Professional Documents

Culture Documents

Materials For Construction For Process Equipment and Piping Systems - Selection and In-Service Performance

Uploaded by

ZoebairOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materials For Construction For Process Equipment and Piping Systems - Selection and In-Service Performance

Uploaded by

ZoebairCopyright:

Available Formats

Materials for Construction for Process Equipment and Piping SystemsSelection and In-Service Performance

Introduction Appropriate material selection is the cornerstone of pressure equipment and piping design, operation and maintenance. Engineers must select materials of construction that provide adequate strength at operating temperatures and pressures, in compliance with applicable construction codes and with regard to their resistance to corrosion and other likely degradation mechanisms, as well as to cost-effectiveness. The acceptability of materials is controlled by the relevant Codes. The ultimate selection of the correct material is the responsibility of the design or fabrication engineer. By listing the design's allowable stresses, the Codes do limit the materials that can be chosen. Only those materials that meet certain requirements as listed in the specifications should be used. The mechanical integrity, safety, and cost-effective operation of plants depend on the in-service performance of the materials of construction throughout the plant life cycle. Metallurgy is a complex science but a general understanding of the major principles is essential to the plant engineers and inspectors This course provides comprehensive and practical understanding of engineering materials and guidance on the methods and best industry practices for the selection of the appropriate materials of construction for specific applications while simultaneously satisfying service requirements, construction Code requirements, and least life cycle costs over the entire plant life. This course will provide a practical overview of ASME BPVC Section II - Materials, as well as some relevant information from the BPVC Section VIII Div.1 and B31.3 Process Piping. All materials have flaws and will degrade in service. The in-service performance of the selected materials is crucial for plant integrity, safety and cost-effective operation. Clear understanding of the degradation mechanisms affecting specific equipment and piping systems is essential so that effective inspection strategies, plans and activities can be implemented to assess their condition and suitability for continued service until the next scheduled shutdown. This course provides concise overviews of best industry practices including: API RP 577 'Welding Inspection and Metallurgy'; API RP 580 and Publ. 581 BRD 'Risk-Based Inspection'; API RP 571 'Damage Mechanisms Affecting Fixed Equipment in the Refining Industry'; API RP 578 'Positive Material Identification'; and API Std. 579-1/ASME FFS-1 'Fitness-For-Service'. This course builds on a focused and practical coverage of engineering materials properties and selection and provides a structured approach to predict, monitor and assess the materials performance in service with the objective of ensuring plant integrity, safety and cost-effective operation.

Seminar Objectives The key objectives of this course are as follows:

Assist participants to clearly understand that the appropriate selection of materials of construction for pressure equipment is the cornerstone of safe, reliable and costeffective plant operation. Enhance participants' awareness of key requirements of relevant design and operation standards and industry practices such as ASME B&PVC and B31.3; ASTM Material Specifications, API 571, 580, 581, 578 and 579, and others. Provide guidelines to participants to identify and locate in-service degradation and appropriate tools for condition assessment and making sound run/repair/replace decisions. Make participants recognize that although all flaws detected by inspection must be evaluated, not all flaws need to be repaired. The proper application of API Std 579-1/ASME FFS-1 for fitness-for-service assessment may obviate the need for some repairs and result in reduced maintenance cost and downtime.

Who Should Attend? This course is particularly valuable for refinery, petrochemical and process plant mechanical and process engineers, technical professionals, inspectors, maintenance personnel, as well as for project and consulting engineers and engineering and technical personnel involved in plant mechanical integrity and reliability. Organisational Impact

The company will achieve improved financial performance through the proper selection of materials of construction based on total life cycle cost principles. The company will be able to achieve measurable improvement in mechanical integrity through improved materials performance and reduced likelihood of failures. The company will be able to enhance its ability to use risk-based inspection and maintenance resulting in lower life cycle costs while complying with codes and standards, and other regulatory requirement.

Personal Impact

Participants will be more able to actively contribute towards reducing the probability of serious failures in pressure equipment and piping systems. Participants will enhance their competence and productivity thereby enhancing their competence and performance level and making additional value added contributions to their organizations.

Competencies Emphasized Delegates will enhance their competencies in the following areas:

Engineering materials properties and selection criteria for specific applications with view to achieving optimum life cycle costs while complying with codes and regulations. Construction codes, standards and recommended practices covering design of pressure equipment and piping systems. Identification and assessment of active degradation mechanisms and the failures they may cause. Hazard identification and risk analysis and management. Application of risk-based methodologies in inspection and maintenance. Fitness-For-Services assessments.

Training Methodology The course combines sound engineering principles, methods, and applicable codes & standards and best industry practices. Actual major incidents as well as industry experience will be reviewed in depth to reinforce every topic.

Seminar Outline

Day 1: Engineering Materials - Types and Properties Engineering Materials I - Overview

Metals - Ferrous and non-ferrous Carbon steel o Alloying elements added to iron base - carbon, manganese, and silicon o Effect of alloying elements on end properties and on fabrication processes o Impurities and their effect - sulfur, phosphorus Alloy steel o Effects of alloying elements o Stainless steels Specialty alloys o Corrosion resistant alloys o High temperature alloys o Erosion resistant alloys

Engineering Materials II

Refractory materials - Types and applications - Examples: Titanium and zirconium Clad Materials - Types; production methods; and typical applications Composite materials - Classes, types and applications Non-Metallic materials - Plastics, ceramics Surface engineered coatings/overlays - Types, specifications and applications o Organic coatings o Metallic coatings o Corrosion resistant cladding

o o o

Corrosion resistant / hard-surface welding Thermal spray coatings Plasma transferred arc (PTA) welded overlays

Metallurgy Basics

The structure of metals and alloys Imperfections in metals and alloys Chemical composition - Unified numbering system (UNS) Physical properties - melting temperature, the thermal conductivity, electrical conductivity, the coefficient of thermal expansion, and density Mechanical properties - Base metals, filler metal and completed welds Tensile and yield strength, ductility, hardness and toughness Heat treatment and effect on material properties

Material Forming and Fabrication

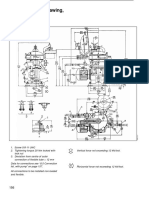

Forming and forging Casting Welding processes - main technologies and consumables currently used in industry Weldability - Carbon equivalent; Shaeffler and WRC diagrams Preheat and Post-Weld heat treatment (PWHT) - Code (B&PV and B31) rules Weld imperfections (discontinuities) commonly encountered with welding processes

Overview of ASME B&PVC Section IX 'Welding and Brazing Qualifications'

This Section contains rules relating to the qualification of welding and brazing procedures as required by other code sections for component manufacture Welding procedure specification (WPS) Procedure qualification record (PQR) Welder performance qualification (WPQ)

Day 2: Materials Selection and Application Material Selection Process and Guidelines

Life cycle cost considerations Factors in material selection in petroleum refineries- type of refinery; type of crude oil processed; service conditions in specific process unit/application, expected service life Oxidation resistance - scale formation Guidelines on the maximum temperature of use of carbon steel and alloy materials Creep properties - The Larson-Miller parameter (LMP) Fatigue properties - Fatigue design (S-N) curves

Materials Standards and Codes

ASME Boiler and Pressure Vessel and Piping Construction Codes

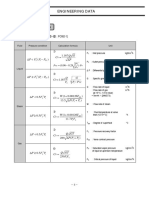

o Allowable stresses o Constraints and limitations o P-Number identificat ASTM Some common material specifications for piping, plates, forgings and castings API RP 941 - Steels for hydrogen service at elevated temperatures and pressures in petroleum refineries and petrochemical plants NACE MR 0175/ISO 15156 'Petroleum and Natural Gas Industries - Materials for Use in H2S-containing Environments in Oil and Gas Production - Parts 1, 2 and 3' Oxidation resistance - scale formation NACE MR0103 'Materials Resistant to Sulfide Stress Cracking in Corrosive Petroleum Refining Environments' PIP (Process Industry Practices) Standards - Example: PIP Piping Material Specification 1CS2S01 Class 150, Carbon Steel, Socket Weld, 0.125 C.A. Process. Fatigue properties - Fatigue design (S-N) curves Overview of ASME B&PVC Section II 'Materials Specifications' - This Section compiles material specifications and material properties for materials used in the construction of ASME components. It contains four parts: o Part A-Ferrous Material Specifications o Part B-Nonferrous Material o Part C-Specifications for Welding Rods o Part D-Properties-(Customary)

Material Selection for Specific Equipment

Refineries and petrochemical plants Power plants Pressure vessels Piping valves and fittings Pumps

Day 3: Degradation of Materials In-Service Material Ageing and Degradation - Overview

Ageing is not about how old equipment is; it's about knowledge of its condition, and how that is changing over time Indicators or symptoms of ageing

Failure Modes and Mechanisms in Materials

Degradation processes - (e.g. corrosion, erosion) Excessive elastic deformation - (e.g. buckling) Fracture - (e.g. fatigue, brittle fracture)

Overview of API RP 571 Damage Mechanisms Affecting Fixed Equipment

This document provides background information on damage that can occur to equipment in the refining and other process industries. It covers over 60 damage mechanisms. It is also an excellent reference for inspection, operations, and maintenance personnel.

Metallurgical Failure Analysis

Overview Case study

Positive Material Identification

Objectives and methodologies (e.g. X-Ray Fluorescence and Optical Emission Spectroscopy) o ASTM- E1916 o Pipe Fabricator Institute PFI-ES42 o API 578 o MSS SP-137-2007 o Material Test Reports

Day 4: Inspection Strategies and on-Destructive Examination Methods Mechanical (Structural) Integrity - Overview

Definition, scope, and key elements - hardware and software issues, human factor, and asset manageme Potential threats to technical integrity in a hazardous environment Regulatory requirements - SH&E, OSHA, SEVESO II Life cycle implications - design/operation/maintenance, management of change

Inspection Strategies and Methods

Real function of inspection Planning and strategies

Inspection Strategies and Methods (continued)

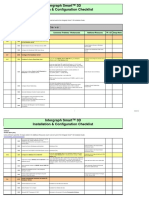

Overview of API RP 580 and RBD 581 - Risk-Based Inspection Overview of API RP 577 Welding Inspection and Metallurgy

Non-Destructive Examination (NDE) Methods and Their Application

Capability of the applicable inspection method vs. discontinuity New developments in NDE methods

Overview of ASME B&PVC Section V 'Nondestructive Examination'

This section contains requirements and methods for non-destructive examination referenced and required by other code sections.

Day 5: Fitness-For-Service Evaluation Introduction to Fracture Mechanics

Overview Illustrative worked examples

Fitness-for-Service Assessment

Overview of API Std. 579-1/ASME FFS-1 Worked examples

Workshop

Case Studies - Failures of Materials in Service

You might also like

- Materials Selection Modeling & SimulationDocument21 pagesMaterials Selection Modeling & Simulationleila hanjani hanantoNo ratings yet

- Kut Epoxy Coating Sf1Document2 pagesKut Epoxy Coating Sf1Arun Chandra BabuNo ratings yet

- Ayaz Ahmed: 10+ Years Mechanical Inspector & Procurement SupervisorDocument11 pagesAyaz Ahmed: 10+ Years Mechanical Inspector & Procurement SupervisorAdnan RafiqNo ratings yet

- Piping Codes & Standards ListDocument10 pagesPiping Codes & Standards ListbratishkaityNo ratings yet

- Oil Production & Process Facilities EngineeringDocument2 pagesOil Production & Process Facilities EngineeringFavoriteNo ratings yet

- Basic Piping PPT-01Document29 pagesBasic Piping PPT-01Binu RajuNo ratings yet

- CH 3 Corrosion KineticsDocument50 pagesCH 3 Corrosion Kineticsميثة الغيثية100% (2)

- Lecture Notes On Equipment SizingDocument48 pagesLecture Notes On Equipment SizingMarge SantacruzNo ratings yet

- r050210803 Chemical Process CalculationsDocument8 pagesr050210803 Chemical Process CalculationsSrinivasa Rao GNo ratings yet

- Chapter 1 - Process Planning, Scheduling and Flowsheet DesignDocument51 pagesChapter 1 - Process Planning, Scheduling and Flowsheet DesignCaroline Eliza MendesNo ratings yet

- Solid Solutions and Phase Diagrams ExplainedDocument1 pageSolid Solutions and Phase Diagrams ExplainedSaniya SohailNo ratings yet

- Basic Process Calculations and SimulatioDocument28 pagesBasic Process Calculations and SimulatioDilipNo ratings yet

- Line Blinds Bleed RingsDocument4 pagesLine Blinds Bleed RingsPerumal KarthikeyanNo ratings yet

- Pipe & Pipe FittingsDocument10 pagesPipe & Pipe FittingsSalim BakhshNo ratings yet

- UDFCD Pipe Material Tech Memo 2010 PDFDocument181 pagesUDFCD Pipe Material Tech Memo 2010 PDFSaga CastañedaNo ratings yet

- Material Properties Requirements For Metallic MaterialsDocument70 pagesMaterial Properties Requirements For Metallic Materialsعزت عبد المنعمNo ratings yet

- MECH 6561/1 - HIGH STRENGTH MATERIALSDocument14 pagesMECH 6561/1 - HIGH STRENGTH MATERIALSVi GaneshNo ratings yet

- CTSPLDocument16 pagesCTSPLpm2013No ratings yet

- AODD Pump Material Selection ChartDocument13 pagesAODD Pump Material Selection ChartthunderNo ratings yet

- Attachment G - EPE Above Ground Coating SpecificationsDocument22 pagesAttachment G - EPE Above Ground Coating SpecificationsJohn RussellNo ratings yet

- Piping NotesDocument33 pagesPiping NotesSyed FarhanNo ratings yet

- 1343172044-64180 Ausenco Acquires PSI PresentationDocument18 pages1343172044-64180 Ausenco Acquires PSI PresentationMarcelo Calderón CruzNo ratings yet

- 1.03 Engineering Calculations PDFDocument93 pages1.03 Engineering Calculations PDFJannel PaetNo ratings yet

- Bestline Mining Supplies LTD - 2010 EditionDocument50 pagesBestline Mining Supplies LTD - 2010 EditionTalabarteria RaygozaNo ratings yet

- Cast Basalt Information SheetDocument4 pagesCast Basalt Information SheetVijayakumar AtthuluriNo ratings yet

- Cv CALCULATION FORMULAS FOR FLUIDSDocument1 pageCv CALCULATION FORMULAS FOR FLUIDSdj22500No ratings yet

- Table 7.3: Sizing and Costing Summary For Decanter Equipment Specification SheetDocument14 pagesTable 7.3: Sizing and Costing Summary For Decanter Equipment Specification SheetThiynes Shanmugam100% (1)

- Piping Fundamentals for EngineersDocument29 pagesPiping Fundamentals for Engineersmaneeshmsanjagiri100% (2)

- Process Equipment Design Guidelines Chapter Ten Pressure Relief Valve Selection and Sizing (Engineering Design Guidelines)Document31 pagesProcess Equipment Design Guidelines Chapter Ten Pressure Relief Valve Selection and Sizing (Engineering Design Guidelines)einsten777No ratings yet

- Material Comparison For Piping MaterialsDocument1 pageMaterial Comparison For Piping Materialskrishna_pipingNo ratings yet

- Metals, Test Methods and Analytical ProceduresDocument1 pageMetals, Test Methods and Analytical ProceduresSARATH KRISHNAKUMARNo ratings yet

- Valve Material TypesDocument3 pagesValve Material TypesimanadbNo ratings yet

- Primavera P6: Project Monitoring DepartmentDocument76 pagesPrimavera P6: Project Monitoring DepartmentMariam SaeedNo ratings yet

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- Mechanical Seals Vs Sealless PumpsDocument7 pagesMechanical Seals Vs Sealless PumpsJesus N RodriguezNo ratings yet

- Plant Tender EZ OffDocument16 pagesPlant Tender EZ OffGowri GaneshNo ratings yet

- Turnaround Services TASDocument20 pagesTurnaround Services TASAlan ChewNo ratings yet

- Ce 1402 Estimation and Quantity SurveyingDocument26 pagesCe 1402 Estimation and Quantity SurveyingNagaraja Prasanna RassNo ratings yet

- PDFDocument7 pagesPDFAngling DharmaNo ratings yet

- PipingDocument54 pagesPipingakhilsyam21No ratings yet

- Chemical TechnologyDocument24 pagesChemical TechnologyAnonymous okVyZFmqqXNo ratings yet

- Proposal Work Flow GuidelineDocument2 pagesProposal Work Flow Guidelineirshad sondeNo ratings yet

- Consumable LasDocument35 pagesConsumable LasAfifYantoMutuHNo ratings yet

- W Wom Manual 112712Document18 pagesW Wom Manual 112712wahyuhendrosNo ratings yet

- Piping Codes: ASME B16 Dimensional CodesDocument9 pagesPiping Codes: ASME B16 Dimensional CodesmaxalfreNo ratings yet

- GTAW Chapter 1Document4 pagesGTAW Chapter 1Renold ElsenNo ratings yet

- Introduction To Heat Exchangers (HXS) : DR Rashid AliDocument36 pagesIntroduction To Heat Exchangers (HXS) : DR Rashid AliUsama IbrahimNo ratings yet

- Centrifugal Pump Systems TipsDocument16 pagesCentrifugal Pump Systems TipsKiran KumarNo ratings yet

- Chemical Plant Process PrincipleDocument29 pagesChemical Plant Process PrincipleDanish Iqbal100% (1)

- RB - Specifications Piping MaterialsDocument21 pagesRB - Specifications Piping MaterialsFalcon PeregrinusNo ratings yet

- Water Supply and Disposal SystemDocument13 pagesWater Supply and Disposal SystemAhmad Fauzan KamarudinNo ratings yet

- Best Practices Engineering GuideFINALDocument4 pagesBest Practices Engineering GuideFINALAnbalagan PrabhuNo ratings yet

- Compare ASME and material specsDocument2 pagesCompare ASME and material specsg_sanchetiNo ratings yet

- Steam Trap and Drain Trap FunctionsDocument23 pagesSteam Trap and Drain Trap FunctionsMallela Sampath KumarNo ratings yet

- Compressors: Reciprocating Compressors Centrifugal Compressors DrivesDocument14 pagesCompressors: Reciprocating Compressors Centrifugal Compressors Drivessteepa22No ratings yet

- Ammonia B PDFDocument9 pagesAmmonia B PDFmehrdad_k_rNo ratings yet

- Bill's Conversion Spreadsheet Revision GuideDocument20 pagesBill's Conversion Spreadsheet Revision GuidesudhirbmaliNo ratings yet

- GLOMACS Materials of Constr. For Process Equipment and Piping SystemsDocument6 pagesGLOMACS Materials of Constr. For Process Equipment and Piping SystemsRoo FaNo ratings yet

- Course Basics of Static Mechanical Equipment - BSM - Virtual Blended DeliveryDocument7 pagesCourse Basics of Static Mechanical Equipment - BSM - Virtual Blended DeliveryNjoku ChijiokeNo ratings yet

- Introduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007Document25 pagesIntroduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007ANILNo ratings yet

- 90 Series (ET1590) InstructionsDocument24 pages90 Series (ET1590) InstructionsZoebairNo ratings yet

- International Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsDocument9 pagesInternational Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsZoebairNo ratings yet

- 1 12 (End)Document17 pages1 12 (End)ZoebairNo ratings yet

- ENZX TechDocument30 pagesENZX TechZoebairNo ratings yet

- Spring-Supported Thrust BearingsDocument4 pagesSpring-Supported Thrust BearingsZoebairNo ratings yet

- Installation and Operating Procedures: Manual Grease InterceptorsDocument8 pagesInstallation and Operating Procedures: Manual Grease InterceptorsZoebairNo ratings yet

- Structures and Mechanisms Classifications GuideDocument1 pageStructures and Mechanisms Classifications GuideminakirolosNo ratings yet

- Appendix B - 20100903 - 145453Document25 pagesAppendix B - 20100903 - 145453AkoKhalediNo ratings yet

- TurbinesDocument19 pagesTurbinesSamarakoon BandaNo ratings yet

- Type of ThreadDocument13 pagesType of ThreadVils ArabadzhievaNo ratings yet

- Ratle Enm Reply Tecnical Prebid Points 080212Document42 pagesRatle Enm Reply Tecnical Prebid Points 080212ZoebairNo ratings yet

- Quality Conference TTL KUDocument6 pagesQuality Conference TTL KUZoebairNo ratings yet

- CA6NMDocument2 pagesCA6NMjoene3No ratings yet

- 1 Technical Data Sheets TurbineDocument7 pages1 Technical Data Sheets TurbineZoebairNo ratings yet

- 8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0Document1 page8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0ZoebairNo ratings yet

- Datasheet TurbineDocument2 pagesDatasheet TurbineZoebairNo ratings yet

- Solutions EngDocument6 pagesSolutions EngZoebairNo ratings yet

- Calculate The Number of Extinguishers Needed in A BuildingDocument3 pagesCalculate The Number of Extinguishers Needed in A BuildingZoebairNo ratings yet

- INDIGENOUS MANUFACTURERS OF SMALL HYDRO TURBINESDocument6 pagesINDIGENOUS MANUFACTURERS OF SMALL HYDRO TURBINESZoebairNo ratings yet

- PJPR0 V 200 Ucturing 0 Data 0 SheetDocument3 pagesPJPR0 V 200 Ucturing 0 Data 0 SheetZoebairNo ratings yet

- Scada SystemDocument1 pageScada SystemZoebairNo ratings yet

- 1 - Layout of H-FrancisDocument1 page1 - Layout of H-FrancisZoebairNo ratings yet

- ANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsDocument3 pagesANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsZoebairNo ratings yet

- Load AcceptanceDocument2 pagesLoad AcceptanceZoebairNo ratings yet

- Construction Specification 71-Water Control Gates: Instructions For UseDocument2 pagesConstruction Specification 71-Water Control Gates: Instructions For UseZoebairNo ratings yet

- CEE 331: Fluid Mechanics, Homework Set 2, SolutionsDocument7 pagesCEE 331: Fluid Mechanics, Homework Set 2, SolutionsZoebairNo ratings yet

- PJPR0 V 200 Ucturing 0 Data 0 SheetDocument3 pagesPJPR0 V 200 Ucturing 0 Data 0 SheetZoebairNo ratings yet

- ANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsDocument3 pagesANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsZoebairNo ratings yet

- 3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalDocument2 pages3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalThanadkitBunkaewNo ratings yet

- 3 Tables Friction Loss AquacultureDocument10 pages3 Tables Friction Loss AquacultureZoebairNo ratings yet

- Mobile Phone: Service ManualDocument129 pagesMobile Phone: Service ManualAlexNo ratings yet

- Detailed Lesson Plan in Science (Solar System)Document7 pagesDetailed Lesson Plan in Science (Solar System)Angelique Pabillona88% (51)

- Homework 1 ME 531 2018 WebDocument4 pagesHomework 1 ME 531 2018 WebEhab WilsonNo ratings yet

- Mini-Com Cat6E - ®TX6 ™ PLUS UTP Coupler ModulesDocument2 pagesMini-Com Cat6E - ®TX6 ™ PLUS UTP Coupler Moduleslejlas77No ratings yet

- BS (English) Dept of English University of SargodhaDocument36 pagesBS (English) Dept of English University of SargodhaFEROZ KHANNo ratings yet

- Instruction Manual Series 854 XTG Level GaugeDocument60 pagesInstruction Manual Series 854 XTG Level GaugeJandri JacobNo ratings yet

- 102DNDocument2 pages102DNManuel ZavalaNo ratings yet

- An Introduction to Heisenberg Groups in Analysis and GeometryDocument7 pagesAn Introduction to Heisenberg Groups in Analysis and Geometrynitrosc16703No ratings yet

- Foundation ProblemsDocument71 pagesFoundation Problemsيقين يقين0% (1)

- 07-02-2023 MS QLNDocument3 pages07-02-2023 MS QLNSummaaaaNo ratings yet

- Tes P 119 10 R0 PDFDocument43 pagesTes P 119 10 R0 PDFAbin Meetu100% (4)

- ManupptDocument65 pagesManupptKrishanarju VenkatesanNo ratings yet

- The Arcane Formulas or Mental AlchemyDocument121 pagesThe Arcane Formulas or Mental AlchemyTim Boire100% (1)

- ¿Cómo Hacerlo?: Dr. Jorge Ramírez Medina, Dr. Guillermo Granados Ruíz EGADE Business SchoolDocument17 pages¿Cómo Hacerlo?: Dr. Jorge Ramírez Medina, Dr. Guillermo Granados Ruíz EGADE Business Schoolgalter6No ratings yet

- Query Operation 2021Document35 pagesQuery Operation 2021Abdo AbaborNo ratings yet

- Smarter Washing Solutions: Modular Wash RangeDocument5 pagesSmarter Washing Solutions: Modular Wash RangeSujesh AnNo ratings yet

- LTE Interview QuestionsDocument10 pagesLTE Interview QuestionsMahesh Pratap100% (1)

- Catering Reserving and Ordering System with MongoDB, Express, Node.js (39Document5 pagesCatering Reserving and Ordering System with MongoDB, Express, Node.js (39radha krishnaNo ratings yet

- ZSL National Red List of Nepal's Birds Volume 2Document636 pagesZSL National Red List of Nepal's Birds Volume 2Tushita LamaNo ratings yet

- ZXJ 10 SPCDocument7 pagesZXJ 10 SPCMuhammad Yaseen100% (1)

- MDS Report Substances of Assemblies and Materials: 1. Company and Product NameDocument17 pagesMDS Report Substances of Assemblies and Materials: 1. Company and Product Namejavier ortizNo ratings yet

- Be Circular Fibre Reinforced ConcreteDocument4 pagesBe Circular Fibre Reinforced ConcreteLim Kang HaiNo ratings yet

- Efficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar ExtractionsDocument10 pagesEfficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar Extractionsxiaoxin zhangNo ratings yet

- Calmark - Birtcher 44 5 10 LF L DatasheetDocument2 pagesCalmark - Birtcher 44 5 10 LF L DatasheetirinaNo ratings yet

- World MultipleDocument271 pagesWorld MultipleatrkpoleNo ratings yet

- Kompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminDocument9 pagesKompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminHendrayana RamdanNo ratings yet

- Cartoon Network, Boomerang & TCM TV Rate Card July - SeptemberDocument11 pagesCartoon Network, Boomerang & TCM TV Rate Card July - SeptemberR RizalNo ratings yet

- Graffiti Model Lesson PlanDocument9 pagesGraffiti Model Lesson Planapi-286619177100% (1)

- NCP 1014Document24 pagesNCP 1014rodricaldasNo ratings yet

- MD SHAFIUL ISLAM 沙菲 ID;20183290290Document23 pagesMD SHAFIUL ISLAM 沙菲 ID;20183290290SHAFIUL SETUNo ratings yet