Professional Documents

Culture Documents

More Delivrance That Fresh Air PDF

Uploaded by

Noushad P HamsaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

More Delivrance That Fresh Air PDF

Uploaded by

Noushad P HamsaCopyright:

Available Formats

Commercial Kitchen Ventilation: More to Deliverance than Fresh Air

Risto Kosonen Halton Oy

Globally in every business ventures, the initial investment and subsequent operating costs are important factors that determine the viability of the venture. In the design of ventilation, the consulter has to consider the life-cycle costs of the whole system in tandem with the comfort of customers and workers.

Concerns over the indoor environment have increased during recent years as a result of knowledge about the significance of thermal conditions and air quality on the health, comfort and productivity of workers. In a commercial kitchen, working conditions are especially demanding. There are four main factors affecting thermal comfort, these being: air temperature, radiation, air velocity and air humidity. At the same time, high emission rates of contaminants are released from the cooking process. Ventilation plays an important role in providing comfortable and productive working conditions and in securing contaminant removal. Labor shortage is a big challenge in commercial restaurants. One reason for the low popularity of kitchen work is the unsatisfactory thermal conditions. Ventilation and air conditioning systems are required in commercial kitchens to: (1) remove odours and particles of fat, (2) comply with hygiene requirements, (3) remove moisture and heat that is generated from the preparation of meals and washing and (4) provide comfortable and productive working conditions. To meet these tasks, supply and exhaust air systems shall be installed in the kitchen areas so that odours, air pollutants, extra heat and moisture are removed. Recent studies have shown that poor indoor air quality has negative impact on thermal comfort, productivity and health issues (Wargocki 1999 and Wyon 1996). Thus, it is possible to demonstrate that an investment to a better ventilation system is profitable already with modest productivity improvements in the workplace. The published studies demonstrate quite clearly the health risk of cooking. Thiebaud (1995) indicates that the fumes generated by frying pork and beef were mutagenic. Hence, the chefs are exposed to relatively high levels of airborne mutagens and carcinogens. Vainiotalo (1993) carried out measurements at eight workplaces. The survey confirmed that cooking fumes contain hazardous components. It also indicated that kitchen worker may be exposed to relatively high concentration of airborne impurities. Although cigarette smoking is considered to be the most important cause of lung cancer, smoking behavior cannot fully explains the epidemiological characteristics of

lung cancer among Asian women, who rarely smoke but contract lung cancer relatively often. Ng (1993) study found that over 97 % of the women in Singapore do not smoke. Thus, the presumable source of indoor air pollution for housewives is passive smoking and cooking. This study indicates that greater relative odds of respiratory symptoms were associated with the weekly frequency of gas cooking. The previous studies depict the importance of the well-designed ventilation in the kitchen. The efficiency of the exhaust system should be specially emphasized. The remove efficiency of the total system must be guaranteed and impurities spreading throughout the kitchen should be prevented.

Figure text:

Normally in commercial kitchens, there is packed all equipment in a small area where kitchen staff are working and preparing dishes. The ventilation in kitchen is vital to ensure that staff will be able to work in a conducive environment with no spillover effects of odours into the dining and surrounding areas.

Exhaust Airflow Rate according to actual load A properly designed and located exhaust hood or exhaust unit of ceiling is essential for effective kitchen ventilation. The ventilation system is used to capture the heat, odour and vapor emitted during cooking process and to contain it until the fan can exhaust them outdoor. The ventilation system also bring the air to refresh the working place by replacing the exhausted air. There are many methods available to calculate the requested airflow rate. For example, the Rule of Thumb method is that the number of air change is taken into consideration. Another method called Face Velocity where the flow rate is established by considering the captured velocity and area under the hood. Both of these methods do not take consideration the type of appliances under the hoods.

Hence in many cases, the estimations always exceed the actual requirements or demands. As for the Heat Load method, consideration is made for the cooking appliance convective heat output, the area of exposure, the distance of the extract unit and the effect of the general ventilation for the contaminant removal efficiency. The main idea is to adjust the required airflow rate based on the convection heat gain or more specific based on the thermal plume of a kitchen appliance. The most well-known code which utilizes this approach is German VDI (VDI 1999). It should be noted that radiated heat can not be removed with the extract system. To maintain sufficient indoor conditions year-round, the air-conditioning system is always needed in the kitchen. Without mechanical cooling, the air temperature in the kitchen will be time to time over 30 deg.C during summer time. That definitely reduces performance of workers. If a hood is not able to capture and contain the foul air within the kitchen area, both humidity and temperature will increase in kitchen and at the same time pollutant will spread over the kitchen and possible to the surrounding dining and shopping areas. Specially high contaminant removal efficiency is critical in the front-cooking restaurants where the actual cooking happen close the customers.

1. Convective Heat

2. Radiated Heat

Figure text:

The sensible heat gain of kitchen appliance should be divided into two part: 1) convective and 2) radiated heat. Only the convective heat is possible to remove with a local ventilation. Because of the radiated heat, the air-conditioning is requested in commercial kitchens. Otherwise, the room temperature will rise over comfortable thermal conditions.

Exhaust Flow

Hydraulic Diameter

Convective Heat Flow

Installation Factor

Flow q

qv, p = (k ( z0 + 1. 7 Dh )

Empirical Coefficient

5/3

( conv )1 / 3 r K ads ) / eff

Hood Efficiency

Factor of General ventilation Height Above Appliance

Figure text:

In the heat load based design, the requested airflow rate is calculated based on the actual convective heat load, the size of the appliance, the installation height of the extract point and the location of the appliance (island, wall or corner installation). Also, the general ventilation and the hood efficiency have an influence on the needed airflow rate.

Meaning of Efficiency As described before, the calculation of the thermal plume is the basis of hood design. The thermal plume from hot appliances takes up the contaminant and heat that are released during the cooking process. If convective heat is not removed directly above the cooking equipment, impurities will spread throughout the kitchen. When appliances are installed under an effective hood, only the radiant heat contributes to the cooling load in the space. Conversely, if the hood is not providing sufficient capture and containment, thereby increasing both humidity and temperature The capture jet technology increases the efficiency of the hoods. The capture jet has the effect of forming a protective barrier that prevents heat, smoke, grease and other contaminants from spilling into the kitchen thereby reducing air-conditioning load and making for a more comfortable and safe environment for employees working in the kitchen. It is possible to get remarkable savings both in investment and life-cycle costs by using high efficient exhaust systems. Also, the energy efficient system is more environmental friendly; the total greenhouse gas emission is much lower. In a series of tests conducted by Architectural Energy Corporation (AEC) in USA, the capture jet hood performed favorably over traditio nal style back shelf hoods. In fact, the exhaust-only hood required 100% greater exhaust air to capture than the capture jet hood during idle conditions and 36% greater exhaust air during cooking conditions (Schrock 2000)

At the same time with this optimization of exhaust flowrate saving can then be infer from a) Operation Cost (power consumption and air conditioning cost to replenish the non convective heat exhausted) b) Initial Capital Investment (due to larger and oversized equipment installation)

Figure text: The hood efficiency is possible to illustrate using Schliering thermal imaging and CFD technologies. The conducted measurements show that with the capture jet (panels over) is possible to improve the hood efficiency compared to normal exhaust hood (panels under). The total approach for the ventilation system should be kept in mind. Application of a low velocity displacement ventilation system allows for a reduction in exhaust airflow by 15 % compared to a conventional mixing ventilation system (VDI 1999). Also, the radiation load from the appliances and other possible heat gains should be handled by

kitchen air-conditioning system. Otherwise, indoor temperature rises over comfortable level. It is recommended to keep a negative air balance (under pressure) compared with the surrounding spaces. In practice this means that the amount of the exhaust airflow rate should be at least 10 % higher than the supply airflow rate in the kitchen. In addition to, the general exhaust should be arranged near the ceiling level. This general exhaust airflow, which amount is 10 % of the total flow, extracts all other heat gains e.g. refrigeration and coffee makers that are not equipped with hood. The efficiency of the exhaust system should be specially emphasized with the ventilated ceiling systems where the exhaust is located at the ceiling level. The capture efficiency of the total system must be guaranteed and spreading of impurities throughout the kitchen should be prevented. The efficiency of the exhaust system can be improved with a small capture jet installed at the ceiling surface. The air jet is projected horizontally across the ceiling, which helps to direct heat and air impurities towards the exhaust. This capture jet represents only about 10 % of the total supply air flow rate. The efficiency of the capture jet concept was studied by Kosonen and Mustakallio (2003). The supply air distribution strategy has a remarkable influence on the pollution removal effectiveness and thermal environments. In the ventilated ceiling, the capture jet could improve the total effectiveness of the ventilation system. In the scenario with capture jet, the average contaminant level in the occupied zone was 40 % lower and the estimated energy saving potential can be as much as 23 %.

Figure text: Contaminant level in the kitchen space without the capture jet (panel over) and with the capture jet (panel under). This depicts that without the capture jet a portion of the plume is re-circulated back to the occupied zone.

REFERENCES

Kosonen R and Mustakallio P (2003) The influence of a capture jet on the efficiency of a ventilated ceiling, International Journal of Ventilation, 1, Issue 3, pp 189-200. Ng T.P.; Hui K.P.; Tan W.C.(1993), Respiratory symptoms and lung function effects of domestic exposure to tobacco smoke and cooking by gas in nonsmoking women in Schrock D, Bagwell D and Livchak A, Quantifying Capture & Containment for Kitchen Exhaust Hoods. Proceedings of Ventilation 2000, Helsinki June 4-7, 2000 Singapore, Journal of Epidemiology and Community Health, Volume 47, Issue 6, 1993, Pages 454-458 Thiebaud, H. P.; Knize, M. G.; Kuzmicky, P. A.; Hsieh, D. P.; Felton, J. S (1995). Airborne mutagens produced by frying beef, pork and a soy-based food, Food and Chemical Toxicology, Volume 33, Issue 10, 1995, Pages 821828 Vainiotalo, Sinikka; Matveinen, Katri (1993), Cooking fumes as a hygienic problem in the food and catering industries, American Industrial Hygiene Association Jour nal, Volume 54, Issue 7, 1993, Pages 376-382 VDI (1999) Standard 2052: Ventilation equipment for kitchens. Verein Deutcher Ingenieure. Wargocki, P., Wyon, D. P., Baik, Y.K., Clausen, G., Fanger, P.O. (1999). Perceived air quality, SBS- symptoms and productivity in an office at two pollution loads. The 8th International Conference on Indoor Air Quality and Climate, Edinburgh, Scotland. Wyon, D. P. (1996). Individual microclimate control: required range, probable benefits and current feasibility. In Proceedings of Indoor Air '96, Institute of Public Health, Tokyo.

You might also like

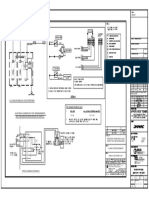

- 003-Ansul R-102 System P & I D-P&IDDocument1 page003-Ansul R-102 System P & I D-P&IDNoushad P HamsaNo ratings yet

- Head PressDocument2 pagesHead PressNoushad P HamsaNo ratings yet

- CVGF svn02b E4Document68 pagesCVGF svn02b E4Noushad P HamsaNo ratings yet

- Chilled Water Pipe SizingDocument2 pagesChilled Water Pipe SizingLarry Bea77% (13)

- HVAC Formula GuideDocument5 pagesHVAC Formula GuidezakirnagarNo ratings yet

- KX SeriesDocument24 pagesKX SeriesNoushad P HamsaNo ratings yet

- HVAC-FormulasDocument1 pageHVAC-FormulasNedunuri.Madhav MurthyNo ratings yet

- RWV Balancing Valve TrainingDocument33 pagesRWV Balancing Valve TrainingNoushad P HamsaNo ratings yet

- Balancing BasicsDocument14 pagesBalancing BasicspbharrisNo ratings yet

- Duct Leakage TestingDocument51 pagesDuct Leakage Testingducatti996chNo ratings yet

- A Guide To Air FiltrationDocument50 pagesA Guide To Air FiltrationNoushad P HamsaNo ratings yet

- CVGF svn02b E4Document68 pagesCVGF svn02b E4Noushad P HamsaNo ratings yet

- CTV Chiller WeightsDocument5 pagesCTV Chiller WeightsNoushad P HamsaNo ratings yet

- Construction Materials E-BookDocument98 pagesConstruction Materials E-BookNoushad P Hamsa100% (1)

- Cvhesvn03den 305Document80 pagesCvhesvn03den 305Noushad P HamsaNo ratings yet

- Energy Planning A Guide To PractitionersDocument75 pagesEnergy Planning A Guide To PractitionersNoushad P HamsaNo ratings yet

- Urban Planning & MEP EbookDocument153 pagesUrban Planning & MEP EbookNoushad P HamsaNo ratings yet

- A Guide To Absorption CoolingDocument54 pagesA Guide To Absorption CoolingNoushad P HamsaNo ratings yet

- A Guide To Air FiltrationDocument50 pagesA Guide To Air FiltrationNoushad P HamsaNo ratings yet

- Dynamic Storage in BuildingsDocument114 pagesDynamic Storage in BuildingsNoushad P HamsaNo ratings yet

- CompressorsDocument7 pagesCompressorssyedahmedsabirNo ratings yet

- Urban Planning & MEP EbookDocument153 pagesUrban Planning & MEP EbookNoushad P HamsaNo ratings yet

- Buffer Tank Hesabı PDFDocument4 pagesBuffer Tank Hesabı PDFDevrim GürselNo ratings yet

- Copper Tube DesignDocument34 pagesCopper Tube DesignNoushad P HamsaNo ratings yet

- Plumbing Installations Home Owner Guide PDFDocument19 pagesPlumbing Installations Home Owner Guide PDFskilmagNo ratings yet

- Building Regulation BookDocument135 pagesBuilding Regulation BookNenad Stjepanovic100% (1)

- Plumbing Installations Home Owner Guide PDFDocument19 pagesPlumbing Installations Home Owner Guide PDFskilmagNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- VHDL ExperimentsDocument55 pagesVHDL Experimentssandeepsingh93No ratings yet

- Unit 2Document76 pagesUnit 2Mithila100% (1)

- Hikmayanto Hartawan PurchDocument12 pagesHikmayanto Hartawan PurchelinNo ratings yet

- Norstar ICS Remote Tools, NRU Software Version 11Document1 pageNorstar ICS Remote Tools, NRU Software Version 11Brendan KeithNo ratings yet

- Directions: Answer The Following Question(s) .: A. B. C. D. E. FDocument6 pagesDirections: Answer The Following Question(s) .: A. B. C. D. E. FdiamondtressNo ratings yet

- BUS STAT Chapter-3 Freq DistributionDocument5 pagesBUS STAT Chapter-3 Freq DistributionolmezestNo ratings yet

- Petroleum GeomechanicsDocument35 pagesPetroleum GeomechanicsAnonymous y6UMzakPW100% (1)

- Java Array, Inheritance, Exception Handling Interview QuestionsDocument14 pagesJava Array, Inheritance, Exception Handling Interview QuestionsMuthumanikandan Hariraman0% (1)

- As Statistics Mechanics 1Document240 pagesAs Statistics Mechanics 1claire zhouNo ratings yet

- Deep Learning: Huawei AI Academy Training MaterialsDocument47 pagesDeep Learning: Huawei AI Academy Training Materialsfadhil muhammad hanafiNo ratings yet

- Engineering Physics Question BankDocument10 pagesEngineering Physics Question BankReji K DhamanNo ratings yet

- DRV IpDocument23 pagesDRV IpTim MarshallNo ratings yet

- MOBICON Mobile Controller For GSM/GPRS Telemetry: 6ai 16-28di /12doDocument2 pagesMOBICON Mobile Controller For GSM/GPRS Telemetry: 6ai 16-28di /12doĐặng Trung AnhNo ratings yet

- Clustering Methods for Data MiningDocument60 pagesClustering Methods for Data MiningSuchithra SalilanNo ratings yet

- Standard Rotary Pulse Encoder Operation Replacement SettingDocument8 pagesStandard Rotary Pulse Encoder Operation Replacement SettingGuesh Gebrekidan50% (2)

- Chapter 5Document14 pagesChapter 5bhavyaNo ratings yet

- Basic Research Approaches and Designs - An Overview - Amoud - 2020Document18 pagesBasic Research Approaches and Designs - An Overview - Amoud - 2020Haaji CommandoNo ratings yet

- Intel Processor Diagnostic Tool HelpDocument44 pagesIntel Processor Diagnostic Tool HelprullfebriNo ratings yet

- Aditya Rahul Final Report PDFDocument110 pagesAditya Rahul Final Report PDFarchitectfemil6663No ratings yet

- Lesson Planning Product-Based Performance TaskDocument8 pagesLesson Planning Product-Based Performance TaskMaricarElizagaFontanilla-LeeNo ratings yet

- Digital Techniques/Electronic Instrument SystemsDocument29 pagesDigital Techniques/Electronic Instrument SystemsE DNo ratings yet

- Stheory Balagtas Activity Lesson 15Document6 pagesStheory Balagtas Activity Lesson 15xVlad LedesmaNo ratings yet

- Reservoir Modelling & Simulation GuideDocument96 pagesReservoir Modelling & Simulation GuideyouungNo ratings yet

- Carbon FibreDocument25 pagesCarbon Fibrejagadish.kvNo ratings yet

- Continuous DeploymentDocument2 pagesContinuous DeploymentVenkat Reddy0% (1)

- Astm E1588.1207649 GSRDocument5 pagesAstm E1588.1207649 GSRjoao carlos100% (1)

- SKM and OKM User ManualDocument36 pagesSKM and OKM User ManualOutlawRNo ratings yet

- Temperature Effect On Voc and IscDocument5 pagesTemperature Effect On Voc and IscAnonymous bVLovsnNo ratings yet

- M.O.E.M.S Practice Packet 2013-2014 PDFDocument20 pagesM.O.E.M.S Practice Packet 2013-2014 PDFrajit kunwar72% (25)

- List of Eligible Candidates Applied For Registration of Secb After Winter 2015 Examinations The Institution of Engineers (India)Document9 pagesList of Eligible Candidates Applied For Registration of Secb After Winter 2015 Examinations The Institution of Engineers (India)Sateesh NayaniNo ratings yet