Professional Documents

Culture Documents

Wall Thickness Calculation - ASME B31.8 2007

Uploaded by

Somi KhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wall Thickness Calculation - ASME B31.8 2007

Uploaded by

Somi KhanCopyright:

Available Formats

ATTACHMENT - X Document No.

X

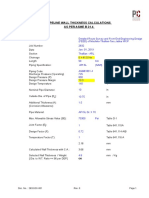

Wall Thickness Calculation of 36in Gas Pipeline (Location Class-3, D.F.=0.5, Corr. Allow.=1.5mm)

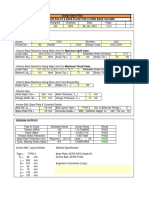

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 DESIGN INPUT Design Code Pipeline Size / Nominal O.D Corrosion Allowance Location Class Design Factor Steel Coefficient of Expansion, Modulus of Elasticity Pressure and Temperature Data Design Pressure Design Temperature (Underground) Installation (backfill) Temp Weld joint factor Temperature Derating Factor A. WALL THICKNESS Grade SMYS of Line Pipe Wall Thickness Calculated tmin = P x D / (2x Sx Fx E x T) + A Next higher API wall thickness D/t Check ( Should be < 96) S tmin t X60 60200 15.5 15.9 58 psi mm mm 415 MPa 0.610 inch 0.626 inch D A F E ASME B31.8 36 in 1.5 mm 3 0.5 0.0000117 2.07E+05 per deg C Mpa 914 mm

6.50E-06 in/in/ C 3.05E+07 Psi

P Td Ti E T

63.5 65 13 1 1

o o

bar g C C

921.0 149.0 55.4

o o

psi g F F

B. EQUIVALENT STRESS CHECK FOR CORRODED PIPE CONDITION Wall thickness (t) Hoop Stress = Sh = PD/2t B.1 Restrained Pipe (Underground) Thermal Stress = ST = a (Ti - Td) E Longitudinal Stress due to pressure = SP = 0.3 Sh Longitudinal Stress, SL SL = SP + ST + SB + SX

14.4 201.6

mm MPa

-125.9 60.5

MPa MPa

0.9 x SMYS = 374 MPa

Without considering SB (Bending stress) and SX (Axial stress due to external loading): SL = SP + ST Longitudinal Stress check : hence SL 0.9 x SMYS Equivalent Stress, SE SE1 = | Sh - SL | SE2 = [ Sh2 + SL2 - Sh SL ]1/2 SE = Max (SE1, SE2) Equivalent Stress check : 0.9 x SMYS = 374 MPa SE 0.9 x SMYS

-65.5 OK

MPa

SE1 SE2 SE hence

267.1 241.1 267.1 OK

MPa MPa MPa

B.2 Unrestrained Pipe (Aboveground) Longitudinal Stress due to pressure = SP = 0.5 Sh Longitudinal Stress, SL SL = SP +SB + SX 0.75 x SMYS = 312 MPa Without considering SB (Bending stress) and SX (Axial stress due to external loading): SL = SP SL 0.75 x SMYS Longitudinal Stress check : hence

100.8

MPa

100.8 OK

MPa

C. MINIMUM BENDING RADIUS Minimum bending radius for underground section is calculated from maximum margin of bending stress, based on Max (SE1, SE2) = 0.9 x SMYS. Hence, bending stress SB = -106.5 MPa R (Minimum Bend Radius) = E D / (2 |Sb|) 889 m D. CHECK ON THINNING DUE TO COLD BENDS: BEND RADIUS = 40 D Inner bend radius divided by diameter, (n) As per PD 8010-1:2004, % of Wall thinning = 50 / (n+1) Pipe thk. before bending = cal thk/(1-thinning %) Available thickness for bending (= Selected thk) Adequacy Check (Pipe thk before bending < Available thk) 39.5 1.23 15.7 15.9 OK % mm mm

Page 1 of 1

You might also like

- Base Plate Design Fixed RevisedDocument8 pagesBase Plate Design Fixed RevisedEngDbt80% (5)

- Reinforcement CheckDocument2 pagesReinforcement Checkviv0102No ratings yet

- Pipe SupportDocument11 pagesPipe SupportAditya Bagus M100% (3)

- Wall Thickness Calculation - ASME B31.8 2007 (Template)Document1 pageWall Thickness Calculation - ASME B31.8 2007 (Template)Hendra Yudistira100% (1)

- Upheaval Buckling Calculation 24Document10 pagesUpheaval Buckling Calculation 24Moustafa Fares100% (1)

- Wall THK Calculation Asme b31.4Document7 pagesWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- Pipeline Anchor Length Calculation PDFDocument3 pagesPipeline Anchor Length Calculation PDFAlvin SmithNo ratings yet

- Design CWR - R0Document38 pagesDesign CWR - R0abhishek5810No ratings yet

- Ineos Com 19 Dera Fabrication Guide Bro 135 Web 1Document76 pagesIneos Com 19 Dera Fabrication Guide Bro 135 Web 1shafeeqm3086No ratings yet

- Design of anchor bolts and base plate for a fixed base columnDocument4 pagesDesign of anchor bolts and base plate for a fixed base columnSuryaSinghNo ratings yet

- Pipeline Anchor Length CalculationsDocument3 pagesPipeline Anchor Length Calculationslsatchithananthan100% (3)

- Pipe cap thickness and coupling rating calculationsDocument2 pagesPipe cap thickness and coupling rating calculationsmasaminathanNo ratings yet

- Storage Tank Design Calculations for Hydrogen PeroxideDocument12 pagesStorage Tank Design Calculations for Hydrogen Peroxidechompink6900No ratings yet

- Calculating saddle dimensions for pipesDocument2 pagesCalculating saddle dimensions for pipesrinabiswas50% (2)

- Gas Line - 20 BargDocument22 pagesGas Line - 20 Bargsaravanakkumar boominahtan100% (1)

- Design of BeamDocument17 pagesDesign of Beamravikiran226100% (1)

- Buried PipeDocument11 pagesBuried PipePrashant Agrawal100% (4)

- Pipeline Calculations - ASAB Gas Lift LinesDocument11 pagesPipeline Calculations - ASAB Gas Lift LinesSaqib LaeeqNo ratings yet

- Wall Thickness Calculation of 36in Gas PipelineDocument1 pageWall Thickness Calculation of 36in Gas PipelineLU1228100% (3)

- PSV Reaction Force CalculationDocument1 pagePSV Reaction Force CalculationAndrei Ionut UtaNo ratings yet

- Above Ground Piping Wall Thickness CalculationsDocument7 pagesAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Combined Stress Calc Rev. 2Document12 pagesCombined Stress Calc Rev. 2babu75% (4)

- Wall Thickness Calculation Verification under StressDocument1 pageWall Thickness Calculation Verification under StresshhgjdfNo ratings yet

- Permissible Elastic Bend Limit Calculations for PipelinesDocument4 pagesPermissible Elastic Bend Limit Calculations for Pipelinesheldermanuel100No ratings yet

- Virtual Anchors For Dummies - M Blackman Jan 09: Modelling in CAESAR IIDocument4 pagesVirtual Anchors For Dummies - M Blackman Jan 09: Modelling in CAESAR IImartin_blackmanNo ratings yet

- Branch Reinforcement Calculation DetailsDocument17 pagesBranch Reinforcement Calculation DetailsVikash Tiwari100% (3)

- Weight CalculatorDocument12 pagesWeight CalculatorShafqat AfridiNo ratings yet

- Virtual Anchor Length - KBRDocument22 pagesVirtual Anchor Length - KBRSammar Adhikari100% (2)

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- API 610 Pump Models of Key Global OEMsDocument1 pageAPI 610 Pump Models of Key Global OEMsshafeeqm3086No ratings yet

- Pipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionDocument2 pagesPipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionImmanuel SNo ratings yet

- Appx-A Formula and CalculationDocument20 pagesAppx-A Formula and CalculationapiscobainNo ratings yet

- 2E7106 Fault Tree Analysis Template in ExcelDocument4 pages2E7106 Fault Tree Analysis Template in ExcelMuhammad IrfanNo ratings yet

- ISO 13623 pipe wall thickness calculation for Mahani-2 projectDocument6 pagesISO 13623 pipe wall thickness calculation for Mahani-2 projectRanjan KumarNo ratings yet

- Dummy Leg JacobsDocument1 pageDummy Leg Jacobsananyo_sengupta0% (1)

- ASME 31 - 8mDocument1 pageASME 31 - 8mMarcoAlbaNo ratings yet

- Pipe Reinforcement Calculation (ASME-B31.3)Document3 pagesPipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Pipe Bend Againts Coating 3LPE AnalisisDocument25 pagesPipe Bend Againts Coating 3LPE Analisisraditia2205100% (1)

- HOT TAP Calculation ThicknessDocument4 pagesHOT TAP Calculation Thicknesscecepsmuhlis67% (3)

- PIPELINE WALL THICKNESS CALCULATIONSDocument24 pagesPIPELINE WALL THICKNESS CALCULATIONSMohsin RazaNo ratings yet

- Area Reinforcement CalculatorDocument5 pagesArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Main Black 1 CM Isometric Grid Paper TemplateDocument1 pageMain Black 1 CM Isometric Grid Paper Templateshafeeqm3086No ratings yet

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- Wall thickness calculation for 36-inch gas pipelineDocument1 pageWall thickness calculation for 36-inch gas pipelinetitir bagchiNo ratings yet

- Pipe Support Span CalculationDocument1 pagePipe Support Span CalculationAshitava SenNo ratings yet

- DummyDocument1 pageDummythopa_nath100% (2)

- ASME B31.3.4.8 Wall Thickness CalculatorDocument26 pagesASME B31.3.4.8 Wall Thickness Calculatoreko123No ratings yet

- Calculation of PipeReinforcement ASMEB31.1Document3 pagesCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- Miter B1 ADocument55 pagesMiter B1 AFarid TataNo ratings yet

- Wall THK Calculation Asme B31.4Document7 pagesWall THK Calculation Asme B31.4ISRAEL PORTILLONo ratings yet

- Pipeline Wall Thickness Calculation SheetDocument4 pagesPipeline Wall Thickness Calculation SheetthehraoNo ratings yet

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Area replacement calculation for CC1 E-1A LNG Vaporizer branchDocument2 pagesArea replacement calculation for CC1 E-1A LNG Vaporizer branchJahsbuck100% (1)

- Load Check For Shoe Welded SupportDocument313 pagesLoad Check For Shoe Welded Supportscrbdgharavi100% (2)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- ASME B31.4 Riser CalcDocument14 pagesASME B31.4 Riser CalcCastorNoroñoNo ratings yet

- Branch Reinforcement Per Asme B31.4 PipelineDocument1 pageBranch Reinforcement Per Asme B31.4 PipelinegateauxboyNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Surge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressDocument17 pagesSurge Analysis: Mostafa Ajjawi, Jr. Engineer 16230 Mr. Barry Howe, Head of Piping StressprashantNo ratings yet

- Gas Line Capacity CalculationDocument2 pagesGas Line Capacity CalculationMario Mendoza100% (1)

- 6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3Document8 pages6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3abdulNo ratings yet

- Pipe Cap Thickness Calculation for ASME Section VIIIDocument9 pagesPipe Cap Thickness Calculation for ASME Section VIIILcm TnlNo ratings yet

- Sample Calculating For Piping Wall Thickness CalculationDocument8 pagesSample Calculating For Piping Wall Thickness CalculationsubhashNo ratings yet

- Tigor EV Brochure 2Document2 pagesTigor EV Brochure 2shafeeqm3086No ratings yet

- Class 6 Algebra Work Sheet-1Document2 pagesClass 6 Algebra Work Sheet-1shafeeqm3086No ratings yet

- Class Vi Mathematics Worksheet Chapter 10 - Mensuration-1Document2 pagesClass Vi Mathematics Worksheet Chapter 10 - Mensuration-1shafeeqm308667% (3)

- Sds Renderoc Plug IndiaDocument9 pagesSds Renderoc Plug Indiashafeeqm3086No ratings yet

- Vetogrout Doc Technical Map en 3503Document2 pagesVetogrout Doc Technical Map en 3503shafeeqm3086No ratings yet

- Ineos Com 19 Dera Resin Selection Guide 002 PDFDocument68 pagesIneos Com 19 Dera Resin Selection Guide 002 PDFprateekmuleNo ratings yet

- Renderoc PlugDocument3 pagesRenderoc Plugtalatzahoor100% (1)

- Honda Amaze BrochureDocument10 pagesHonda Amaze Brochureshafeeqm3086No ratings yet

- (22941932 - Iawa Journal) Effects of Macro - and Micro-Structural Variability On The Shear Behavior of SoftwoodDocument13 pages(22941932 - Iawa Journal) Effects of Macro - and Micro-Structural Variability On The Shear Behavior of Softwoodshafeeqm3086No ratings yet

- I20 PriceDocument1 pageI20 Priceshafeeqm3086No ratings yet

- Amaze Price List 2021Document3 pagesAmaze Price List 2021shafeeqm3086No ratings yet

- Untitled 53Document2 pagesUntitled 53shafeeqm3086No ratings yet

- 35IEC Flyer PDFDocument4 pages35IEC Flyer PDFshafeeqm3086No ratings yet

- CamScanner 12-11-2020 18.42Document7 pagesCamScanner 12-11-2020 18.42shafeeqm3086No ratings yet

- DNV-RTR Specialist Certification PDFDocument6 pagesDNV-RTR Specialist Certification PDFshafeeqm3086No ratings yet

- GuidelinesDocument2 pagesGuidelinessurvisureshNo ratings yet

- T Rec L.1601 201606 I!!pdf eDocument26 pagesT Rec L.1601 201606 I!!pdf eshafeeqm3086No ratings yet

- Ministry of Human Resources and Social Development Launches Labor Reforms For Private Sector WorkersDocument2 pagesMinistry of Human Resources and Social Development Launches Labor Reforms For Private Sector Workersshafeeqm3086No ratings yet

- Osman Sagar PDFDocument1 pageOsman Sagar PDFshafeeqm3086No ratings yet

- Strong Hold: New Standards and Solutions For Piping in Vibratory ServiceDocument8 pagesStrong Hold: New Standards and Solutions For Piping in Vibratory ServicevoldemarprNo ratings yet

- 35IEC Flyer PDFDocument4 pages35IEC Flyer PDFshafeeqm3086No ratings yet

- Osman Sagar PDFDocument1 pageOsman Sagar PDFshafeeqm3086No ratings yet

- Answers For The Assignments Given On 04/06/2020Document2 pagesAnswers For The Assignments Given On 04/06/2020shafeeqm3086No ratings yet

- Materials 12 01025Document12 pagesMaterials 12 01025ShehbazKhanNo ratings yet

- The Story of the Wheel - An Ancient InventionDocument1 pageThe Story of the Wheel - An Ancient Inventionshafeeqm3086No ratings yet