Professional Documents

Culture Documents

Mechanical Services Specification

Uploaded by

tvscribdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Services Specification

Uploaded by

tvscribdCopyright:

Available Formats

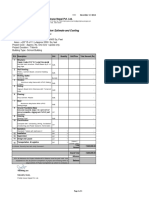

Etihad Pier and Concourse Interim Facility Abu Dhabi International Airport

65% DESIGN SPECIFICATION

18 February 2006

th

VOLUME 3D MECHANICAL

Part 5 Mechanical Services Particular Specification

WSP BUILDINGS BUCHANAN HOUSE 24-30 HOLBORN LONDON EC1N 2HS TEL: 020 7314 5000 FAX: 020 7314 5001

http://www.wspgroup.com Issue/revision Remarks Date Prepared by Signature Checked by Signature Project number File reference 24820283 24820283/7/Main 65% Specification/Volume 3D/Part 5 Nigel Williams Conformed to Contract issue Contract 2 July 2006 Himanshu Kotak

nd

VOLUME 3D CONTENTS 5 PART 5 - MECHANICAL SERVICES PARTICULAR SPECIFICATION 5.1 GENERAL ................................................................................................................................... 5-1 5.1.1 Smoke Control ........................................................................................................................... 5-1 5.1.2 Carbon Monoxide Monitoring .................................................................................................... 5-2 5.1.3 Multi Split System for Pier Fixed Links ................................................................................... 5-2 5.1.4 Multi Split Heat Pump System for Two Huts (Apron Level).................................................... 5-2 5.1.5 Multi Split Heat Pump System for three Huts (Apron Level) .................................................. 5-3 5.2 Mechanical Ventilation System Description ........................................................................ 5-3 5.2.1 The Pier building........................................................................................................................ 5-3 5.2.2 Fixed Links................................................................................................................................. 5-4 5.2.3 The Terminal building ................................................................................................................ 5-4 5.3 Comfort Cooling System Description .................................................................................. 5-6 5.3.1 The Pier building........................................................................................................................ 5-6 5.3.2 Pier connector............................................................................................................................ 5-7 5.3.3 The Terminal building ................................................................................................................ 5-7 5.4 Energy Centre Chilled Water Generation............................................................................. 5-8 5.4.1 General ...................................................................................................................................... 5-8 5.4.2 Chilled Water Generation Plant ................................................................................................. 5-9 5.4.3 Cooling to Energy Centre .......................................................................................................... 5-9 5.5 APPENDIX 1 ............................................................................................................................. 5-11 5.5.1 PREFERRED SUPPLIERS ..................................................................................................... 5-11 5.6 APPENDIX 2 ............................................................................................................................. 5-18 5.6.1 PIER EQUIPMENT SCHEDULES........................................................................................... 5-18 5.7 APPENDIX 3 ............................................................................................................................. 5-64 5.7.1 TERMINAL EQUIPMENT SCHEDULES................................................................................. 5-64 5.8 APPENDIX 4 ........................................................................................................................... 5-135 5.8.1 SUMMARY & SCHEDULE FOR AHUs AND FCUs............................................................. 5-135

Version 1.0

Volume 3D, Part 5

5.1

GENERAL PLEASE NOTE: ON THE LATEST ARCHITECS DRAWING NO. GA 00B18 REV P04, NEW SOC AND CRISIS MANAGEMENT OFFICE HAVE BEEN ADDED. THESE CHANGES ARE NOT REFLECTED ON THE SERVICES DRAWINGS DUE TO THE LATE ADDITION. THE CONTRACTOR SHALL ALLOW FOR ALL BUILDING SERVICES TO BE INSTALLED WITHIN THESE AREAS, BASED UPON SIMILAR ROOM DATA SHEETS. This section of the specification covers the provision of the Mechanical Engineering Services, which are included in the following sections: Mechanical Ventilation Comfort Cooling Energy Centre Chilled Water

This section of the Specification should be read in conjunction with the following documentation: Volume 2 Drawings Volume 3 Specifications, with particular regard to:o o o Volume 3D Part 1: General Conditions Volume 3D Part 2: Description of Works Volume 3D Part 3: Mechanical Services Workmanship and materials.

Together they cover the design, manufacture, supply, delivery to site, erection, testing, setting to work and commissioning of all equipment, accessories and controls. It shall be the tenderers responsibility to seek clarification, if needed, where there is ambiguity in the specification. Diversity has been applied in the occupancy. No further diversity figure is to be applied.

5.1.1

Smoke Control

The Fire Strategy shall be developed during the next design stage to establish the extract requirements for the hot smoke systems. On detection of a fire, the hot smoke extract system shall provide a smoke free zone to facilitate egress from the building.

Mechanical Extract Systems for TERMINAL BUILDING (Departures & Mezzanine levels)

Mechanical extract systems including extract fans, extract ductwork, volume control dampers, shut off dampers, sand trap louvers, controls linked to fire detection system will be provided for all circulation spaces and retail areas. On receipt of a signal from the fire alarm system the smoke extract fan, relevant to the area, will start and dump the hot smoke into the atmosphere at a high level via fire rated ductwork. The make up air fan will start simultaneously and will supply air from an adjacent area.

24820283 2nd July 2006 Conformed to Contract Issue

5-1

WSP

Version 1.0

Volume 3D, Part 5

All equipment shall be designed and rated for hot smoke extract and the system shall operate automatically in the event of a fire alarm. The ductwork shall be fire rated wherever it crosses areas outside of the extract fire zone.

Mechanical Extract Systems for PIER BUILDING and TERMINAL BUILDING (Arrivals level)

Motorised Ventilators (Both for smoke extract and make up air), mounted in the roof, controlled and linked to fire detection system will be provided for Pier Building and all circulation spaces and retail areas in Terminal Building at Arrivals Level and double height spaces. On receipt of a signal from the fire alarm system the smoke extract ventilator, installed in the roof, will open and let the hot smoke pass into the atmosphere. The make up air ventilator, relevant to the area, will open simultaneously and will let air in from atmosphere. The ventilators shall be designed to prevent sand ingress and be thermally and acoustically designed to meet the specification requirements of the roof.

5.1.2

Carbon Monoxide Monitoring Diesel vehicles will be used in the baggage hall and so carbon monoxide monitors shall be provided to continuously monitor the air quality. The monitors shall comprise of NO2 & CO2 monitors at low level and NO and CO monitors at higher level. The monitors shall provide total coverage of the baggage hall and be positioned in accordance with the manufacturers recommendations. The monitors will be connected to the BMS to sound an alarm if the contamination level exceeds a pre set limit.

5.1.3

Multi Split System for Pier Fixed Links

A multisplit twin system (cooling only), comprising of the following, will be provided for plant room and stairs of each fixed link. Internal Unit A wall mounted internal unit having a capacity of 1.8 KW will be installed in each plant room and stairs area. Both internal units will be connected to a single condensing unit. Condensing (Outdoor) Unit A condensing unit matching the capacity of two internal units will be mounted on a suitable plinth on top of the roof. Interconnecting pipe work, necessary fittings, controller and fixtures shall be provided for the operation of the complete system. Testing and commissioning of each system, at the end of installation, will be carried out in accordance with CIBSE guide, British standard and manufacturers recommendations.

5.1.4

Multi Split Heat Pump System for Two Huts (Apron Level)

A multi split Inverter Heat Pump twin system, comprising of the following, will be provided for two huts. Internal Unit A wall mounted internal unit having a capacity of 1.5 KW will be installed in each hut. Both internal units will be connected to a single condensing unit.

24820283 2nd July 2006 Conformed to Contract Issue

5-2

WSP

Version 1.0

Volume 3D, Part 5

Condensing (Outdoor) Unit A condensing unit matching the capacity of two internal units will be installed on a suitable plinth in the adjacent mechanical plant room. Interconnecting pipe work, necessary fittings, controller and fixtures shall be provided for the operation of the complete system. Testing and commissioning of the system, at the end of installation, will be carried out in accordance with CIBSE guide, British standard and manufacturers recommendations.

5.1.5

Multi Split Heat Pump System for three Huts (Apron Level)

A multi split Inverter Heat Pump system, comprising of the following, will be provided for three huts. Internal Unit A wall mounted internal unit having a capacity of 1.5 KW will be installed in each hut. All three internal units will be connected to a single condensing unit. Condensing (Outdoor) Unit A condensing unit matching the capacity of three internal units will be installed on a suitable plinth in the adjacent mechanical plant room. Interconnecting pipe work, necessary fittings, controller and fixtures will be provided for the operation of the complete system. Testing and commissioning of the system, at the end of installation, will be carried out in accordance with CIBSE guide, British standard and manufacturers recommendations.

5.2

Mechanical Ventilation System Description The building addresses three separate demarcation areas: The Pier building Apron level, Departures lounge level and Arrivals corridor level. Fixed Links - Link walkways from the Departures lounges and the Arrivals corridor. The Terminal building Apron level, Mezzanine level, Departures level and Arrivals level facilities.

5.2.1

The Pier building The Pier building has four AHU plant rooms (Nos. 5 to 8) which are located at Apron level. The plant rooms house dedicated AHUs that provides primary fresh air to the Pier building. Outside air is ducted from roof level, via sand trap louvers, down to the AHU plant rooms where it supplies each AHU. All AHU plant room will have a dedicated FCUs to cool the plant space. The primary fresh air supply air handling units consisting of motorized dampers, panel and bag filters, total energy thermal wheel, cooling coil and sensible only thermal wheel, supply and extract fans and air side attenuators. The air will extract at Apron level via acoustic louvers.

24820283 2nd July 2006 Conformed to Contract Issue

5-3

WSP

Version 1.0

Volume 3D, Part 5

Apron level The Apron level comprises of W/Cs, pray rooms, AHU plant rooms, electrical rooms, IT rooms, ramp accommodation, Arrivals coaching lobby and Departures lobbies. AHUs supply conditioned air to W/Cs, pray rooms, ramp accommodation, Arrivals coaching lobby and Departures lobbies. Contaminated air return to AHUs from where it will be dumped into the atmosphere, via individual ductwork from the AHUs and acoustic louvers in the plant rooms. Departures Level The Departures level comprises of departure lounges which are all interconnected, retail units, gate access to the fixed links and stair / lifts to access toilet facilities which are located at Apron level. The departure lounges, at level 1 will have primary fresh air supplied, from the floor below, to the underside of the floor mounted Comfort Cooling Units (CCUS). These are mounted on plinths which enable the fresh air to mix with the recirculated air, before being ducted to high level and supplying conditioned air to the Departure lounges. Extract air, from the Departures lounges will be located within the back wall services zone, taking stale air back to the AHUs within the plant rooms, located at Apron level. Arrivals Level The Arrivals level comprises an Arrivals corridor, Toilets and gate access to the fixed links. The Arrivals corridor has primary fresh air and extract supplied, from Apron level. Primary air will be ducted to supply grilles in the false ceiling. Extract air will be from extract grilles, connected to ductwork within the back wall services zone. 5.2.2 Fixed Links Ventilation System for Fixed Links will be designed and installed as part of Link & Bridge special package. 5.2.3 The Terminal building There are four AHU plant rooms (Nos. 1 to 4) in the Terminal Building which are located at Apron level. The plant rooms house dedicated AHUs that provides conditioned fresh air to the building. Outside air is ducted from roof level down to the AHU plant rooms, via sand trap louvers, where it supplies each AHU. All AHU plant rooms will have dedicated FCUs to cool the plant space. There are two types of AHUs: o The total fresh air supply air handling units consisting of motorized dampers, panel and bag filters, total energy thermal wheel, cooling coil and sensible only thermal wheel, supply and extract fans and air side attenuators. The air will extract at Apron level via louvers. The partial fresh air supply air handling units consisting of motorized dampers, panel and bag filters, thermal wheel, cooling coil, electric heater battery, supply and extract fans and air side attenuators. The air will extract at Apron level via louvers.

Apron Level

24820283 2nd July 2006 Conformed to Contract Issue

5-4

WSP

Version 1.0

Volume 3D, Part 5

The Apron level comprises of baggage handling areas, bonded store, mechanical plant rooms, IT and Electrical Sub-stations. The baggage handling areas will be supplied fresh air at the rate of six air changes per hour from a number of AHUs housed in the plant rooms. Contaminated air returns to AHUs from where it will be dumped into the atmosphere, via individual ductwork from the AHUs and acoustic louvers in the plant rooms. Mezzanine Level The Mezzanine level comprises of a canteen, prayer rooms, toilets, kitchen, staff room, tea making area, offices and lost & found store. AHUs supply conditioned air to all areas. Contaminated return air will be dumped into the atmosphere, via individual ductwork from the AHUs and acoustic louvers in the plant rooms. The toilets will be supplied fresh air at the rate of six air changes per hour where as the kitchen will be supplied fresh air at the rate of twenty air changes per hour and it will have its own exhaust fan. The canteen, offices and prayer rooms will be supplied fresh air at the rate of 8 l/s/person (minimum). The offices will have fresh air from the AHUs via FCUs. Departure Level The departure level comprises of check-in lobby, check-in, security search & passport control, custom area, meet & greet, offices, retail and retail circulation. The pre check-in lobby, check-in, security search & passport control, custom area, meet & greet, retail circulation and offices will be supplied fresh air at the rate of 8 l/s/person (minimum). The retail, retail circulation and offices will have fresh air from the AHUs via FCUs. The toilets will be supplied fresh air at the rate of six air changes per hour from the AHUs housed in the plant rooms. Stale air will be exhausted to the atmosphere, via individual ductwork from the AHUs and acoustic louvers in the plant rooms. Arrivals Level The arrivals level comprises of arrivals circulation corridor, baggage reclaim, passport control, immigration hall, CIP areas, prayer areas, offices, toilets, sanitary & health areas & smoking rooms. Arrivals circulation corridor, baggage reclaim, passport control, immigration hall, CIP areas & prayer areas will be supplied fresh air at the rate of 8 l/s/person where as smoking rooms, sanitary & health areas will be supplied fresh air at the rate of twenty air changes per hour and will have their own exhaust fans. The offices, lounge, food & eating areas, sanitary & health areas & smoking rooms will have fresh air from the AHUs via FCUs. The toilets will be supplied fresh air at the rate of six air changes per hour from the AHUs housed in the plant rooms. Stale air will be exhausted to the atmosphere, via individual ductwork from the AHUs and acoustic louvers in the plant rooms.

24820283 2nd July 2006 Conformed to Contract Issue

5-5

WSP

Version 1.0

Volume 3D, Part 5

5.3

Comfort Cooling System Description The building addresses three separate demarcation areas: The Pier building Apron level, Departures lounge level and Arrivals corridor level. Fixed Links - Link walkways from the Departures lounges and the Arrivals corridor. The Terminal building Apron level, Mezzanine level, Departures level and Arrivals level facilities. The Pier building Apron level The Apron level comprises of W/Cs, pray rooms, AHU plant rooms, electrical rooms, IT rooms, ramp accommodation, Arrivals coaching lobby and Departures lobbies. The Ramp accommodation, Arrivals lobby and Departures lounges will be provided comfort cooling from Fan Coil Units, mounted within the false ceiling, and ducted to supply grilles installed within the false ceiling. These areas will have primary fresh air supplied to the back of the FCUs. All ceiling mounted FCUs will have condensate drains. Mechanical plant rooms are cooled by the FCUs installed in the plant rooms. The W/Cs and pray rooms will be cooled from a ducted fresh air system, supplying primary fresh air to the space. The heat generated in electrical and IT rooms will be taken away by the dedicated FCUs allocated to the areas. IT rooms will have 100 % standby units where as Electrical Substations will have 50 % of the load as standby units. Departures Level The Departures level comprises of departure lounges which are all interconnected, retail units, gate access to the fixed links and stair/ lifts to access toilet facilities which are located at Apron level. Comfort cooling to the Departures lounges is provided from floor standing Comfort Cooling Units (CCUs). These units are recessed into the rear wall services void. The floor standing CCUs will be mounted on plinths where primary fresh air is ducted into; the primary air is supplied from the floor below. Chilled air and fresh air mixes and is then ducted to high level, within the rear wall services void, of the departure lounges where it discharges, through adjustable drum louvers, to the occupied space. The CCUs are to incorporate casing attenuation to reduce noise break out from the units, room side attenuators and upgraded fans to handle the additional resistance from the associated attenuators, ductwork distribution and terminal drum louvers. Return air from the Departures lounges re-circulates through the CCUs through louvered openings that encase the CCUs; the return air re-enters the CCUs at low velocity. The CCUs have condensation drains which drains to the level below. The CCUs operate on a compensated chilled water circuit that supplies chilled water, at a higher temperature. Arrivals Level The Arrivals level comprises an Arrivals corridor; W/Cs and gate access to the fixed links.

5.3.1

24820283 2nd July 2006 Conformed to Contract Issue

5-6

WSP

Version 1.0

Volume 3D, Part 5

The arrivals corridor has floor standing Fan Coil Units which may be recessed into the rear wall services void. These FCUs provide chilled air to the Arrivals corridor which is recirculated through the units. All FCUs have condensate drains, draining to Apron level. 5.3.2 Pier connector Comfort Cooling System for Fixed Links will be designed and installed as part of Link & Bridge special package. 5.3.3 The Terminal building Apron level The Apron level comprises of baggage handing areas, bonded store, AHU plant rooms, electrical rooms and IT rooms. The bonded store and baggage handling areas will be cooled from a ducted fresh air system, supplying conditioned fresh air to the space. As the return air from baggage handling areas is contaminated with smoke it will be dumped into the atmosphere, after recovering the energy, via individual ductwork from the AHUs and acoustic louvers. Twin wheel technology is adopted for the AHUs. The energy components of AHUs will consist of total energy thermal wheel, cooling coil and sensible only thermal wheel thereby reducing the energy demand by half. The pant rooms will have background cooling provided from Fan Coil Units; these units provide chilled air into the rooms, which is re-circulated through the units. Fresh air is supplied to AHUs by individual ductwork via sand trap louvers installed at roof level. The heat generated in electrical and IT rooms will be taken away by the dedicated FCUs allocated to the areas. IT rooms will have 100 % standby units where as Electrical Substations will have 50 % of the load as standby units. Mezzanine level The Mezzanine level comprises of a canteen, prayer rooms, toilets, kitchen, staff room, tea making area, offices and lost & found store. The canteen, toilets, kitchen and prayer rooms will be cooled from a ducted fresh air system, supplying an adjustable quantity of conditioned fresh air to the space. The offices, staff room, tea making areas will be provided comfort cooling from Fan Coil Units. These areas will have primary fresh air supplied to the back of FCUs from AHUs. All FCUs will have condensate drains. Departure level The departure level comprises of check-in lobby, check-in, security search & passport control, custom area, meet & greet, offices, retail and retail circulation. There is an area allocated for retail which is to be developed at a later stage. AHUs are to be included for these areas where as FCUs are to be ignored at this stage. However capped chilled water connections will be provided for the future pipe work. Pre check-in lobby, check-in, security search & passport control, custom area, meet & greet will be cooled from a ducted fresh air system, supplying an adjustable quantity of conditioned fresh air to the space.

24820283 2nd July 2006 Conformed to Contract Issue

5-7

WSP

Version 1.0

Volume 3D, Part 5

The offices will be provided comfort cooling from Fan Coil Units. These areas will have primary fresh air supplied to the back of the FCUs from AHUs. All FCUs will have condensate drains. The toilets will be cooled from a ducted fresh air system, supplying conditioned fresh air to the space. Contaminated return air will be dumped into the atmosphere, after recovering the energy, via individual ductwork from the AHUs and acoustic louvers. Twin wheel technology is adopted for the AHUs. The energy components of AHUs will consist of total energy thermal wheel, cooling coil and sensible only thermal wheel thereby reducing the energy demand by half. Fresh air is supplied to AHUs by individual ductwork via sand trap louvers installed at roof level. The heat generated in IT rooms will be taken away by the dedicated FCUs allocated to the areas. IT rooms will have 100 % standby units. Arrivals level The arrivals level comprises of arrivals circulation corridor, baggage reclaim, passport control, immigration hall, CIP areas, prayer areas, offices, toilets, sanitary & health areas & smoking rooms. Arrivals circulation corridor, baggage reclaim, passport control, immigration hall, CIP areas & prayer areas will be cooled from a ducted fresh air system, supplying an adjustable quantity of conditioned fresh air to the space. The toilets will be cooled from a ducted fresh air system, supplying conditioned fresh air to the space. Contaminated return air will be dumped into the atmosphere, after recovering the energy, via individual ductwork from the AHUs and extract louvers. Smoking rooms, sanitary & health areas will have their own exhaust fans extracting contaminated air directly from these rooms. The offices, sanitary & health areas & smoking rooms will be provided comfort cooling from Fan Coil Units, mounted within the false ceiling, and ducted to supply grilles installed in the false ceiling. These areas will have primary fresh air supplied to the back of the FCUs from AHUs. All ceiling mounted FCUs will have condensate drains. Fresh air is supplied to AHUs by individual ductwork via sand trap louvers installed at roof level. There is an area allocated for food and beverages which is to be developed at a later stage. AHUs is to be included for this area where as FCUs are to be ignored at this stage. However capped chilled water connections will be provided for the future pipe work. 5.4 5.4.1 Energy Centre Chilled Water Generation General The Energy Centre will be located adjacent to the new Pier Building and will provide a primary chilled water generation plant to serve the cooling requirements for the new Terminal Extension and Pier Building. The building will be comprised of two levels; Ground Level and Level 1. The chillers will be located at Ground Level and the Heat rejection plant on the upper level.

24820283 2nd July 2006 Conformed to Contract Issue

5-8

WSP

Version 1.0

Volume 3D, Part 5

5.4.2

Chilled Water Generation Plant Liquid Chillers: The chilled water will be generated by a total of 4no water cooled two-stage liquid chillers, each providing a cooling capacity of 3516 kW. The total cooling capacity will be 10548 kW. A maximum of 3no chillers will satisfy the cooling load of the new Terminal and Pier, and the fourth chiller will be a standby machine. An operational protocol provided by the BMS will rotate the operation of the standby chiller to maintain equal running hours for the compressors. A lead-lag change over sequence will also be incorporated for the 3no duty machines. The compressor motors shall operate on a high voltage supply of 11000 Volts. The chillers shall operate with R134A refrigerant, and a refrigerant storage and recycling system will be provided. The chillers shall include shell and tube evaporators and condensers. The chillers will operate on chilled water temperatures of 6C leaving and 12C return. The chilled water temperature controls shall maintain a constant leaving temperature of 6C. The chiller shall include a microprocessor to modulate the output of the chiller in response to the chilled water return temperature. The chilled water distribution to the Terminal Building and Pier Building shall be pumped from the Energy Centre by buried flow and return pipe work. Two duty operation pumps will share the total flow volume, rated at 50% each. A third pump of equal size will be standby. The chilled water pumps will be inverter driven, although the system will be operated on a constant volume basis. The Chilled water will be distributed to 8no Air Handling Plant rooms located at Apron Level within the Terminal and Pier Buildings. All main air handling units will be provided with primary chilled water at 6C flow and 12C return. The chilled water flow to the cooling coils will be controlled by means of 3-port control valves. Plate heat exchangers will be provided in each plant room to serve the chilled water fan coil units throughout the new buildings. Fan coil units serving externally glazed areas will be provided with chilled water at 10C flow and 16C return. The internal area fan coil units will be fed by chilled water at 6C and 11C. Heat Rejection: Heat rejection shall be achieved by means of dry air coolers. The dry air coolers will be located on the upper open plant area. 4No dry coolers will operate together in parallel, with each chiller. Each chiller will have a dedicated pumped condenser water circuit. The dry cooler control system shall include fan cycling to operate in response to the condenser load requirements.

5.4.3

Cooling to Energy Centre

Chilled water will be piped to the fresh air AHU serving the Office, Workshops, Kitchen, W/Cs and Corridor areas. 24820283 5-9 WSP

2nd July 2006 Conformed to Contract Issue

Version 1.0

Volume 3D, Part 5

Chilled water fan coil units serving the rest of the areas will be provided with chilled water via plate heat exchangers, as indicated on the chilled water schematic.

24820283 2nd July 2006 Conformed to Contract Issue

5-10

WSP

Version 1.0

Volume 3D, Part 5

5.5 5.5.1

APPENDIX 1 PREFERRED SUPPLIERS

24820283 2nd July 2006 Conformed to Contract Issue

5-11

WSP

Version 1.0

Volume 3D, Part 5

Preferred Suppliers Equipment Description Pipe Hangers Expansion Joints Strainers Thermometers Gauges Fire Rated Access Panels Fire stopping Material PPR Pipes Pex Pipe UPVC pipes and fittings Copper pipes and fittings Pipe Flexible Connectors for Chillers, Pumps Motors Starters Motor Control Centres Variable Speed Drives Valves Control Valves Automatic Air Vents Manual Vents Expansion Tanks Air Separators

24820283 2nd July 2006 Conformed to Contract Issue

Manufacturers Grinnell 6727488) (T:02-

Manufacturers Diamond (Ramesh Hira T:04-3478115)

Manufacturers

Manufacturers

Manufacturers

Flexonics Spirax Sarco Trerice Trerice Panel and Louvre Co Ltd Nullifire Ltd Upnor-Germany Comap-France Hepworth Crane Metraflex-U.S.A. (Cheqpoint T:042830095) Westinghouse Cutler Hammer Cutler Hammer Graham Company See Section Crane Spirax Sarco Bell & Gossett Bell & Gossett Bell & Gossett

Weiss Weiss

Hunter Hunter

Aquatherm JRG Sanipex Terrain IMI Yorkshire Proco-U.S.A, Trojan-Japan. Reliance

Wefatherm Viega

Wirsbro

Kembla

Wednesbury

Siemens

ABB

Hattersley Armstrong Amtrol Amtrol Amtrol 5-12

T&A Dole Taco Taco WSP

Version 1.0

Volume 3D, Part 5

Equipment Description Chemical Feeders Strainers Pressure Gauges Thermometers Insulated Couplings Test Plugs Piping Identification Expansion joints Meters and Gauges Pipe Hangers Sound Attenuators Vibration Isolators Acoustic Ducts Acoustic Louvres Insulation adhesive Insulation sealant Insulation Water

Manufacturers Mogul Crane Trerice Trerice Epco Peterson Seton Pipe solutions Trerice Grinnell 6727488) Trox Trox Trox Trox Childers Childers (T:02-

Manufacturers

Manufacturers

Manufacturers

Manufacturers

Weiss Weiss Lochinvar Sisco (Ramesh Hira T:043478115) Brady Engineering Appliances Weiss Carpenter Paterson Kinetics Kinetics Kinetics Kinetics Bakor Bakor Arabian insulation Grinnell (T:026727488) 5-13

Mueller (Unigulf T:04-2223697) Ametek Mueller (Unigulf T:04-2223697)

Ashcroft

Sigmark

Wilmington Plastic Ashcroft Diamond

Ametek & Pipe Shields

Fosters Fosters Kaimann Schuller Armstrong / Rubatex / Imoca / Knauf / Manson

Owens Corning

Fire System Valves Backflow Preventers

24820283 2nd July 2006 Conformed to Contract Issue

Crane Cla-val

Jenkins

WSP

Version 1.0

Volume 3D, Part 5

Equipment Description Pressure Reducing Valves Siamese connections Fire Hose Cabinet Fire Pumps Sprinkler system valves Pressure reducing valves Pumps Sprinkler Heads Automatic dry powder extinguishers Valves Sump Pumps Floor and Area Drains Roof Drains Cleanouts Back water Valves Backflow Preventers Trap Primers Water Hammer Arrestors Water Pressure Reducing Valves Hose Bibb Tap Wall hydrant Post Hydrant

24820283 2nd July 2006 Conformed to Contract Issue

Manufacturers Cla-val National Fire Norsen Nimbus Naffco Check Rite Cla-val Albany Naffco Naffco Kitz SA Armstrong Zurn Zurn Zurn Zurn Watts Zurn PPP Inc Cla-val Watts Zurn Zurn

Manufacturers

Manufacturers

Manufacturers

Manufacturers

Patterson Crane

Unisafe Jenkins

Armstrong Potter

Pullen / Aurora

Grinnell (T:026727488) Grinnell (T:026727488) Crane JR Smith JR Smith JR Smith JR Smith

Reliable Reliable Jenkins Wade Barrett

Viking Viking check rite

Unisafe Unisafe centreline Red-white /

JR Smith JR Smith 5-14 WSP

Version 1.0

Volume 3D, Part 5

Equipment Description Domestic Water Recirculation Pumps Grease Interceptors Manhole covers Domestic Water Expansion Tank Water Storage Tanks Water heaters LPG Distribution & Gas Detection

Manufacturers SA Armstrong Zurn Stanton, Wade, Hepworth, MCPItaly, Ducast, RBA

Manufacturers ITT B&G JR Smith

Manufacturers

Manufacturers

Manufacturers

See section Ariston

Thelmex

Valves

Kitz

Crane

Jenkins

check rite

centreline Red-white Victaulic Armstrong T&A / Watts Dahl / Dezurik

/ / / / /

Air Vents Expansion Tank Refrigerants Refrigerant Valves & specialties Pumps Condensing Units

24820283 2nd July 2006 Conformed to Contract Issue

Spirax Sarco Holden BrookePullen (IMECT:06-5568366) See section

SA Armstrong Carrier

Holden BrookePullen (IMECT:06-5568366) Mitsubishi 5-15

ITT Bell Gossett York

&

lowara Trane WSP

Grundfos / ESPA / Aurora / TACO

Version 1.0

Volume 3D, Part 5

Equipment Description Pressurisation units Water Chillers Chilled water treatment plant Air Cooled Condenser Fan Coil Units (chilled water) Fan Coil Units (DX) Air Handling Units Smoke Control Equipment Fans Balancing Dampers Fire Rated Ductwork Acoustic Duct Lining Fire Dampers Fire & Smoke Dampers Smoke Dampers Backdraft Dampers Manual Volume Control Dampers Pre-Insulated Ductwork Sand Trap Louvres Grilles, Registers &

24820283 2nd July 2006 Conformed to Contract Issue

Manufacturers Bell & Gossett Carrier Culligan Carrier Carrier / EatonWilliams (IPAC) Carrier / Trane Carrier / York Colt Woods Trox Cape Durasteel Technalco Technalco Technalco Technalco Technalco

Manufacturers Holden BrookePullen (IMECT:06-5568366) Trane Aquapack Trane Trane / York Trane Trane / Woods Flakt

Manufacturers TACO York

Manufacturers Armstrong

Manufacturers

Diffusion / VTS Clima VTS Clima VTS Clima

Euroclima Euroclima Euroclima

Klimak Klimak Klimak

Nuaire Titus Flamebar Trox Trox Trox Trox Trox

Vent Axia Price

Penn

Greenheck

Halton Halton Halton Halton Halton

Gilberts Gilberts Gilberts Gilberts Gilberts

Beta Beta Beta Beta Beta

EMTEC Trox

Halton 5-16

Krantz

Gilberts WSP

Version 1.0

Volume 3D, Part 5

Diffusers Electronic Controls & Monitoring

Honeywell

Landis & Gyr

Note This list is intended to show the range of preferred equipment suppliers associated with the Mechanical Services element of this project.

24820283 2nd July 2006 Conformed to Contract Issue

5-17

WSP

Version 1.0

Volume 3D, Part 5

5.6 APPENDIX 2 5.6.1 PIER EQUIPMENT SCHEDULES

24820283 2nd July 2006 Conformed to Contract Issue

5-18

WSP

Version 1.0

Volume 3D, Part 5

List of Pier Equipment Schedules Grilles Schedule Ref. M20-1

Some changes / amendments have been carried out as a result of re-location of equipment, therefore please refer to AHUs and FCUs Schedule in Appendix 4 Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. Air Handling Unit Ref. AHU-1P AHU-2P AHU-3P AHU-4P AHU-5P AHU-6P AHU-7P AHU-8P AHU-9P AHU-10P AHU-11P AHU-12P AHU-13P AHU-14P AHU-15P AHU-16P AHU-EC01 M02-1 M02-2 M02-3

Fan Coil Units Comfort Cooling Units: serving Pier Building Departures Lounges Fan Coil Units Floor Standing Units: serving Pier Building Arrivals Corridor Fan Coil Units Ceiling Mounted Units: serving Pier Building Ramp Level, Ground Floor

24820283 2nd July 2006 Conformed to Contract Issue

5-19

WSP

Version 1.0

Volume 3D, Part 5

Project: AUH Etihad Facility Equipment: Grilles

Schedule ref: M20-1 Sheet of Schedule Rev: Date: Feb 2006

Size (mm) 957x303 Type

Drum

Ref SG01-SG130

Location Departures High Level

Duty (l/s) 1250

Noise Rating (NR) 35

Pressure Drop (Pa)

Model Ref Drum Louvre size 8

Manufacturer: Gilberts or equal and approved.

Additional Information: To include opposed blade damper refer to Mechanical drawings. Finish To suit Architects Specification Plenum boxes Special plenum box with perforated balance plate refer to Mechanical drawings. Notes 1. This schedule shall be read in conjunction with the specification and drawings 2. High level drum louvers for Pier Departure Lounges, in accordance with detail shown on drawings to suit air flow rates of dedicated CCUs.

24820283 2nd July 2006 Conformed to Contract Issue

5-20

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-1P Unit location Plantroom P00.71 Terminal Building Area served Departures Lounge, Departures Level Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 2.94 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

46.6 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

215.8 46/29.2 13.6/12.7 6.5 11.5 10.32

5-21

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

2.94 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

2.94 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-22

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-2P Unit location Plantroom P00.71 Terminal Building Area served Toilets at Apron Level & Arrivals Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 2.9 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

46 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

212.9 46/29.2 13.6/12.7 6.5 11.5 10.18

5-23

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

2.9 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

3.6 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-24

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-3P Unit location Plantroom P00.71 Terminal Building Area served Arrivals Corridor Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 1.44 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

22.8 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

105.72 46/29.2 13.6/12.7 6.5 11.5 5.05

5-25

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

1.44 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

1.44 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-26

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-4P Unit location Plantroom P00.60 Terminal Building Area served Departure Lounges 5&6 Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 2.6 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

41.84 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

193.8 46/29.2 13.6/12.7 6.5 11.5 9.26

5-27

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

2.64 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

2.64 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-28

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-5P Unit location Plantroom P00.60 Terminal Building Area served Arrival Corridor Gate A1 Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 0.72 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

11.4 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

52.86 46/29.2 13.6/12.7 6.5 11.5 2.53

5-29

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

0.72 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

1.72 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-30

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-6P Unit location Plantroom P00.43 Terminal Building Area served Toilets at Apron & Arrivals Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 3.4 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

36.8 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

249.6 46/29.2 13.6/12.7 6.5 11.5 11.93

5-31

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

3.4 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

4.25 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-32

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-7P Unit location Plantroom P00.43 Terminal Building Area served Ramp Accommodation Apron Level Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 1.28 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

20.3 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

93.98 46/29.2 13.6/12.7 6.5 11.5 4.49

5-33

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

1.28 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

1.28 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-34

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-8P Unit location Plantroom P00.43 Terminal Building Area served Arrival Corridor Gates 2, 3, & 4 Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 1.8 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

28.53 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

132.15 46/29.2 13.6/12.7 6.5 11.5 6.32

5-35

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

1.8 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

1.8 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-36

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-9P Unit location Plantroom P00.43 Terminal Building Area served Departures Lounges 6, 7, & 8 Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 4.79 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

75.9 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

351.7 46/29.2 13.6/12.7 6.5 11.5 16.8

5-37

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

4.79 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

4.79 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-38

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-10P Unit location Plantroom P00.18 Terminal Building Area served Departures Lounges 8 & 9 Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 3.45 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

54.69 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

253.3 46/29.2 13.6/12.7 6.5 11.5 12.1

5-39

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

3.45 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

3.45 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-40

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-11P Unit location Plantroom P00.18 Terminal Building Area served Toilets Apron Level Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 0.6 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

9.5 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

44 46/29.2 13.6/12.7 6.5 11.5 2.1

5-41

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

0.6 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

0.75 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-42

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-12P Unit location Plantroom P00.18 Terminal Building Area served Arrivals Corridor Gates 4&5 Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 1.08 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

17.1 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

79.3 46/29.2 13.6/12.7 6.5 11.5 3.79

5-43

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

1.08 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

1.08 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-44

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-13P Unit location Plantroom 4 Terminal Building Area served Arrivals Lobby, Apron Level Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 0.72 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

11.4 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

52.86 46/29.2 13.6/12.7 6.5 11.5 2.53

5-45

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

0.72 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

0.72 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-46

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-14P Unit location Plantroom 4 Terminal Building Area served Departures Lounge, Apron Level Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 1.7 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

26.9 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

124.8 46/29.2 13.6/12.7 6.5 11.5 5.97

5-47

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

1.7 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

1.7 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-48

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-15P Unit location Plantroom 4 Terminal Building Area served Toilets, Apron Level Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 1.6 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

25.36 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

117.47 46/29.2 13.6/12.7 6.5 11.5 5.62

5-49

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

1.6 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

2.1 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-50

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-16P Unit location Plantroom 4 Terminal Building Area served Departures Lounge D1, Apron Level Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 1.92 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

30.4 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

140.97 46/29.2 13.6/12.7 6.5 11.5 6.74

5-51

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

1.92 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

1.92 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-52

WSP

Version 1.0

Volume 3D, Part 5

Air handling unit ref AHU-EC01 Unit location Mezz Plantroom, Energy Centre Area served Energy Centre Plant Areas & Accommodation Maximum dimensions and weight Length mm Width mm Height mm Weight kg Construction Frame Panel construction Double skin Colour/casing finish AHU support/base Base height mm Double stacked Components scheduled in direction of airflow but see drawings for configuration Mixing Box Fresh Air Volume m/s 4.24 (100% outside air) Return Air Volume m/s 0.0

Pre-filter Filter grade Filter type Maximum final flow resistance Bag filter Filter grade Filter type Maximum final flow resistance

Pa

EU3 Panel

Pa

EU7 Pleated Bag

Heating coil (Electric) Heating capacity Air on coil temperature (db) Air off coil temperature (db)

kW C C

67 11.9 25

Cooling Coil (CHW) Cooling Capacity kW Air on temperature (db/wb) C Air off temperature (db/wb) C Water temperature on C Water temperature off C Water flow rate kg/s Hydraulic resistance kPa Inlet Attenuator See Acoustic Data

24820283 2nd July 2006 Conformed to Contract Issue

311.3 46/29.2 13.6/12.7 6.0 12 12.4

5-53

WSP

Version 1.0

Volume 3D, Part 5

Fan (Supply) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics Hz AHU A1 Fan SWL

4.24 To suit final ductwork configuration Backward curved centrifugal Yes Yes, Inverter required 1450 380-415/3/50 Hz Star delta

Inlet attenuator insertion loss Discharge attenuator insertion loss Unit casing insertion loss

Fan (Extract) Air flow rate m/s Resistance external to unit Pa Fan type Motor rating kW Duty/standby motors Motor(s) in air stream Variable speed Maximum motor speed rpm Fan speed rpm Electrical supply Full load current amps Starting current amps Method of start Discharge Attenuator See Acoustic Data Acoustics

3.4 To suit final ductwork configuration Backward curved centrifugal Yes Yes, inverter required 1450 380-415/3/50 Hz Star delta

24820283 2nd July 2006 Conformed to Contract Issue

5-54

WSP

Version 1.0

Volume 3D, Part 5

Some changes / amendments have been carried out as a result of re-location of equipment, therefore please refer to AHUs and FCUs Schedule in Appendix 4

Schedule Ref. M02-1 Fan Coil Units Comfort Cooling Units: serving Pier Building Departures Lounge Water temperatures Primary air supply condition Electrical supply Heating flow Dry bulb 15C Phase 3 Heating return Wet bulb Frequency 50Hz Chilled flow 10C Voltage 400V Chilled return 16C

Cooling Load Sensi Total ble (w) (w) 58000 Room air C 23 RH (%) n/a Heating

External static to unit Minimum supply air temperature Integral condensate pump Nominal flow capacity Head

Water flow rate Nominal Air flow rate (l/s) 5700 Noise level (NR 40

250 Pa 15C Yes

Unit ref

Load (w)

15000

Electric

Location

Room air C 23

Chilled (l/s) 2.31

Heating (l/s) n/a

Fan speed low

Model ref

CCU 1 CCU 2 CCU 3 CCU 4 CCU 5 CCU 6 CCU 7 CCU 8 CCU 9 CCU 10 CCU 11 CCU 12 CCU 13 CCU 14 CCU 15 CCU 16 CCU 17 CCU 18 CCU 19 CCU 20 CCU 21 CCU 22 CCU 23

Pier Departures Lounge (Refer to layout drawings for Locations of units CCU1-26)

yes

IPAC 80-2

24820283 2nd July 2006 Conformed to Contract Issue

5-55

WSP

Version 1.0

Volume 3D, Part 5

Unit ref

Sensible (w)

Total (w)

RH (%)

Load (w)

Electric

Location

Cooling Load

Heating Room air Room air C

Water flow rate Chilled (l/s) Heating (l/s)