Professional Documents

Culture Documents

T-ENG Card

Uploaded by

ViswaChaitanya NandigamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T-ENG Card

Uploaded by

ViswaChaitanya NandigamCopyright:

Available Formats

SUPPLIER AUDIT CHECKLIST Entity: Section 1 Receiving raw inputs, materials, semi-finished products and accessory parts to warehouse,

warehouse managements, release of inventories for production Scores No Criteria Condition of warehouse premises (lighting, heating), availability of restricted areas. Availability of job descriptions for 3 1 0 Good 3 Satisfactory 1 Unsatisfactor y 0 Notes

storekeepers, warehouse loaders, and other manual workers of a warehouse and observance of these job descriptions. Availability (and observance) of approved layout of warehouse and its marking by sectors (areas): by kinds of inventories, by particular features of storage, by arrival, availability of hold area for raw inputs and materials Availability of approved regulatory

documents in respect of conditions for 4 storage, handling, and keeping of raw inputs and materials Guidelines, extracts from Specifications, GOSTs, and etc. Availability of specific instrumentation for 5 maintenance of storage conditions 3 2 0 (temperature, humidity) Guidelines on corrective actions in case of detection of incompliance with storage 6 requirements. Existence of procedure for prevention of release of inadequate materials 7 for production. Availability of adjustment of specific storage equipment conditions for (air 3 1 0 4 2 0 3 2 0

dryer/humidifier, air conditioner) Positioning system and status identification 8 system (non-defective/defective) for 3 2 0 necessary kind of raw input/material Existence of a list of approved suppliers for each group of inventories Existence of a list of items subject for receiving inspection. Establishing criteria 10 pursuant to which products of a supplier shall be come subject for receiving inspection. Availability of equipment, instrumentation, 11 and approved reference samples with valid expiry date necessary for the receiving inspection Procedure governing dealing with supplier of inadequate products. Availability and keeping of necessary 3 1 0 3 2 0 4 2 0

12

accompanying documents for arriving raw 13 inputs and materials; correctness of such documents; keeping quality certificates for arriving raw inputs. Availability of necessary 14 packaging 3 1 0

materials, crating, pallets and etc. ensuring safety of products during storage and transportation within the facility. Availability of necessary loading and and

15

unloading

equipment

(automated

manual) and its condition. 16 17 18 Personnel: skills, availability of schedules for job training. Availability of consignment warehouses at the sites of Purchasers. Availability of buffer warehouse. Level of apprehension stock by at the 3 2 3 1 1 1 0 0 0

personnel 3 1 0

19

participating in the audit of the questions

being asked (level of skills). Results of the assessments Maximum possible score Scores according received to

55

results

of

the

assessment Note: Where it is impossible to assess a particular criterion, average score shall be used in the assessment (50 % of maximum score)

Entity: Section 2 Production Scores No Criteria Good Satisf actory Unsat isfact ory Notes

Organisation of work places of production personnel: Availability of necessary regulatory documents: - operating instructions (availability, visualisation, 1 accessibility); - manuals on operation (maintenance) o equipment; - process parameters cards; - control plan or process worksheets. Visualisation of methods of performing operations (correct incorrect). Visualisation of defects Availability of control samples at workplaces Organisation of workplaces (5S technique) Existence and compliance with production plan at workplace (shift, daily, monthly). Performance of preliminary analysis of product technical specifications to identify key characteristics, parameters of operating procedures affecting them and control techniques. Performing FMEA process, comparison of actual 7 operating procedures with conclusions made according to results of FMEA process. Quality Management Plan in respect of manufactured products and its reflection in operating guidelines. Recording process control results in accordance with Quality Management Plan and procedure of corrective 9 actions in case of deviations from norm of the operating procedures in the course of analysis of the data received. Application of statistical methods for control of production process. Compliance of measurement process documents. equipment and 4 2 0 5 4 0 4 3 0 5 4 0

2 3 4 5

2 3 2 2

1 1 1 1

0 0 0 0

10

11

instrumentation at workplaces with requirements of

Compliance of equipment used for manufacture of 12 products with requirements of standard technical documents. Clutter of Condition manufacturing of equipment premises, and tooling workplaces, repair, 4 2 0

13 14

passages and driveways. maintenance, and identification plates. Maintenance and repair of equipment and tooling Existence of and compliance with maintenance plans and schedules of preventive and planned repairs. Personnel: skills, work load, number of shifts,

2 5

1 2

0 0

15

16

availability of interchange matrix and schedules for job training. Identification of work in progress to establish the level

17

of process step and compliance with process documents (non-defective/defective). Availability of hold area responsible person,

18

accounting for, compliance with schedule (moving in moving out) minimisation of access of unauthorised persons. Regulations on performing works on making good in

19

case any defects are detected in the process of product manufacture. Analysis of quantities and causes for internal spoilage

20

in order to perform corrective actions and to assess their efficiency. Personnel awareness of quality of manufactured

21

products, quantities of incompliant products, claims from consumers, orders and instructions of management (information stands, personnel meetings) Metrological Support existence of the service. Calibration of measurement equipment contracts with certified centres. Existence of and compliance with schedule of calibration (attestation) of measurement equipment. Recording of measurement equipment. Identification of measurement equipment and instrumentation calibration date tag, responsible person, inventory number. Availability of buffer stock

22

23

Level of apprehension by personnel participating in the audit of the questions being asked (level of skills). Maximum score Scores possible received

3 75

Results of the assessments

according to results of the assessment Note: Where it is impossible to assess a particular criterion, average score shall be used in the assessment (50 % of maximum score)

Entity:

Section 3

Finished products handling: storage, packaging, dispatch, transportation

Scores No Criteria Compliance with schedules of delivery of 1 finished goods agreed upon products with in 3 1 0 5 4 0 consumers. Marking of 2 Good Satisfactory Unsatisfactor y Notes

despatched

accordance with specifications and supply contract. Availability and condition of area for packing and storage of finished products. Availability of regulatory documents on storage and of maintenance finished of storage that conditions products that

prevent their damage. Presence of conditions 5

prevent 3 1 0

spoilage of finished products during storage period at warehouse. Monitoring of storage periods. Use of FIFO principle. Organisation of workplaces for packagers

of finished products and for warehouse personnel. Availability of operating instructions, materials, and instruments Analysis of occurrence of defects of

finished

products

during

packing,

8 9

shipping, and unpacking. Use of crating for finished goods, as agreed upon with consumer. Issue of necessary regulatory

3 4

1 2

0 0

accompanying documents. Personnel: skills, work load, number of shifts, availability of interchange matrix and schedules for job training. Availability and condition of necessary loading and unloading equipment and trucks ( lift trucks, electric trucks, trolleys,

10 11

2 2

1 1

0 0

palettes, overhead cranes, and etc.). Collection and removal of household and industrial wastes. Maximum Results assessments of possible score received the Scores according to results of the

12

2 35

assessment Note: Where it is impossible to assess a particular criterion, average score shall be used in the assessment (50 % of maximum score)

Entity: Section 4 Quality management system Scores N o. Criteria Good Satisf actory Unsat isfact ory Notes

Existence of certified Quality Management System (availability of current fundamental documents and 1 compliance with them) / Existence of plan for establishing Quality Management System and preparation for its certification (in case of having no QMS certificate) Monitoring of customer claims, development and implementation of corrective actions Internal audit of QMS, assessment of efficiency of activities implemented in accordance with results of the audit. Organisation of receiving inspection: the receiving 4 inspection is organised in accordance with requirements of documented procedure Equipment of control points (posts): existence of and 5 compliance with operating instructions; visualisation of defects; availability and keeping of regulatory documents Availability of certified technological laboratories or agreements with third party specialised institutions Monitoring of quality of manufactured products, spoilage analysis and systematic solution of problems in case any differences are detected Visualisation of information on stands about quality of manufactured products. Personnel awareness. Availability of feedback in respect of customer claims, development of corrective actions according to results of the claims Systematic informing of consumer about any changes 10 in manufacturing process, used raw inputs and materials, and places of manufacture of products Working with suppliers in respect of quality: system of assessment, holding audits, development of suppliers 4 1 0 2 1 0 5 2 0 5 2 0

11

Personnel: skills, work load, number of shifts, 12 availability of interchange matrix and schedules for job training. 13 Level of apprehension by personnel participating in the audit of the questions being asked (level of skills). Maximum Results of the assessments score Scores possible received 3 1 0 2 1 0

45

according to results of the assessment

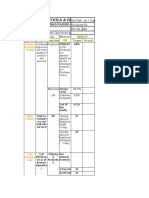

SUPPLIER QUESTIONNAIRE 1) General information about the supplier

Full name of the supplier: ______________________________________________________________ Details (tel., fax, web site, E-mail)

______________________________________________________________ ________________________________________________________________________________

Registered patents for products: please, attach copies (if any)

Whether you possess exclusive rights for sale of products? (For intermediaries. Please, specify names of the products and manufacturer)

Consumer references about products: please, attach copies (if any). 2) Principal suppliers of raw inputs and materials

List of principal kinds of raw inputs and materials: _______________________________________________________________________________________ _______________________________________________________________________________________ _______________________________________________________________________________________ ___________________________________________________________ Whether assessment of Suppliers is performed?

Yes

No

Whether the Supplier requests product certificates and/or Quality Management System of its suppliers?

Yes

No

Existence of receiving inspection of the products arrived

Yes Monitored

No parameters (major):

_______________________________________________________________________________________ _______________________________________________________________________________________ _______________________________________________________________________________________ ___________________________________________________________

Availability of Supplier (sub-supplier) certificates: for products (quality certificate)

Yes

No

For quality management system (ISO 9001)?

Yes

No

3) Quality Management System (Environmental Management System, Occupational Health and Safety Management System) Existence of Quality Directorate (Quality Service) and its major functions: _______________________________________________________________________________________ _______________________________________________________________________________________ _______________________________________________________________________________________ ___________________________________________________________

Existence of certified quality management system (ISO 9001)

Yes

No

If yes: Please, attach copy of the certificate

If No: Programme for establishing Quality Management System and preparation for its certification (please, attach)

Yes

No Planned time of the certification

________________________________________________________________________________

Existence of certified environmental management system (ISO 14001)

Yes

No

Existence of Occupational Health and Safety Management System (OHSAS 18001)

Yes

No

Existence of product control and of process under approved technological processes, and documenting quality data

Yes

No

Existence of final product control and testing in accordance with approved technological processes, and documenting quality data

Yes

No

Existence of certified laboratories (experts) and equipment ensuring monitoring and testing of products

Yes

No

List

of

core

laboratory

equipment:

_______________________________________________________________________________________ _________________________________________________________________________ Whether calibration of measurement equipment is performed on a regular basis (in accordance with schedule)?

Yes

No

Identification and/or backtracking from final products to components and materials used

Yes

No

Existence of procedure for management of inconsistencies emerging in the course of manufacture of products

Yes

No

Whether analysis of efficiency of adjustment activities is performed?

Yes

No

Existence of effective measures to the benefit of UC RUSAL in respect of the issued claims

Yes 4) Production capacities

No

Existence of Equipment Maintenance and Repair System

Yes

No

Existence of equipped repair base and of trained personnel for servicing production equipment to the full extent

Yes

No

Availability of warehousing premises that ensure storage of products in accordance with requirements

Yes 5) Customer satisfaction

No

Existence of documented system for designing products and for confirmation of output design data to requirements of the Customer

Yes

No

Existence of documented system for management of registration and consideration of claims (notices) of customers

Yes 6) Additional information about the company

No

Please, include any additional information in this section characterising the company as prospective and reliable partner _______________________________________________________________________________________ _________________________________________________________________________ 7) Contact details of the person responsible for completion of the questionnaire Please, specify name, position, contact telephone, e-mail ________________________________________________________________________________ Position / name / (Signature / seal)

You might also like

- .0 Inspection of Input MaterialsDocument22 pages.0 Inspection of Input MaterialsSPH PURCHASENo ratings yet

- Logo Perusahaan CAR ISO 9001Document2 pagesLogo Perusahaan CAR ISO 9001Yoepy WijayaNo ratings yet

- S.O 729 and S.O.730 Dated 21-08-1995-SDocument48 pagesS.O 729 and S.O.730 Dated 21-08-1995-SParmod SiwachNo ratings yet

- IATF 16949 Sanctioned Interpretations 1 9 SIs FinalDocument8 pagesIATF 16949 Sanctioned Interpretations 1 9 SIs FinalOdagil BanzatoNo ratings yet

- Needle Metal Contamination Control SOP 2Document16 pagesNeedle Metal Contamination Control SOP 2vikkas vermaNo ratings yet

- Good Distribution Practices A Complete Guide - 2021 EditionFrom EverandGood Distribution Practices A Complete Guide - 2021 EditionNo ratings yet

- Waste-Management Program Audit ChecklistDocument1 pageWaste-Management Program Audit Checklistbionana0% (1)

- NCRDocument2 pagesNCRseafoodshrimps100% (1)

- WAREHOUSE-GMP-TRAININGDocument14 pagesWAREHOUSE-GMP-TRAININGHemant SankhalaNo ratings yet

- Container Loading Procedure PDFDocument8 pagesContainer Loading Procedure PDFZAHID UMARNo ratings yet

- Dosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceDocument5 pagesDosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceMahin patelNo ratings yet

- Manufacturing Process Audit: RatingDocument3 pagesManufacturing Process Audit: Ratingrajesh.bNo ratings yet

- ASMI-OSHMS-PR-12 - Audits Inspections and Preventive - Corrective Actions Procedure.Document11 pagesASMI-OSHMS-PR-12 - Audits Inspections and Preventive - Corrective Actions Procedure.JHUPEL ABARIALNo ratings yet

- Audit Checklist FormDocument12 pagesAudit Checklist Formbiniyam markosNo ratings yet

- Maruti Fabricators: Page 1 of 3 Midc Hingna Nagpur Management Review MeetingDocument3 pagesMaruti Fabricators: Page 1 of 3 Midc Hingna Nagpur Management Review MeetingAnkush Chourasia100% (1)

- Management of Product Safety: 6) Esclation Process & Information FlowDocument2 pagesManagement of Product Safety: 6) Esclation Process & Information FlowrajarajanNo ratings yet

- SOP On Handling of Critical and Non-Critical DeviationsDocument6 pagesSOP On Handling of Critical and Non-Critical DeviationsRajnish PatilNo ratings yet

- Supplier Quality Manual: Zetor Tractors A.S. Trnkova 111 628 00 BRNODocument42 pagesSupplier Quality Manual: Zetor Tractors A.S. Trnkova 111 628 00 BRNOumtNo ratings yet

- Purchasing and Inventory ControlDocument7 pagesPurchasing and Inventory Controlalemtsehaysima49No ratings yet

- Purpose and Scope: Company Name Procedures ManualDocument5 pagesPurpose and Scope: Company Name Procedures ManualOulawan KulchartchaiNo ratings yet

- Audit Checklist (RM Store)Document1 pageAudit Checklist (RM Store)Mohamed ShabirNo ratings yet

- QMS 1004255 SENSATA GSQM - Rev P No Markup BLACK PDFDocument54 pagesQMS 1004255 SENSATA GSQM - Rev P No Markup BLACK PDFJossie FuentesNo ratings yet

- QMS, EMS ChecklistDocument9 pagesQMS, EMS Checklistgayathrisrk001No ratings yet

- Manufacturing Process Audit for Factory ABCDocument18 pagesManufacturing Process Audit for Factory ABCmakubuya nasser100% (1)

- QP-72-03 Customer CommunicationDocument3 pagesQP-72-03 Customer CommunicationSamsudin AhmadNo ratings yet

- Handling of Rejects & ReturnsDocument1 pageHandling of Rejects & ReturnsRosenda MonetteNo ratings yet

- UL's ISO 9000 Registration Program ISO 9001:2000 Quality System ChecklistDocument50 pagesUL's ISO 9000 Registration Program ISO 9001:2000 Quality System ChecklistJayant Kumar JhaNo ratings yet

- FPTFC-PUR-SOP-003 Supplier Qualification and Material Evaluation Procedure Rev. 00 Effectivity Date September 1, 2021Document11 pagesFPTFC-PUR-SOP-003 Supplier Qualification and Material Evaluation Procedure Rev. 00 Effectivity Date September 1, 2021Divina CelestialNo ratings yet

- Form IA-002A (Audit Plan) (07-13-2012)Document2 pagesForm IA-002A (Audit Plan) (07-13-2012)granburyjohnstevens100% (1)

- 9001 Planning Checklist - Production ProcessDocument14 pages9001 Planning Checklist - Production ProcessMowheadAdelNo ratings yet

- Quality Manual Template PDFDocument19 pagesQuality Manual Template PDFvarun sainiNo ratings yet

- F45 Follow Up Audit Report ISO 22000 EnglishDocument13 pagesF45 Follow Up Audit Report ISO 22000 Englishivan stojaovNo ratings yet

- Audit Summary ReportDocument2 pagesAudit Summary Reportas rginorNo ratings yet

- Good Manufacturing Practices in Postharvest and Minimal Processing of Fruits and VegetablesDocument40 pagesGood Manufacturing Practices in Postharvest and Minimal Processing of Fruits and Vegetablesmaya janiNo ratings yet

- Swarda Tools & Dies: Company Wide Quality Objectives ApDocument3 pagesSwarda Tools & Dies: Company Wide Quality Objectives ApSangram KandekarNo ratings yet

- Checklist For OHSAS Audits For A Manufacturing PlantDocument1 pageChecklist For OHSAS Audits For A Manufacturing PlantC P ChandrasekaranNo ratings yet

- Audit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50Document1 pageAudit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50BALACHANDAR SNo ratings yet

- Internal Quality Audit ProcedureDocument2 pagesInternal Quality Audit ProceduremahendraNo ratings yet

- Flowchart of Work Flow Document For A Manufacturing CompanyDocument2 pagesFlowchart of Work Flow Document For A Manufacturing CompanyNicasio AquinoNo ratings yet

- Vendor Registeration FormDocument6 pagesVendor Registeration FormParik AnandNo ratings yet

- (Insert Your Company Name) : Oh&S ManualDocument2 pages(Insert Your Company Name) : Oh&S ManualKhurram ShahzadNo ratings yet

- 3017 Complaints HandlingDocument4 pages3017 Complaints Handlingashu_scribd007No ratings yet

- TD-HSE-FORM-003 Supplier Evaluation FormDocument4 pagesTD-HSE-FORM-003 Supplier Evaluation FormDamalie100% (1)

- Ape-X Sales Process DefinitionDocument4 pagesApe-X Sales Process DefinitionAnkur Dhir0% (1)

- Sop For SopDocument11 pagesSop For SopMorsad AnamNo ratings yet

- 5.43 Purchasing Procedure PDFDocument6 pages5.43 Purchasing Procedure PDFSidney100% (1)

- Control of Nonconforming Outputs ProcessDocument18 pagesControl of Nonconforming Outputs Process124th EAGLECOM KimJaveroNo ratings yet

- RHSP Stores Inventory Management SOPDocument36 pagesRHSP Stores Inventory Management SOPmariamisaseaNo ratings yet

- Crystal Distribution Services, Inc.: PL003 2 04.02.2020 Qa Master Plan 07.20.2021 Jordan Nehl Jordan NehlDocument2 pagesCrystal Distribution Services, Inc.: PL003 2 04.02.2020 Qa Master Plan 07.20.2021 Jordan Nehl Jordan NehlJordanNo ratings yet

- Document NumberingDocument8 pagesDocument NumberingRaja RehaNo ratings yet

- What Is An 8D ReportDocument2 pagesWhat Is An 8D ReportKó ChitNo ratings yet

- QP-55-03 Customer Complaint Suggestion Comment & SurveyDocument6 pagesQP-55-03 Customer Complaint Suggestion Comment & SurveySamsudin AhmadNo ratings yet

- Joncryl 678 TDSDocument2 pagesJoncryl 678 TDSAllen Kam100% (1)

- Sop For Analytical Method ValidationDocument3 pagesSop For Analytical Method ValidationDolly BijaniNo ratings yet

- Form - Nonconforming Part DispositionDocument1 pageForm - Nonconforming Part DispositionSelvaraj SimiyonNo ratings yet

- 5s Checklist OperationDocument1 page5s Checklist OperationDian PeshevNo ratings yet

- QP-QA-05-Control of Non-Conforming ProductDocument2 pagesQP-QA-05-Control of Non-Conforming ProductDebkanta DasNo ratings yet

- GD TopicsDocument2 pagesGD TopicsViswaChaitanya NandigamNo ratings yet

- Annual Repport SKFDocument20 pagesAnnual Repport SKFViswaChaitanya NandigamNo ratings yet

- Product Identification and Traceability: YES NO NADocument1 pageProduct Identification and Traceability: YES NO NAViswaChaitanya NandigamNo ratings yet

- Central Excise ManualDocument391 pagesCentral Excise ManualKushalKale50% (2)

- T-ENG CardDocument14 pagesT-ENG CardViswaChaitanya NandigamNo ratings yet

- Design Considerations or Factors of A Two Wheeler SuspensionDocument44 pagesDesign Considerations or Factors of A Two Wheeler SuspensionViswaChaitanya Nandigam100% (2)

- Letter of Recommendation Sample 1Document1 pageLetter of Recommendation Sample 1Arvind MuraliNo ratings yet

- Manju Philip CVDocument2 pagesManju Philip CVManju PhilipNo ratings yet

- Obsolescence 2. Book Value 3. Depreciation 4. Depletion EtcDocument9 pagesObsolescence 2. Book Value 3. Depreciation 4. Depletion EtcKHAN AQSANo ratings yet

- Brochure - Truemax Concrete Pump Truck Mounted TP25M4Document16 pagesBrochure - Truemax Concrete Pump Truck Mounted TP25M4RizkiRamadhanNo ratings yet

- Impact of Recruitment & Selection on Employee RetentionDocument39 pagesImpact of Recruitment & Selection on Employee RetentiongizawNo ratings yet

- About Version ControlDocument6 pagesAbout Version ControlMaria Kristina Cassandra HeukshorstNo ratings yet

- Addition and Subtraction of PolynomialsDocument8 pagesAddition and Subtraction of PolynomialsPearl AdamosNo ratings yet

- Tutorial 3Document2 pagesTutorial 3prasoon jhaNo ratings yet

- FINAL - Plastic Small Grants NOFO DocumentDocument23 pagesFINAL - Plastic Small Grants NOFO DocumentCarlos Del CastilloNo ratings yet

- Done by Akansha Bharti Harshitha K.N. Ishika Sunil Rajput Rashmi NaikDocument12 pagesDone by Akansha Bharti Harshitha K.N. Ishika Sunil Rajput Rashmi NaikRamya BalanNo ratings yet

- Wsi PSDDocument18 pagesWsi PSDДрагиша Небитни ТрифуновићNo ratings yet

- EE-434 Power Electronics: Engr. Dr. Hadeed Ahmed SherDocument23 pagesEE-434 Power Electronics: Engr. Dr. Hadeed Ahmed SherMirza Azhar HaseebNo ratings yet

- Class 9th Chemistry Unit#4 Structure of MoleculesDocument8 pagesClass 9th Chemistry Unit#4 Structure of MoleculesIrfanullahNo ratings yet

- AC7114-2 Rev N Delta 1Document34 pagesAC7114-2 Rev N Delta 1Vijay YadavNo ratings yet

- K Series Parts List - 091228Document25 pagesK Series Parts List - 091228AstraluxNo ratings yet

- Center of Gravity and Shear Center of Thin-Walled Open-Section Composite BeamsDocument6 pagesCenter of Gravity and Shear Center of Thin-Walled Open-Section Composite Beamsredz00100% (1)

- Executive Education Portfolio Soft Copy-INSEADDocument58 pagesExecutive Education Portfolio Soft Copy-INSEADОля КусраеваNo ratings yet

- BSC6900 UMTS V900R011C00SPC700 Parameter ReferenceDocument1,010 pagesBSC6900 UMTS V900R011C00SPC700 Parameter Referenceronnie_smgNo ratings yet

- Lesson Plan 2018-2019 Term 1Document205 pagesLesson Plan 2018-2019 Term 1Athlyn DurandNo ratings yet

- Plant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirDocument20 pagesPlant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirSharad KokateNo ratings yet

- Critique On A Film Director's Approach To Managing CreativityDocument2 pagesCritique On A Film Director's Approach To Managing CreativityDax GaffudNo ratings yet

- All MeterialsDocument236 pagesAll MeterialsTamzid AhmedNo ratings yet

- Zhihua Yao - Dignaga and The 4 Types of Perception (JIP 04)Document24 pagesZhihua Yao - Dignaga and The 4 Types of Perception (JIP 04)Carlos Caicedo-Russi100% (1)

- Shimano Brakes ManualDocument36 pagesShimano Brakes ManualKon Arva100% (1)

- Strain Gauge Sensor PDFDocument12 pagesStrain Gauge Sensor PDFMario Eduardo Santos MartinsNo ratings yet

- Reaction rate determination and simulation of hydrogenation processDocument3 pagesReaction rate determination and simulation of hydrogenation processToMemNo ratings yet

- OROLO & W. D. GannDocument56 pagesOROLO & W. D. GannGaurav Garg100% (1)

- April 3rd - Asynchronous Class - Questions-4Document3 pagesApril 3rd - Asynchronous Class - Questions-4alidrissiNo ratings yet

- 40 Multiple Choice Questions in Basic StatisticsDocument8 pages40 Multiple Choice Questions in Basic StatisticsLevi CorralNo ratings yet

- 01 Design of Flexible Pavement Using Coir GeotextilesDocument126 pages01 Design of Flexible Pavement Using Coir GeotextilesSreeja Sadanandan100% (1)

- CIGB B164 Erosion InterneDocument163 pagesCIGB B164 Erosion InterneJonathan ColeNo ratings yet