Professional Documents

Culture Documents

DC Machines

Uploaded by

SATHISH441Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DC Machines

Uploaded by

SATHISH441Copyright:

Available Formats

Documentation on DC Machines

Contents:

Principle of operation of DC machines

DC Motors

o Principle of operation

o Commutation

o Armature reaction

o Types of DC Motors and their defining equations

o Power flow

o Losses and efficiency

o Torque-speed characteristics

o Starters

DC generators

o Principle of operation

o Types of generators and their defining equations

o Magnetization characteristics

o Losses and Efficiency

Principle of operation of DC machines:

An Electric machine is a device which converts mechanical energy to electrical energy or

vice versa.

Electric motor converts electrical energy to mechanical energy.

Electric generator converts mechanical energy to electrical energy.

DC motors take DC input, whereas, DC generators give DC output, by means of a

mechanism that converts the internal AC voltage to DC voltage.

DC machines operate on the following three basic principles.

(1) A current-carrying conductor produces a magnetic field in the area around it.

(2) A current-carrying conductor in the presence of a magnetic field has a force

induced on it (motor action).

(3) A moving conductor in the presence of a magnetic field has a voltage induced

in it (generator action).

DC Machine is most often used as a motor. The major advantages of dc machines are

their speed control and torque regulation. DC motors find applications mainly in

automobiles.

DC Motors:

DC motors operate on the principle that when a current-carrying conductor in the

presence of a magnetic field has a force induced on it.

Principle of operation:

The principle of operation of dc motor is explained as follows:

It consists of field winding called stator and an armature winding called rotor, to which

the dc voltage is fed.

In dc motor, the stator poles are supplied by dc excitation current, which produces a dc

magnetic field. The rotor is supplied by the dc current through the brushes, commutator

and coils. The interaction of the magnetic field and the rotor current generates a force that

drives the motor.

The magnetic field lines enter into the rotor from the North Pole and exit toward the

South Pole. The poles generate a magnetic field that is perpendicular to the current

carrying conductors. The interaction between the field and the current produces a Lorentz

force; the force is perpendicular to both the magnetic field and conductor.

The force which is generated turns the rotor until the coil reaches the neutral point in

between the poles of the rotor. At this point, the magnetic field in the rotor becomes zero

along with the force generated. However, the moment of inertia of the motor drives the

motor beyond the neutral zone which changes the direction of the magnetic field reverses.

To avoid this reversal of the direction of force and magnetic reversal, the commutator

changes the current direction, which maintains the anticlockwise rotation.

Before the neutral zone is reached , the current enters in segment 1 of the motor and

come out form segment 2, Therefore, current enters the coil end at slot a and exits from

slot b during this stage. After passing the neutral zone, the current enters segment 2 and

exits from segment 1, this reverses the current direction through the rotor coil, when the

coil passes the neutral zone. The result of this current reversal is the maintenance of the

rotation.

Commutation:

Commutation is the process of converting the AC voltages and currents in the rotor of a

DC machine to DC at its terminals.

In case of generator, the commutator acts as an uncontrolled rectifier which converts the

generated alternating voltage to a direct voltage.

In case of a motor, the commutator acts as an inverter which converts the input DC to AC

to be fed to the motor.

Armature reaction:

Armature reaction is the effect of the magnetic field set up by the armature current on the

distribution of flux under the main poles of the machine.

The effects of armature reaction are,

Cross magnetizing

De-magnetizing

The effect of cross magnetizing effect is distortion of air gap flux, which causes sparking

at the brushes.

The effect of de-magnetizing effect is reduction of main field flux.

Types of DC Motors and their defining equations:

The following is the classification of DC motors:

Separately excited DC motor

Shunt DC motor

Series DC motor

Compound DC motor

o Cumulatively compound

o Differentially compound

Permanent-magnet DC motor

Separately excited DC motor: A separately excited DC motor is a motor whose field

winding is supplied from a separate constant-voltage power supply.

Shunt DC motor: A Shunt DC motor is a motor whose field winding gets its power

directly across the armature terminals of the motor.

a sh

I I +I =

Series DC motor: A series DC motor has its field winding connected in series with the

armature winding.

a sh

I I I = =

Compound DC motor: A compound DC motor has both series and shunt field

windings. If the series field aids the shunt field, it is cumulatively compound, and if the

series field opposes the shunt field, it is differentially compound.

Another classification of Compound DC motor includes,

- Long shunt

- Short shunt

Long Shunt Short shunt

a sh

I I +I =

se a sh

I I I I = = +

Permanent-magnet DC motor: Permanent magnet DC motor has permanent magnets in

place of field winding.

Defining equations:

The applied voltage to the motor is,

b a a brushdrop

V E I R V = + +

2

m a a

P VI I R =

Condition for maximum mechanical power developed is,

a

V

I

2R

=

The back emf at maximum power condition is,

b

V

E

2

=

The maximum power developed is,

2

m(max)

a

V

P

4R

=

Power flow:

The power diagram of DC motor is shown in Figure below.

Losses and efficiency:

There are five categories of losses occurring in DC machines.

1. Electrical or copper losses the resistive losses in the armature and field windings of

the machine.

Armature loss:

2

A A A

P I R =

Field loss:

2

F F F

P I R =

Where I

A

and I

F

are armature and field currents and R

A

and R

F

are armature and field

(winding) resistances usually measured at normal operating temperature.

2. Brush (drop) losses the power lost across the contact potential at the brushes of the

machine.

BD BD A

P V I =

Where I

A

is the armature current and V

BD

is the brush voltage drop. The voltage drop

across the set of brushes is approximately constant over a large range of armature

currents and it is usually assumed to be about 2 V.

Other losses are exactly the same as in AC machines

3. Core losses hysteresis losses and eddy current losses. They vary as

2

B (square of

flux density) and as

1.5

n (speed of rotation of the magnetic field).

4. Mechanical losses losses associated with mechanical effects: friction (friction of the

bearings) and windage (friction between the moving parts of the machine and the air

inside the casing). These losses vary as the cube of rotation speed

3

n .

5. Stray (Miscellaneous) losses losses that cannot be classified in any of the previous

categories. They are usually due to inaccuracies in modeling. For many machines, stray

losses are assumed as 1% of full load.

The efficiency of a DC machine is,

100%

100%

out

in

in loss

in

P

P

P P

P

q

| |

=

|

\ .

| |

=

|

\ .

Torque-speed characteristics:

Assuming that the terminal voltage and other terms are constant, the motors speeds vary

linearly with torque. However, if a motor has an armature reaction, flux-weakening

reduces the flux when torque increases. Therefore, the motors speed will increase. If a

shunt (or separately excited) motor has compensating windings, and the motors speed

and armature current are known for any value of load, its possible to calculate the speed

for any other value of load.

Starters:

The purpose of starters is,

- To protect the motor against damage due to short circuits in the equipment

- To protect the motor against damage from long-term overloads.

- To protect the motor against damage from excessive starting currents (the starting

current of motors is 20 times greater than the motors rated full load current).

- To provide a convenient manner of controlling the operating speed of the motor.

DC generators:

Generators operate on the principle that a moving conductor in the presence of a

magnetic field has a voltage induced in it.

Principle of operation:

The principle of operation is same as that of the motor, except that in case of generator,

the conductors are rotated by mechanical input, and the output is electrical.

Types of generators and their defining equations:

The following is the classification of DC generators:

Separately excited

Self-excited

o Shunt generator

o Series generator

o Compound generator

Cumulatively compound

Differentially compound

Separately excited DC generators use a separate DC source for excitation of their field

winding.

Self-excited DC generators are excited by the voltage generated by itself.

Shunt generator Series generator

L a sh

I I I = +

L a se

I I I = =

Compound Generator

Another classification of Compound DC generator includes,

- Long shunt

- Short shunt

Short shunt Long shunt

For Short shunt,

Series field current

se L

I I =

Shunt field current

se se

sh

sh

V I R

I

R

+

=

Terminal voltage

g a a se se

V E I R I R =

g a

L

Power developed in armature E I

Power delivered to the load VI

=

=

For long shunt,

Series field current

se a L sh

I I I I = = +

Shunt field current

sh

sh

V

I

R

=

Terminal voltage

( )

g a a se

V E I R R =

g a

L

Power developed in armature E I

Power delivered to the load VI

=

=

Magnetization characteristics:

The induced emf in the armature winding of a dc machine is directly proportional to flux

and speed of rotation. Let us assume that the field winding is connected to a variable dc

source that is capable of supplying a desired field current. If the armature terminals are

left open and the armature is rotated at constant speed, then the induced emf in the

armature is

1

E K | = where

1

K is a constant. In other words the induced emf is directly

proportional to the air gap flux. Flux depends on the magneto-motive force (MMF)

provided by the current in the field winding. That is,

f f

K I | = , where

f

K depends on

the operating flux density. Therefore induced emf can now be written as,

1 f f

E K K I =

The magnetic circuit of a dc machine consists of both linear (airgap) and non-linear

(magnetic material of the stator and rotor) parts. Hence,

f

K changes (it decreases as the

magnetic circuit gets saturated) with the change in flux density in the machine. The

relationship between E and If can be determined by measuring the open circuit voltage

(voltage across armature terminals) at different values of

f

I at a constant speed. This

curve is known as open circuit characteristics (OCC). Since E is an indirect measure of

air gap flux (at constant speed of rotation), the curve is similar to the B-H curve of the

magnetic material. For this reason, OCC can also be referred to as the magnetization

curve. It should be noted that E does not start at zero when the field current is zero but at

some value (of the order of 8-10 V). This is due to residual magnetism.

Losses and Efficiency:

Losses in a dc generator are same as that of a dc motor.

The efficiency of a DC generator is,

out

in

out

out

100%

100%

losses

P

P

P

P

q

| |

=

|

\ .

| |

=

|

+

\ .

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Real Gas ThermodynamicsDocument112 pagesReal Gas ThermodynamicsJohn AllenNo ratings yet

- Problems On Beams PDFDocument16 pagesProblems On Beams PDFC j50% (6)

- DPP-1 QuantizationDocument1 pageDPP-1 QuantizationVikasNo ratings yet

- HW2 Solutions FinalDocument5 pagesHW2 Solutions Finalpande_100No ratings yet

- Hydrostatic Forces on SurfacesDocument12 pagesHydrostatic Forces on SurfacesPajhmanAwghanNo ratings yet

- PAP NAV Energie Savings in Twin Propellers DesignDocument14 pagesPAP NAV Energie Savings in Twin Propellers Designyannickjan2005No ratings yet

- ME 555 Stress Analysis Unit 4Document57 pagesME 555 Stress Analysis Unit 4TheoNo ratings yet

- Transmision de Potencia NewDocument12 pagesTransmision de Potencia NewGustavo ArmellaNo ratings yet

- GicDocument155 pagesGicNikita KadamNo ratings yet

- Chapter 14 Modern SpectrosDocument24 pagesChapter 14 Modern SpectrosChicken ChickenNo ratings yet

- Signature RedactedDocument49 pagesSignature RedactedG Pavan KumarNo ratings yet

- A Brief Overview of The Holographic TechnologyDocument5 pagesA Brief Overview of The Holographic TechnologyAltiel Ltd.No ratings yet

- Revised Design Report of Jetty 06.04.2014Document10 pagesRevised Design Report of Jetty 06.04.2014Priodeep Chowdhury100% (2)

- April 2015-Vacuum Drying Chem Eng PDFDocument9 pagesApril 2015-Vacuum Drying Chem Eng PDFAlvaro BarbozaNo ratings yet

- LaminateDocument154 pagesLaminateAbhishek VaggarNo ratings yet

- Energy in Somaliland Novia Thesis - Editing PDFDocument25 pagesEnergy in Somaliland Novia Thesis - Editing PDFAbdirahmanNo ratings yet

- F3 Maths 2012 1stexam Paper1Document3 pagesF3 Maths 2012 1stexam Paper1YiuhangLeung100% (2)

- WRC 538 PDFDocument27 pagesWRC 538 PDFsoojin gu25% (4)

- Reability PDFDocument396 pagesReability PDFMarcelo Ziulkoski100% (1)

- Weather in Kuttiadi - Google SearchDocument1 pageWeather in Kuttiadi - Google Searchsorry Its My StyleNo ratings yet

- 2015-04-21 - 3 - LPE Firemans SyllabusDocument9 pages2015-04-21 - 3 - LPE Firemans SyllabusSumanNo ratings yet

- Acceleration (Inclined Plane)Document5 pagesAcceleration (Inclined Plane)jambunaNo ratings yet

- 2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical ApplicationsDocument6 pages2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical Applicationsultrasonic81No ratings yet

- Bridge Design Report - Docx 150Document17 pagesBridge Design Report - Docx 150nephembaniNo ratings yet

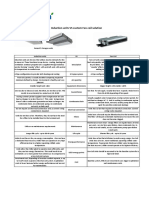

- HotelSolution: Induction Units VS Fan-Coil SolutionDocument1 pageHotelSolution: Induction Units VS Fan-Coil SolutionMoriyasu NguyenNo ratings yet

- Determining Dielectric Constants Using A Parallel Plate CapacitorDocument5 pagesDetermining Dielectric Constants Using A Parallel Plate CapacitorAhmAd GhAziNo ratings yet

- Glazed Aluminum Curtain Walls (Thermawall SM 2600)Document12 pagesGlazed Aluminum Curtain Walls (Thermawall SM 2600)RsjBugtongNo ratings yet

- DPP-3 Jee PDFDocument10 pagesDPP-3 Jee PDFTanmay SagarNo ratings yet

- Basic ChemistryDocument14 pagesBasic ChemistryPitherNo ratings yet

- Design Considerations of High Voltage AnDocument114 pagesDesign Considerations of High Voltage AnEL BRIGHLINo ratings yet