Professional Documents

Culture Documents

Risk Assessment

Uploaded by

Subhransu MohapatraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment

Uploaded by

Subhransu MohapatraCopyright:

Available Formats

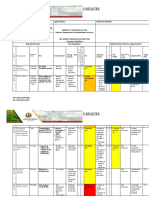

Risk Assessment Activity: Trial blasting at Power House

Sl. No. 1 Risk involved Vibrations caused during Blasting Seismic wave Shock wave, Flying stones Assessment Vibrations may affect the performance of the structure During Trial blasting seismic waves shall be generated due to vibrations. Shock wave may generate and transmit to the adjoining Loading Bay Flying stone may hit protection wall and if weak may fall , detachment of Rubber tyres and wooden logs due to Impact Level Control plan Responsib Remark ility Vibration Control as Sinohydro permissible should be adopted and monitored Action plan need to Sinohydro be implemented. Action plan need to Sinohydro be implemented In case some Sinohydro weakness is noticed same will be attended to desired level to minimise risk Ventilation System Sinohydro shall be installed to evacuate harmful gases through extraction system and supply of fresh air Dust shall be Sinohydro extracted through Ventilation system and the Second Protection wall will minimise the dust

2 3 4

Harmful Harmful gases shall be gases and generated during the heat Blasting which may leak into the adjoin loading bay and existing units working area. Generation of dust Dust will be during the operation. generated Blasting

7 Sl. No. 8

Fire Risk involved Water Drainage

Fire may be generated during Blasting due to hitting of rock fragments Assessment Level Water with muck will be generated during Wet drilling and flow towards the Existing Power house loading bay and also water generated during Fire Fighting. Power Supply may fail due to shock impact transmitting during Blasting

transmission Fire Protection Sinohydro System to be installed Control plan Sinohydro Water drainage Sinohydro system to be provided at appropriate location without affecting the activity. Action plan to be Sinohydro implemented at site

Remark

Power Failure

PLANNING FOR HAZARD IDENTIFICATION, RISK ASSESMENT & DETERMINING CONTROL

1. All the significant risks which are marked S will have control procedures. Method Statement prepared by the contractor and Work Permit issued by competent authorities are followed by the all the engineers, supervisors and workers. To ensure conformance and to evaluate the extent to which people are following the procedures, monitoring is done by the Safety Supervisor/Safety Officer/Site Supervisor/Site Engineers/Construction Manager depending upon the scope defined in the contract. Monitoring frequency depends upon criticality of activity or process and as per the applicable safety conditions for understanding site work (TCE. M4-917) 2. Any non conformity may lead to an extent up to stoppage of work of the process or activity ( Memo Format)

3. Those activities for which the risk can have major or minor consequences on others other activity (like blasting, fire, explosion) are marked Red. 4. All HIRA charts are reviewed wherever there are major changes in activity and processes. All HIRA charts will be revised if corrective & preventive action mandate require such a change. MR, QMS will be the approving authority. 5. All accidents are investigated and corrective and preventive action is taken as per recommendations of investigation report. All significant activities having more risk are controlled by regular checking. Check lists are developed by contractors and reviewed and approved by the site in charge. 6. Training need will be identified and training will be imparted accordingly. 7. To control injuries at site requirement of Personal Protective Equipment (PPE) required PPE will be given to all. will be identified and

REFERENCE

HIRA template used at site, Method statement, Memo format Safety check lists, PPE list. Score card

NOTE: This constitute the procedure for clause 4.3.1

CRITERIA AND GUIDELINES

RISK ASSESMENT MATRIX

Table 1 Severity/ Injury

Ratin g 1

Severity

Injury/Consequence**

Slightly Harmful Superficial injury, minor cuts, bruises, eye irritation from dust, headaches, First Aid Required, temporary discomfort, Damage cost ( property & workplace environment) worth < Rs. 50,000. Harmful Burns, serious sprains, minor fractures, deafness, medical treatment is required, including stitches, Damage cost (property & workplace environment) worth > Rs. 50,000 & < Rs. 1,00,00 Fatal injuries, reportable accident, major fractures, multiple injuries, poisoning, death Property & workplace worth > Rs. 1, 00, 00. environment)

Extremely Harmful

** The words like cutting, falling, slip, spillage, scratches, pinching, fire, explosion, hitting, inhaled, ingestion are also to be included in consequence column along with the injury from above.

disease,

contact,

absorbed,

Table 2 Likelihood/ Probability

Ratin g

Probability

Time Period

Highly Unlikely

> 2 years

Incident/accident observed at one workplace

Unlikely

< 2yreas & > 1 year

Incident/accident observed at one workplace.

Likely

< 1 year

Incident/accident observed at one workplace. May happen.

Table 3 Risk Rating Probability Highly Unlikely (1) Unlikely (2)

Likely (3)

Severity

Slightly Harmful (1)

Acceptable (1)

Acceptable (2)

Non- acceptable (3)

Non- acceptable (4) Harmful Acceptable (2)

Non- acceptable (6)

(2)

Non- acceptable (3) Extremely Harmful (3)

Non- acceptable (6)

Non- acceptable (9)

Table 4 Risk Classification & Action

Risk Classification

Action

Existing control to be maintained Acceptable

Nonacceptable

Formulate/ modify OCP or Work Instructions Impart training

Set program Additional risk control measure

You might also like

- Risk Assessment HP WashingDocument5 pagesRisk Assessment HP WashingAhmad BarriehNo ratings yet

- Risk Assessment RegisterDocument8 pagesRisk Assessment RegisterFareeha Waqar100% (10)

- OHS Risk Register-OldDocument24 pagesOHS Risk Register-OldMohamed Rizwan100% (1)

- Risk Assessment Checklist: Insert Company Logo HereDocument17 pagesRisk Assessment Checklist: Insert Company Logo HereRaffique HazimNo ratings yet

- Risk AssessmentDocument10 pagesRisk Assessmentalamdar321100% (2)

- Risk RegisterDocument37 pagesRisk RegisterSufiyan Farooq100% (1)

- Risk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderDocument5 pagesRisk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderOvais FarooqNo ratings yet

- Guidance of Risk AssessmentDocument31 pagesGuidance of Risk AssessmentBagus Chandra KurniawanNo ratings yet

- Hazard Identification Reporting and Workplace Inspections - Group Safety Standard 11Document7 pagesHazard Identification Reporting and Workplace Inspections - Group Safety Standard 11reneth davidNo ratings yet

- IRP 22 Risk Register 2015Document30 pagesIRP 22 Risk Register 2015Jeya Kumar100% (1)

- Risk Assessment GuidelinesDocument29 pagesRisk Assessment GuidelinesGerald88% (26)

- Risk Register Assmt v1Document24 pagesRisk Register Assmt v1Agus Dohardo ManaluNo ratings yet

- OHS Baseline Risk Assessment - Catering Contract October 2021Document18 pagesOHS Baseline Risk Assessment - Catering Contract October 2021denoiNo ratings yet

- Risk Assessment: Risk:: HazardDocument8 pagesRisk Assessment: Risk:: HazardDevansh VermaNo ratings yet

- Risk Assessment FormDocument50 pagesRisk Assessment FormAndre Porles100% (1)

- ABH Environmental Impact and Aspect RegisterDocument8 pagesABH Environmental Impact and Aspect RegisterOnaFajardoNo ratings yet

- Risk Register 001Document4 pagesRisk Register 001SreekumarNo ratings yet

- Risk ProfilingDocument12 pagesRisk ProfilingedmeanNo ratings yet

- Risk Management PolicyDocument7 pagesRisk Management PolicyMana JeffNo ratings yet

- Risk Assessment Tool ManualDocument19 pagesRisk Assessment Tool ManualChad Skelton100% (3)

- Risk Management PlanDocument46 pagesRisk Management PlanJohn Oo100% (4)

- Hazard Identification Risk Assessment and Risk ControlDocument7 pagesHazard Identification Risk Assessment and Risk ControlChowKC03100% (17)

- Risk Assessment (Draft)Document2 pagesRisk Assessment (Draft)audideadNo ratings yet

- Sample Risk AssessmentDocument12 pagesSample Risk Assessmentpaansaeng82% (17)

- Risk Assessment Sheet For WorkshopDocument6 pagesRisk Assessment Sheet For Workshopsharafudheen_sNo ratings yet

- Risk RegisterDocument7 pagesRisk RegisterAlhad Panwalkar67% (3)

- 2b 1 How To Develop A Risk RegisterDocument2 pages2b 1 How To Develop A Risk Registerpunith1989No ratings yet

- HSE Integrated Management System - Internal Audit GuidanceDocument19 pagesHSE Integrated Management System - Internal Audit Guidancekrunalb@inNo ratings yet

- Register of Environmental Aspects & Impacts: Business Standards SystemDocument4 pagesRegister of Environmental Aspects & Impacts: Business Standards SystemguliNo ratings yet

- Canteen - Risk AssessmentDocument8 pagesCanteen - Risk Assessmentjoshisunil2No ratings yet

- 4.2 - Risk Assessment Project - SAMPLEDocument3 pages4.2 - Risk Assessment Project - SAMPLEDhana Sekar71% (21)

- Health and Safety Management SystemDocument24 pagesHealth and Safety Management SystemEmmanuel WinfulNo ratings yet

- Risk and Opportunity Register: Director, Department of Administrative ServicesDocument4 pagesRisk and Opportunity Register: Director, Department of Administrative ServicesroderickvicenteNo ratings yet

- Dashboard: Risk Assessment MatrixDocument2 pagesDashboard: Risk Assessment MatrixAhmad Saiful Ridzwan Jaharuddin100% (1)

- Risk Assessment Form: Hazard ListDocument2 pagesRisk Assessment Form: Hazard ListJulio Alves100% (1)

- Risk Assessment MatrixDocument1 pageRisk Assessment MatrixAdam McArthurNo ratings yet

- Risk Assessment For Sand Blasting PDFDocument8 pagesRisk Assessment For Sand Blasting PDFOvais FarooqNo ratings yet

- Risk Management ProcedureDocument33 pagesRisk Management ProcedureAdrian Ianca92% (12)

- Risk Management Procedure TemplateDocument35 pagesRisk Management Procedure TemplateJosé Luis Arellano CorderoNo ratings yet

- Safety Risk AssessmentDocument52 pagesSafety Risk Assessmentmujahid113794% (36)

- Risk Assessment TemplateDocument3 pagesRisk Assessment TemplateAustin Akopia BoyaNo ratings yet

- Incident Reporting Policy General Policy Gp8Document28 pagesIncident Reporting Policy General Policy Gp8Marvin CamalNo ratings yet

- Noise: Guide For Risk Assessment in Small and Medium EnterprisesDocument10 pagesNoise: Guide For Risk Assessment in Small and Medium EnterprisesXozanNo ratings yet

- Risk Assessment ProcedureDocument9 pagesRisk Assessment Procedurerslapena100% (3)

- Addressing Risks and Opportunities SOP PDFDocument15 pagesAddressing Risks and Opportunities SOP PDFShahzeb Hassan100% (3)

- Health Safety Risk Assessment Template 1Document4 pagesHealth Safety Risk Assessment Template 1alokcNo ratings yet

- Risk MatrixDocument3 pagesRisk MatrixNuzulul Iman100% (1)

- Risk RegisterDocument9 pagesRisk RegisterKingNo ratings yet

- Business Continuity Plan Administrator Complete Self-Assessment GuideFrom EverandBusiness Continuity Plan Administrator Complete Self-Assessment GuideNo ratings yet

- EQMS Manual & Policy Document Example PDFDocument14 pagesEQMS Manual & Policy Document Example PDFs3dbw0% (1)

- A Practical Approach To Creating A Risk Management PlanDocument4 pagesA Practical Approach To Creating A Risk Management PlanNicoleAbdon0% (1)

- Risk Assessment: Pick & Carry CranesDocument36 pagesRisk Assessment: Pick & Carry CranesAbd Ennacer100% (2)

- Risk Assessment ProcedureDocument4 pagesRisk Assessment ProcedureRameeSahiba100% (1)

- Baseline Risk AssessmentDocument6 pagesBaseline Risk AssessmentPHUMZILENo ratings yet

- Vibration Instruments 7Document1 pageVibration Instruments 7Subhransu MohapatraNo ratings yet

- Street Light PoleDocument1 pageStreet Light PoleSubhransu MohapatraNo ratings yet

- Geeta Madhurya OriyaDocument127 pagesGeeta Madhurya OriyaSubhransu MohapatraNo ratings yet

- PRC ReportDocument1 pagePRC ReportSubhransu MohapatraNo ratings yet

- HANUMANDocument1 pageHANUMANSubhransu MohapatraNo ratings yet

- Fleet Management User ManualDocument8 pagesFleet Management User ManualSubhransu MohapatraNo ratings yet

- Proximity Sensor 10Document1 pageProximity Sensor 10Subhransu MohapatraNo ratings yet

- Vibration Instruments 4Document1 pageVibration Instruments 4Subhransu MohapatraNo ratings yet

- Vibration Instruments 6Document1 pageVibration Instruments 6Subhransu MohapatraNo ratings yet

- Vibration Instruments 2Document1 pageVibration Instruments 2Subhransu MohapatraNo ratings yet

- Vibration Instruments 3Document1 pageVibration Instruments 3Subhransu MohapatraNo ratings yet

- Motor StdsDocument2 pagesMotor StdsSubhransu MohapatraNo ratings yet

- Vibration Instruments 5Document1 pageVibration Instruments 5Subhransu MohapatraNo ratings yet

- Proximity Sensor 11Document1 pageProximity Sensor 11Subhransu MohapatraNo ratings yet

- Proximity Sensor 1Document1 pageProximity Sensor 1Subhransu MohapatraNo ratings yet

- Proximity Sensor 6Document1 pageProximity Sensor 6Subhransu MohapatraNo ratings yet

- Through-Beam Sensors Through-Beam Sensors Through-Beam Sensors Through-Beam SensorsDocument1 pageThrough-Beam Sensors Through-Beam Sensors Through-Beam Sensors Through-Beam SensorsSubhransu MohapatraNo ratings yet

- Proximity Sensor 3Document1 pageProximity Sensor 3Subhransu MohapatraNo ratings yet

- Proximity Sensor 4Document1 pageProximity Sensor 4Subhransu MohapatraNo ratings yet

- Proximity Sensor 4Document1 pageProximity Sensor 4Subhransu MohapatraNo ratings yet

- Cni Tool ListDocument2 pagesCni Tool ListSubhransu MohapatraNo ratings yet

- ANSI Codes PDFDocument3 pagesANSI Codes PDFelectrical_1012000100% (2)

- Respect YourselfDocument5 pagesRespect YourselfSubhransu MohapatraNo ratings yet

- Proximity Sensor 5Document1 pageProximity Sensor 5Subhransu MohapatraNo ratings yet

- Proximity Sensor 2Document1 pageProximity Sensor 2Subhransu MohapatraNo ratings yet

- K) High Voltage Test.: 21 Schedule of Tests 21.1 Type TestsDocument1 pageK) High Voltage Test.: 21 Schedule of Tests 21.1 Type TestsSubhransu MohapatraNo ratings yet

- Motor Test2Document1 pageMotor Test2Subhransu MohapatraNo ratings yet

- Field Inst STD 2Document1 pageField Inst STD 2Subhransu MohapatraNo ratings yet

- Inst STDS 2Document1 pageInst STDS 2Subhransu MohapatraNo ratings yet

- Field Inst STD 3Document1 pageField Inst STD 3Subhransu MohapatraNo ratings yet

- Manual Jib 25 10 02Document256 pagesManual Jib 25 10 02Luis Jose LlobanNo ratings yet

- Transaction AnalysisDocument34 pagesTransaction AnalysisSunil Ramchandani100% (1)

- Activity 2: College of EngineeringDocument3 pagesActivity 2: College of EngineeringMa.Elizabeth HernandezNo ratings yet

- FCE Writing 14 - ArticleDocument4 pagesFCE Writing 14 - Articlepingu70No ratings yet

- Significant Supreme Court RulingsDocument5 pagesSignificant Supreme Court Rulingsapi-307941674No ratings yet

- Piaget and Preoperational StageDocument2 pagesPiaget and Preoperational Stageapi-285179229No ratings yet

- Components of A Rainwater Harvesting SystemDocument38 pagesComponents of A Rainwater Harvesting SystembudiperNo ratings yet

- Magnesium L Threonate For Depression and Anxiety PDFDocument6 pagesMagnesium L Threonate For Depression and Anxiety PDFRocco LamponeNo ratings yet

- Shloka Seminar: - DR Vikas SarochDocument15 pagesShloka Seminar: - DR Vikas SarochDrVikas100% (3)

- Dental Hygienist Learning Outcomes Form v1.2Document32 pagesDental Hygienist Learning Outcomes Form v1.2Karman Deep Singh100% (1)

- P13Document21 pagesP13Saeful AzizNo ratings yet

- Envirotainer RKN E1 Operations ManualDocument46 pagesEnvirotainer RKN E1 Operations ManualJorge de oliveiraNo ratings yet

- From Crème Fraîche To Sour Cream: What's The Difference?Document14 pagesFrom Crème Fraîche To Sour Cream: What's The Difference?Maricel BautistaNo ratings yet

- Rubric On Baking CakesDocument3 pagesRubric On Baking CakesshraddhaNo ratings yet

- Ws - Mea Millennium Ecosystem AssessmentDocument3 pagesWs - Mea Millennium Ecosystem Assessmentapi-305791685No ratings yet

- Case Study MMDocument3 pagesCase Study MMayam0% (1)

- WaterproofingDocument38 pagesWaterproofingPranay GandhiNo ratings yet

- Perdev - Module 9Document9 pagesPerdev - Module 9April Rose CortesNo ratings yet

- Urie BronfenbrennerDocument27 pagesUrie Bronfenbrennerapi-300862520100% (1)

- Chapter 4. Acid Base Problem Set: O O CH CH OH O O-H CH CH ODocument2 pagesChapter 4. Acid Base Problem Set: O O CH CH OH O O-H CH CH Osnap7678650No ratings yet

- English CV Chis Roberta AndreeaDocument1 pageEnglish CV Chis Roberta AndreeaRoby ChisNo ratings yet

- Jurnal RustamDocument15 pagesJurnal RustamRustamNo ratings yet

- Remote Control RC902V1 ManualDocument3 pagesRemote Control RC902V1 ManualdezdoNo ratings yet

- AAA V Edgardo SalazarDocument2 pagesAAA V Edgardo SalazarNiajhan PalattaoNo ratings yet

- PU-133AB - 規格GMXa spc 2022Document5 pagesPU-133AB - 規格GMXa spc 2022Ý TrầnNo ratings yet

- New-DLP Phase2 Assignment-3 Module-B Final-9.8.18Document6 pagesNew-DLP Phase2 Assignment-3 Module-B Final-9.8.18PNo ratings yet

- Reclaimer Inspection ReportDocument51 pagesReclaimer Inspection ReportThiru Malpathi100% (1)

- Separating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationDocument4 pagesSeparating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationAndrea SobredillaNo ratings yet

- Rubber Dam (Tooth Isolation)Document9 pagesRubber Dam (Tooth Isolation)NonoNo ratings yet

- Female Education ThesisDocument48 pagesFemale Education ThesisHashmie Ali73% (11)