Professional Documents

Culture Documents

Inverse Heat Conduction Analysis of Quenching Process Using Finite-Element and Optimization Method

Uploaded by

hsemargOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inverse Heat Conduction Analysis of Quenching Process Using Finite-Element and Optimization Method

Uploaded by

hsemargCopyright:

Available Formats

Finite Elements in Analysis and Design 42 (2006) 10871096

www.elsevier.com/locate/nel

Inverse heat conduction analysis of quenching process using nite-element

and optimization method

Li Huiping, Zhao Guoqun

, Niu Shanting, LuanYiguo

Mould and Die Engineering Technology Research Center, Shandong University, Jinan, Shandong, 250061, PR China

Received 23 November 2004; received in revised form 6 March 2006; accepted 18 April 2006

Available online 9 June 2006

Abstract

The calculation of surface heat transfer coefcient during quenching process is one of the inverse heat conduction problems, and it is a

nonlinear and ill-posed problem. A new method to calculate the temperature-dependent surface heat transfer coefcient during quenching

process is presented, which applies nite-element method (FEM), advanceretreat method and golden section method to the inverse heat

conduction problem, and can calculate the surface heat transfer coefcient according to the temperature curve gained by experiment. In order

to apply the advanceretreat method to the inverse heat conduction problem during quenching process, the arithmetic is improved, so that

the searching interval of optimization can be gained by the improved advanceretreat method. The optimum values of surface heat transfer

coefcient can be easily obtained in the searching interval by golden section method. During the calculation process, the phase-transformation

volume and phase-transformation latent heat of every element in every time interval can be calculated easily by FEM. The temperature and

phase-transformation volume of every element are calculated with the coupling calculation of phase-transformation latent heat.

2006 Elsevier B.V. All rights reserved.

Keywords: Quenching; Inverse heat conduction; Finite-element method; Optimization

1. Introduction

The heat exchange problem with a known initial condition

and boundary condition is a well-posed problem. It can be

solved by mathematical analysis. But if the boundary condition

of heat exchange problem has to be ascertained by measuring

some temperatures in the interior or the surface of the domain,

it can be dened as an inverse heat conduction problem (IHCP).

IHCP has numerous important applications in various sciences

and engineering. For example, the temperature of a very hot

surface is not easily measured directly with sensors. Usually

sensors are placed beneath the surface and the temperature of

the hot surface is estimated by inverse analysis. Other examples

of IHCP are the estimation of unknown temperature-dependent

thermo-physical parameters of materials from the temperature

recordings at the boundary surfaces of the domain [1].

Corresponding author. Tel./fax: +86 531 8395811.

E-mail addresses: lihuiping@sdu.edu.cn (L. Huiping),

Zhaogq@sdu.edu.cn (Z. Guoqun).

0168-874X/$ - see front matter 2006 Elsevier B.V. All rights reserved.

doi:10.1016/j.nel.2006.04.002

IHCP is an ill-posed problem, which is more difcult to solve

than the normal heat exchange problem. Many researchers

have studied the methods of evaluating temperature-dependent

surface heat transfer coefcient. Based on the KarhunenLove

Galerkin procedure, Park and Chung proposed a method for

the solution of inverse problem of estimating the time-varying

strength of a heat source in a two-dimensional heat conduction

system [2]. Osman and Beck [3] treated the problem of esti-

mating the temperature-dependent heat transfer coefcient in

the quenching of a sphere as a nonlinear parameter estimation

problem, and used the sequential function specication method

to estimate the unknown heat transfer coefcients one by one.

According to the temperaturetime data measured at subsurface

locations, Naylor and Osthuizen [4] determined the heat trans-

fer coefcient in a force convective ow over a square prism

using an iterative algorithm. Taler and Zima [5] used the con-

trol volume methods to solve multi-dimensional inverse heat

conduction problem. By this method, the partial heat conduc-

tion equation is replaced by a system of ordinary differential

equations in time, which are then solved sequentially, the pro-

cedure is started at a partial node where sensor is located and

1088 L. Huiping et al. / Finite Elements in Analysis and Design 42 (2006) 10871096

Nomenclature

thermal conductivity, W/m

C

c

p

constant pressure specic heat, J/kg

C

T temperature,

C

j partial differential operator

H

k

convection coefcient, W/m

2

C

T

w

temperature of boundary,

C

boundary of object

W weight function

s curve boundary

N transient thermal capacity matrix

V volume fraction of phase-transformation

density of material, kg/m

3

t time, s

q

v

latent heat of phase transformation, J/m

3

x, y, z rectangular coordinates

H

s

radiation coefcient, W/m

2

C

T

c

temperature of ambience,

C

r radius

J function

K stiffness matrix

H enthalpies, J/m

3

sequentialy marches through space to the surface node.

Hernandez-Morales et al. [6] and Chantasiriwan [7] also stud-

ied the one-dimensional problem of estimating the transient

heat transfer coefcient at the surface of steel bars subjected to

quenching using the sequential function specication method.

According to the temperaturetime data of several interior lo-

cations in the quenching part measured by sensors, Gu et al.

[1,8] used the inverse heat conduction method to estimate the

heat transfer coefcients between quenching part and water or

oil. They did not consider the inuence of phase-transformation

latent heat by using specic steel in their study, and supposed

it was one-dimensional heat conduction along the thickness of

part. Cheng et al. [9] and Chen et al. [10] also estimated the heat

transfer coefcients between quenching part and quenching

medium using the inverse heat conduction method. The results

gained by this method are consistent with the results gained by

experiment. Cheng et al. [11] used the nite-difference method

to solve the inverse-estimating problem of heat conduction

between steel 45 and quenching medium. They considered the

inuence of phase-transformation latent heat in their study.

Their solving precision is not very satisfactory, even though

the process iteration efciency is very high.

In this paper, a new method of estimating the temperature-

dependent surface heat transfer coefcient during quenching

process is presented, which applies nite-element method

(FEM), advanceretreat method and golden section method

to the inverse heat conduction problem, and can calculate

the surface heat transfer coefcient according to the temper-

ature curve obtained by experiment. In order to apply the

advanceretreat method to inverse heat conduction problem

during quenching process, the arithmetic of advanceretreat

method is improved, so that the searching interval of optimiza-

tion can be gained by the improved advanceretreat method,

and then the optimum values of surface heat transfer coef-

cient can be easily obtained in the searching interval by golden

section method. During the calculation process, the phase-

transformation volume and phase-transformation latent heat of

every element in every time interval can be calculated easily

by FEM. The temperature and phase-transformation volume

of every element are calculated with the coupling calculation

of phase-transformation latent heat.

2. FEM modeling of heat conduction and phase

transformation

2.1. FEM modeling of heat conduction

2.1.1. Basic equation

According to the Fourier law, the Fourier heat conduction

equation of transient problem with the phase-transformation

latent heat can be achieved by using conservation of energy in a

rectangular coordinates system. The equation can be written as

j

jx

_

jT

jx

_

+

j

jy

_

jT

jy

_

+

j

jz

_

jT

jz

_

+ q

v

= c

p

jT

jt

, (1)

where is the thermal conductivity, T the temperature of

quenching part, q

v

the latent heat of phase transformation,

the density of material, c

p

the constant pressure specic heat

and t time.

2.1.2. Initial condition

Initial condition is the initial temperature of quenching part.

It is the starting point of calculation. The initial condition at

time t = 0 can be described as

T |

t =0

= T

0

(x, y, z), (2)

where T

0

(x, y, z) is the function of initial temperature.

2.1.3. Boundary condition

Boundary condition is the way of heat exchange between

quenching part and ambience. The boundary condition of

quenching is the third-type condition, and it is the mixed heat

exchange boundary of convection and radiation. It can be

written as

jT

jn

= H

k

(T

w

T

c

) + H

s

_

T

4

w

T

4

c

_

= H(T

w

T

c

),

(3)

where n is the outer normal of boundary surface, H

k

the con-

vection coefcient, H

s

the radiation coefcient, T

w

the temper-

ature of boundary and T

c

the temperature of ambience. H is

the total heat transfer coefcient. It is the estimating goal of

nite-element analysis for inverse heat conduction.

L. Huiping et al. / Finite Elements in Analysis and Design 42 (2006) 10871096 1089

2.1.4. Discretization of temperature eld

Applying the Galerkin principle, the transient heat conduc-

tion partial differential equation with the latent heat of phase-

transformation process can be written as

_ _

D

W

l

_

_

r

j

2

T

jx

2

+ r

j

2

T

jr

2

+

jT

jr

_

+ q

v

r

c

p

r

jT

jt

_

dx dr = 0 (l = 1, 2, . . . , n), (4)

where W is the weight function, D the whole region of integral,

l the serial number of nite-element node, d the full differential

operator and r the radius.

Applying the Green equation to Eq. (4), the following equa-

tion can be obtained:

jJ

D

jT

l

=

_

HrW

l

jT

jn

ds

_ _

D

_

r

_

jT

jx

jW

l

jx

+

jT

jr

jW

l

jr

_

q

v

rW

l

+ rc

p

W

l

jT

jt

_

dx dr = 0, (5)

where

_

is the curve integral of close boundary. For the quad-

rangular nite-element, Eq. (5) can be written as a variational

format of element, and described as

jJ

e

jT

l

=

_ _

e

_

r

_

jT

jx

jW

l

jx

+

jT

jr

jW

l

jr

_

q

v

rW

l

+ rc

p

W

l

jT

jt

_

dx dr

_

e

HrW

l

jT

jn

ds

= K

e

{T }

e

+ N

e

_

jT

jt

_

e

{p}

e

, (6)

where n is the normal direction of boundary, s the curve bound-

ary, K

e

the stiffness matrix of nite-element, N

e

the transient

thermal capacity matrix of nite-element, {p}

e

includes both

the phase-transformation latent heat and boundary conditions

and e is the number of nite-elements.

In the calculation of temperature, the CrankNicolson

method is used [12].

2.1.5. Phase-transformation latent heat

During the cooling process of heat treatment, when there

are phase transformations in the quenching part, phase-

transformation latent heat will be produced. During the heating

process of heat treatment, when there are phase transfor-

mations, phase-transformation latent heat will be absorbed.

Although the latent heat produced in the process of solids

transformation (one solid to another solid) is smaller than the

latent heat produced in the process of solidication or melt,

it is an important factor that cannot be neglected. From the

point of view of mathematics, the basic equation (1) becomes

a highly nonlinear equation due to the latent heat, and it is

more difcult to solve this equation.

In this paper, the material involved is steel, the quenching

process only involves cooling, and the heat source term only

derives from latent heat corresponding to transformations of

austenite during cooling. During the simulation process, the

phase-transformation latent heat produced in the nite-elements

are regarded as the inner heat sources of corresponding ele-

ments, and the correct values of phase-transformation latent

heat are gained by iterative method in every simulating step.

During the quenching process, the inner heat source item q

v

of the basic (1) is produced due to austenitic transformation,

the enthalpy H of austenitic decomposed into pearlite is

1.56 10

9

1.50 10

6

T J/m

3

(where T is temperature in

C

[13]; the enthalpies H(J/m

3

) of austenitic decomposed into

ferrite, bainite and martensite correspond to 5.910

8

, 6.210

8

and 6.4 10

8

, respectively [14,15].

Due to austenitic transformation relating to temperature, the

phase-transformation latent heat is also a linear function of

temperature. The equation for calculating latent heat can be

described as

q

v

= H

f

n+1

f

n

t

= H f , (7)

where f

n

and f

n+1

correspond to the phase-transformation vol-

ume at time t

n

and time t

n+1

, respectively and f is the phase-

transformation volume for a unit time.

2.2. Mathematic modeling of phase transformation

The phase transformations during quenching process is clas-

sied into diffusion-type and non diffusion-type transforma-

tions. The transformations of austenite decomposed into ferrite,

pearlite and bainite are controlled by temperature history. The

JohnsonMehlAvrami equation [16], one of the most popu-

lar kinetic equations, is applied for evaluating volume fractions

of ferrite, pearlite and bainite in the paper. The equation of

diffusion-type transformations can be described as

V = 1 exp(bt

n

), n =

ln

_

ln(1 V

1

)

ln(1 V

2

)

_

ln

_

t

1

t

2

_ ,

b =

ln(1 V

1

)

t

n

1

, (8)

where t

1

and t

2

are the isothermal times of certain tem-

perature and V

1

and V

2

are the volume fractions of phase-

transformations of certain temperature. All of them depend on

Timetemperature transformation (TTT) curve of steel, which

varies with the type of steel.

The JohnsonMehlAvrami equation is valid only for isother-

mal transformations. In order to calculate the phase transfor-

mations by JMA equation and TTT curve, cooling curves are

regarded as a series of small isothermal time steps connected by

instantaneous temperature changes following constant volume

fraction lines. The transformed volume fractions are then calcu-

lated isothermally during each time step. Every phase transfor-

mation is assumed to occur between certain temperature limits.

For the diffusion-type transformation, the incubation period and

the phase-transformation volume fractions can be determined

according to Scheils additivity method [17,18].

The volume fraction of non diffusion-type transformation de-

pends only on temperature, and is not controlled by temperature

1090 L. Huiping et al. / Finite Elements in Analysis and Design 42 (2006) 10871096

history. Not considering the effect of stresses to non diffusion-

type transformation, Koistinen and Marburger [19] described

the equation of non diffusion-type transformation as the func-

tion of temperature:

V = 1 exp[(M

s

T )], (9)

where M

s

is the temperature of martensite beginning to trans-

form. is a constant, whose value varies with the type of steel.

It can be obtained by calculation in TTT curve. For steel P20,

= 0.023.

3. Optimizing model and method

3.1. Optimizing model

In this research, only the heat transfer coefcient is involved,

and other parameters are not involved. For the evaluating

process of inverse heat conduction problem using optimizing

method and FEM, the iterative processes are necessary. In

order to keep the evaluation process continuously and achieve

the desired evaluation precision, it is important to construct a

correct convergence criterion or optimization model. Accord-

ing to the character of evaluating the temperature-dependent

surface heat transfer coefcient during quenching process, the

criterion of convergence is constructed with the measuring

values of temperature eld and the computing values of every

iteration, which can be described as

min f (x) = min {T } = min

_

N

i=1

(T

i

T

i

)

2

, (10)

H

i

/H

min

10,

H

i

/H

max

10,

where f (x) is the standard deviation of the computing values

of temperature eld, N the total number of target points and

min f (x) the target function. When the value of f (x) reaches

the desired precision, the correct surface heat transfer coef-

cient corresponding to certain temperature is gained. In this

study, the minimum value of f (x) is set as 1 10

4

. H

i

is

the surface heat transfer coefcient of ith step, T

i

the measured

value of temperature corresponding to ith step, T

i

the com-

puted value of temperature corresponding to ith step and H

min

and H

max

the lower and upper limits of optimizing interval.

3.2. Searching the optimizing interval

A simple method of searching interval is advanceretreat

method. The principle of this method is stated as follows: Start

to search the interval from certain point along one direction,

and search three points which function values show up-down-

up trend according to certain searching step size; if it is not

successful along this direction, then retreat the starting point

and search the interval along other direction (along an inverse

direction) [20]. During the process of searching interval us-

ing advanceretreat method, as soon as a boundary point is

ascertained, the value of this point will be regarded as the

surface heat transfer coefcient and used in the simulation

programof temperature and phase-transformation elds to eval-

uate the temperatures. The surface heat transfer coefcients be-

tween quenching part and quenching agent are different from

the surface temperatures of quenching part, and the difference

range is very large. For example, the surface heat transfer co-

efcient is about 135 W/m

2

C between 20

C water and the

quenching part of 860

C; the surface heat transfer coefcient

is about 13,491 W/m

2

C between 20

C water and the quench-

ing part of 430

C; the surface heat transfer coefcient is about

4350 W/m

2

C between 20

C water and the quenching part

whose surface temperature is close to room temperature. There-

fore the searching time of an appropriate interval strongly de-

pends on the value of initial step size

s

. If the value of

s

is

bigger, the optimization iterative time of golden section method

is increased largely although the searching time of appropriate

interval is decreased; if the value of

s

is smaller, the search-

ing time of appropriate interval is increased largely although

the optimization iterative time of golden section method is de-

creased. In order to decrease the searching time of appropri-

ate interval when

s

keeps the same value, the advanceretreat

method is improved. The following error function is applied to

evaluate the result.

E() =

_

N

i=1

(T

i

T

i

)

2

,

_

N

i=1

T

i

N

i=1

T

i

0

_

,

_

N

i=1

(T

i

T

i

)

2

,

_

N

i=1

T

i

N

i=1

T

i

<0

_

,

(11)

where is the surface heat transfer coefcient and T

i

the com-

puting values of nite-element node i. T

i

is the objective val-

ues of node i. Its value can be gotten by experiment or other

methods.

The computing values of T

i

will vary with the heat transfer

coefcient in every time interval, and the error values due to the

different heat transfer coefcients can be calculated by Eq. (11).

There is only one appropriate heat transfer coefcient, which

will make the error E() small enough, and this heat transfer

coefcient is the objective. Except this appropriate heat transfer

coefcient, the error E() of other heat transfer coefcients will

be a negative or positive number. The rst job of searching the

appropriate heat transfer coefcient is to ascertain an interval.

One endpoint of the interval can make the error E() to be a

negative number, and other endpoint of the interval can make

the error E() to be a positive number. For every heat transfer

coefcient, the procedure will be applied to calculate the T

i

,

and then the error E() will be calculated by Eq. (11).

The computing procedures of searching an appropriate inter-

val using improved advanceretreat method are as follows:

(i) Select the value of initial searching step size

s

and the

value of initial surface heat transfer coefcient

3

(for the

rst time, the value of

3

is random; for the later times, the

value of

3

is the surface heat transfer coefcient attained in

the former optimization). The value of

3

is sent to the pro-

cedure of evaluating temperature and phase-transformation

L. Huiping et al. / Finite Elements in Analysis and Design 42 (2006) 10871096 1091

Fig. 1. SDL ow chart of improved advanceretreat method.

elds, and the computing values of some node tempera-

tures will be gained. Then the error E

3

= E(

3

) between

computing values and objective values of temperature is

evaluated using Eq. (11). Let kk = 0, where kk is used to

take count of searching times.

(ii) Let the surface heat transfer coefcient =

3

+

s

. The

value of is sent to the program of evaluating temperature

and phase-transformation elds, and the computing values

of some node temperatures will be attained. Then the error

E =E() between computing values and objective values

of temperature is evaluated using Eq. (11). Let kk=kk+1.

(iii) If EE

3

>0, then compare E with E

3

. If |E| <|E

3

|, then

let

s

=2.0

s

,

3

=, E

3

=E, and go to the procedure (ii).

If |E| >|E

3

|, then let

s

=

s

, and go to the procedure

(ii). If |E| = |E

3

|, then go to the procedure (v).

(iv) If E E

3

0, then go to the procedure (v).

(v) Let

l

= min{,

3

},

r

= max{,

3

}, E

l

= min{E, E

3

},

E

r

= min{E, E

3

}.

(vi) Let =(

1

+

r

)/2.0. The value of is sent to the program

of evaluating temperature and phase-transformation elds,

and the computing values of some node temperatures will

be gotten. Then the error E = E() between computing

values and objective values of temperature is evaluated

using Eq. (11). If E E

3

>0, then let E

l

= E,

1

= ,

kk = kk 1. Otherwise let E

r

= E,

r

= , kk = kk 1.

(vii) If kk >1, then go to the procedure (vi). If kk 1, then stop,

and the appropriate interval attained is the interval [

l

,

r

].

The SDL ow chart of improved advanceretreat method is

shown in Fig. 1.

During the process of quenching, the surface heat transfer

coefcients have a wide range. If the general advanceretreat

method is used to search the appropriate interval, the searching

times will increase largely. Suppose the former surface tem-

perature is 400

C, for which the heat transfer coefcient is

11,961 W/m

2

C; the current surface temperature is 430

C, for

which heat transfer coefcient is 13,491 W/m

2

C. The differ-

ence between them is 1530 W/m

2

C. If the step size of search-

ing interval is 5 W/m

2

C, the times of searching the appropri-

ate interval are 1530/5 + 1 = 307. Therefore the program will

spend a lot of time to search the appropriate interval as it is

evaluating temperature and phase-transformation elds every

time.

If the improved advanceretreat method is used to search the

appropriate interval, the step size is not constant, and the later

step size is double the former step size. The interval length will

be (2

n

2

n1

)

s

=2

n1

s

after n times of search. For this in-

terval, the bisearch method is used to continue searching, and

the interval length of

s

will be found after n 1 times of

bisearch. The total times of searching the appropriate interval

1092 L. Huiping et al. / Finite Elements in Analysis and Design 42 (2006) 10871096

are 8 + (8 1) = 15 for the above-mentioned example. Com-

paring the improved advanceretreat method with the general

advanceretreat method, it shows that the searching times of

improved advanceretreat method are reduced largely.

In order to search the appropriate interval, program of evalu-

ating temperature and phase-transformation elds is used time

after time in the searching procedure. The temperature and

phase-transformation elds are not given new values after ev-

ery repeating use. It is just to nd out the values of tempera-

ture eld corresponding to the heat transfer coefcient which

value is the endpoint of interval after cooling for denite time.

So the values of temperature and phase-transformation elds

should be resumed to the original values after every repeat-

ing use. Then the error between computing values and objec-

tive values of temperature is evaluated using Eq. (11), and the

searching direction and the convergent state can be ascertained

according to the error. Only after the appropriate heat transfer

coefcient corresponding to certain objective values of temper-

ature is found out, the temperature and phase-transformation

elds are given new values, and then continue to search the heat

transfer coefcient corresponding to other objective values of

temperature.

3.3. Ascertaining the optimum value of heat transfer coefcient

Golden section method is one of the methods used for eval-

uating the minimum value in the interval of unimodal distribu-

tion function. The principle is that: for reducing the searching

interval which includes the optimum value, the function val-

ues are compared by accepting different tentative points, and

the approximative value of function minimum point will be

achieved when the searching interval is reduced to a prescriptive

value.

Firstly, two tentative points are selected in the interval [a, b].

Suppose the left tentative point is

l

= a + (1 )(b a),

the right tentative point is

r

= a + (b a),

where are the solution of binomial equation

2

+ 1 = 0.

Secondly, evaluate two function values of left and right ten-

tative points according to Eq. (11)

l

= E(

l

),

r

= E(

r

).

According to the characteristics of unimodal distribution func-

tion, if

1

<

r

, there is no minimum value in the interval

[

r

, b]. The interval [

r

, b] can be neglected, and let b =

r

.

The new interval [a,

r

] can be attained. If

1

>

r

, there is no

minimum value in the interval [a,

l

]. The interval [a,

l

] can

be neglected, and let a =

l

. The new interval [

l

, b] can be

attained.

The computing procedures of ascertaining optimum value

of heat transfer coefcient using golden section method are as

follows:

(i) Suppose the appropriate interval searched by improved

advanceretreat method is [a, b], the prescriptive iterative

precision is . The left and right tentative points are

l

= a + (1 )(b a) and

r

= a + (b a),

where =(

51)/2.0. According to Eq. (11), the values

of error are

l

= E(

l

) and

r

= E(

r

).

(ii) If

l

<

r

, then let b =

r

,

r

=

l

,

r

=

l

, and evaluate

the values of

l

and

l

:

l

= a + (1 )(b a),

l

= E(

l

).

If

l

r

, then let a =

l

,

l

=

r

,

l

=

r

, and evaluate

the values of

r

and

r

:

r

= a + (b a),

r

= E(

r

).

(iii) If |b a| , then do the following procedure: if

l

<

r

,

then let =

l

, or else let =

r

, and the value of is the

minimum value to be ascertained. If |b a| >, then go

to the procedure (ii).

The SDL ow chart of golden section method is shown in

Fig. 2.

The computing algorithm of golden section method shows

that the length of interval is

n1

(b a) after n times itera-

tive evaluations. b a is the length of initial interval, which

is equal to the initial searching step size

s

of the improved

advanceretreat method. So the iterative times of golden sec-

tion method depend on the initial interval length, viz. the initial

searching step size

s

of the improved advanceretreat method.

The smaller the value of

s

is, the less the iterative times of

ascertaining appropriate value is.

3.4. Analyzing the iterative times of gold section method

(1) If

l

<

r

, then the interval [

r

, b] will be neglected, and

the new right tentative point can be described by

r

= a

+ (b

) = a + (

r

a) = a +

2

(b a).

Because values are the solutions of binomial equation

2

+

1=0, the new right tentative point can also be described by

r

= a +

2

(b a) = a + (1 )(b a) =

l

.

The new right tentative point is just the left tentative point of

old interval.

L. Huiping et al. / Finite Elements in Analysis and Design 42 (2006) 10871096 1093

Fig. 2. SDL ow chart of gold section method.

(2) If

l

>

r

, then the interval [a,

l

] will be neglected, and

the new left tentative point can be described by

l

= a

+ (1 )(b

) =

l

+ (1 )(b

l

),

Because values are the solutions of binomial equation

2

+

1 =0, the new left tentative point can also be described by

l

= a + (1 )(b a) + (1 )(b a)

= a + (1

2

)(b a) = a + (b a) =

r

.

The new left tentative point is just the right tentative point of

old interval.

That is to say, if values are equal to the solutions of binomial

equation

2

+1=0, only one tentative point and its function

value need be calculated in every iterative calculation except

the rst iterative calculation. So the workload of calculation

can be decreased largely, and the time of optimization also can

be reduced largely.

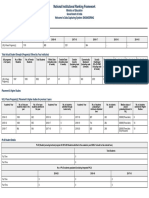

4. Example of evaluating surface heat transfer coefcient

A software is programmed using FEM technology,

advanceretreat method and golden section method. The soft-

ware can evaluate the temperature eld, phase-transformation

eld and surface heat transfer coefcient with the coupling

calculation of phase-transformation latent heat. In order to

verify the software, the temperature curves of several positions

in the quenching part are calculated using the FEM software

packageMARC and user subroutine programmed to evaluate

the phase transformation. During the process of evaluating, the

surface heat transfer coefcient is gained fromRef. [21], and the

thermal physical parameters of material are shown in Fig. 3. The

size of simulation specimen is 40200 mm, and the material

is P20 steel. The material is heated to 850

C. Suppose that this

temperature is kept for sufcient time to ensure the material

transforms into austenite fully. Then the specimen is quenched

in 20

C water. The FEM model includes 640 elements and 729

nodes. The circumference of specimen has adiabatic boundary

condition, except the quenched end. The cooling curves at 0,

30, 60, 100, 150 and 200 mm from the quenched end are shown

in Fig. 4.

According to the temperature curves gained from MARC

software package, the temperature-dependent surface heat

transfer coefcient is calculated using the software that is pro-

grammed in the paper. The FEM model of evaluating surface

heat transfer coefcient is same as the following FEM model.

During the process of evaluating, the required length of interval

is 5 W/m

2

C, and the evaluating precision is 0.01 W/m

2

C.

The ow chart of calculating heat transfer coefcient is shown

in Fig. 5.

According the temperature curves in Fig. 4, the temperature-

dependent surface heat transfer coefcient is calculated. During

the process of calculating, the iterative times of searching the

appropriate interval using advanceretreat method are shown

in Fig. 6 (searching interval). After the appropriate interval is

found out, the iterative times of evaluating the heat transfer

coefcient in the appropriate interval using gold section method

are shown in Fig. 6 (optimization). The curves of heat transfer

1094 L. Huiping et al. / Finite Elements in Analysis and Design 42 (2006) 10871096

Fig. 3. Thermophysical properties of different phases in steel P20 as a function of temperature: (a) specic heat; (b) density; (c) thermal conductivity.

(Mmartensite; Bbainite; Ppearlite; Fferrite; Aaustenite).

Fig. 4. Cooling curves at different distances (mm) from quenched end.

coefcients and temperatures in the quenched end are shown

in Fig. 7.

During the calculation process, the phase-transformation vol-

ume and phase-transformation latent heat of every element

in every time interval can be calculated easily by FEM. The

temperature and phase-transformation volume of every ele-

ment are calculated with the coupling calculation of phase-

transformation latent heat. The heat transfer coefcients calcu-

lated using FEM and the heat transfer coefcients in Ref. [21]

are shown in Fig. 8.

Fig. 5. Flow chart of calculating heat transfer coefcient.

Fig. 8 shows that the heat transfer coefcients gained using

FEM and optimization method correspond well with the results

of Ref. [21]. So the method of evaluating heat transfer coef-

cients represented in the paper is accurate and dependable. The

method can calculate easily the heat transfer coefcients with

the coupling calculation of phase-transformation latent heat.

L. Huiping et al. / Finite Elements in Analysis and Design 42 (2006) 10871096 1095

Fig. 6. Iterative times of searching interval and heat transfer coefcient

optimization.

Fig. 7. Heat transfer coefcient and temperature of end (0 mm) gained by

FEM.

The cooling speed is very rapid in the process of bubble boil,

and the temperature difference can be more than 4050

C in a

period of 0.1 s. But the cooling speed is slow in the process of

convection and lm boil. The slowest temperature difference is

0.010.1

C in a period of 0.1 s. Due to these reasons, the tem-

perature interval is very large in the process of evaluating heat

transfer coefcients, and the difference between the heat trans-

fer coefcients gained using IHCP method and the results of

Ref. [21] is large (Fig. 8(a)). In order to avoid this difference,

a self-adaptable time step is used, which computes the time

step according to the size of temperature difference, and can

improve the precision of evaluating heat transfer coefcients

(Fig. 8(b)).

5. Conclusions

From the temperature curves, the temperature-dependent sur-

face heat transfer coefcients of inverse heat conduction prob-

lem with the phase-transformation latent heat are evaluated us-

ing FEM, the improved advanceretreat method and the golden

section method. During the process of calculation, the phase-

transformation latent heat is coupled with temperature and

Fig. 8. Heat transfer coefcient gained by optimization and reference.

(a) Invariable time step. (b) Self-adaptable time step.

phase-transformation. The heat transfer coefcients gained us-

ing FEM and optimization method are compared with the re-

sults of reference. It shows that the precision of the method

given in this paper is satisfactory, and the convergence speed

of iteration is very rapid.

The temperature curves are obtained using FEM soft-

ware package and special user subroutine developed in

this paper. According to these temperature curves, the

temperature-dependent surface heat transfer coefcients can

be evaluated. If the temperature curves of several posi-

tions in the quenched part are measured by experiment, the

temperature-dependent surface heat transfer coefcients can

also be evaluated using the software programmed in this

paper.

Acknowledgment

This research work has been supported by the National Sci-

ence Foundation for Distinguished Young Scholars of China

50425517 and Foundation of New Century Excellent Talents

Plan of the Education Ministry of China.

References

[1] J.F. Gu, J.S. Pan, M.J. Hu, Inverse heat conduction analysis of synthetical

surface heat transfer coefcient during quenching process, J. Shanghai

Jiaotong Univ. 32 (1998) 1822.

1096 L. Huiping et al. / Finite Elements in Analysis and Design 42 (2006) 10871096

[2] H.M. Park, O.Y. Chung, J.H. Lee, On the solution of inverse heat

transfer problem using the KarhunenLoeve Galerkin method, Heat Mass

Transfer 42 (1999) 127142.

[3] A.M. Osman, J.V. Beck, Investigation of transient heat transfer coef-

cients in quenching experiments, Heat Transfer 112 (1990) 843848.

[4] D. Naylor, P.H. Osthuizen, Evaluation of an inverse heat conduction

procedure for determining local convective heat transfer rates, in:

Proceedings of the First Conference on Inverse Problems in Engineering,

ASME, New York, 1993, p. 125.

[5] J. Taler, W. Zima, Solution of inverse heat conduction problems

using control volume approach, Heat Mass Transfer 42 (1999)

11231140.

[6] B. Hernandez-Morales, J.K. Brimacombe, E.B. Hawbolt, Charact-

erization of the boundary condition in heat treatment operations using an

inverse heat conduction algorithm, in: Proceedings of the ASME Heat

Transfer Division, ASME, New York, 1995, p. 559.

[7] S. Chantasiriwan, Inverse determination of steadystate heat transfer

coefcient, Heat Mass Transfer 27 (2000) 11551164.

[8] J.F. Gu, J.S. Pan, M.J. Hu, Computer measurement and calculation on

heat transfer coefcients of quenchants, Hot Working Technol. 5 (1998)

1314.

[9] M. Cheng, X.Z. Xu, J. Cheng, Study on heat transfer condition between

workpiece/medium boundary during quenching process, J. North China

Inst. Technol. 18 (1997) 104109.

[10] N.L. Chen, J.S. Pan, B. Liao, C.Y. Gao, Measurement and calculation

of the heat transfer coefcient of dynamic quenchant, Hot Working

Technol. 3 (2002) 67.

[11] H.M. Cheng, H.G. Wang, T.L. Chen, Solution of heat conduction inverse

problem for steel 45 during quenching, Acta Metall. Sin 33 (1997)

467472.

[12] X.Q. Kong, The Application of Finite Element Method in the Heat

Transfer, Science Press, Beijing, 1998 p. 134.

[13] S. Denis, S. Sjstrm, A. Simon, Coupled temperature, stress, phase

transformation calculation, model numerical illustration of the internal

stresses evolution during cooling of a eutectoid carbon steel cylinder,

Metall. Trans. A 18A (1987) 12031212.

[14] K.F. Wang, S. Chandrasekar, H.T.Y. Yang, Experimental and

computational study of the quenching of carbon steel, J. Manuf. Sci.

Eng. 119 (1997) 257265.

[15] B. Buchmayr, J.S. Kirkaldy, Modeling of the temperature eld,

transformation behavior, hardness and mechanical response of low alloy

steels during cooling from the austenite region, Heat Treat. 8 (1990)

127136.

[16] A.W. Johnson, R.F. Mehl, Reaction kinetics in processes of nucleation

and growth, Trans. AIME 135 (1939) 416425.

[17] F.M.B. Fernandes, S. Denis, A. Simon, Mathematical model coupling

phase transformation and temperature evolution during quenching of

steels, Mater. Sci. Technol. 1 (1984) 838844.

[18] D. Pont, J.M. Bergheau, M. Rochette, R. Fortunier, Identication of

kinetic model for anisothermal metallurgical transformations in steels,

in: Proceedings of the 1994 Second International Symposium on Inverse

Problems-ISIP94, France, 1994, pp. 151156.

[19] D.F. Koistinen, R.E. Marburger, General equation prescribing the extent

of the austensite transformation in pure iron-carbon alloys and plain

carbon steels, Acta Metall. 7 (1959) 5060.

[20] Y. Xue, Optimization Theory and Method, Beijing Industry University

Press, Beijing, 2001 p. 142.

[21] C. Hakan, A.E. Tekkaya, W. Schuler, Effect of boundary conditions and

workpiece geometry on residual stresses and microstructure in quenching

process, Mater. Technol. 67 (1996) 501506.

You might also like

- Hsu 2004Document14 pagesHsu 2004quanckmNo ratings yet

- Superposition Method For The Simulation of Heat TransferDocument22 pagesSuperposition Method For The Simulation of Heat Transfergogoikhirud0No ratings yet

- Synopsis Group 2Document8 pagesSynopsis Group 2Uzair NadeemNo ratings yet

- A Numerical Analysis of Freezing and Melting With ConvectionDocument10 pagesA Numerical Analysis of Freezing and Melting With Convectiontanvisureka23No ratings yet

- 10 1016@j Icheatmasstransfer 2018 02 001Document5 pages10 1016@j Icheatmasstransfer 2018 02 001daniel sernaNo ratings yet

- Heat Transfer Blue Print ObjectivesDocument11 pagesHeat Transfer Blue Print Objectivesdawit solomonNo ratings yet

- Conjugate ConduccionForcedConvection CylinderDocument11 pagesConjugate ConduccionForcedConvection CylinderFrancisco SalazarNo ratings yet

- Welding FormulaDocument6 pagesWelding FormulachirpynikNo ratings yet

- Term PaperDocument23 pagesTerm PaperUday RajNo ratings yet

- Experimental Inverse Analysis For The Determination of Boundary Conditions in The Parallel Hot Wire TechniqueDocument12 pagesExperimental Inverse Analysis For The Determination of Boundary Conditions in The Parallel Hot Wire TechniquefguiriNo ratings yet

- Lecture 2 Unsteady State Heat TransferDocument5 pagesLecture 2 Unsteady State Heat TransferMahir MahmoodNo ratings yet

- Thermal Stress Analysis of Rectangular Plate Due To Convection Using Finite Element MethodDocument7 pagesThermal Stress Analysis of Rectangular Plate Due To Convection Using Finite Element Methodزهرة اللوتسNo ratings yet

- Modelling Liquid-Solid Phase Changes With Melt ConvectionDocument17 pagesModelling Liquid-Solid Phase Changes With Melt ConvectionLuis Felipe Gutierrez MarcantoniNo ratings yet

- 2007.1.experimental Study On The Heat Transfer at The Heat Exchanger of The Thermoacoustic Refrigerating SystemDocument8 pages2007.1.experimental Study On The Heat Transfer at The Heat Exchanger of The Thermoacoustic Refrigerating SystemMayur PKNo ratings yet

- Numerical Modelling of Two Dimensional Heat Transfer in Steady State RegimeDocument9 pagesNumerical Modelling of Two Dimensional Heat Transfer in Steady State RegimeSibasish SahuNo ratings yet

- Three-Dimensional Transient Heat Conduction Analysis With Non-Linear Boundary Conditions by Boundary Element MethodDocument12 pagesThree-Dimensional Transient Heat Conduction Analysis With Non-Linear Boundary Conditions by Boundary Element MethodAshvanee GargNo ratings yet

- Heat Transfer - Transient Hyperbolic Conduction in Hollow CylinderDocument6 pagesHeat Transfer - Transient Hyperbolic Conduction in Hollow CylinderthomasoburNo ratings yet

- Analytical Exact Solutions of Heat Conduction Problems For Ani So Tropic Multi-Layered MediaDocument13 pagesAnalytical Exact Solutions of Heat Conduction Problems For Ani So Tropic Multi-Layered MediaSK NGNo ratings yet

- Exact Analytical and Numerical Solutions For Convective Heat TransferDocument10 pagesExact Analytical and Numerical Solutions For Convective Heat TransferAli HegaigNo ratings yet

- Numerical Solution of One-Phase Stefan Problems by The Heat Balance Integral Method, Part I-Cylindrical and Spherical GeometriesDocument15 pagesNumerical Solution of One-Phase Stefan Problems by The Heat Balance Integral Method, Part I-Cylindrical and Spherical GeometriesMisael Garcia VazquezNo ratings yet

- Vdocuments - MX - Conduction and Convection Phenomena Through A Conduction and Convection PhenomenaDocument16 pagesVdocuments - MX - Conduction and Convection Phenomena Through A Conduction and Convection PhenomenaAndrew RichardsonNo ratings yet

- Numerical Investigation of Heat Transfer and Fluid Flow Around The Rectangular Flat Plane Confined by A Cylinder Under Pulsating FlowDocument9 pagesNumerical Investigation of Heat Transfer and Fluid Flow Around The Rectangular Flat Plane Confined by A Cylinder Under Pulsating FlowMohmmed MahmoudNo ratings yet

- HTC SingleFin in Water 031506Document5 pagesHTC SingleFin in Water 031506Anya CooperNo ratings yet

- Fem WaveDocument6 pagesFem WavechrissbansNo ratings yet

- ThermoDocument8 pagesThermoLau YeowhongNo ratings yet

- Prediction of Heat Transfer in An Axisymmetric Turbulent Jet Impinging On A Flat PlateDocument11 pagesPrediction of Heat Transfer in An Axisymmetric Turbulent Jet Impinging On A Flat PlateSylvainDMinesNo ratings yet

- 10 1 1 860 2828Document13 pages10 1 1 860 2828Pabitra MandalNo ratings yet

- Term Paper of MTH:201: TopicDocument9 pagesTerm Paper of MTH:201: Topicshailesh singhNo ratings yet

- A Numerical Strudy For The Estimation of A Convection Heat Transfer Coefficient During A Metallurgical Jominy End QuenchDocument11 pagesA Numerical Strudy For The Estimation of A Convection Heat Transfer Coefficient During A Metallurgical Jominy End QuenchIbnu RasyidNo ratings yet

- General Temperature Rise Solution For A Moving Plane Heat Source Problem in Surface GrindingDocument10 pagesGeneral Temperature Rise Solution For A Moving Plane Heat Source Problem in Surface Grindingmaxwellrejil1988No ratings yet

- An Inverse Problem in Estimating Simultaneously The Effective Thermal Conductivity and Volumetric Heat Capacity of Biological TissueDocument13 pagesAn Inverse Problem in Estimating Simultaneously The Effective Thermal Conductivity and Volumetric Heat Capacity of Biological TissueAmir JoonNo ratings yet

- Ait Adine2009Document13 pagesAit Adine2009Hamza FarajiNo ratings yet

- Monde 2010Document7 pagesMonde 2010曾帅No ratings yet

- Heat DisspatedDocument8 pagesHeat DisspatedMurtadha AhmedNo ratings yet

- Stretching-Shrinking Longitudinal Fins of Rectangular Profile and HeatDocument5 pagesStretching-Shrinking Longitudinal Fins of Rectangular Profile and HeatJuan Esteban Lopez100% (1)

- Alhadad 2018Document9 pagesAlhadad 2018cemilNo ratings yet

- Research Inventy: International Journal of Engineering and ScienceDocument5 pagesResearch Inventy: International Journal of Engineering and ScienceinventyNo ratings yet

- Finite Element Analysis of Coupled Thermoelasticity PDFDocument8 pagesFinite Element Analysis of Coupled Thermoelasticity PDFCarlosNo ratings yet

- Desarrollo Térmicamente FlujoDocument34 pagesDesarrollo Térmicamente FlujoLuisAngelVargasNo ratings yet

- Full Lab Report Lab 6 Heat ExchangerDocument35 pagesFull Lab Report Lab 6 Heat ExchangerAmir Al-Aiman100% (1)

- Daz 2001Document9 pagesDaz 2001Abdur RashidNo ratings yet

- Finite Element Galerkin Methods For Multi-Phase Stefan ProblemsDocument16 pagesFinite Element Galerkin Methods For Multi-Phase Stefan ProblemschrissbansNo ratings yet

- Analysis of Unsteady Heat Conduction Through Short Fin With Applicability of Quasi TheoryDocument15 pagesAnalysis of Unsteady Heat Conduction Through Short Fin With Applicability of Quasi TheoryFawziyyah AgboolaNo ratings yet

- Ichmt 2019Document11 pagesIchmt 2019Sarvjeet singhNo ratings yet

- New Methodology For CFD Three-Dimensional Simulation of A Walking Beam Type Reheating Furnace in Steady State-Casal2015Document29 pagesNew Methodology For CFD Three-Dimensional Simulation of A Walking Beam Type Reheating Furnace in Steady State-Casal2015Beto MurrNo ratings yet

- Energies: Online Determining Heat Transfer Coe Monitoring Transient Thermal StressesDocument13 pagesEnergies: Online Determining Heat Transfer Coe Monitoring Transient Thermal Stressessparky sparkyNo ratings yet

- J Aej 2017 01 034Document10 pagesJ Aej 2017 01 034oguierNo ratings yet

- Bao Lin Wang2005Document15 pagesBao Lin Wang2005rezza ruzuqiNo ratings yet

- OzawaT Thermochim Acta 253 (1995) 183-188Document6 pagesOzawaT Thermochim Acta 253 (1995) 183-188Irina PucicNo ratings yet

- ChE 154Document16 pagesChE 154DennisShinNo ratings yet

- Experimental Transient Natural Convection Heat Transfer From A Vertical Cylindrical TankDocument8 pagesExperimental Transient Natural Convection Heat Transfer From A Vertical Cylindrical TankGeorge MaliarisNo ratings yet

- Kazal HAQ, Kamal Sha, Analysis of Periodic Heat Transfer Through ExtendeDocument19 pagesKazal HAQ, Kamal Sha, Analysis of Periodic Heat Transfer Through ExtendeakamNo ratings yet

- 0pCpjH-NxfAUXgOvL3P1mIOmTjI1ECWApWg 0NLo-xpUjx9xCkpRLuxzc zKFWW5uSil0xj8GA9UD2dnakTqE9Qqr0LIfGAMz4y1UQlEwzV7Document10 pages0pCpjH-NxfAUXgOvL3P1mIOmTjI1ECWApWg 0NLo-xpUjx9xCkpRLuxzc zKFWW5uSil0xj8GA9UD2dnakTqE9Qqr0LIfGAMz4y1UQlEwzV7Mohammed TahaNo ratings yet

- Transferencia de Calor Con COMSOL MultiphysicsDocument6 pagesTransferencia de Calor Con COMSOL Multiphysicsggggggggggg32No ratings yet

- Integration of A Fin Experiment Into The Undergraduate Heat Transfer LaboratoryDocument11 pagesIntegration of A Fin Experiment Into The Undergraduate Heat Transfer LaboratoryRyanNo ratings yet

- Inverse Estimation of Boundary Heat Flux For Heat Conduction ModelDocument22 pagesInverse Estimation of Boundary Heat Flux For Heat Conduction ModelJinsoo KimNo ratings yet

- Rocket Stress Analysis by SundarDocument7 pagesRocket Stress Analysis by Sundarபொன்னியின் செல்வன்No ratings yet

- Greens SolutionDocument9 pagesGreens SolutionLetícia MotaNo ratings yet

- HeatDocument82 pagesHeatLUVAI KIOKONo ratings yet

- Institute Name: RGUKT-RK Valley (IR-E-C-45102)Document7 pagesInstitute Name: RGUKT-RK Valley (IR-E-C-45102)hsemargNo ratings yet

- Slip CastingDocument10 pagesSlip CastinghsemargNo ratings yet

- ARCH NIRF FrameworkDocument63 pagesARCH NIRF FrameworkhsemargNo ratings yet

- Answer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NameDocument1 pageAnswer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NamehsemargNo ratings yet

- RGUKT Audio QuoteDocument1 pageRGUKT Audio QuotehsemargNo ratings yet

- Mse314 315 316Document390 pagesMse314 315 316hsemargNo ratings yet

- © 1890 Nature Publishing GroupDocument4 pages© 1890 Nature Publishing GrouphsemargNo ratings yet

- Foundry Technology PatternsDocument36 pagesFoundry Technology PatternshsemargNo ratings yet

- Lecture 1423455076Document199 pagesLecture 1423455076hsemargNo ratings yet

- ADBCYears 01Document1 pageADBCYears 01hsemargNo ratings yet

- The Key Role of Impurities in Ancient Damascus Steel BladesDocument13 pagesThe Key Role of Impurities in Ancient Damascus Steel BladeshsemargNo ratings yet

- Liberty Ships Brittle Fracture (Final)Document5 pagesLiberty Ships Brittle Fracture (Final)hsemargNo ratings yet

- Ce2253 Applied Hydraulic Engg Qus Bank PDFDocument13 pagesCe2253 Applied Hydraulic Engg Qus Bank PDFthamilarasuNo ratings yet

- CHAPTER 1 FluidsDocument24 pagesCHAPTER 1 FluidsIvan JadeNo ratings yet

- Manual CTI Technical Manual PDFDocument39 pagesManual CTI Technical Manual PDFaricomen43% (7)

- First Push 2024 Grade 12 Marking Guide March 2024Document12 pagesFirst Push 2024 Grade 12 Marking Guide March 2024lemonlululu1No ratings yet

- 3 IdiotsDocument6 pages3 IdiotsvonashNo ratings yet

- Cellular Automaton: Automata, Homogeneous Structures, Cellular Structures, Tessellation Structures, and Iterative ArraysDocument18 pagesCellular Automaton: Automata, Homogeneous Structures, Cellular Structures, Tessellation Structures, and Iterative Arraysgerte_yuewNo ratings yet

- Sem - MTMM (David A. Kenny)Document8 pagesSem - MTMM (David A. Kenny)AJayNo ratings yet

- Fundamentals of Aircraft SystemsDocument353 pagesFundamentals of Aircraft SystemsVishal Wagh100% (4)

- Hooke's Law (4Document30 pagesHooke's Law (4Clark Harold Balido50% (2)

- GeomaticaDocument5 pagesGeomaticaAlcantaraSusyNo ratings yet

- Práctica GrafcetDocument11 pagesPráctica GrafcetJaimeNo ratings yet

- 15 Design For Safety HazanDocument12 pages15 Design For Safety Hazansauravsagar14No ratings yet

- Xilinx Spartan3 Device ReliabilityDocument118 pagesXilinx Spartan3 Device ReliabilityRaffi SkNo ratings yet

- Pak 37 17 18Document39 pagesPak 37 17 18Lift carry LapsittingNo ratings yet

- 4Document13 pages4Aruna KumarasiriNo ratings yet

- Density AltitudeDocument4 pagesDensity AltitudesubhashcbNo ratings yet

- PLSC 0013Document7 pagesPLSC 0013balaji100% (1)

- LUO - 2014 - A New Degassing Membrane Coupled Upflow Anaerobic Sludge BlanketDocument7 pagesLUO - 2014 - A New Degassing Membrane Coupled Upflow Anaerobic Sludge BlanketThobiasNo ratings yet

- Astm D2573 D2573M 18Document4 pagesAstm D2573 D2573M 18deptrailaikieuNo ratings yet

- Potential Difference WorksheetDocument2 pagesPotential Difference WorksheetDigCity DiggNo ratings yet

- KontloDocument3 pagesKontloX'mix ĐreamerNo ratings yet

- Electron Diffraction Lab Report - KatzerDocument7 pagesElectron Diffraction Lab Report - Katzerapi-489811472No ratings yet

- Natural ColorDocument14 pagesNatural ColorleeNo ratings yet

- Tov Implant CatalogDocument24 pagesTov Implant CatalogMykolas LukoševičiusNo ratings yet

- SteckDocument354 pagesStecknaruto100% (1)

- 4B-Velocity Profiles (2021)Document18 pages4B-Velocity Profiles (2021)ArinaAdilaNo ratings yet

- Sheldon S File 3Document7 pagesSheldon S File 3NATHANIEL YACASNo ratings yet

- Radiation ProcessesDocument20 pagesRadiation ProcessesAnmol MalgotraNo ratings yet

- Eaton 120641 FAZ C10 2 NA DC en - GBDocument2 pagesEaton 120641 FAZ C10 2 NA DC en - GBCarlos Garcia Jacome DarkerNo ratings yet

- High Voltage Testing LaboratoryDocument6 pagesHigh Voltage Testing LaboratoryMohd Izham IdrisNo ratings yet