Professional Documents

Culture Documents

500KW Final Technical Specification R4

Uploaded by

Osama IbrahimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

500KW Final Technical Specification R4

Uploaded by

Osama IbrahimCopyright:

Available Formats

OUR REFERENCE : 12-0166 M PW R4

TECHNICAL SPECIFICATION

QUANTITY 3 - MAIN GENERATING SETS

G&M Model having a Prime Power output of 625KVA/500KW,380volt, 3phase,50hz,1500rpm comprising MAN D2842LE301 Heat Exchanger cooled marine engine close coupled to a STAMFORD HCM 634G single bearing Marine AC alternator.

d-SMART500MAN

ENGINE TECHNICAL DATA Number of cylinder Cylinder arrangement Cycle Induction system Cooling system 12 Vee Formed 4-stroke Turbocharged/Intercooled Heat exchanger cooling

Cooling System Heat Exchanger cooled Sea Water pump Thermostatically controlled cooling system Expansion Tank Fresh water pump Low coolant level sensor Governor and Fuel System Electronic speed governor to ISO 8528 G3 Duel Skinned Fuel piping with leak monitor Fuel inlet connection Fuel return connection Fuel shutoff valve - 24Volt - energise to run Duplex fuel filter Intake and Exhaust System Water cooled exhaust manifold Water cooled turbocharger Dry exhaust outlet Stainless Steel exhaust bellows Spark Arrestor exhaust silencer Dry air cleaner Lubricating System Flat bottomed cast iron sump Closed engine breather Lub oil cooler Duplex oil filter Sump pump

Primary Starting 24volt/ 6.6kw starting motor 28volt/55amp charge alternator Electric start from ship supplied 24v DC supply Gauge senders for the following comprising of Oil Pressure WaterTemperature Switches comprising of Lubricating low oil pressure. High water temperature. Engine supplied with Lloyds certificate Engine supplied with EIAPP certificate

ALTERNATOR TECHNICAL DATA Stamford HCM 634G Single bearing AC brushless, self-exciting, self-regulating, synchronous, air cooled alternator. Automatic Voltage Regulator giving regulation within +1% Drip proof and screen protected to IP 23 Class 'H' insulation with Class 'F' temperature rise The alternator will accept an overload of 110% for 1 hour in any 12 hour period and 150% for 30seconds after reaching stable temperature. Alternator complete with : Anti-condensation heater Quadrature droop kit Thermistor probes (Alarm/Shutdown) Alternator supplied with Lloyds certificate

GENERATING SET BASEFRAME/ANTI-VIBRATION MOUNTS The engine / alternator will be close coupled via a single bearing disc coupling and mounted onto a steel base rails incorporating a drip tray. Marine grade spring type anti-vibration mounts for fitting to the underside of the baseframe.

FACTORY TEST Full testing will be carried out at 25%, 50%, 75% 100% and 110 % load and all alarm and shutdown systems will be functionally checked in the presence of a Lloyds Surveyor. The complete generating set will be supplied with the appropriate Lloyds Certificate.

The generating set will be painted in a Paint System with a Top Coat to RAL 9016.

CONTROL PANEL A G&M d-SMART control panel will be mounted on the generating set. The standard functions on the G&M d-SMART Full Class Marine control panel are : The full class control system is housed in a painted mild steel IP65 enclosure with hinged door or lid. Mounting is either (horizontal) alternator top mounting (via rubber A/V mounts) or remote (vertical) wall mounting to suit customer specific requirements. The full class control system is managed by a microprocessor controller c/w backlit LCD operator interface and control pushbuttons. The controller handles operational control, alarms and shutdowns for the generator set. From the local control panel the following functions are available on the microprocessor controller: o Start generator. o Stop generator. o Mode select. o Horn/fault reset. o Full interrogation of the controller menus on the LCD interface. Additionally to the microprocessor controller the control panel facia includes the following: o Emergency stop pushbutton with shroud. o Local/remote access key switch. o 80dBa @ 0.1m audible alarm sounder.

Shutdown Events: Digital input for low lubricating oil pressure (not on emergency sets). Digital input for high coolant temperature (not on emergency sets). Digital input for emergency stop. Mag Pickup Input for overspeed & underspeed shutdown. Any other user configured shutdown inputs. Any shutdown event will activate the common shutdown telemetry V.F.C.

Alarms: Battery volts out of limits. Start failure. Stop failure. Pick-up failure. Analogue input monitoring for low lubricating oil pressure. Analogue input monitoring for high lubricating oil temperature. Analogue input monitoring for low coolant pressure. Analogue input monitoring for high coolant temperature. Any other user configured alarm inputs. Any alarm event will activate the common alarm telemetry V.F.C.

Analogue Data Displayed on Controller LCD: Engine R.P.M. viewable via LCD graphic gauge with value text. All configured hardwired analogue inputs viewable via bar graph indicators with value text. Analogue information from the engine ECM viewable via bar graph indicators with value text. Battery volts viewable via bar graph indicators with value text.

Statistics Displayed On Controller LCD: Hours Run. Number of successful starts. Number of un-successful starts. Time remaining to service requirement.

Miscellaneous Information Displayed on Controller LCD: Digital I/O points status (input/output channel on/off status). Alarm Lists. Engine Basic Settings / Alarm Parameters.

Telemetry Signals (Volt Free Changeover Contacts): Common Shutdown. Common Alarm. Emergency Stop Activated (Shutdown). Remote Klaxon / Common Alarm 2. Engine Running. Ready For Remote Start. DC Supply Failure.

Engine ECM Canbus (J1939): Optional canbus connection (J1939) for communication to engine ECM.

Remote Operation & Monitoring: Digital inputs for remote start, remote stop, & remote acknowledge. Remote signals should be pulsed (1 Second Minimum) N/O volt free contacts. Digital input for remote emergency stop, signal should be held N/C healthy, open to stop volt free contact. Optional Modbus connection via RS232 (max 10m) for remote control and system monitoring of the d-SMART control system. Note: The range can be extended to 1000m by the use of an optional RS232 to RS485 converter. G&M will provide Modbus registers, Modbus manual section and the contact details of the controller manufacturer technical support line to assist in the Modbus integration with clients monitoring system

DOCUMENTATION Generating Set Supplied with Quantity 3 Hard Copies of the following documentation packs: Operators / Maintenance Manual Spare Parts Manual Schematic/Wiring Diagrams Certificate of Origin MAN Engine Inspection Certificate endorsed by Lloyds Stamford Alternator Inspection Certificate endorsed by Lloyds Factory Load Test Certificate Certificate endorsed by Lloyds Torsional Vibration Calculation endorsed by Lloyds EIAPP Certificate inclusive of MARPOL ANNEX VI TIER II endorsed by Lloyds Warranty Certificate detailing warranty 18 months from date of despatch or 12 months from date of commissioning, whichever is the sooner.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Solutions Manual Continuum Mechanics Lai 4th EdittionDocument246 pagesSolutions Manual Continuum Mechanics Lai 4th Edittiondiego_dave89% (18)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Part # Is 0032192-70: Eldorado Eldorado Eldorado Eldorado National National National NationalDocument1 pagePart # Is 0032192-70: Eldorado Eldorado Eldorado Eldorado National National National NationalmnvijaybabuNo ratings yet

- Density Variation in Finite Volume SchemesDocument5 pagesDensity Variation in Finite Volume Schemeshhqq2010No ratings yet

- NASA ERAST Program Develops High-Altitude UAVsDocument17 pagesNASA ERAST Program Develops High-Altitude UAVsEgz AguilarNo ratings yet

- Product DataDocument8 pagesProduct DataOsama IbrahimNo ratings yet

- Indicial NotationsDocument6 pagesIndicial NotationsOsama IbrahimNo ratings yet

- B.Yousefzedah EuroNoise ASTM-E-2611-17 STL Using Two Loads MethodDocument4 pagesB.Yousefzedah EuroNoise ASTM-E-2611-17 STL Using Two Loads MethodOsama IbrahimNo ratings yet

- Product DataDocument8 pagesProduct DataOsama IbrahimNo ratings yet

- Numerical solution of buoyancy-driven laminar and turbulent flowsDocument76 pagesNumerical solution of buoyancy-driven laminar and turbulent flowsOsama IbrahimNo ratings yet

- Bruce Irons Revolutionized FEMDocument16 pagesBruce Irons Revolutionized FEMasd123456789asdcomNo ratings yet

- MOOCSDocument2 pagesMOOCSOsama IbrahimNo ratings yet

- 03 CFD NotesDocument155 pages03 CFD NotesOsama IbrahimNo ratings yet

- Numerical solution of buoyancy-driven laminar and turbulent flowsDocument76 pagesNumerical solution of buoyancy-driven laminar and turbulent flowsOsama IbrahimNo ratings yet

- Chapter 5 - Numerical Methods in Heat ConductionDocument1 pageChapter 5 - Numerical Methods in Heat ConductionOsama IbrahimNo ratings yet

- The SIMPLE Algorithm For Pressure-Velocity Coupling: ME 448/548 NotesDocument26 pagesThe SIMPLE Algorithm For Pressure-Velocity Coupling: ME 448/548 Noteskassu303No ratings yet

- 2000 - Enhancing Forced Convection Heat Transfer From Multiple Protruding HeatDocument7 pages2000 - Enhancing Forced Convection Heat Transfer From Multiple Protruding HeatOsama IbrahimNo ratings yet

- Vismat Material V-Ray For SketchupDocument19 pagesVismat Material V-Ray For SketchupAmer GonzalesNo ratings yet

- Presentation FileDocument10 pagesPresentation FileInnoVentureCommunityNo ratings yet

- HP w2007 w2007v SMDocument75 pagesHP w2007 w2007v SMfeliNo ratings yet

- Solution of EX2 Measurement of Liquid Electric C OnductivityDocument4 pagesSolution of EX2 Measurement of Liquid Electric C OnductivityArifiantoNo ratings yet

- 59-Form and Plot Frame Editor PDFDocument70 pages59-Form and Plot Frame Editor PDFAries TsaiNo ratings yet

- FD FX Brochure Update 072020Document9 pagesFD FX Brochure Update 072020Alex PomaNo ratings yet

- UDR MANUFACTURE ManufacturesDocument8 pagesUDR MANUFACTURE ManufacturesQuadri Consultancy ServicesNo ratings yet

- Twice As Sharp Operators ManualDocument34 pagesTwice As Sharp Operators ManualLeonardo CHTZNo ratings yet

- (1)Document119 pages(1)Virginia Rosales OlmosNo ratings yet

- International Log Building StandardsDocument19 pagesInternational Log Building Standardsursind100% (1)

- Stoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer TabletsDocument6 pagesStoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer Tabletsgabbal009No ratings yet

- Product Catalog: Ipe ProfilesDocument2 pagesProduct Catalog: Ipe ProfilesGokul royalveritasNo ratings yet

- DESIGN II - ChemTran General Reference GuideDocument332 pagesDESIGN II - ChemTran General Reference GuideDebabrata MitraNo ratings yet

- Linux CommandsDocument2 pagesLinux CommandsVishwas BeedeNo ratings yet

- Optimal Design & Operation of RO Systems 3-Day SeminarDocument10 pagesOptimal Design & Operation of RO Systems 3-Day SeminarasankandessNo ratings yet

- Explorador Ww90j6410cwec Version 02Document13 pagesExplorador Ww90j6410cwec Version 02Cristi PopescuNo ratings yet

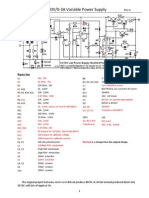

- Modified 0-30V - 0-3A Variable Power Supply - Rev.2Document2 pagesModified 0-30V - 0-3A Variable Power Supply - Rev.2Manuel Cereijo NeiraNo ratings yet

- Data Collector 2.03.00Document20 pagesData Collector 2.03.00vyaskingNo ratings yet

- Proposed Rule: Domestic Mail Manual: Domestic Mailing Services New StandardsDocument45 pagesProposed Rule: Domestic Mail Manual: Domestic Mailing Services New StandardsJustia.comNo ratings yet

- Software TestingDocument3 pagesSoftware TestingDr. P. N. Renjith Associate Professor - CSENo ratings yet

- PARTSDocument10 pagesPARTSTestrooteNo ratings yet

- Sectional Results: Sofistik 2020Document28 pagesSectional Results: Sofistik 2020ec05226No ratings yet

- FTS ScaleoEUserManualEN 10 1082177Document2,044 pagesFTS ScaleoEUserManualEN 10 1082177JNo ratings yet

- Sooad ManualDocument19 pagesSooad ManualRakhiNo ratings yet

- MET312 Non Destructive Testing SyllabusDocument8 pagesMET312 Non Destructive Testing SyllabusHARI KRISHNANNo ratings yet

- Stand Cons T DetailsDocument164 pagesStand Cons T DetailsmirfanjpcgmailcomNo ratings yet

- Seedburo Germinator Controls and Monitoring InstrumentsDocument2 pagesSeedburo Germinator Controls and Monitoring InstrumentsJhony Rengifo SolsolNo ratings yet

- Multi-disciplinary profile of IS/IT outsourcing researchDocument47 pagesMulti-disciplinary profile of IS/IT outsourcing researchIsabel MirandaNo ratings yet