Professional Documents

Culture Documents

Operations Management

Uploaded by

Timothy TaiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operations Management

Uploaded by

Timothy TaiCopyright:

Available Formats

THE UNIVERSITY OF HONG KONG FACULTY OF BUSINESS AND ECONOMICS School of Business BUSI0023A_IIMT3635A Operations and Quality Management

2013-2014 First Semester

I. Course and Instructor Information Instructor: Avi Taheri Email: Taheri@hku.hk, avitaheri@gmail.com Office: 13-F KK Leung Building- room 1319 Phone: 3917-1640 Consultation times: By appointment Pre-requisites: NA Schedule: Wednesday 9:30am 12:20pm Class Room: KKLG102 Textbook: Operations Management William J. Stevenson & Sum Chee Chuong McGraw Hill, 9th Edition ISBN 978-007-127062-5

II. Course Description and Objectives This course provides a general introduction into the basic concepts and principles of management of manufacturing and service operations. Emphasis will be on both the quantitative and qualitative aspects of operations management with the intention to give students exposure to the major topics in operations management. Operations management has traditionally been defined as a transformation process. Inputs (such as material, machines, labor, management, and capital) are transformed into outputs (goods and services). Operations management works to ensure that the transformation process is performed efficiently and that the output is of greater value than the sum of the inputs. Over the past twenty years, operations management focused less on cutting cost but more on quality improvement. Quality was no longer a technical issue, but a business issue. Quality is considered a key competitive advantage and all operation functions inside the organization focused on the firms ability to produce goods or services that meet customers expectations. This course is designed to give the student a perspective of operations and quality management within the changing facets of global competition. Course objectives

1. To understand the evolution of operations and quality management 2. To understand the fundamental concept of operations strategy 4. To understand the major concepts of quality management 5. To integrate a generic framework for managing operations and quality improvement 6. To explore the concept of customer value as a source of competitive advantage

III. Learning Outcomes On completion of this course, students should be able to ILO1. Develop an understanding of the complex issues surrounding operations and quality management in manufacturing and service operations. ILO2. Use systematic approaches in assessing operations and quality capability of organizations. ILO3. Apply process improvement tools to redesign an organization operations process. ILO4. Develop skills in the design and implementation of an effective operations management system. IV. Alignment of Program and Course Outcomes Program Learning Outcome 1. Acquisition and internalization of knowledge and skills in key functional areas 2. Application and integration of business knowledge 3. Inculcating professionalism and leadership 4. Developing global outlook 5. Mastering communication skills Course Learning Outcome ILO1, ILO2, ILO3, ILO4 ILO2, ILO3, ILO4 ILO1, ILO4 ILO1 ILO3, ILO4

V. Teaching and Learning Activities 1. Lecture: Interactive lectures on major concepts and issues with PowerPoint slides are conducted. Students will be invited to share their view and experience in applying the concepts. 2. In-class discussion: Discussion questions and case studies will be provided to encourage a group or individual student to participate in discussions and share views. 3. Video: Students are required to discuss a specific set of questions based on the video. 4. Industrial exposures: To expose students to operations and quality management in a realworld setting, either corporate executives will be invited to give their perspectives and experiences or field trips to industries in the region will be arranged. Students will be required to submit a one-page paper on what was learned and discovered from the speaker.

5. Individual case analysis: Students will study and analyze a given case; propose suggestions and recommendations and write a report to be submitted. 6. Group project: Students will be divided into groups and will conduct a processreengineering project. Each group makes a 30-minute presentation and submits a group report. VI. Assessment Individual Attendance, Participation and quiz Individual Paper- Case Studies Group Project Total VII. Standards for assessment Individual Paper Each student will be required to complete an individual case study based on a case assigned during the term. The case would be on process management or international process standard. Each student will be required to conduct a process audit of a company and submit a report in assessing the operations processes of the company. The grading will factor in: 3. Content of the report 4. Writing Style 5. Presentation and Discussion Group Project Students will be divided into groups and will conduct a process-reengineering project. Each group makes a 25-minute presentation and submits a group report. The group presentation and group report will be evaluated based on the five criteria (i.e., presentation style, content coverage, articulation on critical issues, use of process improvement tools, quality of interaction at the Q&A session, and the content of the report). In determining the grade, input from other groups evaluation and their questions are being considered. Grading Criteria ILO A+ A AILO1 ILO2 ILO3 ILO4 Very Good to Extremely well Preparation for all criteria. 20% 40% 40% 100%

B+ B BGood to Very Good Preparation for all criteria.

C+ C CFair to Good in all criteria

D+ D Fair in all criteria

F Fail to submit papers and no preparation for criteria

Attendance and Participation Attendance will be taken for the lectures. The attendance and individual sharing in class will be considered in assigning points for attendance and individual participation. VIII. Academic Conduct The University Regulations on academic dishonesty will be strictly enforced! Please check the University Statement on plagiarism on the web: http://www.hku.hk/plagiarism/

IX. Course Schedule

SESSION

TOPIC Introduction to Operations Management Major Topics: Introduction to operations management and its relevance in todays organization. A brief history of operations and quality management and the issues and trends in business. Discussion of assignments: Individual paper and Group project Required Reading: Course Textbook - Chapter 1 Designing Operations: Competitiveness, Strategy and Productivity Major Topics: The issues of competition, strategy and productivity and its fitting of operational activities into corporate strategy. Tutorial: Case studies. Required Reading: Course Textbook Chapter 2 Designing Operations: Product and Service Design Major Topics: The impact of product and service design on operations and organizational performance. Design of product and services with legal, environmental and ethical considerations. Tutorial: Case studies. Group Project: Submission of Groups and Leaders Required Reading: Course Textbook Chapter 4 Designing Operations: Capacity Planning Major Topics: Strategic capacity planning to achieve a match between the long-term supply capacities and the predicted long-term demand of an organization. Group and Individual Project Discussion Required Reading: Course Textbook Chapter 5

4 Sep, 2013 Session 1

11 Sep, 2013 Session 2

18 Sep, 2013 Session 3

25 Sep, 2013 Session 4

Designing Operations: Management of Quality Major Topics: The concept of quality control and process control. Evolution of quality management; definition of quality and the tools. Tutorial: Case studies. Submission of Group Project Industry choice- page outline Required Reading: Course Textbook Chapter 9 Designing Operations: Sustainability 9 Oct, 2013 Session 6 Major Topics: Describing corporate social responsibility, sustainability and disassembly. Tutorial: Case studies Required Reading: handout

2 Oct. 2013 Session 5

16 Oct 2013

Reading Week Field trips just before or after

Designing Operations: Quality Management Major Topics: Designing quality into process. Tutorial: Case studies. Submission of Individual papers Required Reading: Course Textbook Chapter 10 Managing Operations: Supply Chain Management Major Topics: Definition of supply chain management, its needs and the steps for creating an effective SCM. Tutorial: Case studies. Group Project Discussion Required Reading: Course Textbook Chapter 11 Managing Operations: Inventory and scheduling Major Topics: Requirement for effective inventory and scheduling. Tutorial: Case studies. Final Group Project Discussion Submission of Group papers on midnight of Nov 10th Required Reading: Course Textbook Chapter 12

23 Oct 2013 Session 7

30 Oct, 2013 Session 8

6 Nov, 2013 Session 9

13 Nov, 2013 Session 10 20, Nov 2013 Session 11 27 Nov, 2013 Session 12

Project Presentations

Project Presentations

Project Presentations and Summary

You might also like

- GMP Guild For Cosmetic IngredientDocument48 pagesGMP Guild For Cosmetic IngredientLennon Tan Qin JiNo ratings yet

- Quantative Studies For MGMTDocument507 pagesQuantative Studies For MGMTMahesh KumarNo ratings yet

- Clause-By-Clause Explanation of ISO 9001:2015: Qcs Management Pvt. LTDDocument19 pagesClause-By-Clause Explanation of ISO 9001:2015: Qcs Management Pvt. LTDALOKE GANGULYNo ratings yet

- BIQ-S AuditDocument13 pagesBIQ-S AuditAngie Guerrero100% (1)

- MCQs - CompiledDocument11 pagesMCQs - Compiledfahadkhanffc100% (1)

- Question # 1 (A) Define Scope and Significance of Operation ManagementDocument11 pagesQuestion # 1 (A) Define Scope and Significance of Operation ManagementHuzaifa KhalilNo ratings yet

- Design and Technology: Product DesignDocument33 pagesDesign and Technology: Product DesignZulfadli SyamimNo ratings yet

- MGMT3347 Unit Outline S2 2015Document17 pagesMGMT3347 Unit Outline S2 2015DoonkieNo ratings yet

- Mba 206Document240 pagesMba 206Operation ResearchNo ratings yet

- Important Definations - Risk ManagmentDocument11 pagesImportant Definations - Risk ManagmentomerNo ratings yet

- Running and Operating A Successful BusinessDocument16 pagesRunning and Operating A Successful BusinessObert SanyambeNo ratings yet

- APQPDocument62 pagesAPQPYogaditya ModukuriNo ratings yet

- ISO 13485 Why and HowDocument29 pagesISO 13485 Why and HowMarlin PohlmanNo ratings yet

- Revisi PPT2-Design of Goods and ServicesDocument52 pagesRevisi PPT2-Design of Goods and ServicesAbdul GhoniNo ratings yet

- Lecture 1 (Final) - Chapter 1 - Introduction To Quantitative AnalysisDocument24 pagesLecture 1 (Final) - Chapter 1 - Introduction To Quantitative Analysisvivi AnNo ratings yet

- Final Final Report of OpmDocument19 pagesFinal Final Report of OpmphirlayayadilNo ratings yet

- Combur 10 M 100 STR - EsDocument2 pagesCombur 10 M 100 STR - EsVictor Manuel Parra Torres50% (4)

- Practice Questions MGT 632: Business Research Methods/ MGB 114: Research MethodsDocument9 pagesPractice Questions MGT 632: Business Research Methods/ MGB 114: Research MethodsVishal SharmaNo ratings yet

- Strategic Management Case Study AnalysisDocument10 pagesStrategic Management Case Study AnalysisTân NguyênNo ratings yet

- Corporate Finance Management Note, MBA, Sharif University, Persian, 2007Document171 pagesCorporate Finance Management Note, MBA, Sharif University, Persian, 2007meisam hejaziniaNo ratings yet

- Marketing Management QUESTION PAPERDocument5 pagesMarketing Management QUESTION PAPERKuthubudeen T M50% (2)

- Good Occupational Health PracticeDocument197 pagesGood Occupational Health Practicebenny1004100% (1)

- QMS Internal Auditor Course SyllabusDocument2 pagesQMS Internal Auditor Course SyllabusRaviLifewideNo ratings yet

- Operations Management Notes Lecture 1Document4 pagesOperations Management Notes Lecture 1Shirley Soriano-QuintoNo ratings yet

- Chapter 1 - Introduction To Failure Analysis and PreventionDocument8 pagesChapter 1 - Introduction To Failure Analysis and PreventionSayedMahdyNo ratings yet

- Questionnaire & Form DesignDocument41 pagesQuestionnaire & Form DesignAjithreddy BasireddyNo ratings yet

- Goal Setting, Analysis, Strategy Formation, Strategy Implementation, and Strategy MonitoringDocument2 pagesGoal Setting, Analysis, Strategy Formation, Strategy Implementation, and Strategy MonitoringAngel Marie DemetilloNo ratings yet

- Principles of Management in 40 CharactersDocument5 pagesPrinciples of Management in 40 CharactersVloudy Mia Serrano PangilinanNo ratings yet

- MBM301 STRATEGIC MANAGEMENT Case Studies Quiz - Hints For Case Studies Unit 1Document3 pagesMBM301 STRATEGIC MANAGEMENT Case Studies Quiz - Hints For Case Studies Unit 1Yogita NarangNo ratings yet

- Ch01 SolutionsDocument4 pagesCh01 SolutionshunkieNo ratings yet

- NABARD BrochureDocument3 pagesNABARD BrochureptdineshaNo ratings yet

- Assignment On Strategic Evaluation & ControlDocument13 pagesAssignment On Strategic Evaluation & ControlShubhamNo ratings yet

- Module 3 Assessements & ActivitesDocument2 pagesModule 3 Assessements & ActivitesKristine TiuNo ratings yet

- ManagementDocument16 pagesManagementSahar Al-JoburyNo ratings yet

- IU DBA Research MethodsDocument4 pagesIU DBA Research MethodsHASHEZK1988No ratings yet

- Operations ResearchDocument185 pagesOperations ResearchriddhiNo ratings yet

- Quantitative Techniques and MethodDocument165 pagesQuantitative Techniques and MethodSaravana G SaravanaNo ratings yet

- Supply Chain Performance: Achieving Strategic Fit and ScopeDocument24 pagesSupply Chain Performance: Achieving Strategic Fit and ScopeRahul VermaNo ratings yet

- Operation ResearchDocument25 pagesOperation Researchmahmoud khaterNo ratings yet

- MM 4311Document3 pagesMM 4311Mc KeanzjNo ratings yet

- BUAD 837 Individual AssignmentDocument5 pagesBUAD 837 Individual AssignmentUnachukwu Sopulu SopsyNo ratings yet

- F-06 814 SyllabusDocument8 pagesF-06 814 SyllabusDeniz GüngörNo ratings yet

- International Business Course OutlineDocument19 pagesInternational Business Course Outlinezaibi1No ratings yet

- Maximizing profit for newspaper salesDocument12 pagesMaximizing profit for newspaper salesBhargav D.S.No ratings yet

- Zikmund Business Research Methods Chapter 1Document19 pagesZikmund Business Research Methods Chapter 1ToobaNo ratings yet

- 5.03E Ethics Case Study Workplace DiscriminationDocument1 page5.03E Ethics Case Study Workplace DiscriminationJezza Mae Gomba RegidorNo ratings yet

- Chapter 10 Human Resources ManagementDocument7 pagesChapter 10 Human Resources ManagementRio Acid CabelNo ratings yet

- SCDL - PGDBA - Finance - Sem 2 - Production & Operations ManagmentDocument32 pagesSCDL - PGDBA - Finance - Sem 2 - Production & Operations Managmentapi-376241991% (11)

- Types of Growth StrategiesDocument12 pagesTypes of Growth StrategiesRachel HaileNo ratings yet

- Final MT 6003 New QBDocument27 pagesFinal MT 6003 New QBAshokNo ratings yet

- Idoc - Pub - Strategic Management Test Bank and Solutions Manual PDFDocument3 pagesIdoc - Pub - Strategic Management Test Bank and Solutions Manual PDFWalid Mohamed Anwar0% (1)

- What Is Operational Research?: Why Is OR Needed?Document3 pagesWhat Is Operational Research?: Why Is OR Needed?Suvidha DixitNo ratings yet

- Strategic QuestionsDocument1 pageStrategic Questionsঅচেনা একজনNo ratings yet

- BA5207-Marketing Management PDFDocument11 pagesBA5207-Marketing Management PDFSsc FoundationsNo ratings yet

- MBA 631 Quantitative Analysis for Management Decision MakingDocument6 pagesMBA 631 Quantitative Analysis for Management Decision Makingwondimu teshomeNo ratings yet

- 4th Year Course OutlineDocument18 pages4th Year Course OutlineEbsa AdemeNo ratings yet

- Investment and Portfolio ManagementDocument16 pagesInvestment and Portfolio ManagementmudeyNo ratings yet

- Strategic ManagementDocument4 pagesStrategic ManagementA CNo ratings yet

- Syllabus Corso Strategia 2020-21Document7 pagesSyllabus Corso Strategia 2020-21Enri GjondrekajNo ratings yet

- Research Process Steps 1-3Document34 pagesResearch Process Steps 1-3Saleh MohammadNo ratings yet

- COLEGIO DE STA. ANA POLICY EXAMDocument3 pagesCOLEGIO DE STA. ANA POLICY EXAMMARITONI MEDALLANo ratings yet

- Strategic ManagementDocument28 pagesStrategic Managementaditisurve11No ratings yet

- Key Chap 3Document20 pagesKey Chap 3Đức Đặng0% (1)

- Chapter1 - Statistics For Managerial DecisionsDocument26 pagesChapter1 - Statistics For Managerial DecisionsRanjan Raj UrsNo ratings yet

- StudentDocument16 pagesStudentJayne Carly CabardoNo ratings yet

- Assignment: TopicDocument12 pagesAssignment: TopicAthul RNo ratings yet

- MBA - Strategic Management + AnswersDocument24 pagesMBA - Strategic Management + AnswersOlusegun Olasunkanmi PatNo ratings yet

- Files-2-Presentations Malhotra ORGNL PPT 11Document40 pagesFiles-2-Presentations Malhotra ORGNL PPT 11Saeed Ur RehmanNo ratings yet

- Value Chain Management Capability A Complete Guide - 2020 EditionFrom EverandValue Chain Management Capability A Complete Guide - 2020 EditionNo ratings yet

- International Strategic Management A Complete Guide - 2020 EditionFrom EverandInternational Strategic Management A Complete Guide - 2020 EditionNo ratings yet

- Production And Operations Management A Complete Guide - 2020 EditionFrom EverandProduction And Operations Management A Complete Guide - 2020 EditionNo ratings yet

- Economic History of ChinaDocument37 pagesEconomic History of ChinaTimothy TaiNo ratings yet

- Introduction To Constitutional LawDocument12 pagesIntroduction To Constitutional LawTimothy TaiNo ratings yet

- PRC Civil ProcedureDocument32 pagesPRC Civil ProcedureTimothy TaiNo ratings yet

- PRC Civil LawDocument40 pagesPRC Civil LawTimothy TaiNo ratings yet

- Taiwan and Hong KongDocument13 pagesTaiwan and Hong KongTimothy TaiNo ratings yet

- PRC Administrative LawDocument37 pagesPRC Administrative LawTimothy TaiNo ratings yet

- General Customary Law and The Hong Kong CourtsDocument31 pagesGeneral Customary Law and The Hong Kong CourtsTimothy TaiNo ratings yet

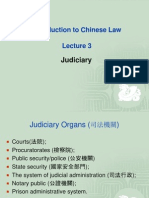

- Lecture 3 JudiciaryDocument39 pagesLecture 3 JudiciaryTimothy TaiNo ratings yet

- TQM at Tata PowerDocument105 pagesTQM at Tata PowerAakash Tanwar100% (1)

- Quality Management of McDonaldDocument8 pagesQuality Management of McDonaldRonalyn AriolaNo ratings yet

- Profile of Indian Foundry IndustryDocument18 pagesProfile of Indian Foundry IndustryMilan JanaNo ratings yet

- PmqaDocument12 pagesPmqaAswathy AnilkumarNo ratings yet

- A Critical Evaluation of The EFQM ModelDocument23 pagesA Critical Evaluation of The EFQM ModelAhmed Redwan100% (1)

- How To Eliminate Cost of Poor Quality COPQDocument3 pagesHow To Eliminate Cost of Poor Quality COPQsudar1477No ratings yet

- EDISON Group Profile PDFDocument56 pagesEDISON Group Profile PDFAnonymous KAIphjNdLzNo ratings yet

- Service Quality in Marketing Hotels & ResortsDocument8 pagesService Quality in Marketing Hotels & ResortsIFa SHaNo ratings yet

- World Class Manufacturing PracticesDocument5 pagesWorld Class Manufacturing PracticesSumit_Raj_Patn_8373No ratings yet

- Case Study Quality System Mangement NIBMDocument24 pagesCase Study Quality System Mangement NIBMajay100% (1)

- Thesis On LeanDocument34 pagesThesis On Leanidris_ali_7No ratings yet

- WEEK 2 Reading Materials - SMP - PDFDocument24 pagesWEEK 2 Reading Materials - SMP - PDFMd Abdullah Al ArmanNo ratings yet

- Chapter 3Document72 pagesChapter 3Glyza Avila100% (1)

- 2014PapersProceeding - MHTSPS - Za SajtDocument443 pages2014PapersProceeding - MHTSPS - Za SajtRamona SuharoschiNo ratings yet

- Oracle Quality User's GuideDocument366 pagesOracle Quality User's GuidedumbadittidumbNo ratings yet

- Politeknik Sultan Azlan Shah: Disediakan Oleh: No MatrikDocument13 pagesPoliteknik Sultan Azlan Shah: Disediakan Oleh: No MatrikRaffique HazimNo ratings yet

- Waterproofing Membranes & Sealants GuideDocument30 pagesWaterproofing Membranes & Sealants GuideBobNo ratings yet

- Catalogo de Acsesorios Interiores de PeterbiltDocument182 pagesCatalogo de Acsesorios Interiores de PeterbiltJuan Carlos FuentesNo ratings yet