Professional Documents

Culture Documents

Bituminous Works & Culverts

Uploaded by

Dheeraj ThakurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bituminous Works & Culverts

Uploaded by

Dheeraj ThakurCopyright:

Available Formats

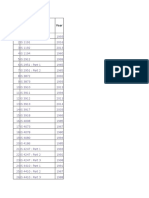

Item no.

1.01

1.02

1.02.a 1.02.b 1.02.b.i 1.02.b.ii 1.02.c 1.02.d

Description Bill No. 1: SITE CLEARANCE Clearing and Grubbing Road Land (Cleaning and grubbing road land including uprooting rank vegetation grass bushes shrubs saplings and trees girth upto 300 mm removal of stumps of trees of all girth size cut earlier and disposal of unserviceable materials and stacking of serviceable material to be used or auctioned including removal and disposal of top organic soil not exceeding 150 mm in thickness ) complete as per technical specification clause 201 and as directed by the Engineer. Dismantling of structures (dismantling of existing structures like culverts, bridges, retaining walls and other structures comprising of masonry cement concrete, wood work, steel work, including T&P and scaffolding wherever necessary, sorting the dismantled material, disposal of unserviceable material and stacking the serviceable material with all lifts and lead complete as per technical specification clause 202 and section 2800. Stone Masonry Pavement Structure (i) Bituminous Course (ii) Granular Course Guard stones / KM stones/ Sign post/ Hectometre stones Stone Pitching/ boulder apron/ brick soling/ stone soling Total for Bill No. 1 Bill No. 2: Earthworks Roadway excavation and drainage in all kinds of soil such as pick work, jumper work soft and hard rock including chilling wedging out of rock and blasting, if required and saturated soil and their intermediate classification in all heights and depths including dressing trimming and compacting the cut formation in accordance with requirement of lines grades and cross fall complete as per technical specification clause 301 and all cut material except stone (which can be recovered) will be the property of contractor and disposal of excess material shall be in according to the EMP. The recovery of stone shall be made @ Rs. 170/cum ( One hundred seventy ) from the total quantity -494701.299cum------- on prorata basis as per increase or decrease in the total quantity for a minimum quantity of 82613Cum on prorata basis as per increase of decrease in the quantity of actual earthwork carriedout.Rate of Stone Recovery is Exclusive of Royalty as applicable. (In all type of soil) Embankment construction with material obtained from borrow pits (Construction of embankment with approved material obtained from borrow pits with all lifts and leads, transporting to site, spreading, grading to required slope and compacting to meet requirement of table 300-2) complete as per drawing and technical specification clause 305. Construction of embankment with suitable materials deposited at site from roadway and drainage excavation and foundation of other structures graded and compacted to meet requirement of table 300-2 complete as per technical specification clause 305. Construction of sub-grade with suitable material deposited at site from roadway and drainage excavation and foundation of other structures graded and compacted to meet requirement of table 300-2 complete as per technical specification clause 305. Construction of hard shoulder with approved granular material having a minimum CBR of 20% from approved borrow areas as per technical specifications clause 407 including all leads and lifts complete. Striping and storing of top soil by road side at 15m internal and reapplication on embankment slopes, cut slopes and other areas in localities where the available embankment material is not conducive to plant growth and disposal of unsuitable soil with all lifts and leads as per technical specifications clauses 301 and 305.

Unit

Ha

m3 m3 m3 No. m3

2.01

m3

2.02

m3

2.03

m3

2.04

m3

2.05

m3

2.06

m3

2.07

2.08

2.09

2.1

2.11 2.01 A

Loosening and recompacting existing sub-grade and shoulder ground upto a level of of 500 mm below the Subgrade level, watered, graded and compacted in layers to meet requirement of table 300-2 in all kinds of soil as per technical specification clauses 301 and 305. Construction of raised median / Island fill above road level with approved material deposited at site from roadway cutting and excavation for drain and foundation of other structures, spread graded and compacted with all leads and lifts complete as per technical specification clauses 305 and 407. Making 50 mm x 50 mm furrows, 25 mm deep 450 to the centreline of the road and at one metre interval in the existing thin bituminous wearing course including sweeping and disposal of excavated material to all lifts and leads as per technical specification clause 404.3.1 and 501. Construction of subsurface drain with Geosynthetic lining of trench & perforated pipe of 100mm internal diameter of PVC, closely jointed, perforations ranging from 3 mm to 6 mm depending upon size of material surrounding the pipe with 150 mm bedding below the pipe and 500 mm cushion above the pipe, cross section of excavation 450 x 550 mm excavated material to be utilised in roadway at site, complete as per technical specification clause 309. Preparation of Subgrade in rocky formation for correcting surface irregularities as per Technical Specifications Clause No. 301.6. BILL No. 2A- RECOVERY OF STONES IN ROAD WORK Recovery of Stones as per item No. 2.01 andTechnical Specifications Clause 301. Total for Bill No. 2 Bill No. 3: SUB-BASE COURSE & BASE COURSE (Non Bituminous) Constructing Granular Sub-base (GSB) with approved materials conforming to Grading-I (Table 400-1) with all lifts and by mixing in a mechanical mixed plant at OMC, all complete as per Technical Specifications Clause 401. Construction of wet mix Macadam (WMM) base and profile correcting course with approved material including premixing the material with water at OMC in mechanical mix plant carriage of mixed Material by tipper to site , laying in uniform layers with paver in sub- base /base course on well prepared surface and compacting with vibratory roller to achieve the desired density complete as per drawing and technical specification clause 406. Cement Treated Crushed Rock or combination as per clause 403.2 and table 400.4 in Sub base/ Base ( providing , laying and spreading Material on a prepared sub grade, adding the designed quantity of cement to the spread Material , mixing in place with rotavator , grading with the Motor grader and compacting with the road roller at OMC to achieve the desired unconfined compressive strength and to form a layer of sub-base/base.) Total for Bill No. 3 Bill No. 4: BASE AND SURFACE COURSES (Bituminous) Providing and laying bituminous prime coat over granular surface with bituminous emulsion including clearing of road surface and spraying primer complete as per technical specification clause 502 @ 6 kg to 9 kg per 10 Sqm. Providing and laying bituminous tack coat with bituminous emulsion using emulsion pressure distributor complete as per technical specification clause 503. Over granular surface treated with primer ( @ 2.5 kg/10 sqm ) Over bituminous surface (@2 kg / 10 sqm ) Providing and laying dense graded bituminous macadam as with 60-90 TPH batch type HMP using crushed aggregates of specified grading, premixed with bituminous binder @ 4.0 to 4.5 per cent by weight of total mix and filler, transporting the hot mix to work site, laying with a hydrostatic paver finisher with sensor control to the required grade, level and alignment, rolling with smooth wheeled, vibratory and tandem rollers to achieve the desired compaction as per MoRTH specification clause No. 507 (Table 50010) complete in all respects.

m3

m3

m2

Lm

m2 m3

3.01

m3

3.02

m3

3.03

m3

4.01 4.02 4.02.a 4.02.b

m2

m2 m2

4.03

m3

4.04

Providing and laying Bituminous concrete with 60 - 90 TPH batch type HMP using crushed aggregates of specified grading , premixed with bituminous binder of penetration grade S55 (50/60 Grade with modifier Bitumen ( CRMB ) minimum @ 5 % of mix and filler , transporting the hit mix to work site , laying with a hydrostatic paver finisher, with sensor control to the required grade , level and alignment, rolling with smooth wheeled vibratory and tandem rollers to achieve the desired compaction complete in all respects as per technical specification clause 509 and Publication IRC : SP:53-1999. Total for Bill No. 4 Bill No. 5: CULVERTS Dismantling of structures ( dismantling of existing structures like culverts, bridges, retaining walls and other structures comprising of masonry, cement concrete, wood work, steel work, including T&P and scaffolding wherever necessary, sorting the dismantled material, disposal of unserviceable material and stacking the serviceable material with all lifts and leads complete as per Technical Specification clause 202 . Brick Masonry Stone Masonry Plain Cement Concrete Reinforced cement concrete including straightening and cutting of bars and separating them completely Hume pipes guard rails, gutters and fencing Guard stones/ KM stones/ Sign Post/ Hectometre Stones Dismantling of Railing Stone Pitching / boulder apron/ brick soling/ Stone soling Earthwork in excavation of foundation of structures in all kinds of soil such as pick work, jumper work, soft and hard rock including chilling, wedding out of rock and blasting, if required and saturated soil and their intermediate classification in all heights and depths includes dressing, trimming, compacting the cut formation in accordance with requirement with lines grades as per drawing and Technical specification, including setting out, construction of shoring and bracing, removal of stumps and other deleterious matter, dressing of sides and bottom and backfilling with approved material including all lifts and leads. The recovery of stone shall be made @ Rs. 170/cum (Rupees One Hundred Seventy Only) for a minimum quantity of -466.384 cum on prorata basis as per increase or decreases in the quantity of actual earthwork carried out complete as per drawings and Technical Specifications Clause No. 304.Rate of Stone Recovery is Exclusive of Royalty as applicable. In all types of soil Providing and laying in position Plain Cement Concrete of Grade M15 in levelling Course below foundations and approach slabs, cut-off wall, headwall, etc. complete as per drawings and Technical Specifications Sections 1500, 1700, 2100 and 2700. Providing and laying in position Reinforced Cement Concrete of Grade M25 in Foundations, Wing walls, headwalls, retaining walls complete as per drawings and Technical Specifications Sections 1500, 1700, 2100 and 2200. Providing and laying in position Reinforced Cement Concrete of Grade M25 in box cell, structures for culverts complete as per drawings and Technical Specifications Sections 1500, 1700 and 2200. Providing & fixing in position HYSD(TMT) Fe 415 grade reinforcement bars in foundations, substructures, box structure complete as per drawings and Technical Specification section 1600. Providing & fixing in position HYSD(TMT) Fe 415 grade reinforcement bars in superstructures etc. complete as per drawings and Technical Specification section 1600. Providing and laying boulder apron for bed protection works complete as per drawings and Technical Specifications clause no 2503. Providing and laying 150mm thick flat rigid apron embedded in 300mm thick concrete grade M15 for bed protection works with all leads & lifts as per drawings & Technical Specifications Clauses 2503.

m3

5.01

5.01.a 5.01.b 5.01.c 5.01.d 5.01.e 5.01.f 5.01.g 5.01.h

m3 m3 m3 m3 Lm Nos. Lm m3

5.02

5.02.a

m3

5.03

m3

5.04 5.05 5.06 5.07 5.08 5.09

m3 m3 MT MT m3 m3

5.1 5.10.i 5.11 5.12

Providing and fixing in position Expansion joints complete as per drawings and Technical Specifications Section 2600. (I) Filter Type Moulded Providing and fixing in position drainage spouts complete as per drawings and Technical Specifications Clauses 2705. Providing and fixing 80mm dia. NB MS pipe rail on crash barrier complete including providing three or more coats of epoxy paint of approved colour, make and quality over a coat of epoxy primer complete as per drawings and Technical Specifications Sections 1900 and 2700. Providing and laying in position Reinforced Cement Concrete grade M25 in approach slabs including reinforcement and bituminous joint filler with joint sealing compound between approach slab and dirt wall complete as per drawings and Technical Specifications Sections 1500,1600,1700 and 2700. Providing and laying in position Reinforced Cement Concrete grade M40 in crash barriers including reinforcement providing bituminous fibber board and Polysulphide joint filler at expansion joints/ gap locations complete as per drawings and Technical Specifications Clause No. 809 and Sections 1500, 1600, 1700 and 2700. Providing & fixing weep holes in abutment walls, wing walls, head walls, return walls and retaining walls with 100 mm dia. PVC pipe, extending through the full width of the structure with slope of 1V: 20H towards drawing face complete as per drawings and Technical Specifications Clause 2706. Providing & painting of structure no. span arrangement and flow directions complete as per drawings and Technical Specifications Section 800. Providing and laying back filling behind abutments, wing walls, retaining walls, return walls or any other area with selected imported granular materials of approved quality complete as per drawings and Technical Specifications Clauses 305 and 710.1.4.of IRC:78 Appendix-6 & 2200. (a) c=0, (b) > 300, (c.) =1.8t/m3 Providing and laying filter media behind box structure, wing walls, retaining walls and return walls with granular materials/stone crushed aggregates satisfying the requirements laid down in clause 2504.2.2 to a thickness of not less than 600 mm with smaller size towards the soil and bigger size towards the wall and provided over the entire surface behind abutment, wing wall and return wall to the full height compacted to a firm condition complete as per drawings and Technical Specifications Section 305 and 2500. Providing and Laying Shalitex Board in expansion gap as per Technical Specifications section 2605 or directed by the Engineer in charge. Providing and laying in position Plain Cement Concrete of Grade M15 in cut-off wall, headwall, Retaining wall, parapet wall, breast wall etc with all leads & lifts. complete as per drawings and Technical Specifications Sections 1400, 1500, 1700, 2100 and 2700. Providing, laying and jointing NP-4 Reinforced Cement Concrete pipe conforming to the requirements of IS:458 including testing of joints all complete as per Technical Specifications Sections 1000, 2900 and IRC:SP 13-2004. 900 mm dia BILL NO. 5A : RECOVERY OF STONES IN CULVERT WORK Recovery of Stones as per item No. 5.02 andTechnical Specifications Clause 304. Total for Bill No. 5 Bill No. 6: BRIDGES

M Nos. Lm

5.13

m3

5.14

m3

5.15 40.2 5.17 5.17.a

Lm Nos.

m3

5.18

m3

5.19 5.2

m2 m3

5.21

5.21.a 5.01A

Lm m3

6.01

6.01.a 6.02 6.03 6.04 6.05 6.06 6.06.a 6.07 6.07.i 6.08 6.08.i 6.08.ii 6.09 6.1 6.11 6.12

6.13 6.14 6.14.b 6.14.I 6.14.I.a 6.14.I.b 6.14.I.c 6.14.II 6.14.II.a

Earthwork in excavation of foundation of structures in all kinds of soil such as pick work, jumper work, soft and hard rock including chilling, wedding out of rock and blasting, if required and saturated soil and their intermediate classification in all heights and depths includes dressing, trimming, compacting the cut formation in accordance with requirement with lines grades as per drawing and Technical specification, including setting out, construction of shoring and bracing, removal of stumps and other deleterious matter, dressing of sides and bottom and backfilling with approved material including all lifts and leads. The recovery of stone shall be made @ Rs. 170/cum (Rupees One Hundred Seventy Only) for a minimum quantity of -------3571.174cum-----on prorata basis as per increase or decreases in the quantity of actual earthwork carried out complete as per drawings and Technical Specifications Clause No. 304.Rate of Stone Recovery is Exclusive of Royalty as applicable. In all types of soil Providing and laying in position Plain Cement Concrete of Grade M15 in levelling Course below open foundations, pile caps, approach slabs and annular filling around foundation in rock complete as per drawings and Technical Specifications Sections 1500, 1700 and 2700. Cleaning all existing old reinforcement to remove rust using sand blasting as per technical specifications section 1600 Drilling and fixing in position HYSD(TMT) Fe 415 grade reinforcement bars in substructures etc. in old concrete complete as per drawings and Technical Specification section 1600. Providing and laying in position Plain Cement Concrete of Grade M20 in cut-off walls complete as per drawings and Technical Specifications Sections 1500, 1700, 2100 and 2700. Providing and laying in position Reinforced Cement Concrete in open foundations complete as per drawings and Technical Specifications Sections 1500, 1700, 2100 and 2200. Grade M 30 Providing and laying in position Reinforced Cement Concrete in piers, peir cap, pedestals, cantilever/counter fort abutments, abutment cap, dirt walls, wing walls, retaining walls, median wall etc. complete as pet drawings and Technical Specifications Sections 1500, 1700, and 2200. (a) Grade M 30 Providing and laying in position Reinforced Cement Concrete in superstructure complete as per drawings and Technical Specifications Sections 1500, 1700, 2300 and clauses A-5. Solid Slab of grade M 30 T-Beam and Slab of grade M 30 Providing & fixing in position HYSD(TMT) Fe 415 grade reinforcement bars in foundations complete as per drawings and Technical Specification section 1600. Providing & fixing in position HYSD(TMT) Fe 415 grade reinforcement bars in substructures etc. complete as per drawings and Technical Specification section 1600. Providing & fixing in position HYSD(TMT) Fe 415 grade reinforcement bars in superstructure etc. complete as per drawings and Technical Specification section 1600. Providing and laying in position Reinforced Concrete grade M35 in box girder & Voided Slab superstructure including pedestals complete as per drawings and Technical Specifications Sections 1500, 1700 and 2300. Providing and laying in position 65mm thick wearing coat consisting of 40mm thick bituminous concrete overlaid with a 25mm thick layer of mastic asphalt over deck slab after applying prime coat complete as per drawings and Technical Specifications Clause No.502, 509, 515 and Section 2700. Providing and fixing in position bearings true to line and level complete as per drawings and Technical Specifications Section 2000. (B) POT and PTFE bearings Pinned bearings of Horizontal load carrying capacity in longitudinal direction and traverse direction a) In longitudinal direction 80t in transverse direction 15t b) In longitudinal direction 120t in transverse direction 45t c) In longitudinal direction 170t in transverse direction 40t Free/Guided Bearings of vertical load carrying capacity a) 200t capacity

m3 m3 MT MT m3

m3

m3

m3 m3 MT MT MT m3

m2

Nos. Nos. Nos. Nos.

6.14.II.b 6.14.II.c 6.15 6.15.i 6.15.ii 6.15.iii 6.16 6.17

6.18

6.19

6.2

6.21 6.22 6.23 6.23.a 6.24 6.25 6.26

b) 300t capacity c) 360t capacity Providing and fixing in position Expansion Joints complete as per drawings and Technical Specifications Section 2600. Providing 20mm thick premoulded Asphaltic joints complete as per drawing and technical specifications section 2600. Strip seal type accommodating a movement of 70mm Copper Strip type accommodating a movement of 70mm Providing and fixing in position drainage spouts complete as per drawings and Technical Specifications Clause 2705. Providing and fixing in position with clamps 100mm dia. PVC down take and runner pipe including joining with drainage spout pipe, providing couplers, bends etc. in ROBs, Grade separators and underpasses complete as per drawings Providing and fixing 80mm dia. NB MS pipe rail on crash barrier complete including providing three or more coats of epoxy paint of approved colour, make and quality over a coat of epoxy primer complete as per drawings and Technical Specifications Sections 1900 and 2700. Providing and laying in position Reinforced Cement Concrete grade M30 in approach slabs including reinforcement providing bituminous fibber board and Polysulphide joint filler with joint sealing compound between approach slab and dirt wall complete as per drawings and Technical Specifications Sections 1500, 1600,1700 and 2700. Providing and laying in position Reinforced Cement Concrete grade M40 in crash barriers including reinforcement, providing bituminous fibber board and Polysulphide joint filler at expansion joints/ gap locations complete as per drawings and Technical Specifications Clause No. 809 and Sections 1500, 1600, 1700 and 2700. Providing & fixing weep holes in abutments, splayed wing wall, median wall, retaining wall or any other earth retaining structure complete as per drawings and Technical Specifications Clause 2706. Providing & painting of structure no. span arrangement and flow directions complete as per drawings and Technical Specifications Section 800. Providing and laying back filling behind abutments, wing walls, return walls with selected imported granular materials of approved quality complete as per drawings and Technical Specifications Clauses 305 and Appendix-6 of IRC: 78-2000. (a) c=0, (b) > 300, (c.) =1.8t/m3 Providing and laying filter media behind abutment, wing walls, retaining walls and return walls complete as per drawings and Technical Specifications Section 305 and 2500. Providing and laying in position hand packed boulder pitching on slopes of embankment, in front of abutments and in launching apron complete as per drawings and Technical Specifications Section 2500. Providing and laying filter material underneath stone pitching in slope complete as per drawings & Technical Specification Section 2500. Dismantling of structures ( dismantling of existing structures like culverts, bridges, retaining walls and other structures comprising of masonry, cement concrete, wood work, steel work, including T&P and scaffolding wherever necessary, sorting the dismantled material, disposal of unserviceable material and stacking the serviceable material with all lifts and leads complete as per Technical Specification clause 202 and section 2800. Brick Masonry Stone Masonry Plain Cement Concrete Reinforced cement concrete including straightening and cutting of bars and separating them completely Dismantling of Railing

Nos. Nos.

Lm Lm Lm Nos. Lm

Lm

m3

m3

Nos. Nos.

m3 m3 m3 m3

6.27

6.27.a 6.27.b 6.27.c 6.27.d 6.27.e

m3 m3 m3 m3 Lm

6.28

6.28.a 6.28.a.i 6.28.a.ii 6.28.a.iii 6.28.b 6.28.b.i 6.28.b.ii 6.28.b.iii 6.29 6.01A

Providing, fitting and fixing in position true to line and level seismic restrainers assembly conforming to IRC: 83 Part II with all accessories (including elastomeric bearing, provision of stainless steel plates and mild steel plates and fixing arrangements etc.) complete as per manufacturer design duly approved by the Engineer and as per drawings, Technical Specifications Sections 1900, 2000, and Clause No. A-12 of Additional Technical Specifications for the following lateral load capacity. a) Longitudinal Seismic restrainers of capacity I) 40 T capacity ii) 50 T capacity iii) 120 T capacity b) Transverse Seismic restrainers of capacity I) 75 T capacity ii) 120 T capacity iiii) 150 T capacity Providing and Laying Shalitex Board in expansion gap as per technical specifications section 2605 or directed by the engineer in charge. BILL NO. 6A RECOVERY OF STONES IN BRIDGES WORK Recovery of Stonesasper item No. 6.01 andTechnical Specifications Clause 304. Total for Bill No. 6 Bill No. 7: DRAINAGE AND PROTECTION WORKS Earthwork in excavation for construction of protection works in all kinds of soil such as pick work, jumper work, soft and hard rock including chilling, wedging out of rock and blasting, if required and saturated soil and their intermediate classification in all heights and depth includes dressing, trimming and compacting the cut formation in accordance with requirement with lines grades as per drawing and Technical specification, including setting out, construction of shoring and bracing, removal of stumps and other deleterious matter, dressing of sides and bottom to all lifts and leads. The recovery of stone shall be made @ Rs. 170/cum (Rupees One Hundred Seventy Only) for a minimum quantity of 1023.39cum on prorata basis as per increase or decrease in the quantity of actual earthwork carried out complete as per drawings and Technical Specifications Clause No. 304 and Additional Technical Specification Clause No. A-4.Rate of Stone Recovery is Exclusive of Royalty as applicable. In all types of excavation Construction of drainage chute including construction of bell mouth at entry complete as per drawing and Additional Technical Specifications Clause No. A-2. Construction of energy dissipation basin at toe of chutes complete as per drawing and Technical Specifications Sections 1500 and 1700. Providing and laying in position Plain Cement Concrete grade M-15 in drain, levelling course below retaining walls, gabions, encasing of pvc pipe, etc. complete as per drawing and Technical Specifications Sections 1500 and 1700. Providing and laying in position Plain Cement Concrete grade M-15 in V-drain all along the toe of the cut sections complete as per drawing and Technical Specifications Sections 1500 and 1700. Providing and constructing gabion walls for retaining earth with segments of PVC coated GI wire and filled with boulders with least dimension of 250 mm complete as per drawings and Additional Technical Specification Clause No. A- 12. Providing and laying in position Plain Cement Concrete of Grade M15 in covered & uncovered drain etc with all leads & lifts. complete as per drawings and Technical Specifications clause 309 & Sections 1400. Providing M20 RCC slab including reinforcement over stone masonry drain as per specifications and as directed by the Engineer Providing and laying in position Plain Cement Concrete of Grade M15 in cut-off wall, headwall, Retaining wall, parapet wall, breast wall etc with all leads & lifts. complete as per drawings and Technical Specifications Sections 1400, 1500, 1700, 2100 and 2700.

Nos. Nos. Nos. Nos. Nos. Nos. m2 m3

7.01

7.01.a 7.02 7.03 7.04 7.05 7.06

m3 Lm Nr. m3 Lm m3

7.07 7.08 7.09

m3 m3 m3

7.1 7.11 7.12 7.13

7.14 7.15 7.16 7.16.a 7.16.b 7.16.c 7.17

7.18 7.19 7.2 7.21 7.01A

Providing weep holes with 100 mm dia PVC pipe in retaining walls complete as per drawing and Technical Specifications Clause No. 2706. Providing and laying filter material behind retaining wall complete as per Technical Specifications 710.1.4.of IRC:78 Appendix-6 ,Clause No. 305 and 2200. Laying of Geotextile as filter membrane behind gabions etc. complete as per drawings and Technical Specifications Section 700. Construction of a narrow filter sub-surface drain consisting of perforated 200 mm internal diameter pipe laid in narrow trench surrounded by a Geotextile filter fabric as per Clause No. 309.3.5 including excavation and backfilling. Construction of 800 mm x 800 mm outlet chamber of Plain Cement Concrete M15 for subsurface drain including Reinforced Cement Concrete cover and outlet pipe complete as shown in the drawings and as directed by the Engineer. Providing and laying backfill material of approved design behind the retaining wall conforming to the drawings and Technical Specifications Clause No. 305. Furnishing, assembling, filling and erecting Gabion Wire Mesh System as per the Additional Technical Specifications Clause No. A-13. Woven Wire Mesh Gabion Backfill Furnishing, drilling, installing and grouting of Dowels, to the dimensions, lines and grades shown in the the drawing or as determined by the Engineer and in conformity to the Additional Technical Specifications Clause No. A-14. Providing 60mm thick shotcrete in two layers including welded wire fabric of size 100mm x 100 mm x 4mm dia in first layer complete as per drawings, Technical Specifications clause No. 2807 and as directed by the Engineer. Providing rock net to protect rock face with proper scaling and nailing with 30cm nails as per specifications and as directed by the Engineer. Providing RCC retaining wall with M30 grade concrete excluding reinforcement as per specifications and as directed by the Engineer. Providing & fixing in (Retaining wall) position HYSD(TMT) Fe 415 grade reinforcement bars in substructures etc. complete as per drawings and Technical Specification section 1600. BILL NO. 7A RECOVERY OF STONES IN DRAINAGE AND PROTECTION WORKS Recovery of Stones as per item No. 7.01 andTechnical Specifications Clause 301 &304. Total for Bill No. 7 Bill No. 8: TRAFFIC SIGNS, MARKINGS & OTHER ROAD APPURTENANCES Providing and laying plain cement concrete Kerb (M-20 Grade) complete as per drawing and technical specification clause 408 sections 1500,1700 and 400. For kerb without channel Supplying and fixing sign boards including the cost of posts, fixtures, foundation, fitting and fixing, Sheeting will be made of encapsulated lens type of Retro-reflective type and messages/ borders will be screen printed complete as per technical specification clause 801 and as directed by Engineer. Informatory Sign, direction sign and destination sign. Informatory Sign 60 x 60 Cautionary/ Warning signs, Regulatory signs and Mandatory signs. Triangular 900 mm / Square 600mm x 600mm side. Triangular 600 mm / Circular 600mm side. Octagon 900 mm side. Chevron Sign 1800mm x 600mm Providing and laying pavement marking with hot applied thermoplastic paints conforming to ASTM D-36/ BS 3262 (Part-I) complete as per drawing & technical specification clause 803. Lane/centreline/ edge marking / transverse and any other marking.

Lm m3 m2 Lm

Nr. m3

m2 m3 m3 Lm

m2 m2 m3 MT. m3

8.01 8.01.a 8.02 8.02.a 8.02.b 8.02.c 8.02.d 8.02.e 8.02.f 8.02.g 8.03 8.03.i

Lm

m2 No. No. No. No. No.

m2

8.03.ii 8.03.iii 8.04 8.05 8.05.a 8.05.b 8.05.c 8.06 8.06.a 8.06.b 8.06.c 8.07 8.08 8.09 8.1 8.11

directional arrows, lettering etc. as per drawing No. 61 of technical Type Design and Intersection of National Highways. Diagonal / Chevron marking. Providing 2 coats of systemic enamel painting over one coat of cement primer on Kerb, Median opening and other Structural as Additional Technical Specification A-1 Providing and fixing RCC/PCC hectometre, kilometre and 5th kilometre stones complete as per drawing and technical specification clause 804 (including cost of reinforcement painting and marking.) Hectometre stone Kilometre stone 5th km. stone Providing and fixing Road Delineators complete as per drawing and technical specification clause 805 and direction of the Engineer. Roadway Indicators with Reflectors Hazard Markers Object Markers Providing and erecting R.C. Guard stone including cost of reinforcement and two coats of painting with ready mix oil bound paint complete as per drawing and technical specification clause 806. Providing utility ducts of 300mm dia. NP-3 RCC Hume pipe in urban areas/ Service road as per drawing and technical specification section 2900. Supplying and fixing of Road Studs ( Raised Pavement Markers) Conforming to ASTM D4280 type "H" in position as indicated on the drawings or as directed by Engineer as per technical specification clause 812. Providing and constructing traffic calming measures (Runble Strips) as per drawing and technical specifications and as per direction of the Engineer. Providing shelter in Bus Bays as per drawing and addition technical specification A-10 and as per direction of Engineer. Providing and erecting a "W" metal beam crash barrier comprising of 3 mm thick corrugated sheet metal beam rail, 70 cm above road/ ground level, fixed on ISMC series channel vertical post, 150 x 75 x 5 mm spaced 2m centre to centre, 1.8 m high, 1.1 m below ground/road level, all steel parts and fitments to be galvanized by hot dip process, all fittings to conform to IS: 1364, metal beam rail to be fixed on the vertical post with a spacer of channel section 150 x 75 x 5 mm 330 mm long complete as per clause 810. Total for Bill No. 8 Bill No. 9: MISCELLANEOUS AND TRAFFIC SAFETY WBM Grading - 1 Providing, laying, spreading and compacting stone aggregates of specific sizes to water bound macadam specification including spreading in uniform thickness, hand picking, rolling with three wheel 80-100 kNstatic roller in stages to proper grade and camber, applying and brooming, stone screening /binding material to fill up the interstices of coarse aggregate, watering and compacting to the required density Grading 1 as per technical specification clause 404 of MORT&H. WBM Grading - 2 Providing, laying, spreading and compacting stone aggregates of specific sizes to water bound macadam specification including spreading in uniform thickness, hand picking, rolling with Smooth wheel 80-100 kN static roller in stages to proper grade and camber, applying and brooming, stone screening /binding material to fill up the interstices of coarse aggregate, watering and compacting to the required density Grading 2 as per technical specification clause 404 of MORT&H. Providing and applying tack coat with bitumen emulsion (RS-1) using emulsion distributor at the rate of 0.35 to 0.40 kg per Sqm on the granular base (not primed) treated with primer & cleaned with hydraulic broom as per technical specification clause 503

No. No. m2

No. No. No.

No. No. No. No. Lm Nr. m2 Nr.

8.12

Lm

9.01

Cum

9.02

Cum

9.03

Sqm

9.04

9.05 9.05.i 9.06 9.06.a 9.07 9.08

9.09

9.1 9.10.i 9.11

9.12 9.13 9.14

Carrying out treatment and repairs to pot holes and any necessary patching to existing bituminous carriageway surfacing using bitumen of 60/70 grade complete as per technical specification clause 3004 and as per the directions of the Engineer. Construction of temporary diversion and providing traffic safety and control where necessary and as per direction of the Engineer including maintenance thereof complete as per drawing and technical specification clause 112. 3.75 m wide Providing and Maintaining Safety barricading during construction with necessary markings, warning lights, sign boards, flags etc. complete as per drawing and technical specification clause 112 and as per the direction of the Engineer. For Deviation and Barricading Colour photographs (2 prints of 15cm x 10cm each) with soft copy stored in CD and printed photos in album as per technical specification clause 125. Colour photographs (2 prints of 15cm x 10cm each) with soft copy stored in CD and printed photos in album as per technical specification clause 125 - but additional prints (size 15cm x 10cm ) of colour record photographs. Supplying colour video cassette and CD ROM records before the construction, during construction stage and after construction, consisting of each set of edited master cassettes and CD with 4 copies each of cassettes and CD ROMs complete as per technical specification clause 126. Providing, installing, commissioning and testing of street lighting system of suitable height with all brackets, luminaries, pillar box, photo cell timer cum contactor, cabling, earthing and all other necessary accessories and arrangement for making street lighting system complete and functional as shown in drawing and technical specification and as directed by Engineer. Lighting Standard with Double Arm/ Luminaire Open - Graded Premix Surfacing (Providing, laying and rolling of open - graded premix surfacing of 20mm thickness composed of 3.2 mm to 5.6 mm aggregates either using penetration grade bitumen or cut-back or emulsion to required line, grade and level including mixing in a suitable plant, laying and rolling with a smooth wheeled roller 8-10 tonne capacity, finished to required level and grades. Providing and laying of premix sand seal coat with HMP of appropriate capacity not less than 75 tonnes/ hours using crushed stone chipping 6.7mm size and penetration bitumen of suitable grade. Routine Maintenance work inclusive of Grading of Shoulders & existing carriageway & Maintenance of cross Drainage Structures, Making of Earthen drain

m2

Lm

Lm No. No.

Set

No. m2

m2 Km

Routine Maintenance work inclusive of Grading of Shoulders & Maintenance of cross Drainage Structures Km per Year for the completed partially handed over sections by the contractor during defect liability period. Total for Bill No. 9 Schedule of DayworkRates: 1. Labour

10.A 10.A.a 10.A.b 10.A.c 10.A.d 10.A.e 10.A.f 10.A.g 10.A.h 10.A.i

SCHEDULE (A) - LABOUR Operator Bitumen labour Blacksmith Carpenter Fabricator/ Fitter / Welder Blaster Labourer Mason Chowkidar for watch & Ward Total for Bill No. 10.A Schedule of DayworkRates: 2. Materials SCHEDULE (B) - MATERIAL

Hour Hour Hour Hour Hour Hour Hour Hour Hour

10.B

10.B.B 10.B.b 10.B.c 10.B.d 10.B.e 10.B.f

Bitumen 60/70 grade (bulk) conforming to IS: 73 Modifier Bitumen Cement conforming to IS: 8112 Coarse aggregate for concrete / WBM Coarse sand as per MOST specification Brick as per IS: 1077 Total for Bill No. 10.B Schedule of Daywork Rates: 3. Contractors Equipment SCHEDULE (C) - CONTRACTOR'S EQUIPMENT ( With Operator, POL, Etc.) Deployment of Truck mounted utility crane ( 8 -10 MT capacity ) Deployment of JCB Bull Dozer Size upto 200 KW Mobile concrete batching / mixing plant Motor Grader Pneumatic Tyred Roller Pumping Set (5 hp) Pumping Set (10 hp) Roller Static (8-10 tonne) Roller Vibratory (1-2 tonne width about 1 m) Roller Vibratory (8-10 tonne static) Truck (10/12 tonnes) Truck mounted water tanker (10 tonnes) Wheel Loader (1.5 cum) Total for Bill No. 10.C Bill No. 11: ENVIRONMENTAL MEASURES Disposal of Excess Material (Part of EMAP) with all leads & lifts . Compaction of the disposed surface area using adequate quantity of water at the disposal location by road rollers and other machineries. Preparation of 'Contractors' consolideted Typical Debris Disposal Plan'of the project in accordance with the EMP for all disposal areas as per the guidelines provided in the EMP Guideline-6 &14. Construction Cement Concrete Platform with stone masonry wall enclosure for municipal waste / garbage collection points along project road at specified locations and as per standard specifications of civil works Redevelopment of oxbow lands suitable to parking in settlement areas along rural/ non-urban/ forest stretches at 1 selected locations as per standard specifications of civil works Construction of cement concrete platform with stone masonry parapet and MS railing at 2 selected locations for valley view as per standard Civil Works specifications Construction of silt trap to avoid silting of the water body at three locations as per the drawing provided in the Appendix -7 at three locations as specified in the Appendix 8. Total for Bill No. 11

T T T m3 m3 Per 1000

10.C 10.C.C 10.C.b 10.C.c 10.C.d 10.C.e 10.C.f 10.C.g 10.C.h 10.C.i 10.C.j 10.C.k 10.C.l 10.C.m 10.C.n

Eqpt hrs. Eqpt hrs. Eqpt hrs. Eqpt hrs. Eqpt hrs. Eqpt hrs. Eqpt hrs. Eqpt hrs. Eqpt hrs. Eqpt hrs. Eqpt hrs. Eqpt hrs. Eqpt hrs. Eqpt hrs.

11.1 11.2 11.3 11.4 11.5 11.6 11.7

m3 m2 No. No. No. No. m

GROSS TOTAL Recovery of stones Grand Total

Quantity

Rate

Amount

61

42150

2571150

638 5354 8031 195 1572

225 530 425 250 175

143550 2837620 3413175 48750 275100 9289345

621223.878

195

121138656.2

7000

260

1820000

132238.601

175

23141755.18

109286.372

125

13660796.5

36950.514

1025

37874276.85

15000

175

2625000

20735.52

225

4665492

57

245

13965

76663.5

25

1916587.5

10552

355

3745960

14873 103743.766

75 95

1115475 9855657.77 221573622

45752.659

945

43236262.76 low

77747.272

1245

96795353.64

9200

1425

13110000

153141616.4

304628

65

19800820

304490 348500

35 33

10657150 11500500

26325

9945

261802125

14831

11145

165291495

469052090

12 47 17 174 526 30 226 5315

245 245 295 950 75 250 90 175

2940 11515 5015 165300 39450 7500 20340 930125

17154

205

3516570

5701

3700

21093700

1784 3851 392 36 6729 1987

5675 6235 68000 68500 845 9600

10124200 24010985 26656000 2466000 5686005 19075200

3400 262 1876

445 945 745

1513000 247590 1397620

98

10365

1015770

591

9000

5319000

1160 174

225 3000

261000 522000

6688

650

4347200

5082

645

3277890

377 4796

1945 3700

733265 17745200

822 466

4000 95

3288000 44270 153522650

22072 8000 15 8 39

225 3700 70000 68000 4500

4966200 29600000 1050000 544000 175500

1995

6745

13456275

9808

6745

66154960

496 160 996 146 200 763

7000 7000 68000 68500 69000 7000

3472000 1120000 67728000 10001000 13800000 5341000

2000

1245

2490000

1 7 3 3

80000 110000 150000 195000

80000 770000 450000 585000

14 6

245000 275000

3430000 1650000

42 108 23 158 132

345 15000 7500 945 350

14490 1620000 172500 149310 46200

464

745

345680

170

10745

1826650

151

12445

1879195

1728 8

225 3000

388800 24000

22191 1390 149 25

650 645 900 645

14424150 896550 134100 16125

15 115 19 105 35

245 245 295 950 90

3675 28175 5605 99750 3150

3 14 6 2 14 6 20 3572 1945 95 38900 339340 249320280

30261 1190 60 3685 40851 3386

225 1145 3700 3700 1100 2600

6808725 1362550 222000 13634500 44936100 8803600

2105 250 66933

4245 11050 3700

8935725 2762500 247652100

69263 35768 2938 712

225 645 195 355

15584175 23070360 572910 252760

84 31916

7500 645 175

630000 20585820

27490 2683 18510 125

175 2200 645 300

4810750 5902600 11938950 37500

48 240 2638 334 1023

845 1500 6745 68000 95

40560 360000 17793310 22712000 97185 459506680

1224

750

918000

83 48 85 13 13 10

12000 5650 6100 5100 12000 16000

996000 271200 518500 66300 156000 160000

18538

700

12976600

18 18 460

1200 2700 70

21600 48600 32200

192 39 9

4000 3000 6000

768000 117000 54000

595 30 30 300 850 1830 625 10

945 3000 1500 500 1500 425 600 300000

562275 90000 45000 150000 1275000 777750 375000 3000000

4800

3500

16800000

40179025

1070

1550

1658500

2080

1750

3640000

20822

25

520550

18300

275

5032500

197

2300

453100

1900 2 2

300 2500 2500

570000 5000 5000

3500

7000

5 41650

30000 182

150000 7580300

41650 38 48

62 150000 150000

2582300 5700000 7200000 35104250

1190 595 500 500 500 60 4280 60 892

2 2 2600 600 10

475 1785 300 30 588 30 30 30 30 30 300 475 60 1166

621224 25632 1 4 1 1 150

315 60 100000 15000 200000 200000 5000

195685560 1537920 100000 60000 200000 200000 750000 198533480 1989223038 121619451.2 1867603587

You might also like

- Pradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Document4 pagesPradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Lucky TraderNo ratings yet

- BOQ of 3 SitesDocument25 pagesBOQ of 3 SitesJampani HymavathiNo ratings yet

- Rate Analysis of Boundry Wall (100mtr) S.no Description Nos/No of Bar Length Breath Height 1 ExcavationDocument6 pagesRate Analysis of Boundry Wall (100mtr) S.no Description Nos/No of Bar Length Breath Height 1 ExcavationJITENDRA KUMARNo ratings yet

- Quotation Tree Plantation - 3Document1 pageQuotation Tree Plantation - 3Shivendra KumarNo ratings yet

- 2.hydroseeding by - BhoomiDocument1 page2.hydroseeding by - BhoomiShivendra KumarNo ratings yet

- WRD Water ResourcesDocument32 pagesWRD Water ResourcesatgsganeshNo ratings yet

- Budgetory Offer For Civil Works From L&T For Tamakoshi 3 HEPDocument7 pagesBudgetory Offer For Civil Works From L&T For Tamakoshi 3 HEPBidur GautamNo ratings yet

- Shri Sai Gabion & Fencing: LimitedDocument2 pagesShri Sai Gabion & Fencing: LimitedShivendra KumarNo ratings yet

- Sample rate analysis for resin grouted rock boltDocument1 pageSample rate analysis for resin grouted rock boltkuldip_1973No ratings yet

- RatesDocument1 pageRatesBidur GautamNo ratings yet

- List of Works Live in MarketDocument15 pagesList of Works Live in MarketAayush Goel grr XI100% (1)

- Hume Pipe Culvert EstimateDocument10 pagesHume Pipe Culvert Estimatedhiraj KumarNo ratings yet

- Alidrain AD250 PVD Method Statement - Revision 0Document5 pagesAlidrain AD250 PVD Method Statement - Revision 0Roziman Hj HajonNo ratings yet

- BOQ Estimate PKG 01 Modified On 30.09.21Document18 pagesBOQ Estimate PKG 01 Modified On 30.09.21surendra KumarNo ratings yet

- Boq of Solu Hydro Power Project PKG 1Document37 pagesBoq of Solu Hydro Power Project PKG 1vijayNo ratings yet

- Morth Section 700Document3 pagesMorth Section 700Psrawat RawatNo ratings yet

- Macdrain Installation DetailsDocument1 pageMacdrain Installation DetailsadrianNo ratings yet

- As4678 Soil NailingDocument54 pagesAs4678 Soil NailingC BNo ratings yet

- Rockfall Mitigation NH-22 Case StudyDocument4 pagesRockfall Mitigation NH-22 Case StudyRaghavNo ratings yet

- Slope ProtectionDocument3 pagesSlope Protectionshima2727No ratings yet

- 1.0 Technical Specification Structure180215Document179 pages1.0 Technical Specification Structure180215Shantanu SinghNo ratings yet

- Sheet Pile Brochure 2022Document8 pagesSheet Pile Brochure 2022bayzuraNo ratings yet

- Maximum Dry Density (Proctor)Document3 pagesMaximum Dry Density (Proctor)ratoooooja24No ratings yet

- Basic Rate UttarakhandDocument17 pagesBasic Rate UttarakhandShivendra KumarNo ratings yet

- Pile CatalogueDocument8 pagesPile CatalogueMohamad AmirulbaharudinNo ratings yet

- F) 50 M3 Masonry RCC Sandwich Clean Water Reservoir: Earth WorkDocument4 pagesF) 50 M3 Masonry RCC Sandwich Clean Water Reservoir: Earth WorkEng GaaxeelNo ratings yet

- Bill of Quantities for Bituminous Road Work at Suzlon GeneratorsDocument8 pagesBill of Quantities for Bituminous Road Work at Suzlon GeneratorsEr. Naseem SayyedNo ratings yet

- Bill of QuantityDocument14 pagesBill of QuantityAshok KcNo ratings yet

- HPC 600 MM Single Row 7.5 MDocument4 pagesHPC 600 MM Single Row 7.5 MgagajainNo ratings yet

- Boq of Fire StationDocument8 pagesBoq of Fire StationKANWARNo ratings yet

- ID - Brochure - EROSION CONTROL FOR DAM & CUT SLOPEDocument20 pagesID - Brochure - EROSION CONTROL FOR DAM & CUT SLOPEiqbalNo ratings yet

- Construction RPFuldayFeb 2018 PDFDocument187 pagesConstruction RPFuldayFeb 2018 PDFShiba Shankar SatapathyNo ratings yet

- Technical Specification Boomer WE3 C - 18 - 9851 2471 01c - Web - tcm820-1533277Document4 pagesTechnical Specification Boomer WE3 C - 18 - 9851 2471 01c - Web - tcm820-1533277Pedro Suárez VargasNo ratings yet

- SCH-B Pragatipath Navsari DTP80 CRDocument100 pagesSCH-B Pragatipath Navsari DTP80 CRKETANNo ratings yet

- System Description Polyslope S - ENDocument4 pagesSystem Description Polyslope S - ENlojzemulec5966No ratings yet

- Part S22 Soil Nailing Nov 2014Document7 pagesPart S22 Soil Nailing Nov 2014Anonymous ECNRVD0RNo ratings yet

- Analysis For RE Wall - Standard RatesDocument2 pagesAnalysis For RE Wall - Standard Ratesrohit kumarNo ratings yet

- Fosroc GeotexDocument3 pagesFosroc GeotexBalasubramanian AnanthNo ratings yet

- EstimateDocument14 pagesEstimateAnonymous fQLEF2tQpqNo ratings yet

- Alternate To Ghat-Ki-Guni by Construction of Tunnel in Jhalana Hills JaipurDocument46 pagesAlternate To Ghat-Ki-Guni by Construction of Tunnel in Jhalana Hills JaipurDevendra SharmaNo ratings yet

- Cost Estimation BundDocument26 pagesCost Estimation BundAnonymous UUw70xirbl100% (1)

- Sector 7 Infrastructure Cost AnalysisDocument129 pagesSector 7 Infrastructure Cost AnalysisSunil Kumar GeraNo ratings yet

- Ganga Nagar Lab BuildingDocument19 pagesGanga Nagar Lab BuildingAyush TiwariNo ratings yet

- Karnataka PWD SR 11-12Document446 pagesKarnataka PWD SR 11-12NITESH SINGHNo ratings yet

- TechFab India product portfolioDocument1 pageTechFab India product portfolioSharief ShaikNo ratings yet

- DSR 18-19 Konkan RegionDocument422 pagesDSR 18-19 Konkan Regionhiyogs100% (5)

- Design Principle of Gabion Retaining WallDocument11 pagesDesign Principle of Gabion Retaining WallAbhilash AbhiNo ratings yet

- Field Density Test (SRM)Document2 pagesField Density Test (SRM)manish upadhyay0% (1)

- Sheduled of Rates, PWD - MizoramDocument12 pagesSheduled of Rates, PWD - MizoramBaguma Grace GariyoNo ratings yet

- Stabilising Soil with Permeation GroutingDocument4 pagesStabilising Soil with Permeation GroutingAndrea David RodriguesNo ratings yet

- Pi FormDocument4 pagesPi FormJoshua NdaloNo ratings yet

- Rate Analysis 15-09 Final Road LATESTDocument18 pagesRate Analysis 15-09 Final Road LATESTKotoju Rajitha SaisindhujaNo ratings yet

- RD - PROTECTION WORKDocument34 pagesRD - PROTECTION WORKMuthusamy ArumugamNo ratings yet

- Ramagondanahalli CC Drain 5.00lakhsDocument8 pagesRamagondanahalli CC Drain 5.00lakhschandru shekarNo ratings yet

- PWD UTTRAKHAND DSR REPORT 2014-2015 EARTHWORK RATESDocument184 pagesPWD UTTRAKHAND DSR REPORT 2014-2015 EARTHWORK RATESankitabiswas840% (2)

- Data Cepwd Aproved Q1 201516Document305 pagesData Cepwd Aproved Q1 201516rajeeshmp1No ratings yet

- 05 Geobag (Terra Sack)Document4 pages05 Geobag (Terra Sack)dixmitNo ratings yet

- Failure of An Embankment Treated With Vacuum Preloading MethodDocument4 pagesFailure of An Embankment Treated With Vacuum Preloading MethodtangkokhongNo ratings yet

- Estimate of SBTWDocument17 pagesEstimate of SBTWSaral MajumderNo ratings yet

- BOQ Rates 2192020Document16 pagesBOQ Rates 2192020SLC Infra CvrNo ratings yet

- Hoist CapacityDocument10 pagesHoist CapacityDheeraj ThakurNo ratings yet

- Is 13041 1991 PDFDocument9 pagesIs 13041 1991 PDFDheeraj ThakurNo ratings yet

- Codes & StandardDocument9 pagesCodes & StandardMuhammad SalahudeenNo ratings yet

- Design Philosophy For de Icing of The Gates: IntroductionDocument1 pageDesign Philosophy For de Icing of The Gates: IntroductionDheeraj ThakurNo ratings yet

- D 4541045416Document7 pagesD 4541045416Dheeraj ThakurNo ratings yet

- Tagetesminuta Cultivationphytochemistry PDFDocument24 pagesTagetesminuta Cultivationphytochemistry PDFDheeraj ThakurNo ratings yet

- 10Document5 pages10Dheeraj ThakurNo ratings yet

- Beekeeping BasicsDocument102 pagesBeekeeping Basicsibd1ibuc100% (1)

- Design Calculations of Trash RackDocument3 pagesDesign Calculations of Trash RackDheeraj Thakur100% (4)

- Beekeeping BasicsDocument102 pagesBeekeeping Basicsibd1ibuc100% (1)

- CrossFlow Turbine DesignDocument70 pagesCrossFlow Turbine DesignLaercio Ribeiro Filho82% (11)

- Cross PlotDocument1 pageCross PlotDheeraj ThakurNo ratings yet

- Codes & StandardDocument9 pagesCodes & StandardMuhammad SalahudeenNo ratings yet

- D 4541045416Document7 pagesD 4541045416Dheeraj ThakurNo ratings yet

- Tagetesminuta-Cultivation Phyto ChemistryDocument24 pagesTagetesminuta-Cultivation Phyto ChemistryDheeraj ThakurNo ratings yet

- COP-Bungee (Final Draft) - Combined PDF Version PDFDocument42 pagesCOP-Bungee (Final Draft) - Combined PDF Version PDFEdgar Barrientos VilcasNo ratings yet

- Hydrology: QuantitativeDocument4 pagesHydrology: QuantitativeDheeraj ThakurNo ratings yet

- The Perils of Bungee Jultiww4GDocument3 pagesThe Perils of Bungee Jultiww4GDheeraj ThakurNo ratings yet

- Is 1343 1980 PDFDocument68 pagesIs 1343 1980 PDFpriyankaNo ratings yet

- WVI - My Green Bin - V5Document9 pagesWVI - My Green Bin - V5Dheeraj ThakurNo ratings yet

- Track Rope Calculations For Reversible Ropeways: L U I N L V LDocument3 pagesTrack Rope Calculations For Reversible Ropeways: L U I N L V LDheeraj ThakurNo ratings yet

- Krishnapillai 353-360Document8 pagesKrishnapillai 353-360Sya FiqahNo ratings yet

- Flow-induced vibration of long-span gates - Part I: Model developmentDocument24 pagesFlow-induced vibration of long-span gates - Part I: Model developmentDheeraj ThakurNo ratings yet

- Is 15117 2002 PDFDocument32 pagesIs 15117 2002 PDFDheeraj ThakurNo ratings yet

- Automatic aeroponic irrigation system based on ArduinoDocument13 pagesAutomatic aeroponic irrigation system based on ArduinoDheeraj ThakurNo ratings yet

- Impact Erosion Prediction Using The Finite Volume Particle Method With Improved Constitutive ModelsDocument11 pagesImpact Erosion Prediction Using The Finite Volume Particle Method With Improved Constitutive ModelsDheeraj ThakurNo ratings yet

- Abdelhaleem2017 PDFDocument11 pagesAbdelhaleem2017 PDFDheeraj ThakurNo ratings yet

- Impact Erosion Prediction Using The Finite Volume Particle Method With Improved Constitutive ModelsDocument11 pagesImpact Erosion Prediction Using The Finite Volume Particle Method With Improved Constitutive ModelsDheeraj ThakurNo ratings yet

- Saha2015 PDFDocument6 pagesSaha2015 PDFDheeraj ThakurNo ratings yet

- Penstock WeldingDocument2 pagesPenstock WeldingDheeraj ThakurNo ratings yet

- SBC - Code - 303 Soil & FoundationDocument99 pagesSBC - Code - 303 Soil & FoundationNour FayedNo ratings yet

- Asha Chuhan DSR MICRO-PROJECTDocument18 pagesAsha Chuhan DSR MICRO-PROJECTAsha ChuhanNo ratings yet

- Introduction To Foundation EngineeringDocument2 pagesIntroduction To Foundation EngineeringMelvin EsguerraNo ratings yet

- Proposed Construction of Cold Storages (2500 MT) Chaluvathimmanahalli in Chikkaballapur DistDocument49 pagesProposed Construction of Cold Storages (2500 MT) Chaluvathimmanahalli in Chikkaballapur Distyashas sNo ratings yet

- Analysis and Design of a 12-Storey RC BuildingDocument40 pagesAnalysis and Design of a 12-Storey RC BuildingAboalmaaliNo ratings yet

- Drawing ChecklistDocument13 pagesDrawing ChecklistManoj Ashok Baraskar75% (4)

- WIDAC Abbreviated Foundation Coffman GolderDocument60 pagesWIDAC Abbreviated Foundation Coffman GolderIng Ricardo HernándezNo ratings yet

- Pre-Activity Assessment: Foundations WorksheetDocument2 pagesPre-Activity Assessment: Foundations Worksheetjoel lantongNo ratings yet

- Chapter 1 Fondation IDocument33 pagesChapter 1 Fondation IKubaNo ratings yet

- Precast Sample DesignDocument10 pagesPrecast Sample DesignmathuNo ratings yet

- Kolkata Police Training AcademyDocument77 pagesKolkata Police Training AcademyMonjit RoyNo ratings yet

- Pile Foundations Part-1Document42 pagesPile Foundations Part-1mohanty_anantakumar6332No ratings yet

- Soil Report PDFDocument32 pagesSoil Report PDFNagender KumarNo ratings yet

- (Lymon C. Reese, William M. Isenhower, Shin-TowerDocument619 pages(Lymon C. Reese, William M. Isenhower, Shin-TowerMarcos Antonio Hernandez MatusNo ratings yet

- Geotechnical Design Considerationsfor Onshore Wind Turbine Shallow FoundationsDocument14 pagesGeotechnical Design Considerationsfor Onshore Wind Turbine Shallow Foundationszhenyu su100% (1)

- ProjectDocument38 pagesProjectdhanabalNo ratings yet

- Imlibun - Bill - Ra - 03Document179 pagesImlibun - Bill - Ra - 03Anil PuvadaNo ratings yet

- Finite Element Analysis in Geotechnical Engineering-Vol2Document448 pagesFinite Element Analysis in Geotechnical Engineering-Vol2Harish Lambadi77% (13)

- Foundation Design For An Immersed Tunnel With CDM and SCP Soil Improvement of Soft Marine ClayDocument8 pagesFoundation Design For An Immersed Tunnel With CDM and SCP Soil Improvement of Soft Marine ClayRonald HeijmansNo ratings yet

- Velliyamkallu Heritage Park Restoration WorksDocument25 pagesVelliyamkallu Heritage Park Restoration Workslifelinegroups nilNo ratings yet

- Wisconsin Commercial Building CodeDocument103 pagesWisconsin Commercial Building Codeneeraj856No ratings yet

- Analysis and Design of Multi Storey Residential Building Using StaadDocument66 pagesAnalysis and Design of Multi Storey Residential Building Using Staadalenrider88% (8)

- Building Construction GuideDocument44 pagesBuilding Construction GuideDanishhadi100% (1)

- Marking Scheme Q5Document3 pagesMarking Scheme Q5dexterbox1No ratings yet

- Full Report FoundationDocument21 pagesFull Report FoundationAjimu Sulaiman100% (1)

- Spread FootingDocument12 pagesSpread FootingmyNo ratings yet

- Types of FDN or PilesDocument15 pagesTypes of FDN or PilesSnaz_nedainNo ratings yet

- 4185hYYBqH 1 3 3 Gravity Retaining and Supporting WallspdfDocument48 pages4185hYYBqH 1 3 3 Gravity Retaining and Supporting WallspdfThan Thar Lin LaeNo ratings yet

- Principles of Foundation Engineering, SI 7ed - Utan RepairedDocument815 pagesPrinciples of Foundation Engineering, SI 7ed - Utan RepairedRubi C.g.100% (15)

- 7-Foundation DampingDocument81 pages7-Foundation DampingHerrera Rojas WillarNo ratings yet