Professional Documents

Culture Documents

Sheet: Reducing Falls in Construction: Safe Use of Extension Ladders

Uploaded by

jefhdezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sheet: Reducing Falls in Construction: Safe Use of Extension Ladders

Uploaded by

jefhdezCopyright:

Available Formats

FactSheet

Reducing Falls in Construction: Safe Use of Extension Ladders

Workers who use extension ladders risk permanent injury or death from falls and electrocutions. These hazards can be eliminated or substantially reduced by following good safety practices. This fact sheet examines some of the hazards workers may encounter while working on extension ladders and explains what employers and workers can do to reduce injuries. OSHAs requirements for extension ladders are in Subpart XStairways and Ladders of OSHAs Construction standards. What is an Extension Ladder?

Also known as portable ladders, extension ladders usually have two sections that operate in brackets or guides allowing for adjustable lengths. (See Figure 1, below.) Because extension ladders are not self-supporting they require a stable structure that can withstand the intended load.

PLAN Ahead to Get the Job Done Safely.

Use a ladder that can sustain at least four times the maximum intended load, except that each extra-heavy duty type 1A metal or plastic ladder shall sustain at least 3.3 times the maximum intended load. Also acceptable are ladders that meet the requirements set forth in Appendix A of Subpart X. Follow the manufacturers instructions and labels on the ladder. To determine the correct ladder, consider your weight plus the weight of your load. Do not exceed the load rating and always include the weight of all tools, materials and equipment. A competent person must visually inspect all extension ladders before use for any defects such as: missing rungs, bolts, cleats, screws and loose components. Where a ladder has these or other defects, it must be immediately marked as defective or tagged with Do Not Use or similar language. Allow sufficient room to step off the ladder safely. Keep the area around the bottom and the top of the ladder clear of equipment, materials and tools. If access is obstructed, secure the top of the ladder to a rigid support that will not deflect, and add a grasping device to allow workers safe access. Set the ladder at the proper angle. When a ladder is leaned against a wall, the bottom of the ladder should be one-quarter of the ladders working length away from the wall. For access to an elevated work surface, extend the top of the ladder three feet above that surface or secure the ladder at its top. Before starting work, survey the area for potential hazards, such as energized overhead power lines. Ladders shall have

Figure 1: Extension Ladder

nonconductive side rails if they are used where the worker or the ladder could contact exposed energized electrical equipment. Keep all ladders and other tools at least 10 feet away from any power lines. Set the base of the ladder so that the bottom sits securely and so both side rails are evenly supported. The ladder rails should be square to the structure against which it is leaning with both footpads placed securely on a stable and level surface. Secure the ladders dogs or pawls before climbing. When using a ladder in a high-activity area, secure it to prevent movement and use a barrier to redirect workers and equipment. If the ladder is placed in front of a door, always block off the door.

TRAIN Workers to Use Extension LaddersSafely.

Employers must train each worker to recognize and minimize ladder-related hazards.

PLAN. PROVIDE. TRAIN.

Three simple steps to prevent falls.

Safe Ladder UseDO:

Maintain a 3-point contact (two hands and a foot, or two feet and a hand) when climbing/ descending a ladder. Face the ladder when climbing up or descending. Keep the body inside the side rails. Use extra care when getting on or off the ladder at the top or bottom. Avoid tipping the ladder over sideways or causing the ladder base to slide out. Carry tools in a tool belt or raise tools up using a hand line. Never carry tools in your hands while climbing up/down a ladder. Extend the top of the ladder three feet above the landing. (See Figure 2.) Keep ladders free of any slippery materials.

Figure 2: Ladder extending three feet above the landing area.

Safe Ladder UseDO NOT:

Place a ladder on boxes, barrels, or unstablebases. Use a ladder on soft ground or unstable footing. Exceed the ladders maximum load rating. Tie two ladders together to make them longer. Ignore nearby overhead power lines. Move or shift a ladder with a person or equipment on the ladder. Lean out beyond the ladders side rails. Use an extension ladder horizontally like aplatform.

PROVIDE the Right Extension Ladder for the Job with the Proper Load Capacity.

Select a ladder based on the expected load capacity (duty rating), the type of work to be done and the correct height. There are five categories of ladder duty ratings. Type IAA* IA I II III Duty Rating Special Duty Extra Duty Heavy Duty Medium Duty Light Duty Use Rugged Industrial Industrial Commercial Household Load 375 lbs. 300 lbs. 250 lbs. 225 lbs. 200 lbs.

Source for Types IA, I, II, III: Subpart XStairways and Ladders, Appendix A (American National Standards Institute (ANSI)) 14.1, 14.2, 14.5 (1982)) of OSHAs Construction standards. Source for Type IAA: ANSI 14.1, 14.2, 14.5 (2009), which are non-mandatory guidelines.

OSHA standard: 29 CFR 1926 Subpart XStairways and Ladders American National Standards Institute standard: ANSI A14.1, A14.2, A14.5Ladder Safety Requirements (Not an OSHA standard, included to be used as guidance to meet OSHAs requirements) Employers using extension ladders must follow the ladder requirements set forth in 29 CFR 1926 Subpart X. Per Appendix A to Subpart X of Part 1926Ladders, ladders designed in accordance with the following ANSI standards will be considered in accordance with 29 CFR 1926.1053(a)(1): ANSI A14.1-1982American National Standard for LaddersPortable WoodSafety Requirements, ANSI A14.2-1982American National Standard for LaddersPortable MetalSafety Requirements, and ANSI A14.5-1982American National Standard for LaddersPortable Reinforced PlasticSafety Requirements. State plan guidance: States with OSHA-approved state plans may have additional requirements for avoiding falls from ladders. For more information on these requirements, please visit: www.osha.gov/dcsp/ osp/statesstandards.html. Most OSHA offices have compliance assistance specialists to help employers and workers comply with OSHA standards. For details call 1-800-321-OSHA (6742) or visit: www.osha.gov/htm/RAmap.html.

This is one in a series of informational fact sheets highlighting OSHA programs, policies or standards. It does not impose any new compliance requirements. For a comprehensive list of compliance requirements of OSHA standards or regulations, refer to Title 29 of the Code of Federal Regulations. This information will be made available to sensory-impaired individuals upon request. The voice phone is (202) 693-1999; teletypewriter (TTY) number: (877) 889-5627.

DOC FS-3660 05/2013

You might also like

- Sheet: Reducing Falls in Construction: Safe Use of StepladdersDocument2 pagesSheet: Reducing Falls in Construction: Safe Use of StepladdersjefhdezNo ratings yet

- Reducing Falls from Job-made Wooden LaddersDocument2 pagesReducing Falls from Job-made Wooden LaddersjefhdezNo ratings yet

- Ladder SafetyDocument27 pagesLadder SafetySantanu Kumar Sahu100% (1)

- Portable Ladder Safety Program 09Document6 pagesPortable Ladder Safety Program 09Patrick BolenNo ratings yet

- Test Method For Earthwork Compaction Control by Nuclear GaugeDocument29 pagesTest Method For Earthwork Compaction Control by Nuclear GaugeLennieCartujanoLuceñoNo ratings yet

- New Scaffold TagsDocument36 pagesNew Scaffold TagsPaolo AzurinNo ratings yet

- Scaffold Work HandoutDocument2 pagesScaffold Work HandoutRija Hossain100% (1)

- Scaffolding Safety Guideline: KAS-Scaffolding - Fast Then. Fast NowDocument9 pagesScaffolding Safety Guideline: KAS-Scaffolding - Fast Then. Fast Nowfaizal4yaNo ratings yet

- Safe Use of Ladders: Personnel DivisionDocument6 pagesSafe Use of Ladders: Personnel DivisionKheireddine AounallahNo ratings yet

- Aerial Lifts FactsheetDocument2 pagesAerial Lifts Factsheetomar santosNo ratings yet

- Emergency Response & Rescue Planning: by Mr. G. S. Saini Director, National Civil Defence CollegeDocument90 pagesEmergency Response & Rescue Planning: by Mr. G. S. Saini Director, National Civil Defence CollegeTomNo ratings yet

- Welding PPE GuideDocument9 pagesWelding PPE Guidecyrelle rose jumentoNo ratings yet

- 01-Ppe Eng PDFDocument17 pages01-Ppe Eng PDFZaki AdamouNo ratings yet

- OSHA Fall Protection Trainer GuideDocument39 pagesOSHA Fall Protection Trainer Guidedroffilcz27100% (1)

- Niversity of Eicester: P W P R E & F M DDocument27 pagesNiversity of Eicester: P W P R E & F M DFOZCANNo ratings yet

- OSHA Construction Scaffolding Safety StandardsDocument70 pagesOSHA Construction Scaffolding Safety StandardsAAQUEEB100% (2)

- Warehouse Inspection ReportDocument3 pagesWarehouse Inspection ReportjomarkdNo ratings yet

- Confined Spaces TrainingDocument3 pagesConfined Spaces Traininghello3232No ratings yet

- Guide Spray Painting 415Document24 pagesGuide Spray Painting 415MuthuKumarNo ratings yet

- Working at Height EbookDocument14 pagesWorking at Height EbookSubhi El Haj SalehNo ratings yet

- Peabody Rigging ProgramDocument36 pagesPeabody Rigging ProgramNadeem100% (1)

- Material Handling On Construction Sites: HerniaDocument4 pagesMaterial Handling On Construction Sites: HerniaCarl Kyu100% (1)

- D B P G: UST EST Ractice UideDocument21 pagesD B P G: UST EST Ractice UideBellaCasa BuildersNo ratings yet

- 605 Study Guide - Confined Space SafetyDocument42 pages605 Study Guide - Confined Space SafetyWilliam Bautista100% (1)

- Fall Protection English 10-10-07Document187 pagesFall Protection English 10-10-07Richard BurtonNo ratings yet

- Risk Assessment For Heaven. INC Short FilmDocument2 pagesRisk Assessment For Heaven. INC Short FilmHarryGeorgePrestonNo ratings yet

- Material Handling SafetyDocument46 pagesMaterial Handling SafetyAnonymous w6TIxI0G8lNo ratings yet

- Walking and Working SurfacesDocument21 pagesWalking and Working Surfacesahmed naveed100% (1)

- Confined Space Hazard Evaluation Survey FormDocument2 pagesConfined Space Hazard Evaluation Survey FormEdward100% (1)

- Safety of LaddersDocument13 pagesSafety of LadderssalekojicNo ratings yet

- 1 Fall Hazards Participant GuideDocument38 pages1 Fall Hazards Participant GuidecharibackupNo ratings yet

- Work at Heights Self Assessment SheetDocument4 pagesWork at Heights Self Assessment SheetBalogun IsaacNo ratings yet

- Machine Safety in ConstructionDocument27 pagesMachine Safety in ConstructionSawyu Nandar100% (1)

- Ladder SafetyDocument10 pagesLadder SafetysachinoakNo ratings yet

- Did You Know There'S A Lot More To Ladder Safety Than Safely Climbing ItDocument1 pageDid You Know There'S A Lot More To Ladder Safety Than Safely Climbing ItBalaji ThiaguNo ratings yet

- 7 Scaffolding SafetyDocument15 pages7 Scaffolding SafetyMithlesh SinghNo ratings yet

- Concrete and Masonry SafetyDocument57 pagesConcrete and Masonry SafetyZabNo ratings yet

- Manual HandlingDocument13 pagesManual Handlingppkuldeep4No ratings yet

- SWMS 71 - Use of Curing ChemicalDocument2 pagesSWMS 71 - Use of Curing ChemicaleastNo ratings yet

- Land Surveyors Safety TipsDocument6 pagesLand Surveyors Safety TipsJigg PelayoNo ratings yet

- Materials HandlingDocument43 pagesMaterials Handlingkevin punzalan100% (41)

- Manual Handling and Back SafetyDocument23 pagesManual Handling and Back SafetyDie HArdNo ratings yet

- Slips FallsDocument51 pagesSlips FallsSham AranNo ratings yet

- Construction Job Safety/Hazard Analysis Job #: Location/Description: OwnerDocument33 pagesConstruction Job Safety/Hazard Analysis Job #: Location/Description: OwnerHortencio SamuelNo ratings yet

- Construction PPE GuideDocument7 pagesConstruction PPE Guideiims jobsNo ratings yet

- Office Safety PosterDocument2 pagesOffice Safety PosterAndrei MargaritNo ratings yet

- Crane Safety Program EssentialsDocument11 pagesCrane Safety Program Essentialssekhargm100% (1)

- Working at Height PresentationDocument11 pagesWorking at Height PresentationAbdul Hameed OmarNo ratings yet

- Scaff and Mewp and HeightDocument24 pagesScaff and Mewp and HeightRmr ReyesNo ratings yet

- Construction Safety Equipments: Apeksha Hemanth Nishant Nikhil PrajwalDocument19 pagesConstruction Safety Equipments: Apeksha Hemanth Nishant Nikhil Prajwalshivarajs12340987No ratings yet

- Fall ProtectionDocument69 pagesFall Protectionamin100% (1)

- Saudi Aramco Q&ADocument12 pagesSaudi Aramco Q&AAzad pravesh khanNo ratings yet

- Calculate Rated LoadDocument34 pagesCalculate Rated LoadAngel Ortega100% (2)

- Weight Breaking LoadDocument1 pageWeight Breaking LoadEric McElroyNo ratings yet

- Ms - Tree Felling With Single Lorry OperationDocument2 pagesMs - Tree Felling With Single Lorry OperationWr Ar100% (1)

- Personal protective equipment Complete Self-Assessment GuideFrom EverandPersonal protective equipment Complete Self-Assessment GuideRating: 5 out of 5 stars5/5 (1)

- Registro Ml y m2 Ph y Pintura Pld3 Rev 0Document1 pageRegistro Ml y m2 Ph y Pintura Pld3 Rev 0jefhdezNo ratings yet

- Rtaa Svx01a en - 09012005Document178 pagesRtaa Svx01a en - 09012005jars03180950100% (1)

- 3 Energy Insights Seminar HotelDocument25 pages3 Energy Insights Seminar HoteljefhdezNo ratings yet

- Hotwater DrivenabsorptionchillersDocument43 pagesHotwater DrivenabsorptionchillersjefhdezNo ratings yet

- RLC PRC005 E4 - 0110Document60 pagesRLC PRC005 E4 - 0110jefhdez0% (1)

- Rtaa IomDocument140 pagesRtaa IomjefhdezNo ratings yet

- 1 - Introduction On BECDocument12 pages1 - Introduction On BECjefhdezNo ratings yet

- Trane Rtaa en Rtab r22 Eng2Document32 pagesTrane Rtaa en Rtab r22 Eng2jefhdez67% (3)

- Chillers Checklist BookDocument1 pageChillers Checklist BookZoheb SharieefNo ratings yet

- RLC prc016 en - 1106Document48 pagesRLC prc016 en - 1106Aldrin AbuegNo ratings yet

- 4-1 - Cooling Tower ApplicationDocument48 pages4-1 - Cooling Tower ApplicationjefhdezNo ratings yet

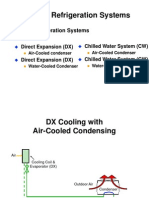

- Ref. System TypeDocument21 pagesRef. System TypejefhdezNo ratings yet

- 1 - Trane HVAC Products Update 2011Document44 pages1 - Trane HVAC Products Update 2011varshneyrk@rediffmail.comNo ratings yet

- Trane 3 Green RefrigerantDocument55 pagesTrane 3 Green RefrigerantEdward SiuNo ratings yet

- Trane 4 Chiller Plant ControlsDocument28 pagesTrane 4 Chiller Plant ControlsEdward Siu100% (3)

- 3 Energy Insights Seminar HotelDocument25 pages3 Energy Insights Seminar HoteljefhdezNo ratings yet

- Trane - 2 - VPF Hong Kong Rv1Document43 pagesTrane - 2 - VPF Hong Kong Rv1Edward SiuNo ratings yet

- 1 - Introduction On BECDocument12 pages1 - Introduction On BECjefhdezNo ratings yet

- Li-ION Battery Charger FeaturesDocument2 pagesLi-ION Battery Charger Featureshariyadi aryoNo ratings yet

- Chemistry How To Make Stuff PDFDocument184 pagesChemistry How To Make Stuff PDF2967449CEENo ratings yet

- Cardiopulmonary System: Relevant Anatomy & Physiology: HeartDocument12 pagesCardiopulmonary System: Relevant Anatomy & Physiology: HeartJulia SalvioNo ratings yet

- Medication - Safety - v4 Last Update 2015Document81 pagesMedication - Safety - v4 Last Update 2015Retno PalupiNo ratings yet

- Approach To Malabsorption (SANJAY)Document58 pagesApproach To Malabsorption (SANJAY)Sanjay KumarNo ratings yet

- Mercedes ManDocument7 pagesMercedes Manien yeyenNo ratings yet

- Porter's Diamond Model Explains Nations' Success in IT CompetitionDocument30 pagesPorter's Diamond Model Explains Nations' Success in IT CompetitionKuthubudeen T MNo ratings yet

- Matrix Algebra by A.S.HadiDocument4 pagesMatrix Algebra by A.S.HadiHevantBhojaram0% (1)

- Earthbag House For HaitiDocument22 pagesEarthbag House For HaitiRaymond KatabaziNo ratings yet

- Polycab HT XlpeDocument33 pagesPolycab HT Xlpezafrikhan875No ratings yet

- Why Check Valves SlamDocument2 pagesWhy Check Valves SlamBramJanssen76No ratings yet

- Technical PaperDocument6 pagesTechnical PaperSIJO MONACHANNo ratings yet

- Horizontal Projectile WSDocument3 pagesHorizontal Projectile WSForsbergPhysicsNo ratings yet

- Engineering Mechanics Lectures PDFDocument83 pagesEngineering Mechanics Lectures PDFluay adnanNo ratings yet

- Eplob Eplob/A Epmob Epmob/A: PhotocellsDocument2 pagesEplob Eplob/A Epmob Epmob/A: PhotocellsSupuran RichardoNo ratings yet

- I Wanna Be Yours Arctic Monkeys Love SongDocument3 pagesI Wanna Be Yours Arctic Monkeys Love SongAndréia E NiltonNo ratings yet

- Nest Installation GuideDocument8 pagesNest Installation GuideOzzyNo ratings yet

- @MedicalBooksStore 2016 AntibioticDocument349 pages@MedicalBooksStore 2016 Antibioticant bee100% (1)

- Module 6 - FormworksDocument8 pagesModule 6 - FormworksAldrich Francis Ortiz Peñaflor100% (1)

- Dell Precision Workstations: The #1 Workstations in The WorldDocument7 pagesDell Precision Workstations: The #1 Workstations in The WorldDiego RodriguezNo ratings yet

- 7H17-28 Clearances and Wear Limits PDFDocument3 pages7H17-28 Clearances and Wear Limits PDFDimitris K100% (1)

- Artikel Ilmiah FikriDocument6 pagesArtikel Ilmiah FikriViola Mei DamayantiNo ratings yet

- Lession Plan - MIDocument21 pagesLession Plan - MINithya SannidhiNo ratings yet

- 1 SM PDFDocument14 pages1 SM PDFSiti HamsyiahNo ratings yet

- Inkontinensia Urin: Dr. Adhi Permana, SPPDDocument35 pagesInkontinensia Urin: Dr. Adhi Permana, SPPDTiara KhairinaNo ratings yet

- Service Manual: EQ1030T47D-820 Light Commercial TruckDocument175 pagesService Manual: EQ1030T47D-820 Light Commercial TruckYonny ColqueNo ratings yet

- MACRO XII Subhash Dey All Chapters PPTs (Teaching Made Easier)Document2,231 pagesMACRO XII Subhash Dey All Chapters PPTs (Teaching Made Easier)Vatsal HarkarNo ratings yet

- FHM Espana 2010 12 PDFDocument2 pagesFHM Espana 2010 12 PDFBrandenNo ratings yet

- Chapter 1 - Introduction To Machinery PrinciplesDocument27 pagesChapter 1 - Introduction To Machinery PrinciplesYousab CreatorNo ratings yet

- 1B Cosmos-Standard - Technical - Guide - v40Document45 pages1B Cosmos-Standard - Technical - Guide - v40carla deiddaNo ratings yet