Professional Documents

Culture Documents

Centrifugal Casting

Uploaded by

durim-fcb4435Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centrifugal Casting

Uploaded by

durim-fcb4435Copyright:

Available Formats

Centrifugal Casting

Page 1 of 3

Login | Register for free!

Home News

Estimators

Parts

Widgets

Processes

Materials

Suppliers

Die Cast Publications Essential reading for the world's leading Die Casting companies www.castool.com Military Armor Castings High Quality Military Castings All Alloys, from 3 grams to 150 lbs www.spokaneindustries.com Hydroforming Sheet-Metal/Tube Hydroforming with Water-punch Technology. Contact Us! InoxVeneta.com/Hydroforming

Overviews

Processes Polymer Processing Blow Molding Injection Molding Metal Injection Molding Thermoforming Metal Casting Centrifugal Casting Die Casting Investment Casting Permanent Mold Sand Casting Shell Mold Casting Machining Milling Turning Hole-making Drill Size Chart Tap Size Chart Sheet Metal Fabrication Forming Cutting with shear Cutting without shear Gauge Size Chart Additive Fabrication SLA FDM SLS DMLS 3D Printing Inkjet Printing Jetted Photopolymer LOM Materials Metals Plastics Case Studies Cost Analysis Part Redesign Product Development Resources

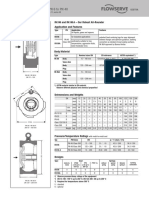

Centrifugal Casting

Centrifugal casting, sometimes called rotocasting, is a metal casting process that uses centrifugal force to form cylindrical parts. This differs from most metal casting processes, which use gravity or pressure to fill the mold. In centrifugal casting, a permanent mold made from steel, cast iron, or graphite is typically used. However, the use of expendable sand molds is also possible. The casting process is usually performed on a horizontal centrifugal casting machine (vertical machines are also available) and includes the following steps: 1.

Ceramco, Inc. We make high temperature ceramics. High quality parts. Buy American!

www.ceramcoceramics.com

Refractory Metal Alloys Tungsten, Molybdenum, Zirconium, Tantalum, Titanium, Niobium Nitinol

www.marketech-metals.com

http://www.custompartnet.com/wu/centrifugal-casting

10/13/2010

Centrifugal Casting

Page 2 of 3

Curriculum Resources Glossary

Mold preparation - The walls of a cylindrical mold are first coated with a refractory ceramic coating, which involves a few steps (application, rotation, drying, and baking). Once prepared and secured, the mold is rotated about its axis at high speeds (300-3000 RPM), typically around 1000 RPM. 2. Pouring - Molten metal is poured directly into the rotating mold, without the use of runners or a gating system. The centrifugal force drives the material towards the mold walls as the mold fills. 3. Cooling - With all of the molten metal in the mold, the mold remains spinning as the metal cools. Cooling begins quickly at the mold walls and proceeds inwards. 4. Casting removal - After the casting has cooled and solidified, the rotation is stopped and the casting can be removed. 5. Finishing - While the centrifugal force drives the dense metal to the mold walls, any less dense impurities or bubbles flow to the inner surface of the casting. As a result, secondary processes such as machining, grinding, or sand-blasting, are required to clean and smooth the inner diameter of the part. Centrifugal casting is used to produce axi-symmetric parts, such as cylinders or disks, which are typically hollow. Due to the high centrifugal forces, these parts have a very fine grain on the outer surface and possess mechanical properties approximately 30% greater than parts formed with static casting methods. These parts may be cast from ferrous metals such as low alloy steel, stainless steel, and iron, or from nonferrous alloys such as aluminum, bronze, copper, magnesium, and nickel. Centrifugal casting is performed in wide variety of industries, including aerospace, industrial, marine, and power transmission. Typical parts include bearings, bushings, coils, cylinder liners, nozzles, pipes/tubes, pressure vessels, pulleys, rings, and wheels.

Centrifugal Casting Return to top

Capabilities

Typical Feasible Thin-walled: Shapes: Thin-walled: Cylindrical Complex Solid: Cylindrical Solid: Complex Part size: Diameter: 1 - 120 in. Length: Up to 50 ft. Weight: Up to 5 tons Materials: Metals Alloy Steel Carbon Steel Cast Iron Stainless Steel Aluminum Copper Nickel 32 - 500 in Surface finish - Ra: 63 - 500 in Tolerance: 0.01 in. 0.002 in.

http://www.custompartnet.com/wu/centrifugal-casting

10/13/2010

Centrifugal Casting

Page 3 of 3

Max wall thickness: 0.1 - 5.0 in. 0.1 - 5.0 in. Quantity: 100 - 10000 1 - 10000 Days Lead time: Weeks Advantages: Can form very large parts Good mechanical properties Good surface finish and accuracy Low equipment cost Low labor cost Little scrap generated Disadvantages: Limited to cylindrical parts Secondary machining is often required for inner diameter Long lead time possible Applications: Pipes, wheels, pulleys, nozzles Compare with: Go

Disclaimer: All process specifications reflect the approximate range of a process's capabilities and should be viewed only as a guide. Actual capabilities are dependent upon the manufacturer, equipment, material, and part requirements.

Return to top

About CustomPartNet About Us Contact Us Privacy Policy List Your Company Advertise

Process Overviews Injection Molding Sand Casting Milling Die Casting Glossary

Cost Estimators Injection Molding Estimator Machining Estimator Die Casting Estimator Sand Casting Estimator . . . see all estimators

Widgets Speed and Feed Calculator Drill Size/Tap Size Chart Clamping Force Calculator Volume/Weight Calculator . . . see all widgets

Copyright 2009 CustomPartNet. All Rights Reserved.

http://www.custompartnet.com/wu/centrifugal-casting

10/13/2010

You might also like

- 131kuzmic PDFDocument1 page131kuzmic PDFdurim-fcb4435No ratings yet

- Rockmatez-Portable Hardness TesterDocument4 pagesRockmatez-Portable Hardness Testerdurim-fcb4435No ratings yet

- Hardening Stainless SteelsDocument1 pageHardening Stainless Steelsdurim-fcb4435No ratings yet

- Rječnik-Zavarivanje (EN-BA)Document8 pagesRječnik-Zavarivanje (EN-BA)Adnan KaraahmetovicNo ratings yet

- Motivation LetterDocument2 pagesMotivation Letterdurim-fcb4435No ratings yet

- 12121in-Tech Template 2013 TemplateDocument4 pages12121in-Tech Template 2013 Templatedurim-fcb4435No ratings yet

- Rječnik-Zavarivanje (EN-BA)Document8 pagesRječnik-Zavarivanje (EN-BA)Adnan KaraahmetovicNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cost Estimate Breakdown For TTC and Rebuild WorkshopsDocument10 pagesCost Estimate Breakdown For TTC and Rebuild WorkshopsHarold de Mesa100% (1)

- Daily Progress ReportDocument2 pagesDaily Progress ReportmkpqNo ratings yet

- rk86 enDocument2 pagesrk86 enMohd Farhan ZulkepliNo ratings yet

- CortadorDocument7 pagesCortadorMarco DiazNo ratings yet

- Recommendations For Assessment Eurocodes For Bridges: Chris R HendyDocument12 pagesRecommendations For Assessment Eurocodes For Bridges: Chris R Hendymicael_89100% (1)

- Kern 440 Precision Balance - Service ManualDocument11 pagesKern 440 Precision Balance - Service ManualScott Tyler100% (2)

- E Cospace: AE Aterial SpecificationDocument5 pagesE Cospace: AE Aterial SpecificationAsraff Abdul RahmanNo ratings yet

- 20samarat Annd1Document35 pages20samarat Annd1Prabhakar Tiwari100% (1)

- JORC DrainsDocument36 pagesJORC DrainsMod KaewdaengNo ratings yet

- Tank lining for storage tanksDocument4 pagesTank lining for storage tanksturboconchNo ratings yet

- Glassy Metals IIIDocument265 pagesGlassy Metals IIICristian HoreaNo ratings yet

- Bioreactors TypesDocument6 pagesBioreactors TypesHeinerMontalvoNo ratings yet

- CNG Cylinder Design and SafetyDocument53 pagesCNG Cylinder Design and SafetyMartha GamalNo ratings yet

- Installation, 2 F E: FreezerDocument24 pagesInstallation, 2 F E: FreezerDamian FulgoniNo ratings yet

- Dresser RDocument2 pagesDresser RdanielNo ratings yet

- HA-YS310 Basic Seminar PL ENG 170126 (MHa) PDFDocument36 pagesHA-YS310 Basic Seminar PL ENG 170126 (MHa) PDFEduardo Expósito EspinosaNo ratings yet

- Welding Dissimilar MetalsDocument6 pagesWelding Dissimilar MetalsNitintak100% (1)

- Thermal Power Plant Layout and OperationDocument77 pagesThermal Power Plant Layout and OperationAlexNo ratings yet

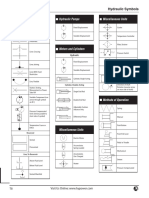

- Fluid Power Symbols PDFDocument4 pagesFluid Power Symbols PDFsanisah1245100% (1)

- Electrolysis PDFDocument37 pagesElectrolysis PDFHarini SridharanNo ratings yet

- Asupu Nano BubblesDocument10 pagesAsupu Nano BubblesAgung50% (2)

- 80 Degree FreezerDocument6 pages80 Degree FreezerDaryl ChianNo ratings yet

- Protect Tanks From Overpressure and Vacuum PDFDocument7 pagesProtect Tanks From Overpressure and Vacuum PDFJohn SmithNo ratings yet

- TD TIW - Project HSE Trend Action Plan - January 2023 - Material and Tool Handling and StorageDocument1 pageTD TIW - Project HSE Trend Action Plan - January 2023 - Material and Tool Handling and StorageMuhammad Sanaan Ul HasnainNo ratings yet

- Proposal AACDocument23 pagesProposal AACHery Dimitriy100% (1)

- Architectural Woodwork Specification GuideDocument8 pagesArchitectural Woodwork Specification GuideRonnell RepilNo ratings yet

- Introduction To HydraulicDocument28 pagesIntroduction To HydraulicMohamed ElmakkyNo ratings yet

- Bertrand Medioni: For The Degree Master of Science in Architecture Studies at The June, 1987Document86 pagesBertrand Medioni: For The Degree Master of Science in Architecture Studies at The June, 1987Đào Duy TùngNo ratings yet

- COMPOSITE WING OPTIMALIZATION USING FEM ANALYSES SYSTEMS by Miroslav Spišák - Peter MalatinDocument3 pagesCOMPOSITE WING OPTIMALIZATION USING FEM ANALYSES SYSTEMS by Miroslav Spišák - Peter MalatinVesa RäisänenNo ratings yet

- Webasto Thermo Top E Corsa C EnglishDocument4 pagesWebasto Thermo Top E Corsa C EnglishCata Stefan0% (1)