Professional Documents

Culture Documents

Winchester Model 70 Special Supplement

Uploaded by

carlosfanjul10 ratings0% found this document useful (0 votes)

189 views0 pagesBOSS(tm) gives The Model 70 a degree of accuracy found only on expensive custom rifles. Barrel vibrations are the primary cause of rifle inaccuracy. U.s. Repeating Arms Co. Has developed patented technology to reduce barrel vibrations.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBOSS(tm) gives The Model 70 a degree of accuracy found only on expensive custom rifles. Barrel vibrations are the primary cause of rifle inaccuracy. U.s. Repeating Arms Co. Has developed patented technology to reduce barrel vibrations.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

189 views0 pagesWinchester Model 70 Special Supplement

Uploaded by

carlosfanjul1BOSS(tm) gives The Model 70 a degree of accuracy found only on expensive custom rifles. Barrel vibrations are the primary cause of rifle inaccuracy. U.s. Repeating Arms Co. Has developed patented technology to reduce barrel vibrations.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

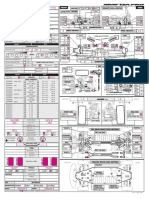

THE BOSS AND YOUR MODEL 70.

(BALLISTIC OPTIMIZING SHOOTING SYSTEM)

These are additional instructions specific to your BOSS

equipped Model 70 rifle. Please read and understand the

cautions and proper handling procedures outlined in this

booklet and in your Model 70 owners manual, before

using your new BOSS equipped rifle. If you are missing

the operating manual for your rifle, we will send you a

free manual on request.

WARNING: THE BOSS INCLUDES A RECOIL

VIDES SUBSTANTIAL INCREASED

NOISE / MUZZLE BLAST. ALWAYS WEAR

ING LOSS OR DAMAGE.

REDUCING MUZZLE BRAKE WHICH PRO-

HEARING PROTECTION TO PREVENT HEAR-

CAUTION: THE THREADING ON YOUR BAR-

REL IS FOR COMPONENTS FOR THE

U.S. REPEATING ARMS CO. BOSS ONLY. DO

NOT INSTALL ANY OTHER DEVICE ONTO THE

WINCHESTER MODEL 70 BOSS BARREL. DO

NOT INSTALL THE BOSS DEVICE ON ANY

RIFLE WHICH IS NOT DESIGNED AND FITTED

FOR THE BOSS BY U.S. REPEATING ARMS

CO. DOING SO MAY CAUSE SERIOUS INJURY

OR DEATH TO YOURSELF OR OTHERS.

The Model 70 is considered by many to be the most per-

fectly designed rifle ever. The Model 70 is a rifle of histo-

ry and unequalled modern performance especially with

the revolutionary BOSS. U.S. Repeating Arms Co. is

excited to offer this incredible new patented technology

on the Winchester Model 70.

The BOSS gives the Model 70 a degree of accuracy found

only on expensive custom rifles. The Model 70 offers the

rifleman the best of two worlds: traditional craftsmanship

and the latest in modern rifle technology. Now, more

than ever, it is truly The Riflemans Rifle.

HOW THE BOSS WORKS

Barrel vibrations are the primary cause of rifle inaccuracy.

Every time a rifle is fired, barrel vibrations are set in

motion. These vibrations occur in all directions, even

back and forth along the axis of the barrel. They are

influenced by many factors such as bullet type, bullet

weight, primers, different powders and even barrel config-

urations.

The BOSS (Ballistic Optimizing Shooting System) is an

adjustable weight that alters rifle barrel vibrations. By

adjusting the weight on the BOSS, you can tune your

rifle to specific ammunition, allowing a bullet to consis-

tently exit the rifle muzzle at the optimum point in barrel

1

vibration. At this optimum point, either at the peak or

valley of a vibration wave, the rifle barrel is momentarily

motionless. The suggested sweet spots (found on a sepa-

rate sheet supplied with this manual) are the starting

points for determining the optimum accuracy of your

BOSS equipped Model 70. Once the true sweet spot is

determined for a given ammunition, your rifle will consis-

tently deliver extraordinarily tight groups. The BOSS

allows you to tune your rifle to your ammunition to get

the optimum accuracy for all available factory loads.

When adjusted to the sweet spot, the BOSS will com-

pensate for slight deviations in ammunition velocity.

The BOSS will not, however, compensate for poor shoot-

ing or flyers caused by low quality bullets and ammuni-

tion.

TO OBTAIN THE HIGHEST LEVEL OF ACCU-

RACY FROM YOUR RIFLE IT IS RECOMMEND-

ED THAT THE RIFLE BORE BE CLEANED

EVERY 25 TO 30 ROUNDS. SEE CLEANING

LET FOR CLEANING PROCEDURES.

THE RIFLE BORE SECTION OF THIS BOOK-

MUZZLE BRAKE FEATURE

The unique exhaust hole pattern on the BOSS provides

considerable recoil reduction. Recoil reduction of the

BOSS ranges from 30% to 50% depending on caliber,

weight of rifle, etc.

You will experience an increase in noise and concussion

(muzzle blast) when a BOSS equipped rifle is fired.

Hearing protectors (shooting ear plugs or muffs) should

always be worn to guard against hearing damage when

shooting a BOSS equipped rifle. Wear shooting glasses to

protect your eyes from flying particles. Always keep a safe

distance between the muzzle of your firearm and any per-

sons nearby, as muzzle blast, debris and ejecting shells

could inflict serious injury.

BOSS SPECIFICATIONS

The BOSS body length is 2 inches for most calibers. The

size of the gas vent holes and hole pattern is the same for

most calibers. The size of the bullet exit hole is the same

for all calibers except for the 338 Win. Mag. The thread

system for the 338 Win. Mag. is different from other cal-

ibers to rule out the possibility of accidentally or deliber-

ately switching components and creating an unsafe

combination.

2

THE SWEET SPOT

WARNING: THE .338 CALIBER BOSS HAS A

RENTLY AVAILABLE CALIBERS. SWITCHING

IBERS TO THE .338 BARREL COULD CAUSE A

RESTRICTION OR OBSTRUCTION RESULTING

IN POSSIBLE INJURY OR DEATH TO THE

SHOOTER OR OTHERS.

Each BOSS consists of a micro-adjustable locknut and

body (See Figure 1). The body of the BOSS consists of a

weight and muzzle brake. The weight and muzzle brake

are affixed by LOCTITE. To obtain the utmost accuracy

from your BOSS equipped Model 70 it is very important

that the micro-adjustable locknut and body are fully

tightened before firing.

LARGER EXIT BORE THAN ALL OTHER CUR-

BOSS COMPONENTS FROM DIFFERENT CAL-

Precision accuracy is achieved by calibrating your rifle

caliber and ammunition with a sweet spot setting. The

sweet spots for your Model 70 are found listed on a sep-

arate sheet supplied with this manual. If you are missing

the sweet spot sheet or if there is no sweet spot listing

for your rifle caliber or ammunition, call U.S. Repeating

Arms Co. at 1-800-945-1392. Sweet spot settings were

determined through extensive testing by US. Repeating

Arms Co. Research and Development staff. Sweet spots

may vary between rifles of identical specifications with a

given ammunition. Even one quarter of a turn away from

the sweet spot can cause a group to spread as much as

one inch or more. We suggest you use our suggested

sweet spot setting as a starting point in determining the

exact sweet spot setting for your particular rifle and

make adjustments accordingly. Note: any change in

BOSS setting may slightly alter your rifles point of

impact. Its recommended you set the BOSS sweet spot

setting before sighting in your rifle for windage and eleva-

tion. The BOSS was tested in full turn, 1/2 and 1/4 turn

increments. Tighter groups may be achieved with the

BOSS tested in other positions.

3

PRELIMINARY ADJUSTMENTS

Before adjusting your rifle to the sweet spot, it is impor-

tant that your BOSS is calibrated with the barrel. This

will ensure that your rifle is consistent with those tested

by U.S. Repeating Arms Co. Research and Development

when BOSS suggested sweet spots were determined.

To find out if your BOSS needs to be calibrated, loosen

the micro-adjustable locknut until it bottoms out on the

threads of the BOSS or will not loosen any further. If

your BOSS is calibrated, the 0 on the micrometer

adjustment ring will line up with the longitudinal hatch

mark on the barrel (See Figure 2).

If the 0 isnt aligned with the longitudinal hatch mark,

you will need to calibrate your BOSS. Move the microm-

eter adjustment ring, on the bottom of the locknut, so

that when bottomed out on the threads the 0 is aligned

with the vertical hatch mark. To adjust the micrometer

adjustment ring, insert your fingernail or a small pointed

object in the split of the ring and simply rotate the ring

(See Figure 3).

TUNING YOUR RIFLE TO THE SWEET SPOT

Full turn sweet spot setting or graduations are numbered

0-10 and inscribed on the barrel of your rifle. Smaller,

1/10 turn increments are inscribed at the rear of the lock-

nut. (Refer to Figure 4.) To set the sweet spot, the

4

micro-adjustable locknut is turned either clockwise or

counterclockwise until it rests on the desired sweet spot

number inscribed on your rifles barrel. One full revolu-

tion of the locknut indicates one full change in setting or

one index mark on the barrel. 1/10 turn increments are

set by turning the micro-adjustable locknut until the

desired setting lines up with the longitudinal hatch mark

on the barrel. IMPORTANT: When adjusting the sweet

spot make sure you grip the knurled surface of the micro-

adjustable locknut. The knurled portion of the locknut

and micrometer adjustment ring must rotate together to

ensure a precise sweet spot setting and retainment of

proper calibration.

CAUTION: WHEN SETTING THE SWEET

SPOT ON YOUR RIFLE MAKE CERTAIN YOUR

RIFLE IS FULLY UNLOADED AND THAT THE

RIFLES SAFETY IS IN THE ON SAFE

POSITION AND YOUR RIFLE IS POINTED IN A

SAFE DIRECTION.

THE SUGGESTED SWEET SPOTS FOR

RATE SHEET SUPPLIED WITH THIS MANUAL.

IF YOU ARE MISSING THE SWEET SPOT

SHEET OR IF YOUR RIFLES CALIBER OR

AMMUNITION IS NOT ON THE LIST,

YOUR MODEL 70 ARE LISTED ON A SEPA-

CALL U.S. REPEATING ARMS CO. AT

1-800-782-4440.

EXAMPLE 1

1. Suppose you have a 270 caliber Model 70 and are

sighting in with 150 gr. cartridges. Referring to the sweet

spot chart you will find the average sweet spot is 2.5

for a 270 caliber with 150 gr. ammo.

2. After having made sure your BOSS is calibrated,

rotate the locknut counterclockwise two and one half full

revolutions. The edge of locknut should line up or rest on

the marking for 2 on the barrel.

NOTE: It is not necessary to calibrate your BOSS on the

5

barrel with every change in sweet spot setting.

However, you should check your BOSS periodically to

assure that it is aligned.

3. Since the sweet spot is listed as 2.5, the 5 inscribed

on the micrometer adjustment ring should line up with

the hatch mark on the barrel (See Figure 4).

4. Tighten the body of the BOSS so it is secure against

the locknut. Use the special wrench supplied with your

rifle (see Figure 5).

CAUTION: REMOVE THE WRENCH BEFORE

FIRING YOUR RIFLE.

EXAMPLE 2

1. Suppose you have a 30-06 Sprg. Model 70 with

150 gr. cartridges. Referring to the sweet spot chart you

will find the average sweet spot is 1.8.

2. Adjust your BOSS and rotate the micro-adjustable

locknut counterclockwise until the edge of the locknut

lines up or rests on the marking for 1 on the barrel.

3. Since the sweet spot is listed as 1.8, the 8 inscribed

on the micrometer adjustment ring should line up with

the hatch mark on the barrel (See Figure 6).

4. Using the special wrench, tighten the body of the

BOSS so it is secure against the locknut. Your BOSS sys-

tem is now calibrated for 150 gr. ammo for 30-06 Sprg.

6

MORE PRECISE ADJUSTMENTS

If you desire to obtain even tighter groupings, turn the

micro-adjustable locknut 1/4 of a turn clockwise from the

sweet spot, and fire your rifle at your target. If groups

open up, turn the locknut counterclockwise and shoot at

different 1/4 turn settings until you are satisfied with your

groupings. Again, sweet spots may vary between rifles of

identical specifications with a given ammunition. As in

any sighting-in process, best results are obtained through

trial and error. You may need to retune the BOSS should

you decide to shoot different brands, lots and types of

ammunition.

Be sure to keep a record of your rifles sweet spots, especially

if you use your rifle for different game and shoot different loads.

CAUTION: WHEN ADJUSTING THE SWEET

SPOT NEVER SET THE BOSS BEYOND THE

10 SETTING ON THE BARREL.

With the BOSS set beyond 10, the BOSS could become

loose, misaligned or fall off when firing the rifle. This

could result in serious injury to yourself or others.

IMPORTANT: Each time you set the sweet spot, the

body of the BOSS must be tight against the micro-

adjustable locknut. Failure to keep the components tight-

ly locked will adversely affect accuracy. NOTE: The

action mounting screws on your Model 70 should be fully

tightened (See Figure 7). If the screws are loose, tighten

the front screw first, then the rear trigger guard screw.

Always leave the middle screw snug, hand tight only.

CARE OF YOUR BOSS-EQUIPPED MODEL 70.

The BOSS is a precision instrument.

IN ORDER FOR THE BOSS TO OPERATE

EFFECTIVELY IT IS VERY IMPORTANT YOUR

RIFLE REMAINS IN THE SAME CONDITION IT

ESSARY FOR YOUR RIFLES BARREL TO

BEDDED.

WAS PURCHASED. IT IS ABSOLUTELY NEC-

REMAIN FREE-FLOATING AND PROPERLY

7

To check for adequate clearance, it is recommended that

a piece of paper, folded once, be able to pass between the

barrel and stock without any interference. If the barrel is

not free-floating, take your rifle to a competent gunsmith

or send it to U.S. Repeating Arms Co. Service Center.

Special bedding of the action on your BOSS equipped

Model 70 rifle is installed at the factory and aids greatly

in improving accuracy. If you have any modifications

done to your stock, make sure the bedding has not been

altered. If the bedding on your rifle has been modified

send your rifle to a U.S. Repeating Arms Co. Service

Center.

SPECIAL INSTRUCTIONS

ON CLEANING THE RIFLE BORE

To maintain utmost accuracy from your BOSS equipped

rifle, or any rifle, extensive testing has proven that the

rifle bore must be cleaned every 25 to 30 rounds.

CAUTION: BEFORE CLEANING YOUR RIFLE

MAKE CERTAIN YOUR RIFLE IS FULLY

UNLOADED, THE MAGAZINE IS

UNLOADED / REMOVED, THE SAFETY IS IN

THE ON SAFE POSITION AND YOUR RIFLE

IS POINTED IN A SAFE DIRECTION.

We highly recommend that your rifle be cleaned with the

BOSS installed on your barrel. Remove the bolt and clean

from the breech end.

Modern cartridge jackets are made mainly of copper and

zinc. These metals glide easier and increase barrel life, how-

ever, residues from copper and zinc also stick to the barrel

and require more frequent cleaning. As top benchrest shoot-

ers have known for decades, copper solvent is the key to

cleaning a barrel for optimum accuracy. The recommended

cleaning procedure is as follows:

1. Clean the bore with a good powder solvent to remove all

traces of powder residue. Performing this step before the

application of a copper solvent will prevent the bore from

refouling with copper so readily.

2. Swab the bore with a good copper solvent using the

manufacturers recommended procedure. After neutralizing

the solvent, generally with oil, it is important to swab the

bore dry. Swabbing the bore dry will reduce copper buildup.

NOTE: DO NOT USE SOLVENTS OF DIFFERENT

MANUFACTURERS CONCURRENTLY. A CHEMI-

CAL REACTION MAY RESULT THAT WILL COR-

RODE EVEN STAINLESS STEEL BARRELS. IT IS

ERS RECOMMENDATIONS EXACTLY.

IMPORTANT TO FOLLOW THE MANUFACTUR-

8

3. If absolutely necessary, the BOSS may be removed to

facilitate cleaning.

Clean the BOSS by removing the locknut and body from

the rifle. With the components disassembled, wipe each

component with oil. Lightly oil all threads and make sure

exhaust holes on the body of the BOSS are free of

obstructions.

4. Reassemble your BOSS by screwing on the micro-

adjustable locknut then the BOSS body. After taking

apart the BOSS it will be necessary to reset the sweet

spot and it may be necessary to recalibrate the BOSS.

MAKE CERTAIN ALL CLEANING PATCHES

ARE REMOVED FROM THE BARREL AND

EXHAUST HOLES IN THE BODY OF THE BOSS

BEFORE FIRING YOUR RIFLE.

5. When firing for extreme accuracy, after cleaning the

bore it is recommended two fouling shots be fired before

shooting for accuracy. Additionally, it is recommended

the rifle be allowed to cool every three rounds.

REMINDER

If your Sweet Spot listing card is missing from this man-

ual, or if your caliber is not listed, call U.S. Repeating

Arms Company for information: 1-800-7820-4440.

KP950334-94525A

9

You Are Responsible For Firearms Safety

As a gun owner, you accept a set of demanding responsibilities. How seriously you take these

responsibilities can mean the difference between life and death. Failure to follow any of these

instructions can cause extensive damage to your gun and/or possible serious injury or death to

yourself and others. There is no excuse for careless or abusive handling of any firearm. At all

times handle any firearm with intense respect for its power and potential danger.

PLEASE READ AND UNDERSTAND ALL OF THE CAUTIONS, PROPER HANDLING PROCEDURES

AND INSTRUCTIONS OUTLINED IN THE OWNERS MANUAL BEFORE USING YOUR NEW

FIREARM.

1. ALWAYS KEEP THE MUZZLE OF YOUR RIFLE POINTED IN A SAFE DIRECTION, even

though you are certain that the rifle is unloaded. Never point any firearm at anything you

do not intend to shoot. Be extremely alert and aware of all persons and property within

the range of your ammunition.

2. NEVER RELY TOTALLY ON YOUR RIFLE'S MECHANICAL " SAFETY" DEVICE. The word

"safety" describes a gun's trigger block mechanism, sear block mechanism, hammer

block mechanism or firing pin block mechanism. These mechanical devices are designed

to place your gun in a SAFER status. No guarantee can be made that the gun will not fire

even if the "safety" is in the "on safe" position. See "Operations of the Safety" for

instructions on operation of YOUR gun's "safety."

LIKE ANY MECHANICAL DEVICE, A " SAFETY" CAN SOMETIMES FAIL; IT CAN BE

JARRED OR INADVERTENTLY MANIPULATED INTO AN UNSAFE CONDITION.

Mechanical "safeties" merely aid safe gun handling and are no excuse for pointing your

rifle's muzzle in an unsafe direction.

While it is a good idea to "test" your rifle's mechanical "safeties" periodically for proper

function, NEVER TEST IT WHILE YOUR RIFLE IS LOADED OR POINTED IN AN UNSAFE

DIRECTION

Safe gun handling does not stop with your gun's mechanical "safety devices -- it starts

there. Always treat your rifle with the respect due a loaded, ready-to-fire firearm.

3. WHENEVER YOU HANDLE A FIREARM, OR HAND IT TO SOMEONE, ALWAYS OPEN THE

ACTION IMMEDIATELY, VISUALLY CHECK YOUR RIFLE'S CHAMBER, FEED MECHANISM

AND MAGAZINE.

Make certain they do not inadvertently contain any ammunition. Always keep the

chamber empty and "safety" in the "on safe" position unless shooting is imminent.

4. DO NOT TRANSPORT YOUR RIFLE LOADED, WHETHER IN A SCABBARD, GUN CASE, OR

OTHER CONTAINER.

5. HUNTING FROM ELEVATED SURFACES SUCH AS TREE STANDS IS DANGEROUS, and

may increase the risk of handling a firearm. The following rules should always be

observed by you and those you hunt with: Always make certain that the stand being used

is safe and stable. Always make certain that your firearm is unloaded when it is being

taken up to and down from the stand. Always make certain that your firearm is not

dropped from the stand, or dropped while it is being taken up to or down from the stand.

Remember, a loaded firearm may discharge when dropped, even with the safety in the

"on safe" position.

6. BEWARE OF BARREL OBSTRUCTIONS, for the safety of both your gun and yourself.

Mud, snow, and an infinite variety of other obstructions may inadvertently lodge in a

barrel bore. It takes only one small obstruction to cause dangerously increased pressures

that can ruin (swell or rupture) the finest rifle barrels.

BEFORE CHECKING FOR A BARREL OBSTRUCTION, BE CERTAIN NO LIVE ROUND IS IN

THE CHAMBER AND THAT THE MAGAZINE IS REMOVED AND FEED MECHANISMS ARE

COMPLETELY EMPTY. PLACE THE " SAFETY" IN THE " ON SAFE" POSITION.

Look through the barrel to be sure it is clear of any obstruction. If an obstruction is seen,

no matter how small it may be, clean the bore with a cleaning rod and patch as described

in "Cleaning and Maintenance Suggestions." Before the first firing, clean the bore

with a cleaning rod and patch, and wipe away any anti-rust compound in the

action/chamber areas.

7. ALWAYS UNLOAD YOUR RIFLE WHEN NOT IN USE. REFER TO " UNLOADING THE RIFLE"

FOR AN EXPLANATION OF HOW TO UNLOAD YOUR RIFLE PROPERLY.

As a safety precaution, it is preferable to disassemble your gun for storage. Store your

gun and ammunition separately -- well beyond the reach of children. Take all safeguards

to ensure your rifle does not become available to untrained, inexperienced or unwelcome

hands.

8. USE THE PROPER AMMUNITION.

The barrel and action of this rifle have been made with substantial safety margins over

the pressures developed by established American commercial loads. Nevertheless,

Browning assumes no liability for incidents which occur through the use of cartridges of

nonstandard dimensions which develop pressures in excess of commercially available

ammunition with standards established by the Sporting Arms and Ammunitions

Manufacturers' Institute (SAAMI).

BE ALERT TO THE SIGNS OF AMMUNITION MALFUNCTION.

If you detect an off sound or light recoil when a cartridge s fired, DO NOT LOAD

ANOTHER CARTRIDGE INTO THE CHAMBER. Open the action and remove all cartridges

from the magazine, chamber and action areas. With the action open, glance down the

barrel to make sure that an obstruction does not remain in the barrel. If there is an

obstruction, completely clear the barrel before loading and firing again. Failure to follow

these instructions can cause extensive damage to your gun and possible serious injury to

yourself and others.

MAKE SURE OF ADEQUATE VENTILATION IN THE AREA THAT YOU DISCHARGE A

FIREARM. WASH HANDS THOROUGHLY AFTER EXPOSURE TO AMMUNITION OR

CLEANING A FIREARM.

Lead exposure can be obtained from discharging firearms in poorly ventilated areas,

cleaning firearms or handling ammunition. Lead is a substance that has been known to

cause birth defects, reproductive harm and other serious injury.

9. DO NOT SNAP THE FIRING PIN ON AN EMPTY CHAMBER -- THE CHAMBER MAY NOT BE

EMPTY!

Treat every gun with the respect due a loaded gun, even though you are certain the gun is

unloaded.

10. KEEP FINGERS AWAY FROM THE TRIGGER WHILE UNLOADING, LOADING, UNTIL YOU

ARE READY TO SHOOT.

11. BE SURE OF YOUR TARGET AND BACKSTOP.

Particularly during low light periods. Know the range of your ammunition. Never shoot

at water or hard object.

12. ALWAYS UNLOAD YOUR RIFLE'S CHAMBER BEFORE CROSSING A FENCE, CLIMBING A

TREE, JUMPING A DITCH OR NEGOTIATING OTHER OBSTACLES.

Refer to "Unloading The Rifle" for instructions on the unloading of your rifle. Never

place your loaded rifle on or against a fence, tree, car or other similar object.

13. WEAR EYE AND EAR PROTECTION WHEN SHOOTING.

Unprotected, repeated exposure to gunfire can cause hearing damage. Wear ear protectors

(shooting ear plugs or muffs) to guard against such damage. Wear shooting glasses to

protect your eyes from flying particles. Allow proper distance (eye relief) between the

scope and your eye when firing a scoped rifle or shotgun. Always keep a safe distance

between the muzzle of your firearm and any persons nearby, as muzzle blast, debris and

ejecting shells could inflict serious injury. Also, wear eye protection when disassembling

and cleaning your shotgun to prevent the possibility of springs, spring-tensioned parts,

solvent or other agents from contacting your eyes.

14. DROPPING A LOADED GUN CAN CAUSE AN ACCIDENTAL DISCHARGE even with the

"safety" in the "on safe" position. Be extremely careful while hunting or during any

shooting activity, to avoid dropping any firearm.

15. IF YOUR RIFLE FAILS TO FIRE, KEEP THE MUZZLE POINTED IN A SAFE DIRECTION.

Hold this position for a minimum of 30 seconds. Carefully open the action and remove

the cartridge. If the primer is indented, the cartridge should be disposed of in a way that

cannot cause harm. If the primer is not indented, your firearm should be examined by a

qualified gunsmith and the cause of the malfunction should be corrected before further

use.

16. BE DEFENSIVE AND ON GUARD AGAINST UNSAFE GUN HANDLING AROUND YOU AND

OTHERS.

Don't be timid when it comes to gun safety. If you observe other shooters violating any of

these safety precautions, politely suggest safer handling practices.

17. BE CERTAIN YOUR RIFLE IS UNLOADED BEFORE CLEANING. Because so many gun

accidents occur when a firearm is being cleaned, special and extreme care should be

taken to be sure your gun is unloaded before disassembly, cleaning and reassembly. Keep

ammunition away from the cleaning location. Never test the mechanical function of any

firearm with live ammunition.

18. TEACH AND SUPERVISE FIREARMS SAFETY TO ALL MEMBERS OF YOUR FAMILY --

ESPECIALLY TO CHILDREN AND NONSHOOTERS.

Closely supervise newcomers to the shooting sports. Encourage enrolling in

hunting/shooting safety courses.

19. NEVER DRINK ALCOHOLIC BEVERAGES OR TAKE ANY TYPE OF DRUGS BEFORE OR

DURING SHOOTING.

Your vision and judgment could be dangerously impaired, making your gun handling

unsafe to you and to others.

20. READ AND HEED ALL WARNINGS in this instruction book, on ammunition boxes and

with all accessories that you install on your firearm. It is your responsibility to secure the

most up-to-date information on the safe handling procedures of your Browning gun.

Browning assumes no liability for incidents which occur when unsafe or improper gun

accessories or ammunition combinations are used.

21. PERIODIC MAINTENANCE -- AVOID UNAUTHORIZED SERVICING.

Your rifle is a mechanical device which will not last forever, and as such, is subject to

wear and requires periodic inspection, adjustment and service. Browning firearms should

be serviced by a Browning Recommended Service Center or by Browning's service

facility in Arnold, Missouri. Browning cannot assume any responsibility for injuries

suffered or caused by unauthorized servicing, alterations or modifications of Browning

firearms.

22. BROWNING RESERVES THE RIGHT TO REFUSE SERVICE ON FIREARMS THAT HAVE

BEEN ALTERED, ADDED TO OR SUBSTANTIALLY CHANGED.

Removal of metal from barrel(s), or modification of the firing mechanism and/or

operating parts may lead to Browning's refusal of service on such firearms. Browning

will charge the owner parts and labor to return the firearm to original Browning

specifications.

DO NOT, UNDER ANY CIRCUMSTANCES, ALTER THE TRIGGER, SAFETY OR PARTS OF

THE FIRING MECHANISM OF THIS OR ANY OTHER FIREARM. FAILURE TO OBEY THIS

WARNING MAY RESULT IN INJURY OR DEATH TO YOURSELF OR OTHERS.

BE CAREFUL!

You might also like

- 08 Compound ManualDocument14 pages08 Compound ManualjrockwaterNo ratings yet

- Compound Bow Owner's Manual GuideDocument26 pagesCompound Bow Owner's Manual Guidejohn powers100% (1)

- 2019 Owner's Manual: Members of The ATA 2200 Stringtown Rd. Evansville, IN 47711 800 - 694 - 9494 - Fax 812 - 467 - 1245Document28 pages2019 Owner's Manual: Members of The ATA 2200 Stringtown Rd. Evansville, IN 47711 800 - 694 - 9494 - Fax 812 - 467 - 1245JomiltonNo ratings yet

- Millett Long Range Scope (Lrs-1) Instructions and Operation ManualDocument24 pagesMillett Long Range Scope (Lrs-1) Instructions and Operation ManualMiguel Angel Jimenez BlandinoNo ratings yet

- 2020 Prime Black Manual Converted 1Document8 pages2020 Prime Black Manual Converted 1Fadriadi Syam100% (1)

- Manual Bear 2012Document36 pagesManual Bear 2012Diego RocabadoNo ratings yet

- 09 Browning Archery Users GuideDocument12 pages09 Browning Archery Users Guideendara123456aNo ratings yet

- Olympic Arms AR-15 ManualDocument26 pagesOlympic Arms AR-15 ManualCurt BriscarNo ratings yet

- Lock N Load Headspace Comparator Kit Instructions1674495305Document2 pagesLock N Load Headspace Comparator Kit Instructions1674495305mfp3011No ratings yet

- 2011 Martin Compound ManualDocument21 pages2011 Martin Compound ManualDamiano MastroiacoNo ratings yet

- Browning A-5 (Auto-5) Shotgun ManualDocument25 pagesBrowning A-5 (Auto-5) Shotgun Manualrn0982No ratings yet

- Barrett Firearms - REC10 - Operators Manual 8.5x5.5 ALL REVB 17278Document22 pagesBarrett Firearms - REC10 - Operators Manual 8.5x5.5 ALL REVB 17278Ricardo C TorresNo ratings yet

- 2014 Bear Adult Bow ManualDocument40 pages2014 Bear Adult Bow Manualjohn0% (1)

- Barrel Conversion Kit: Operator InstructionsDocument10 pagesBarrel Conversion Kit: Operator Instructionsmikeabramson316No ratings yet

- Winchester Super x2 Sporting Shotgun SupplementDocument8 pagesWinchester Super x2 Sporting Shotgun Supplementcarlosfanjul1No ratings yet

- Winchester Model 70 Bolt Action Rifle Owner's Manual: LicenseeDocument0 pagesWinchester Model 70 Bolt Action Rifle Owner's Manual: Licenseecarlosfanjul1No ratings yet

- Piston Instrc2618Document2 pagesPiston Instrc2618Oliver TonnaNo ratings yet

- HOYT 2012 Compound Bow User ManualDocument16 pagesHOYT 2012 Compound Bow User ManualSofiaProtopsaltiNo ratings yet

- Riflescope Instruction ManualDocument14 pagesRiflescope Instruction ManualAwal PanallNo ratings yet

- Sotic Rifle ManualDocument11 pagesSotic Rifle ManualRhavi Dwi HamintokoNo ratings yet

- 2012 Winchester Repeatingarms CatalogDocument56 pages2012 Winchester Repeatingarms Catalogtyrant88No ratings yet

- 04-Coupling 304 Motor-Gear PDFDocument12 pages04-Coupling 304 Motor-Gear PDFManuel Díaz VilloutaNo ratings yet

- Catalogue: Guns For GenerationsDocument38 pagesCatalogue: Guns For GenerationsRidha AbbassiNo ratings yet

- Crosmanm 1Document21 pagesCrosmanm 1resister100% (1)

- BFG 50 ManualDocument2 pagesBFG 50 ManualMisaelJordiJermiaNo ratings yet

- Manual FXRevolutionDocument12 pagesManual FXRevolutionArne-Christer SteenNo ratings yet

- Colt Scope 3x - 4x (M16 and AR15)Document4 pagesColt Scope 3x - 4x (M16 and AR15)Vincenzo100% (3)

- 2001 Martin Compound Bow ManualDocument24 pages2001 Martin Compound Bow Manualjohn100% (1)

- Rifle Scope Owners Manual SFP 2017Document40 pagesRifle Scope Owners Manual SFP 2017scorpyon40No ratings yet

- Manual - BSA - MeteorDocument11 pagesManual - BSA - Meteorlinpok50% (2)

- CZ Usa 2016 Product CatalogDocument73 pagesCZ Usa 2016 Product Catalogstjohn45100% (2)

- Guide to Setting Up Your Hoyt Recurve BowDocument20 pagesGuide to Setting Up Your Hoyt Recurve BowCharlie VanTasselNo ratings yet

- BA STEYR EVO 10 enDocument26 pagesBA STEYR EVO 10 enAnwar AnwarNo ratings yet

- Bix'n Andy Trigger Installation & Care InstructionsDocument8 pagesBix'n Andy Trigger Installation & Care Instructionsrob256789No ratings yet

- BannerRiflescopes 1LIM Revb1013 WebDocument20 pagesBannerRiflescopes 1LIM Revb1013 WebMaria Fernanda Velasco DuffyNo ratings yet

- 2014BearAdultBowManual PDFDocument40 pages2014BearAdultBowManual PDFEdgars MurnieksNo ratings yet

- 1-6x FFP User ManualDocument20 pages1-6x FFP User ManualRaymon Kennedy OrtizNo ratings yet

- PWS Manual 3.2.21 1Document12 pagesPWS Manual 3.2.21 1thomaschevalier.cgNo ratings yet

- Certified': Rule 3 - Equipment Rule 3 - EquipmentDocument4 pagesCertified': Rule 3 - Equipment Rule 3 - EquipmentAl BareNo ratings yet

- Tuned 1911 Trigger Job GuideDocument4 pagesTuned 1911 Trigger Job GuideDustin Gray100% (1)

- Hoyt Manual - 2013Document36 pagesHoyt Manual - 2013JohnNo ratings yet

- Posp 4x24 Pso-1 Rifle Scopes Instruction ManualDocument4 pagesPosp 4x24 Pso-1 Rifle Scopes Instruction ManualPlainNormalGuy2100% (1)

- Thank You For Choosing Pse!: Compound Bow User's GuideDocument44 pagesThank You For Choosing Pse!: Compound Bow User's GuideNanang Jaka Perdana0% (1)

- c147f30cf75ce501f899ce13a377fd3bDocument44 pagesc147f30cf75ce501f899ce13a377fd3bCălin Adrian PerțeNo ratings yet

- How To Drill A Rifle BarrelDocument6 pagesHow To Drill A Rifle BarrelMaria Donoghue50% (2)

- BA STEYR EVO 10 en PDFDocument26 pagesBA STEYR EVO 10 en PDFAnwar Anwar100% (1)

- Laser Bore Sighter Instruction Manual 74-0100Document40 pagesLaser Bore Sighter Instruction Manual 74-0100Isidro CMNo ratings yet

- Web ManualDocument54 pagesWeb ManualfethiaktuncNo ratings yet

- Riflescope: Instruction ManualDocument60 pagesRiflescope: Instruction ManualHassan ObaidNo ratings yet

- Xtreme Bullets Reloading ManualDocument48 pagesXtreme Bullets Reloading ManualdanielNo ratings yet

- Thompson Center Arms Product Catalog 2013Document56 pagesThompson Center Arms Product Catalog 2013Smith & WessonNo ratings yet

- Winchester Model 70 Bolt Action Rifle Owner's Manual: LicenseeDocument32 pagesWinchester Model 70 Bolt Action Rifle Owner's Manual: Licenseehelsfjord100% (1)

- Jaguar Take-Down Owners Manual: If You Have Additional Questions Please Call Customer Service at 509-529-2554Document4 pagesJaguar Take-Down Owners Manual: If You Have Additional Questions Please Call Customer Service at 509-529-2554bb1966100% (1)

- Headspace GuideDocument7 pagesHeadspace Guideusn212100% (2)

- Hoyt 2002 Recurve ManualDocument21 pagesHoyt 2002 Recurve Manualsneeze.ninjaNo ratings yet

- How To Build A Suppressor: Stability CalculatorDocument4 pagesHow To Build A Suppressor: Stability CalculatorHoscoFoods75% (4)

- Building a Home Defense Remington 870 ShotgunFrom EverandBuilding a Home Defense Remington 870 ShotgunRating: 3.5 out of 5 stars3.5/5 (5)

- Gun Digest Book of Tactical Weapons Assembly/Disassembly, 3rd Ed.From EverandGun Digest Book of Tactical Weapons Assembly/Disassembly, 3rd Ed.Rating: 4.5 out of 5 stars4.5/5 (2)

- Winchester Wildcat Bolt-Action Rifle Owner's ManualDocument24 pagesWinchester Wildcat Bolt-Action Rifle Owner's Manualcarlosfanjul1No ratings yet

- Walther Pricelist 1938Document9 pagesWalther Pricelist 1938carlosfanjul1No ratings yet

- Winchester Model 63 22 Caliber Bolt Action RifleDocument0 pagesWinchester Model 63 22 Caliber Bolt Action Riflecarlosfanjul1No ratings yet

- Winchester Super x2 Sporting Shotgun SupplementDocument8 pagesWinchester Super x2 Sporting Shotgun Supplementcarlosfanjul1No ratings yet

- Winchester Super X™ Rifle Autoloader Owner's ManualDocument28 pagesWinchester Super X™ Rifle Autoloader Owner's Manualcarlosfanjul1No ratings yet

- Winchester Supreme Over/Under Shotgun Owner's Manual: LicenseeDocument0 pagesWinchester Supreme Over/Under Shotgun Owner's Manual: Licenseecarlosfanjul1No ratings yet

- Winchester Sx-Ar™ Autoloading Rifle Owner's ManualDocument32 pagesWinchester Sx-Ar™ Autoloading Rifle Owner's Manualcarlosfanjul1No ratings yet

- Winchester Super X Pump, Pump-Action Shotgun Owner's ManualDocument36 pagesWinchester Super X Pump, Pump-Action Shotgun Owner's Manualcarlosfanjul1No ratings yet

- Winchester Model 9422 Lever Action Rifle Owner's Manual: LicenseeDocument0 pagesWinchester Model 9422 Lever Action Rifle Owner's Manual: Licenseecarlosfanjul1No ratings yet

- Winchester Super x2 Practical ShotgunDocument4 pagesWinchester Super x2 Practical Shotguncarlosfanjul1No ratings yet

- Winchester Super X2 Semi-Automatic Shotgun Owner's Manual: LicenseeDocument0 pagesWinchester Super X2 Semi-Automatic Shotgun Owner's Manual: Licenseecarlosfanjul1No ratings yet

- Winchester Select Over and Under Shotgun Owner's ManualDocument34 pagesWinchester Select Over and Under Shotgun Owner's Manualcarlosfanjul1No ratings yet

- Winchester Super x2 Practical SupplementDocument0 pagesWinchester Super x2 Practical Supplementcarlosfanjul1No ratings yet

- Winchester Super X 3 12 and 20 Gauge Autoloading Shotgun Owner's ManualDocument44 pagesWinchester Super X 3 12 and 20 Gauge Autoloading Shotgun Owner's Manualcarlosfanjul1No ratings yet

- Winchester Model 9422 & Model 9417 Rimfire Lever Action Rifle Owner's ManualDocument0 pagesWinchester Model 9422 & Model 9417 Rimfire Lever Action Rifle Owner's Manualcarlosfanjul1No ratings yet

- Winchester Model 9410 Lever Action Shotgun Owner's Manual - Top-Tang Safety VersionDocument0 pagesWinchester Model 9410 Lever Action Shotgun Owner's Manual - Top-Tang Safety Versioncarlosfanjul1No ratings yet

- Winchester Model 1885 Rimfire - Om - SDocument0 pagesWinchester Model 1885 Rimfire - Om - Scarlosfanjul1No ratings yet

- Winchester Model 1895 Lever Action Rifle Owner's Owner's ManualDocument0 pagesWinchester Model 1895 Lever Action Rifle Owner's Owner's Manualcarlosfanjul1No ratings yet

- Winch Ester Model 1895 Rifle Takedown SupplementDocument15 pagesWinch Ester Model 1895 Rifle Takedown SupplementJohn CiganekNo ratings yet

- Winchester Model 1895 Lever Action Rifle Owner's Owner's ManualDocument0 pagesWinchester Model 1895 Lever Action Rifle Owner's Owner's Manualcarlosfanjul1No ratings yet

- Winchester Model 1400 - 1500 XTR With Winchoke, RangerDocument0 pagesWinchester Model 1400 - 1500 XTR With Winchoke, Rangercarlosfanjul1No ratings yet

- Winchester Model 1892Document24 pagesWinchester Model 1892carlosfanjul1100% (1)

- Winchester Model 1886 Takedown Lever Action RifleDocument0 pagesWinchester Model 1886 Takedown Lever Action Riflecarlosfanjul1No ratings yet

- 9410 Ownersmanual Om SDocument0 pages9410 Ownersmanual Om STorentSpyNo ratings yet

- Winchester Model 1894 Rifle Owner's ManualDocument36 pagesWinchester Model 1894 Rifle Owner's Manualcarlosfanjul10% (1)

- Winchester Model 1885Document0 pagesWinchester Model 1885carlosfanjul1No ratings yet

- Winchester Model 1885 2Document13 pagesWinchester Model 1885 2carlosfanjul1No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Winchester Model 1886 Lever Action RifleDocument0 pagesWinchester Model 1886 Lever Action Riflecarlosfanjul1No ratings yet

- Winchester Model 1885 CarbineDocument12 pagesWinchester Model 1885 Carbinecarlosfanjul1No ratings yet

- Reid 618hr Ins Man Part ListDocument20 pagesReid 618hr Ins Man Part ListzuhzuhzuhNo ratings yet

- RUELCO - Diff Pressure SwitchDocument2 pagesRUELCO - Diff Pressure SwitchAiman Hilmi Aiman HilmiNo ratings yet

- Distribuidores de Perfumes Originales al Por MayorDocument97 pagesDistribuidores de Perfumes Originales al Por MayorChristian Arias VeraNo ratings yet

- JUCivil91Reunion2016 Magazine PDFDocument65 pagesJUCivil91Reunion2016 Magazine PDFArup RoyNo ratings yet

- TK Fuel EXe ServiceManual MY23 en-US Rev1 2022-07-14Document19 pagesTK Fuel EXe ServiceManual MY23 en-US Rev1 2022-07-14MartinNo ratings yet

- 20 Guitar Lessons PDFDocument18 pages20 Guitar Lessons PDFNikko Rafael Nobleza100% (8)

- Clinical Data Fisiotek HP2Document28 pagesClinical Data Fisiotek HP2Alexandra NadinneNo ratings yet

- Motorcycle Mechanics General Manual PDFDocument270 pagesMotorcycle Mechanics General Manual PDFkillfreely83% (47)

- Xray t2r Pro Asphalt Rubber Spec Basic Setup SheetDocument1 pageXray t2r Pro Asphalt Rubber Spec Basic Setup Sheeteric hipolNo ratings yet

- Lesson 7: Do You Like Tennis?Document3 pagesLesson 7: Do You Like Tennis?Georgina Martinez PaniaguaNo ratings yet

- Braxton Gamett 1Document3 pagesBraxton Gamett 1api-704363594No ratings yet

- Kill Team Part2Document4 pagesKill Team Part2raegmachine100% (2)

- Allison M6610&S6610 Series PDFDocument2 pagesAllison M6610&S6610 Series PDFluisedonossaNo ratings yet

- Kavikulaguru Kalidas Sanskrit University Diploma in Vastushastra SyllabusDocument8 pagesKavikulaguru Kalidas Sanskrit University Diploma in Vastushastra SyllabusmadforudayNo ratings yet

- 2010 F1 European Grand Prix TimetableDocument2 pages2010 F1 European Grand Prix Timetableboribon1227No ratings yet

- Overhead Squat and Balance Tests ResultsDocument4 pagesOverhead Squat and Balance Tests ResultsJoseph Patrick OcapanNo ratings yet

- ANZ NetSetGO! Coaching Resource-RUNDocument34 pagesANZ NetSetGO! Coaching Resource-RUNberneNo ratings yet

- Current Affairs December 2021 PDFDocument15 pagesCurrent Affairs December 2021 PDFRAJAKUMAR R (R.K.R)No ratings yet

- MembersListVIIthAssembly 3Document1 pageMembersListVIIthAssembly 3lakshayNo ratings yet

- Online Sports Betting Nigeria & Live Betting Odds at SportyBetDocument1 pageOnline Sports Betting Nigeria & Live Betting Odds at SportyBetOlumide BamideleNo ratings yet

- BMW x1Document8 pagesBMW x1zeffrey_49736No ratings yet

- Summative Test Dressmaking 9 Q4 W5-6Document3 pagesSummative Test Dressmaking 9 Q4 W5-6Irish Jane TabelismaNo ratings yet

- Kalinga Racers SMAE-SKDC Cost ReportDocument3 pagesKalinga Racers SMAE-SKDC Cost Reportanon_276464684No ratings yet

- Plaid and SimpleDocument2 pagesPlaid and SimpleMiguel Paolo CelestialNo ratings yet

- Perfumes Dama PH PERFUMESDocument3 pagesPerfumes Dama PH PERFUMESAngel Ramses BasilioNo ratings yet

- Td42 Engine Manual: Read/DownloadDocument2 pagesTd42 Engine Manual: Read/DownloadЭ. Мөнх-оргил33% (3)

- Lansink Appraisals 1Document1 pageLansink Appraisals 1Tayyaba YounasNo ratings yet

- Monkey D. Luffy Crochet PatternDocument7 pagesMonkey D. Luffy Crochet PatternJeffryNo ratings yet

- Relaxing at CamarilloDocument6 pagesRelaxing at CamarilloMichaelBrandonScott_No ratings yet

- Technoledge: Infotech Pvt. LTDDocument2 pagesTechnoledge: Infotech Pvt. LTDanandhugsNo ratings yet