass3444No ratings yet

- CHAPTER 2 - Motion in Two DimensionDocument8 pagesCHAPTER 2 - Motion in Two Dimensionmass3444No ratings yet

- 12 - Fatigue of MetalsDocument55 pages12 - Fatigue of Metalsvoldemorts100% (1)

- Design of Camprofile SANDUDocument6 pagesDesign of Camprofile SANDUmass3444No ratings yet

- 02 ForgingDocument58 pages02 ForgingRavindra ReddyNo ratings yet

- Is.4163.2004 Inclusion RatingDocument43 pagesIs.4163.2004 Inclusion Ratingmass3444100% (1)

- BR Cat BN STD I-uk-De-f r01 0Document0 pagesBR Cat BN STD I-uk-De-f r01 0mass3444No ratings yet

- Fundamentals of Centrifugal PumpsDocument120 pagesFundamentals of Centrifugal Pumpswholenumber100% (1)

- EMD ReplacementPartsCatalog No.191for645Engines PartADocument99 pagesEMD ReplacementPartsCatalog No.191for645Engines PartAmass3444100% (1)

- Cent Pum-NbDocument27 pagesCent Pum-Nbmass3444No ratings yet

- Welded ConnectionsDocument8 pagesWelded ConnectionsNitesh SinghNo ratings yet

- Strength of Materials by S K Mondal TQ-1 PDFDocument431 pagesStrength of Materials by S K Mondal TQ-1 PDFAbhijit BiswasNo ratings yet

- Curtain Wall Calculation PDFDocument134 pagesCurtain Wall Calculation PDFAlaaBadwy100% (1)

- Beushausen, BesterDocument10 pagesBeushausen, BesterEbrahim FlorisNo ratings yet

- A Comparative Study of the Mechanical Properties of High-strength Β-titanium AlloysDocument14 pagesA Comparative Study of the Mechanical Properties of High-strength Β-titanium AlloysMárcia SilvaNo ratings yet

- Impact of D-T Ratio On Circular Concrete-Filled High-Strength Steel Tubular Stub Columns Under Axial Compression, 2018 (Shiming Zhou) PDFDocument14 pagesImpact of D-T Ratio On Circular Concrete-Filled High-Strength Steel Tubular Stub Columns Under Axial Compression, 2018 (Shiming Zhou) PDFPhan Đào Hoàng HiệpNo ratings yet

- B 863 PDFDocument5 pagesB 863 PDFGrato Jr SingcoNo ratings yet

- SSINA - Designer's Handbook - Stainless Steel FastenersDocument23 pagesSSINA - Designer's Handbook - Stainless Steel FastenersSerguei DobrinNo ratings yet

- Introduction To Static Failure TheoriesDocument5 pagesIntroduction To Static Failure TheoriesNicola FarolfiNo ratings yet

- Surface Vehicle Standard: Rev. JUN1998Document45 pagesSurface Vehicle Standard: Rev. JUN1998Sandeep Goud ChatlaNo ratings yet

- Theoretical Moment-Curvature Relationships For Reinforced Concrete Members and Comparison With Experimental DataDocument11 pagesTheoretical Moment-Curvature Relationships For Reinforced Concrete Members and Comparison With Experimental DatavinayNo ratings yet

- 1 WELDING INSPECTION - STEELSDocument115 pages1 WELDING INSPECTION - STEELSrahim_335162856100% (3)

- 2 ND ConferenceDocument404 pages2 ND ConferenceAntonio Tomas Gonzalez LosaNo ratings yet

- 2tech Data - MF PET (300 601-td-0219)Document4 pages2tech Data - MF PET (300 601-td-0219)Ismacahyadi Mohamed JaisNo ratings yet

- Errata: Date of Issue: Affected PublicationDocument8 pagesErrata: Date of Issue: Affected PublicationAbrahim A Verde ANo ratings yet

- Iridium Platinum AlloysDocument9 pagesIridium Platinum Alloysnguyen9si9nguyenNo ratings yet

- ICCBT2008 - Properties & Applications of CeraCem Ultra High Performance Self Compacting ConcreteDocument10 pagesICCBT2008 - Properties & Applications of CeraCem Ultra High Performance Self Compacting ConcreteYuliusRiefAlkhalyNo ratings yet

- Scope and Summary: CautionDocument3 pagesScope and Summary: Cautionrafael_figueroaNo ratings yet

- Technical Specifications For Bird Flight DiverterDocument19 pagesTechnical Specifications For Bird Flight DiverterVidyavathiDavuluriNo ratings yet

- Connection - IDEA StatiCa PDFDocument18 pagesConnection - IDEA StatiCa PDFDaniel TuerosNo ratings yet

- Use of Coconut Husk Fiber Improves Concrete StrengthDocument3 pagesUse of Coconut Husk Fiber Improves Concrete StrengthZeen BiboNo ratings yet

- INTRODUCTIONDocument19 pagesINTRODUCTIONjohn devonNo ratings yet

- M 120Document40 pagesM 120ilkinNo ratings yet

- Increase Allowable Stress CodeDocument9 pagesIncrease Allowable Stress Codewenny_tpdNo ratings yet

- Flexural Behaviour of RC One-Way Slabs Reinforced Using PAN Based Carbon Textile GridDocument13 pagesFlexural Behaviour of RC One-Way Slabs Reinforced Using PAN Based Carbon Textile GridShaker QaidiNo ratings yet

- 4.project ReportDocument38 pages4.project ReportJagadeeshan SivanNo ratings yet

- Resume Analysis Tension of MembersDocument14 pagesResume Analysis Tension of MembersZahra AuliaNo ratings yet

- Is 6874 2008Document16 pagesIs 6874 2008Christian GaussNo ratings yet