Professional Documents

Culture Documents

Ash Rae Clean Room Design Guide Content Draft

Uploaded by

Quan TranOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ash Rae Clean Room Design Guide Content Draft

Uploaded by

Quan TranCopyright:

Available Formats

ASHRAE Design Guide For Cleanrooms

Notes to Subcommittee Members: 1. The second draft of the Table of Contents shows a preliminary coverage of possible topics. The Contents and coverage will be subject to revising for continuous improvements by the authors, contributors and reviewers during the writing, editing, review and refinement processes. A few modifications have been made from Draft 1 to reflect valuable suggestions from committee members: Each Section will have its own Bibliography List to allow readers in searching for related references only. Sustainabilityrelated topics have been merged into a separate Chapter called Cleanroom Design for Sustainability. Book volume will be between 120,000-150,000 words, Estimated Words is tentatively assigned behind each Section title to allow authors to control the sizes of their respective Sections/Chapters to ensure the book properly structured and well balanced. Larger cleanroom market sectors will relatively have more coverage.

2.

3.

Table of Contents

(Second Draft by W. Sun. 8/30/2008)

PREFACE ACKNOWLEDGEMENTS SECTION 1 CLEAMROOM FUNDAMENTALS (18-22K words)

Chapter X Introduction Cleanrooms and Clean Zones International Standards for Cleanroom Design Classification of Cleanrooms Class Required by Various Industries Cleanroom Airflow Sources of Contaminants Inside Cleanrooms Effect of Human Interference Chapter X Airborne Particulate Contaminants Properties of Airborne Particles Dispersion of Airborne Contaminants Particle Size Distribution Contamination Risks and Assessment Sampling Techniques Particle Counters Filtration Mechanisms Fibrous Filters Membrane Filters Type and Construction of High Efficiency Filters Testing of High Efficiency Filters Airborne Ultrafine Particles and Measurement Airborne Macroparticles and Measurement Statistical Analysis Chapter X Surface Particulate Contaminants Surface Particle Deposition Particle Adhesion to Surfaces Rate of Deposition of Non-volatile Residue (NVR) Particle Deposition Velocity Surface Particle Measurement Particle Identification and Electron Microscopy Scanning

Product Cleanliness Levels Surface Cleaning Chapter X Airborne Molecular Contamination Typical Contaminants Outgassed Organic Compounds from Cleanroom Materials and Components Classification Parameters for Consideration Measurement, Testing and Compliance Chapter X Liquidborne Contaminants Particles in Process Liquids Liquid-borne Particle Counters Liquid Filtration Chapter X Microbial Contaminations Principles of Bio-contamination Control Determine Airborne Bio-contamination Through Sampling Sampling Devices Evaluation and Expression of Sampling Data Determine Surface Bio-contamination Determine Bio-contamination in Liquids Cleaning and Disinfection Bibliography SECTION 2 CLEANROOM DESIGN AND ENVIRONMENTAL CONTROL SYSTEMS (30-36K words) Chapter X Basic Requirements and Planning Contamination Control and Cleanliness Requirements Site Selection and Services Requirement Building Configurations and Plans Critical Flow Arrangements-Personnel, Material, Product and Waste Architectural and Structural Considerations Indoor Environmental Quality and Requirements Outdoor Emission Requirement Life Safety Security and Access Control Regulations Project Size, Scope, Budget and Schedule Chapter X Design Considerations Architectural Layout Airflow Patterns Unidirectional Flow Non-unidirectional Flow Mixed Flow Air Patterns Effectiveness and Computer-Aided Flow Modeling Indoor Design Conditions Makeup Air Process Exhaust Filtration Systems Cooling and Heating Loads Determination of Required Room Air Change Rate and Air Velocity and Modeling Basic Primary, Secondary and Tertiary HVAC System Configurations Single Makeup System without Return Air Single Makeup System with Return Air Single Makeup System with Recirculating Fan Single Makeup System with Recirculating AHU System Single Makeup System with Recirculating Fan and Recirculating AHU System

Primary, Secondary and Tertiary System Variations, Psychrometric Analysis and Selection Airflow Direction Control Between Rooms Room Pressure Differential Criteria Pressurization Systems and Design Basics Single Room Pressurization Methods Multiple-Room (Suite) Pressurization Pressurization Controls Airlock Selections and Utilizations Application of Mini-Environments Contamination Control Concepts Filtration and Airflow Management Environmental Control and Monitoring External and Facility Support Applications of Other Separative and Transfer Devices Submicron Contamination and Design Practices Microorganisms (Viables) and Control Considerations Fire Safety Electrostatic Charge and Grounding Cleanroom Lighting Electrical Systems Communication Systems Noise and Vibration Controls Sizing and Redundancy Chapter X Utility Services for Process Environmental, Health and Safety (EHS) Considerations Dry Clean Compressed Air Fume Exhaust and Scrubber System Solvent System Drain Waste Neutralization System House Vacuum System Process Cooling Water Ultra-Pure Water System Clean Steam System Production and Transmission of High Purity Gases Waste Gas Abatement Systems Control of Volatile Organic Compounds Fire Protection Chapter X Cleanroom Design for Sustainability Considerations for Sustainability Energy Conservation & Cost-Saving Concepts Energy Utilizations, Balance and Modeling Chapter X Cleanroom Construction Layout and Approval of Installations Construction Materials and Surface Finishes Integration in Design and Construction Bibliography SECTION 3 TESTING, CERTIFICATION, COMMISSIONING AND QUALIFICATION (12-16K words) Chapter X Cleanroom Testing, Certification & Commissioning Cleanroom Testing Standards Testing Based on Occupancy States As-built At-rest Operational Typical Cleanroom Testing Equipment and Instrumentation

Required (Basic) Test - Airborne Particle Counts for Classifications Optional (Additional) Tests Airborne Particle Counts for Ultrafine Particles Airborne Particle Counts for Macroparticles Airflow Volume, Velocity and Uniformity Air Pressure Differences Installed Filter System Leakage Airflow Direction and Visualization Temperature, Humidity and Uniformities Electrostatic and Ion Generator Particle Surface Deposition Recovery Containment Leak Conductivity Airborne Microbial Counts Surface Microbial Counts Lighting Level and Uniformity Noise and Vibration Levels Cleanroom Commissioning Chapter X Cleanroom Qualifications Regulatory Validation Requirements Various Qualification Protocols and Plans Bibliography SECTION 4 CLEANROOM OPERATIONS (6-7K words)

Chapter X Operation General Requirements Contamination (Particulate and Microbial) Control in Operation Cleanroom Disciplines Personnel Hygiene, Practices and Garments (Clothing, Masks, Gloves, and etc.) Materials, Equipment and Machinery Entry/Exit of Personnel, Material, Product and Waste Cleaning and Decontamination Chapter X Methods for Verifying Cleanliness Ultraviolet Light High Illuminance Oblique White Light Continuous Flowing Duct Method Reservoir Method Contact Plate for Flat Surfaces Swab for Non-Flat Surfaces Bibliography SECTION 5 - CLEANROOMS IN SEMICONDUCTOR & MICROELECTRONIC FACILITIES (15-18K words) Chapter X General Considerations Design Considerations for Semiconductor and Microelectronic Cleanrooms Design Criteria and Indoor Air Quality Filtration and Equipment Environmental, Health and Safety & Risk Assessment Chapter X Design for Fabrication, Process and Manufacturing Semiconductor FAB Facilities Microelectronic Product Manufacturing Facilities Nanotech Facilities Facility Planning and Architectural Plan

Typical Process Diagrams Spaces Configurations Airflow Arrangement in Semiconductor and Microelectronic Cleanrooms Particle Emissions from Equipment and Process Room Air Ionization Treatment of Airborne Molecular Contamination Design Considerations of Micro-vibration and Noise ESD Controls in Cleanroom Environments Off-Wafer Measurement of Contaminants On-Wafer Measurement of Particles and Molecular Contaminants Deposition of Molecular Contaminants in Gaseous Environments Organic Contamination Removal Gases and Chemicals Bibliography SECTION 6 - CLEANROOM IN PHARMACEUTICAL AND MEDICAL DEVICES FACILITIES (15-18K words) Chapter X General Considerations Design Considerations for Pharmaceutical Cleanrooms Current Good Manufacturing Practices (cGMP) Facility Planning and Architectural Plan Building Code Compliance Pharmaceutical Process Flow Mechanical Utilities and High Purity Water and Steam Containment/Isolation Environmental, Health and Safety & Risk Assessment Chapter X Design for Facilities Oral Solid Dosage Facilities Sterile Manufacturing Facilities API Facilities Lab Facilities Packaging Facilities Medical Devices Facilities Controls, Monitoring and Alarms Chapter X Qualifications Validations Qualification Plan and Acceptance Criteria GMP-Compliant Qualification Protocols Installation Qualification (IQ) Operational Qualification (OQ) Performance Qualification (PQ) Bibliography SECTION 7 CLEANROOMS IN HEALTHCARE & BIO-TECH FACILITIES Chapter X General Requirements Healthcare Facilities Design Guidelines and Standards Major Airborne Pathogens Infection Control Risk Assessment (ICRA) Airborne and Surface Microbial Contaminations Control of Particle and Microbiological Contaminations Sterilization Disinfection Radiation/UV Treatment Filtration (10-12K words)

Architectural and Design Considerations Ventilation, Room Pressure and Filtration Requirements Certification and Qualifications Chapter X Cleanroom Technologies in Airborne Infection Control Spaces Operating Room Infection Isolation Room Protective Environment Critical-Care Room Pharmacy Bio-safety Labs Bio-tech Facilities Bibliography SECTION 8 CLEANROOMS IN AEROSPACE, OPTICAL, AUTOMOTIVE, FOOD PROCESSING & OTHER INDUSTRIES (10-14K words) Chapter X Cleanrooms in Aerospace Industries Chapter X Cleanrooms in Optical Devices Industries Chapter X Cleanrooms in Automotive Industries Chapter X Cleanrooms in Food Processing Industries Chapter X Other Cleanroom Applications Bibliography

TERMINOLOGY

(3-4K words)

You might also like

- Hospital Pharmacy Assignment Submitted To: DR Zubair Malik Submitted By: Ansar Mushtaq (20) Topic of AssignmentDocument9 pagesHospital Pharmacy Assignment Submitted To: DR Zubair Malik Submitted By: Ansar Mushtaq (20) Topic of AssignmentAnsar MushtaqNo ratings yet

- Evaluating FFU Placement and Cleanroom Lighting OptionsDocument3 pagesEvaluating FFU Placement and Cleanroom Lighting OptionsThanh NhatNo ratings yet

- Comparison Table of Differential Pressure Rev02Document4 pagesComparison Table of Differential Pressure Rev02Arshavin Watashi WaNo ratings yet

- CLEAN ROOM DESIGN - CASE STUDY Zbook - 2017Document30 pagesCLEAN ROOM DESIGN - CASE STUDY Zbook - 2017ton_bela4911100% (1)

- HVAC in Hospital PDFDocument7 pagesHVAC in Hospital PDFMohammed Toema100% (1)

- Energy-efficient cleanrooms - reducing consumption through analysisDocument11 pagesEnergy-efficient cleanrooms - reducing consumption through analysisshamu081No ratings yet

- Percent Outdoor Air (%OA) Calculation and Its Use: Application NoteDocument7 pagesPercent Outdoor Air (%OA) Calculation and Its Use: Application NoteAce Glen GarciaNo ratings yet

- Airborne Particulate Cleanliness ClassesDocument4 pagesAirborne Particulate Cleanliness ClassesaKureishiNo ratings yet

- Laminar Flow Plenum BoxDocument2 pagesLaminar Flow Plenum BoxRajesh Kashyap100% (1)

- Clean Room PDFDocument62 pagesClean Room PDFMuhammad DanishNo ratings yet

- Particle Counting and Environmental Monitoring in Pharma CleanroomsDocument93 pagesParticle Counting and Environmental Monitoring in Pharma Cleanroomsdavincicode888No ratings yet

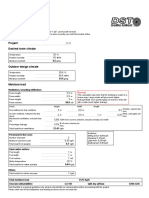

- Moisture Load CalculationDocument2 pagesMoisture Load CalculationNguyễn Anh TuấnNo ratings yet

- HTTP WWW - Bryair.com Manuals Man07Document17 pagesHTTP WWW - Bryair.com Manuals Man07rama deviNo ratings yet

- CO2 Sensor RoomDocument8 pagesCO2 Sensor RoomTrần Khắc ĐộNo ratings yet

- Difficulties Testing HEPA Filters VolumetricallyDocument3 pagesDifficulties Testing HEPA Filters Volumetricallyzivko13No ratings yet

- Introductory Sessions For The AC Design Guide, 2003 EditionDocument50 pagesIntroductory Sessions For The AC Design Guide, 2003 Editionener3333No ratings yet

- Specification Unit Quantity: AHU Indoor Central - Station Air Handling Unit Air Handling UnitsDocument4 pagesSpecification Unit Quantity: AHU Indoor Central - Station Air Handling Unit Air Handling Unitssawen faraidunNo ratings yet

- Microbiology Clean Room Design SpecificationDocument2 pagesMicrobiology Clean Room Design SpecificationMHNADNo ratings yet

- Cleanroom Design in 10 Easy StepsDocument5 pagesCleanroom Design in 10 Easy StepsWerner SchrammelNo ratings yet

- NIH BSL-3 SpecificationsDocument21 pagesNIH BSL-3 SpecificationsRobin RubinaNo ratings yet

- EAU S1 - Fan SelectionDocument1 pageEAU S1 - Fan SelectionMohsin ShaikhNo ratings yet

- Cleanroom Design in 10 Easy StepsDocument10 pagesCleanroom Design in 10 Easy StepsNEDALNo ratings yet

- HVAC Design For Cleanroom FacilitiesDocument33 pagesHVAC Design For Cleanroom FacilitieslakshminarayananNo ratings yet

- Technical Overview On AHUDocument12 pagesTechnical Overview On AHUJahidul IslamNo ratings yet

- Acoustic Calculation of Ventilation SystemsDocument49 pagesAcoustic Calculation of Ventilation SystemsHari Babu DharmavarapuNo ratings yet

- Pharmaceutical Facility DesignDocument27 pagesPharmaceutical Facility Designmdalt9180No ratings yet

- Cleanroom Design in 10 Easy StepsDocument8 pagesCleanroom Design in 10 Easy StepsPhạm Quang HuyNo ratings yet

- HVAC Pharmaceutical FacilitiesDocument36 pagesHVAC Pharmaceutical FacilitiesMd. JewelNo ratings yet

- Clean RoomDocument5 pagesClean Roomsenthilarasu5100% (1)

- Clean RoomDocument136 pagesClean RoomEriko SepacioNo ratings yet

- Clean Rooms L Essentiel 3Document4 pagesClean Rooms L Essentiel 3Sweekar BorkarNo ratings yet

- Treated Fresh Air Guidelines by BryairDocument13 pagesTreated Fresh Air Guidelines by BryairRajanNo ratings yet

- Double Skin Modular Air Handling Unit: Product CatalogueDocument54 pagesDouble Skin Modular Air Handling Unit: Product CatalogueYasinta Dewi PradinaNo ratings yet

- Clean Room TechnoDocument71 pagesClean Room TechnoAhmed MostafaNo ratings yet

- Ahu 6 Alternate ArrangementDocument4 pagesAhu 6 Alternate Arrangementnaresh100% (1)

- Everything You Need to Know About CleanroomsDocument2 pagesEverything You Need to Know About CleanroomsMai Phuong Phan TranNo ratings yet

- Excel Clean Room TechnologiesDocument9 pagesExcel Clean Room Technologiesxlcleantech100% (2)

- Air Change RateDocument18 pagesAir Change Ratemumbaimale20009776No ratings yet

- Hvac Layout - Second Floor - r2 - CSSD - Ahu Room PrintDocument4 pagesHvac Layout - Second Floor - r2 - CSSD - Ahu Room Printලහිරු විතානාච්චිNo ratings yet

- CLEAN ROOM PresentationDocument54 pagesCLEAN ROOM PresentationSanjay Gade100% (1)

- EU GMP Annex 1 - Sterile Medicinal Product - 2008Document16 pagesEU GMP Annex 1 - Sterile Medicinal Product - 2008tungquacert100% (1)

- Introduction to Clean Room WebinarDocument91 pagesIntroduction to Clean Room WebinarPriyawan SukisnoNo ratings yet

- HEPA Cleanroom Filter Testing PDFDocument4 pagesHEPA Cleanroom Filter Testing PDFprovaoralNo ratings yet

- DOP Test ProtocolDocument10 pagesDOP Test ProtocolIzi100% (2)

- Clean Room SpecificationsDocument4 pagesClean Room Specificationsminimoy86No ratings yet

- Surrogate TestingDocument7 pagesSurrogate Testingnavas1972No ratings yet

- HVAC Rev1Document54 pagesHVAC Rev1Blank SermNo ratings yet

- Cleanroom Design That Terra Recommends: Cost vs. Coverage: Evaluating FFU PlacementDocument3 pagesCleanroom Design That Terra Recommends: Cost vs. Coverage: Evaluating FFU PlacementdesignselvaNo ratings yet

- Ah HVAC System 04Document41 pagesAh HVAC System 04A OmairaNo ratings yet

- (Heating Ventilation & Air Conditioning System) : Career Scope Course HighlightsDocument2 pages(Heating Ventilation & Air Conditioning System) : Career Scope Course HighlightsMilind KshirsagarNo ratings yet

- FI NotesDocument1,069 pagesFI NotesparadoxendazzlingNo ratings yet

- NEBB CPT Standard for Certified Testing of CleanroomsDocument7 pagesNEBB CPT Standard for Certified Testing of CleanroomsBhavik Thakar100% (1)

- LP Gas CalculationDocument4 pagesLP Gas Calculationlutfi awnNo ratings yet

- 2012 VAV Boxes Energy Efficiency, Air Leakage and ASHRAE 90.1Document29 pages2012 VAV Boxes Energy Efficiency, Air Leakage and ASHRAE 90.1din_thorpe3248No ratings yet

- Cleanroom Technology: Fundamentals of Design, Testing and OperationFrom EverandCleanroom Technology: Fundamentals of Design, Testing and OperationNo ratings yet

- Clean RoomDocument322 pagesClean RoomCalin Truta100% (11)

- Aditya FluidsDocument11 pagesAditya FluidsAditya RanjanNo ratings yet

- SYNFASANsupsup Synthetic Media PDFDocument2 pagesSYNFASANsupsup Synthetic Media PDFQuan TranNo ratings yet

- Din 779Document13 pagesDin 779Vicky Gautam100% (1)

- Pressure Gauge Connection GuideDocument2 pagesPressure Gauge Connection GuideQuan TranNo ratings yet

- Isdkp 0705Document1 pageIsdkp 0705Quan TranNo ratings yet

- Kitchen Exhaust Duct Access Doors: Model Keda-A - Side / Top of Duct InstallationDocument2 pagesKitchen Exhaust Duct Access Doors: Model Keda-A - Side / Top of Duct InstallationQuan TranNo ratings yet

- Comparison EU Standards Vs ASHRAE 52Document6 pagesComparison EU Standards Vs ASHRAE 52moejamal800% (1)

- Misc Filter PanelsDocument5 pagesMisc Filter PanelsQuan TranNo ratings yet

- Comparison EU Standards Vs ASHRAE 52Document6 pagesComparison EU Standards Vs ASHRAE 52moejamal800% (1)

- Misc Filter PanelsDocument5 pagesMisc Filter PanelsQuan TranNo ratings yet

- Kitchen Exhaust Duct Access Doors: Model Keda-A - Side / Top of Duct InstallationDocument2 pagesKitchen Exhaust Duct Access Doors: Model Keda-A - Side / Top of Duct InstallationQuan TranNo ratings yet

- Gauge Cocks - Needle Values - SiphonsDocument1 pageGauge Cocks - Needle Values - SiphonsQuan TranNo ratings yet

- UL555S Smoke Damper SpecificationsDocument3 pagesUL555S Smoke Damper SpecificationsQuan TranNo ratings yet

- External Louvers: ERM-A Weather LouverDocument2 pagesExternal Louvers: ERM-A Weather LouverQuan TranNo ratings yet

- Dampers: FDC-T Curtain Type Fire DamperDocument2 pagesDampers: FDC-T Curtain Type Fire DamperQuan TranNo ratings yet

- KD-TH Heavy Duty Non Return DamperDocument2 pagesKD-TH Heavy Duty Non Return DamperQuan TranNo ratings yet

- External Louvers: ERM-A Weather LouverDocument2 pagesExternal Louvers: ERM-A Weather LouverQuan TranNo ratings yet

- 03adt - HD T PDFDocument3 pages03adt - HD T PDFQuan TranNo ratings yet

- PATTLNK - 982010 - 210-Ground Source Heat PumpsDocument4 pagesPATTLNK - 982010 - 210-Ground Source Heat PumpsQuan TranNo ratings yet

- Mechanical TagDocument1 pageMechanical TagQuan TranNo ratings yet

- Pages 109 CityPleatDocument1 pagePages 109 CityPleatQuan TranNo ratings yet

- Hydro Plast - EngDocument36 pagesHydro Plast - EngQuan TranNo ratings yet

- Desiccant Wheel Cleaning ProcedureDocument2 pagesDesiccant Wheel Cleaning ProcedureQuan TranNo ratings yet

- Pages 112 - CitySorbDocument1 pagePages 112 - CitySorbQuan TranNo ratings yet

- News 8Document8 pagesNews 8mghgolNo ratings yet

- Cac Khai Niem Co Ban Ve QuatDocument60 pagesCac Khai Niem Co Ban Ve QuatQuan TranNo ratings yet

- Pages 111 - CityCarbDocument1 pagePages 111 - CityCarbQuan TranNo ratings yet

- Desiccant General Arrangement DrawingDocument1 pageDesiccant General Arrangement DrawingQuan TranNo ratings yet

- MDI Cleanroom Training Guide and Users ManualDocument10 pagesMDI Cleanroom Training Guide and Users ManualKai SchipperNo ratings yet

- Qip Ice 31 Stirling EnginesDocument20 pagesQip Ice 31 Stirling EnginesChetanPrajapatiNo ratings yet

- Quantum wells and quantum dots for photonics and electronics fundamentalsDocument8 pagesQuantum wells and quantum dots for photonics and electronics fundamentalswuasamomNo ratings yet

- Intro CsamtDocument4 pagesIntro CsamtJoshLeighNo ratings yet

- Rota Meter Flow-MeasurementDocument18 pagesRota Meter Flow-MeasurementMudit BhatiaNo ratings yet

- Energy Dissipation in StructuresDocument20 pagesEnergy Dissipation in StructuresTommy SidebottomNo ratings yet

- Kevin Case StudyDocument19 pagesKevin Case Studymobile legend practiceNo ratings yet

- Hermetic CAN&CNFDocument20 pagesHermetic CAN&CNFkikechuNo ratings yet

- CalibrationDocument13 pagesCalibrationAmanjit SinghNo ratings yet

- Christiaan HuygensDocument3 pagesChristiaan HuygenssarayooNo ratings yet

- Manuel Des Donnã©es Techniques AQUACIAT LD 150-600 (SEER LT)Document12 pagesManuel Des Donnã©es Techniques AQUACIAT LD 150-600 (SEER LT)umarmirza83No ratings yet

- IMSc Syllabus BIT MESRA PDFDocument83 pagesIMSc Syllabus BIT MESRA PDFGautam DuttaNo ratings yet

- Datasheet Uni Flex ASB Open Top RadiusDocument4 pagesDatasheet Uni Flex ASB Open Top RadiusIkki Muhammad AssidqiNo ratings yet

- Tugasan BDC4013 - Sem 2 0809Document4 pagesTugasan BDC4013 - Sem 2 0809Shinee JayasilanNo ratings yet

- ANSI Z97.1 SummaryDocument4 pagesANSI Z97.1 SummaryAli YalazNo ratings yet

- Fermi Dirac StatisticsDocument15 pagesFermi Dirac StatisticsRiya SalujaNo ratings yet

- MIT 2.004 Dynamics and Control II Problem Set 1 SolutionsDocument6 pagesMIT 2.004 Dynamics and Control II Problem Set 1 SolutionsFatih TokgözNo ratings yet

- A35 AnswersDocument15 pagesA35 AnswersSeanNo ratings yet

- Artificial LightingDocument2 pagesArtificial LightingAzleen SyamimiNo ratings yet

- Arch 415-S&TD - M2 - T3 - W3Document24 pagesArch 415-S&TD - M2 - T3 - W3Harvey JudalenaNo ratings yet

- CHE3044F Reactor Design Tutorial ProblemsDocument4 pagesCHE3044F Reactor Design Tutorial ProblemsnmhatityeNo ratings yet

- ETA210756 CrossFix Facade System ConsDocument34 pagesETA210756 CrossFix Facade System ConsJelena GraovčevićNo ratings yet

- Durham E-Theses: Novel Block Co-Polymers As Potential Photonic MaterialsDocument118 pagesDurham E-Theses: Novel Block Co-Polymers As Potential Photonic MaterialsWassini BensNo ratings yet

- Applications of Thermo Gravimetric Analysis (Tga)Document13 pagesApplications of Thermo Gravimetric Analysis (Tga)Usman GhaniNo ratings yet

- Double-effect evaporator problem - steam flow rate, solids content, steam economy, cooling water flowDocument19 pagesDouble-effect evaporator problem - steam flow rate, solids content, steam economy, cooling water flowKristiani Dewi PasaribuNo ratings yet

- 4th International Conference On Thermal Equipment, Renewable Energy and Rural Development PDFDocument500 pages4th International Conference On Thermal Equipment, Renewable Energy and Rural Development PDFMittapalli SaikiranNo ratings yet

- 10 1039@d0py01036gDocument39 pages10 1039@d0py01036gLuisaCenchaNo ratings yet

- Chiller System Design and Control1Document11 pagesChiller System Design and Control1حيدر محمدNo ratings yet

- Rancangan Pengajaran Harian 2013: Topik CHAPTER 3 FORCES AND PRESSURE (Bernoulli's Principle) Objektif AM Objektif KhasDocument11 pagesRancangan Pengajaran Harian 2013: Topik CHAPTER 3 FORCES AND PRESSURE (Bernoulli's Principle) Objektif AM Objektif KhasJubile A NelsonNo ratings yet

- Magnetic Field IndicatorsDocument2 pagesMagnetic Field IndicatorsdantegimenezNo ratings yet

- Counterfort Retaining Wall B.C. Punamia 05-Feb-2012Document44 pagesCounterfort Retaining Wall B.C. Punamia 05-Feb-2012Lokesh Sharma40% (5)